Abstract

Metal organic frameworks (MOFs) and particularly copper benzene-1,3,5-tricarboxylate (HKUST-1) are excellent materials for gas storage (e.g., CH4, N2, H2 adsorption) and gas separation. In this work, reduced graphene oxide (RGO)–HKUST-1 mechanical mixtures were studied in order to reveal the effect of RGO content on the pressure tolerance of the texture and heat conductivity. HKUST-1 was obtained by two different synthesis routes. Air-dried MOF and RGO were thoroughly mixed prior to the compression. Powder XRD and Raman spectroscopy were used to characterize the response of the crystal structure, while low-temperature nitrogen adsorption was used the follow the adsorption properties of the pellets. Finally, the "flash" heat pulse method was used to assess the thermal properties. The gas adsorption isotherms revealed that the adsorption capacity decreases when RGO is added. Based on Raman and XRD results, we found that the synthesis route has an effect on multiple scales. We experimentally confirmed that evaluation of the thermal diffusivity requires a model more complex than the simple Fourier equation, due to the inherent heterogeneous structure of the material. A good approximation of the Fourier coefficient of thermal diffusivity was obtained using the parameters of the Guyer–Krumhansl equation. The heat pulse experiments also revealed possible size-dependent behavior.

Similar content being viewed by others

Introduction

Gas adsorption by highly porous materials is of great interest for its potential in overcoming multiple environmental and ecological challenges. Whether for H2 or CH4 adsorption and their delivery as fuel, CO2 capture for tackling global warming, or biogas separation, adsorption by solid sorbents is a versatile solution. From among the novel materials, metal organic frameworks (MOFs) seem ideal for these applications due to their outstanding properties, among which well-developed permanent porosity, tunability, relatively simple synthesis, etc. MOFs are excellent materials for multiple applications such as gas storage (e.g., CH4, N2, H2 adsorption), gas separation, gas sensing, catalysis, CO2 sequestration, etc. [1]. Concerning methane storage performance, copper benzene-1,3,5-tricarboxylate (Cu3btc2) possesses outstanding methane adsorption capacity that meets the volumetric DoE target of 263 cm3 (STP) CH4 cm−3 adsorbent 298 K and 65 bar [2]. Moreover, it is already produced on an industrial scale, which is an outstanding advantage.

However, although apparently the perfect material, it also has disadvantages. MOFs with free metal sites are susceptible to water. In the presence of moisture, the Cu-coordinated linkers in HKUST-1 are gradually replaced by water molecules, leading to progressive deterioration of the MOF structure [3]. Poor water resistance is therefore an immense shortcoming of HKUST-1 compared to extensively used “traditional” porous materials such as zeolites or porous carbons. Strategies to increase the stability of the MOF toward water include application of hydrophobic ligands, incorporation of hydrophobic molecules (fluorine molecules, carbon nanotubes, etc.), ligand substitution to functionalize the MOF surface, thermal treatment, among others [4]. Polymers are also proposed to make the MOF surface hydrophobic and therefore more resistant to water. [3, 5, 6]. Incorporation of carbon nanoparticles such as graphene oxide (GO) could also improve the humidity resistance of HKUST-1 [7].

An additional drawback is the poor thermal conductivity of MOFs which compromises both their gas uptake and working capacity, as the thermal conductivity and heat capacity of MOFs are generally low and difficult to fundamentally improve [8]. Heat evolved during adsorption may result in substantial swing in temperature and compromises the adsorption related performance unless it is dissipated fast and efficiently enough. It is still unclear as what is the role of the intrinsic thermal properties play in the thermal management of these systems [8]. The most intensively studied strategies to circumvent this weakness either aim to change the chemical composition of these materials [9] or again, to use composites. Carbon nanoparticles of outstanding thermal conductivity are an obvious choice. Cortés-Suárez and coworkers successfully grew HKUST-1 on the surface of conductive SWCNTs without loss of surface area or pore volume. Five m/m% SWCNTs even increased the surface area from 1410 m2 g−1 to 1714 m2 g−1 [10]. Wang et al. obtained aluminum framework composites by annealing aluminum foam—dopamine mixtures. The thermal conductivity of their optimized composite was almost three times higher than that of the parent aluminum foam [11].

Although MOF adsorbents might reach outstanding gas uptakes, their use at industrial scale is also limited since the product is still in powder form. Several techniques have been studied for shaping MOFs, e.g., pelletization, extrusion, granulation, or spray drying [12]. Binder-free pelleting may be the best solution, but amorphization of the crystalline structure during the compression process results in loss of porosity.

Composites with an appropriate thermally conductive nanostructured material could provide a solution to all the above challenges. They may enhance the mechanical stability and the water resistance as well as the thermal conductivity of the MOF—carbon associated systems [13]. To tackle this issue, various nanostructured carbon materials, like activated carbon [4], biochar [14], resorcinol–formaldehyde aerogel [15], single-wall carbon nanotube (SWCNT) [10], graphene, or graphite oxide [1, 7, 16,17,18,19,20,21,22], have been proposed to enhance the mechanical resistance of the MOF frameworks.

In spite of its crucial practical importance, there are only a limited number of papers focusing on the thermal properties of the MOF or its composites. Most of these publications are based on model calculations [8, 23]. The thermal conductivity models of MOFs most often rely on Fourier’s law as well as the evaluation of early thermal conductivity measurements [23,24,25], however, molecular dynamics (MD) simulations found that nanostructured materials show diverse non Fourier effects [26]. Recently, Wieme et al. studied the thermal conductivity, heat capacity, and thermal expansion of MOFs with MD methods and pointed out the relevance of the density and the chemical nature of the metal component of the MOF [8]. Molecular dynamics simulation and model calculations revealed that the thermal conductivity of HKUST-1 is severely affected by the perfection required of the crystals: even a few missing linker defects, considerably lower the heat conductivity [27]. Experimental thermoreflectance measurements performed on single-crystal HKUST-1 revealed that adsorbates filling the pores, such as water or short chain alcohols, greatly reduce both the thermal diffusivity and the thermal conductivity of the MOF [28]. Li et al. [29] proposed a novel rational heat-conducting modification of HKUST-1 by combining it with boron nitride fibers. Incorporation of graphite flakes into HKUST-1 crystals was found to improve the structural stability of the embedded nanocrystals during compressions and resulted in appreciable improvement in the thermal conductivity properties, as proved by photothermal heating experiments [30].

In this work, reduced graphene oxide (RGO)–HKUST-1 mechanical mixtures were studied in order to reveal the effect of RGO on the texture and the thermal properties. HKUST-1 obtained by two different synthesis routes was mixed with RGO in systematically varying ratios prior to the compression. Powder XRD and Raman spectroscopy were used to characterize the response of the crystal structure, while low temperature nitrogen adsorption was used the follow the adsorption properties of the pellets. The thermal properties were assessed by the "flash" heat pulse method. Our experimental results confirmed that such highly porous MOF samples can show a behavior that cannot be modeled using Fourier's law. In other words, when one attempts to determine the characteristic thermal properties (such as the thermal diffusivity), the standard approach could lead to significant errors. This property of MOF samples was unknown up to this point. This notably affects any thermal design procedures, and with the present paper, we wish to highlight these properties and offer an effective and more accurate methodology on how to handle and characterize the samples. The experimental thermal data were evaluated with the Fourier and a “continuum” Guyer–Krumhansl (GK) equations [31]. Based on these investigations, we offer a solution how to find the thermal diffusivity for such heterogeneous materials.

Experimental

Materials

HKUST-1

HKUST-1 (C18H6Cu3O12, M: 604.87 g/mol) was synthesized under solvothermal conditions following Wang et al. [32] at 80 °C. Benzene-1,3,5-tricarboxylic acid (H3btc), copper(II) nitrate trihydrate (Cu(NO3)2.3 H2O), and absolute ethanol (CH3CH2OH; 99.5%) were purchased from Merck. High-purity water of Millipore grade was used for the synthesis. All chemicals were used without further purification. H3BTC dissolved in ethanol was thoroughly mixed with the aqueous solution of Cu(NO3)2.3H2O in stoichiometric ratio in a Teflon lined autoclave (Parr Instrument). After eliminating the air with argon gas (T45 from Linde) bubbling, the autoclave was sealed and kept at 80 °C for 24 h. After cooling to room temperature, the obtained turquoise crystals are washed with ethanol to remove all unreacted components. Finally, the crystals were filtered, air-dried and stored in a desiccator filled with freshly activated silica. The fine crystalline material was investigated without further crushing or grinding (HL set].

HKUST-1 was also obtained in a fast room temperature self-assembly of H3BTC and Cu(NO3)2∙3 H2O in ethanol [33]. After 10 min, the crystals were separated, thoroughly washed with ethanol, dried, and stored as above (GM set). Samples were outgassed at 383 K in vacuum (activation) directly before the gas adsorption measurements.

Reduced graphene oxide (RGO)

1.1 mass% aqueous GO suspension was obtained from natural graphite with an improved Hummer’s method [34, 35]. Reduced graphite oxide (RGO) was prepared from this suspension with ascorbic acid in a basic NH4OH environment according to Fernández-Merino et al. [36]. The freeze-dried chemically reduced graphite oxide consists of 1.3-nm-thick flakes with an average layer distance 0.36 nm. It contains 87.1 at% C, 9.9 at% O, and 3.0 at% N, based on it X-ray photoelectron spectroscopy (XPS) analysis [37]. The RGO was stored in a brown glass bottle until further use.

Manufacturing the composites and pellets

HKUST-1 and RGO mixtures were thoroughly homogenized in various m/m ratios in an agate mortar. Pellets were prepared at ambient temperature by compressing 100-mg mixed powder in a 13-mm-diameter sample holder at 25 bar for 10 min in an OL57 hydraulic press [15].

Characterization methods

Scanning electron microscopy (SEM, JEOL JSM 6380LA, Jeol Ltd. Tokyo, Japan) was used to study the morphology of the composites. Samples were fixed to a copper sample holder with conductive carbon tape followed by gold coating to increase the electrical conductivity of the samples. Powder X-ray diffraction (XRD, X’Pert Pro MPD, PANalytical Bv., Almelo, The Netherlands) patterns were obtained in the range 2θ = 4–84° using an X’celerator type detector and Cu Kα radiation with Ni filter foil (λ = 1.5408 Å) and a “zero-background Si single crystal” sample holder. The Search&Match algorithm of the HighScore Plus (PANalytical Bv., Almelo, The Netherlands) software was used for phase identification according to either the international Powder Diffraction File (PDF4 + , Release 2023, International Centre of Diffraction Data, ICDD, Pennsylvania, USA) or Cambridge Structural Database (CSD, version 5.44, Cambridge Crystallographic Data Centre, CCDC [38]) using the in-built powder pattern generator algorithm of the Mercury software [39]. Raman spectra were obtained on a LabRAM (Horiba Jobin Yvon) instrument. The laser source was a λ = 532 nm Nd:YAG (laser power at the focal point 15 mW). A 0.6 OD filter was used to reduce the power of the beam. Parameter optimization and data analysis were performed by a LabSpec 5 software. Low-temperature (-196 °C) nitrogen adsorption measurements were performed after 24-h degassing at 383 K on a NOVA 2000e (Quantachrome, USA) automatic volumetric instrument. The apparent surface area SBET was determined using the Brunauer–Emmett–Teller (BET) model [40]. Pore volumes V0.20 and V0.95 were estimated from the amount of vapor adsorbed at p/p0 = 0.20 and 0.95, respectively, assuming that the adsorbed gas fills the corresponding pores as a liquid. The Dubinin–Radushkevich (DR) plot [41] was used to calculate the micropore volume Vmicro. The pore size distributions were computed by the Barrett–Joyner–Halenda (BJH) method [42].

Thermal behavior

A well known and widely used method for determining the thermal diffusivity of various materials is the "flash" heat pulse experiment [43, 44]. The method itself is simple. A sample, which is thin with respect to its area, is excited by a thermal pulse on the front face and the change in temperature is measured on the rear face (Fig. 1). The excitation time is short, only 0.01 s. In the measuring device, the excitation pulse is provided by a flash lamp, which excites the front face of the sample. The temperature rise is measured with a K-type thermocouple in contact with the rear face. The thermocouple outputs are isolated during the measurement to minimize the various electrical noise sources and to prevent the excitation pulse source from introducing any disturbance into the thermocouple circuit and thus into the measurement itself. An important element of the measurement is the trigger signal, i.e., the signal that shows exactly when the sample is excited. This is detected and recorded by a photovoltaic sensor, which induces a voltage in response to light. The measured signals are recorded by a PC oscilloscope. After the measurement, the rear side temperature is evaluated using the Fourier and GK equations according to [31].

The arrangement of the “flash” heat pulse experiment [45]

Results

The nomenclature and composition of the pellets

As the synthesis route affects the size of the developing MOF crystals [32, 46], therefore the HKUST-1 samples studied in this work were prepared either in solvothermal route (HL, according to [32]) providing larger or simple room temperature self-assembly under ambient conditions (GM, according to [33]), providing smaller crystalline particles. Table 1 lists the composition and the nomenclature of the compressed disks. GO-free samples were also characterized in as-received powder form to reveal the effect of applied compression (distinguished as HL powder and GM powder, respectively).

Characterization

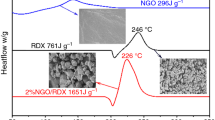

Figure 2 compares the SEM micrographs of the samples. In order to reveal the most representative images, different magnifications were selected. The typical crystalline form of the MOF particles can be clearly distinguished in the HL series, even in the compressed state (HL-0). The crystals obtained with room temperature self-assembly are smaller, their edges are less clear, and their surface is rough.

The low resolution SEM images of the pellet cross-sections clearly show that the RGO forms crimped multilayer sheaves within the MOF matrix. The distribution, though far from ideal, seems to be slightly more uniform in the GM set.

The combined effect of the mixing and compression on the crystalline morphology was studied by powder XRD (Fig. 3). In both sets of samples, the wide flat signal of the graphenic component becomes visible above 20 m/m% RGO content. The reference data from Powder Diffraction File database (PDF4 + , Release 2023, International Centre of Diffraction Data, ICDD; ref. No. 00–064-0936) and the Miller indices reported by Yang et al. [47] were used for identification.

XRD patterns of compressed components and composites. Diffractograms of uncompressed the RGO and MOF samples are plotted as well. HKUST-1-related diffractograms were normalized to their (222) peak. Assigned according to PDF4 + , Release 2023, International Centre of Diffraction Data, ICDD; ref. No. 00–064-0936

The (222) and (731) peaks were selected from the powder XRD patterns of HKUST-1 crystals for closer observation [15, 47]. The position of these peaks does not change in any of the samples (2θ = 11.87 ± 0.11 and 2θ = 26.20 ± 0.12, respectively). Although the (222) peak is much more intense than that of (731), their intensity ratio varies only weakly. The intensity ratios of the two selected peaks I(731)/I(222) together with the increasing noise obviously marks a reduction of the (222) diffraction peaks. In the compressed composites, an extension of the mean size or the ordered domains was observed with increasing RGO content. The interlayer spacing d of the lattices was obtained from Bragg’s law [48],

n is the diffraction order 1, λ is the wavelength of the X-ray (λ = 1.5406 Å) ,and \({\uptheta }\) is the Bragg angle. The mean size of the ordered crystallites Lc was derived with the Scherrer formula, Eq. (2) [49].

The shape factor K = 0.9 [50] and FWHM (in radian) stands for the full width of the corresponding peak at half maximum. The corresponding data are shown in Table 2.

The interlayer distance of the samples is affected neither by the pressure nor by the RGO content, although these effects have some impact on the crystallite size in the HL series.

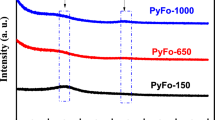

The Raman spectra were detected in the Raman shift range 210–2000 cm−1 using a λ = 532 nm laser source (Fig. 4). The doublet around 500 cm−1, which is related to Cu–O stretching modes involving oxygen atoms of carboxylate bridges, seems to be more visible in the pure MOF after compression. The peak at 828 cm−1, together with the one at 725 cm−1, was assigned as the C–H out-of-plane bending modes of the benzene ring, while the 1006 cm−1 corresponds to the symmetric stretching of C = C. The peaks in the 1460–1600 cm−1 region mark the symmetric and asymmetric stretching of O-C-O (1469 cm−1 and 1530 cm−1, respectively) and the C = C symmetric stretching of the benzene ring (1613 cm−1) [51,52,53].

The two most intense peaks in the central region, i.e., the C–H band at ca 825 cm-1 and the C = C symmetric stretching at ca 1005 cm−1, were selected for closer analysis of the MOF. The Raman spectra of the as-received activated (heat treated at 110 °C) and compressed MOFs are compared in Figure S1. While the position of these peaks is barely affected by the additional treatment, their intensity ratios are sensitive both to water removal (i.e., activation) and to compression. Activation suppresses the relative intensity of the symmetric stretching of the C = C in the rings, and the latter has an opposite effect: the intensity of the two peaks becomes more similar. The iconic G and D bands of the added RGO are easily recognizable in all the relevant samples, in spite of the overlap with some of the MOF signals. As the RGO gave no signal below 1100 cm−1, comparison of the selected intensity ratios allows one to follow the HKUST-1 independently (Table 3). In both series, the addition of RGO suppresses the ratio of the intensities corresponding to C–H bending and C = C stretching, IC–H/IC=C. Compression of the RGO in the presence of the corresponding HKUST-1 particles leads to an increase of the defect sites in the RGO regions.

Based on these results, we can conclude that the mechanical treatment during the mixing and the compression has an effect at multiscale levels. External pressure destroys the crystalline HKUST-1 particles and leads to a more compact structure, while reducing the mean size of the ordered domains. The pore morphology also suffers severe alteration: the almost exclusively microporous MOF structure is converted to a micro-mesoporous texture along with a dramatic loss of the gas storage capacity. The majority of the damage in these characteristics occurs already at 25 bar. Raman spectra reveal that the influence of compression may be more than simply physical.

We can gain information about the morphological changes at an even lower scale from low temperature nitrogen adsorption isotherms (Fig. 5 a, b). In addition, we can also assess the gas storage capability of the composites from these data.

The difference between the two powder samples should be emphasized: practically, the total adsorption capacity of the HL sample derives from the micropores, while the GM sample possesses micropores and narrow macropores in almost equal ratio. External pressure results in loss of microporosity and formation of mesoporosity, revealing a uniform closure of the hysteresis loops at an estimated pore diameter of 4 nm. Comparison of the isotherms shows that only the uncompressed HL sample possesses a fine structure at p/p0 ≈ 0.1 [15]. The effect of compression is even more obvious from the pore size distribution curves derived from the adsorption branches (Fig. 5c, d). Further, characteristic data from the isotherms are given in Table 4. All the listed values confirm that compression substantially ruins the nanoscale morphology of the MOF. The surface area drops as an effect both of compression and the addition of RGO. In the GM set, however, RGO displays a protective effect.

The above results indicate that the pore morphology also suffers a severe alteration: the almost exclusively microporous MOF structure is converted to a micro-mesoporous texture along with a dramatic loss of the potential gas storage capacity.

Thermal behavior of the composite pellets

In recent years, it has been observed that the thermal behavior of heterogeneous materials deviates from the classical Fourier equation, leading to different thermal diffusivity, and its determination requires the existence of additional thermal parameters. Such heterogeneity can be found in metal foams, in layered composites or in porous parts of rocks. The so-called GK equation is successfully applied in these experiments, but these evaluations result in computationally intensive work, using numerous numerical solutions, even if the initial value of the parameters can be well estimated. In addition to the well-known Fourier equation evaluation method, an evaluation method for the GK equation has been developed for the evaluation of the experiments [31], thus allowing a more accurate determination of the thermal parameters of the samples, using the thermal behavior of the material over time. In the one-dimensional case, these models read,

where \(\tau_{{\text{q}}}\) is the relaxation time, κ is a sort of intrinsic length scale, and \(\alpha\) is the thermal diffusivity. Additionally, the GK model can return the solution of the Fourier equation when \(\kappa^{2} /\tau_{{\text{q}}} = \alpha\), this is called Fourier resonance [45].

The aim of this study is to determine the effective thermal parameters. The samples that we are testing are porous, directly contaminated to obtain better thermal properties. However, they result in heat conduction over multiple time scales. For these reasons, the exact determination of the thermal parameters is not possible with the Fourier equation, which is a single time scale model, and thus it is not sufficient to describe the transient behavior of such samples. The continuum GK equation we use is only formally identical to the original GK equation based on phonon hydrodynamics. Our continuum model does not use phonons, so the coefficients (e.g., the relaxation time) do not inherit its interpretation from kinetic theory. The Fourier equation contains one cooling and one conduction time scale for a given experimental setup. In the case of the GK equation, the convection contribution (cooling) is inherited, but two conduction time scales are now incorporated, required for the proper transient description of the heterogeneous specimens.

These aspects are revealed by the analytical solutions of the Fourier and GK equations. For simplicity, we show the expressions for the rear face and its one-term representation, i.e., only the first term is used from the infinite series [31], which reads

where h is the heat transfer coefficient and α is the thermal diffusivity of the sample. In the GK heat equation, the rear face temperature history can be expressed as:

which is also a 'one-term approximate solution'. In this equation, \(x_{1}\) and \(x_{2}\) represent the conduction time scales. For further details, we refer to ref. [31]. The evaluation procedure is based on the determination of h, \(x_{{\text{F}}}\), \(x_{1}\), and \(x_{2}\), depending on the model. These are eligible to determine the effective parameters appearing in the heat Eqs. (5) and (6).

The experiments were carried out on a total of ten samples, four times on each sample. In cases where graphene was not present in the samples, Fourier equation evaluation proved sufficient, but this only involved two samples. In the other eight cases, the GK equation was needed to determine the exact thermal parameter and to model the temperature profile for curve fitting.

When evaluating the samples, it was observed that the samples that do not contain graphene (HL-0 and GM-0) can be fitted with the Fourier equation. The fit of the HL-0 sample is shown in Fig. 6. It is observed that the measurement and Fourier fitting run together everywhere and the difference between the two curves is negligible. Furthermore, we draw attention to the sample thickness in these cases (Table 5): the HL-0 and GM-0 samples, to which the Fourier equation applies, are notably larger than all the other samples. This result could imply a possible size-dependent thermal behavior, since the sample thickness largely influences the relevant conduction time scales. As a consequence, the corresponding thermal diffusivity values fall outside the trend shown based on the other samples (see later Fig. 8 for comparison).

For the samples with graphene, Fourier fitting was not sufficient, it is observed that the Fourier heat equation models a slower temperature rise during the initial phase, and then it becomes faster, overshooting the measured data. Therefore, the Fourier fitting cannot be reliably applied in such situations, and the GK equation is utilized to obtain a more detailed description. Firstly, it offers parameters to cover both time scales. Secondly, it can be used to estimate a diffusivity parameter that can be used in the Fourier equation for slow heat conduction processes with

that is, averaging the diffusion time scales found with the GK equation.

Applying the evaluation by the GK equation to the same data series yields a much more accurate curve coinciding with the data series, in which the difference between the two is negligible (Fig. 7). Table 5 shows the thermal parameters for the samples, the thermal diffusivity from Fourier and GK evaluations, the GK parameters, and the comparison between the Fourier thermal diffusivity \({\upalpha }_{{\text{F}}}\) and its approximation by \({\upalpha }_{{{\text{slow}}}}\).

Figure 8 compares the thermal diffusivity of the samples obtained with different process technologies. The trend is the same for the Fourier and GK values, although the former always gives significantly higher values

In the case where no graphene was present in the samples, Fourier fitting was sufficient. However, thinner samples have markedly lower thermal diffusivity, but this is not the consequence of the graphene content. The thermal diffusivity increases monotonically with increasing graphene content. In the cases where the GK fit had to be used for accurate fitting and thermal parameter determination, it is possible to examine how the average of the time scales given by GK differ from that given by Fourier. It is also remarkable that the ‘slow process approximation’ of the Fourier thermal diffusivity is always larger than the value predicted by the best Fourier fit.

Conclusions

HKUST-1 samples from two different synthesis routes were used to manufacture HKUST-1–RGO mechanical composites of 0–50 mass% RGO content. Although the XRD and Raman techniques derived features of the pristine MOFs were similar, the macroscopic size, shape, and the surface of the particles were very different. The synthesis route also provided pristine MOFs with different porosity. The thermal diffusivity of the composites was assessed by the "flash" heat pulse method, and the experimental data were acceptably modeled with the GK equation, as our diffusivity measurements experimentally proved that the Fourier model is unable to model our samples. As expected, addition of RGO has a positive effect: the thermal parameter increases monotonically with increasing RGO content. The trend is more obvious for MOF crystals of smaller size, owing to their better contact with RGO sheets. The methodology applied for the assessment of the thermal behavior of the composites could be promising to optimize the synthesis–composition–gas uptake properties. However, we also wish to emphasize that size-dependent behavior can be present as well, and these samples seem to be sensitive in this respect.

References

Alfe M, Policicchio A, Lisi L, Gargiulo V. Solid sorbents for CO2 and CH4 adsorption: The effect of metal organic framework hybridization with graphene-like layers on the gas sorption capacities at high pressure. Renew Sustain Energy Rev. 2021. https://doi.org/10.1016/j.rser.2021.110816.

Peng Y, Krungleviciute V, Eryazici I, Hupp JT, Farha OK, Yildirim T. Methane storage in metal−organic frameworks: current records, surprise findings, and challenges. J Am Chem Soc. 2013. https://doi.org/10.1021/ja4045289.

Ding M, Jiang HL. Improving water stability of metal–organic frameworks by a general surface hydrophobic polymerization. CCS Chemistry. 2021. https://doi.org/10.31635/ccschem.020.202000515.

Ansone-Bertina L, Ozols V, Arbidans L, Dobkevica L, Sarsuns K, Vanags E, Klabins M. Metal-organic frameworks (MOFs) containing adsorbents for carbon capture. Energies. 2022. https://doi.org/10.3390/en15093473.

Zhang W, Hu Y, Ge J, Jiang HL, Yu SH. A facile and general coating approach to moisture/water resistant metal-organic frameworks with intact porosity. 2014. J Am Chem Soc. https://doi.org/10.1021/ja509960n.

Tian N, Gao Y, Wu J, Luo S, Dai W. Water-resistant HKUST-1 functionalized with polydimethylsiloxane for efficient rubidium ion capture. New J Chem. 2019. https://doi.org/10.1039/C9NJ03632F.

Wang H, Zheng QR, Zhang X, Wu M. Development of HKUST-1 composites for methane storage by adsorption through incorporation and carbonization. Res Eng. 2023. https://doi.org/10.1016/j.rineng.2023.101098.

Wieme J, Vandenbrande S, Lamaire A, Kapil V, Vanduyfhuys L, Van Speybroeck V. Thermal engineering of metal−organic frameworks for adsorption applications: A molecular simulation perspective. ACS Appl Mater Interfaces. 2019. https://doi.org/10.1021/acsami.9b12533.

Healy C, Patil KM, Wilson BH, Hermanspahn L, Reid NCH, Howard BI, Kleinjan C, Kolien J, Payet F, Telfer SG, Kruger PE, Bennett TD. The thermal stability of metal-organic frameworks. Coord Chem Rev. 2020. https://doi.org/10.1016/j.ccr.2020.213388.

Cortés-Suárez J, Celis-Arias V, Beltrán HI, Tejeda-Cruz A, Ibarra IA, Romero-Ibarra JE, Sánchez-González E, Loera-Serna S. Synthesis and characterization of an SWCNT@HKUST-1 composite: Enhancing the CO2 adsorption properties of HKUST-1. ACS Omega. 2019. https://doi.org/10.1021/acsomega.9b00330.

Wang B, Yan Y, Lin J, Cai Y, Cao J, Qi J. Efficient multi-path heat dissipation of aluminum framework composites assisted with high crystalline carbon coating. Carbon. 2023. https://doi.org/10.1016/j.carbon.2023.118040.

Yeskendir B, Dacquin JP, Lorgouilloux Y, Courtois C, Royer S, Dhainaut J. From metal-organic framework powders to shaped solids: recent developments and challenges. Mater Adv. 2021. https://doi.org/10.1039/d1ma00630d.

Liu XW, Sun TJ, Hu JL, Wang SD. Composites of metal-organic frameworks and carbon-based materials: preparations, functionalities and applications. J Mater Chem A. 2016. https://doi.org/10.1039/C5TA09924B.

Zhao Y, Seredych M, Zhong Q, Bandosz T. Aminated graphite oxides and their composites with copper-based metal-organic framework: in search for efficient media for CO2 sequestration. RSC Adv. 2013. https://doi.org/10.1039/C3RA40817E.

Domán A, Nagy B, Nichele LP, Srankó D, Madarász J, László K. Pressure resistance of copper benzene-1,3,5-tricarboxylate-carbon aerogel composites. Appl Surf Sci. 2018. https://doi.org/10.1016/j.apsusc.2017.11.251.

Domán A, Madarász J, Sáfrán G, Wang Y, László K. Copper benzene-1,3,5-tricarboxylate (HKUST-1)-graphene oxide pellets for methane adsorption. Microporous Mesoporous Mater. 2021. https://doi.org/10.1016/j.micromeso.2021.110948.

Al-Naddaf Q, Al-Mansour M, Thakkar H, Rezaei F. MOF-GO hybrid nanocomposite adsorbents for methane storage. Ind Eng Chem Res. 2018. https://doi.org/10.1021/acs.iecr.8b03638.

Domán A, Klébert S, Madarász J, Sáfrán G, Wang Y, László K. Graphene oxide protected copper benzene-1,3,5-tricarboxylate for clean energy gas adsorption. Nanomaterials. 2020. https://doi.org/10.3390/nano10061182.

Huang W, Zhou X, Xia Q, Peng J, Wang H, Li Z. Preparation and adsorption performance of GrO@Cu-BTC for separation of CO2/CH4. Ind Eng Chem Res. 2014. https://doi.org/10.1021/ie501040s.

Policicchio A, Zhao Y, Zhong Q, Agostino RG, Bandosz T. Cu-BTC/aminated graphite oxide composites as high-efficiency CO2 capture media. ACS Appl Mater Interfaces. 2014. https://doi.org/10.1021/am404952z.

Solovtsova OV, Shkolin AV, Men’shchikov IE, Knyazeva MK, Fomkin AA, Tsivadze AYu, Aksyutin OE, Ishkov AG, Khozina EV. Functional composite adsorbents based on metal-organic frameworks in a carbon matrix applied for methane storage. Prot Met Phys Chem Surf. 2019. https://doi.org/10.1134/S2070205119060303.

Xu F, Yu Y, Xia Q, Wang H, Li J, Li Z. Ultrafast room temperature synthesis of GrO@HKUST-1 composites with high CO2 adsorption capacity and CO2/N2 adsorption selectivity. Chem Eng J. 2016. https://doi.org/10.1016/j.cej.2016.05.143.

Huang BL, McGaughey AJ, Kaviany M. Thermal conductivity of metal-organic framework 5 (MOF-5): Part I. Molecular dynamics simulations. Int J Heat Mass Trans. 2007;50(3–4):393–404. https://doi.org/10.1016/j.ijheatmasstransfer.2006.10.002.

D.R. Poirier, G.H. Geiger, G.H. Fourier’s Law and Thermal Conductivity of Materials. In: Transport Phenomena in Materials Processing. Springer, Cham. (2016) https://doi.org/10.1007/978-3-319-48090-9_6

Huang BL, Ni Z, Millward A, McGaughey AJH, Uher C, Kaviany M, Yaghi O. Thermal conductivity of a metal-organic framework (MOF-5): Part II Measurement. Int J Heat Mass Trans. 2007;50:405–11. https://doi.org/10.1016/j.ijheatmasstransfer.2006.10.001.

P. Desmarchelier, E. Nikidis, J. Kioseoglou, Y. Nakamura, A. Tanguy, K. Termentzidis. Beyond Fourier Thermal Management at the Nanoscale. 28th International Workshop on Thermal. Investigations of ICs and Systems, THERMINIC 2022, Sep 2022, Dublin, Ireland. https://doi.org/10.1109/THERMINIC57263.2022.9950603

Islamov M, Babaei H, Wilmer CE. Influence of missing linker defects on the thermal conductivity of metal−organic framework HKUST-1. ACS Appl Mater Interfaces. 2020. https://doi.org/10.1021/acsami.0c16127.

Babaei H, DeCoster ME, Jeong M, Hassan ZM, Islamoglu T, Baumgart H, McGaughey AJH, Redel E, Farha OK, Hopkins PE, Malen JA, Wilmer CE. Observation of reduced thermal conductivity in a metal-organic framework due to the presence of adsorbates. Nat Commun. 2020. https://doi.org/10.1038/s41467-020-17822-0.

Li J, Liu L, Shah SJ, Tang Y, Jiang S, Mu G, Man Q, Zhao Z, Zhao Z. Construction of novel Heat-conducting Cu-based MOF nanocomposite (HK-mBNNS/PVDF) film for highly efficient Ad-/desorption of toluene. Chem Eng J. 2023;15(456):140964.

Farrando-Perez J, Rodrıguez-Castillo M, Martínez-Escandell M, Monge M, Silvestre-Albero J. Improved thermal management in HKUST-1 composites upon graphite flakes incorporation: Hydrogen adsorption properties. Int J Hydrogen Energy. 2023. https://doi.org/10.1016/j.ijhydene.2023.05.357.

Fehér A, Kovács R. On the evaluation of non-Fourier effects in heat pulse experiments. Int J Eng Sci. 2021. https://doi.org/10.1016/j.ijengsci.2021.103577.

Wang F, Guo H, Chai Y, Li Y, Liu C. The controlled regulation of morphology and size of HKUST-1 by “coordination modulation method.” Microporous Mesoporous Mater. 2013. https://doi.org/10.1016/j.micromeso.2013.02.023.

Tian T, Zeng Z, Vulpe D, Casco ME, Divitini G, Midgley PA, Silvestre-Albero J, Tan JC, Moghamad PZ, Fairen-Jimenez D. A sol–gel monolithic metal–organic framework with enhanced methane uptake. Nat Mater. 2018. https://doi.org/10.1038/NMAT5050.

Hummers WS Jr, Offeman RE. Preparation of graphitic oxide. J Am Chem Soc. 1958;80(6):1339. https://doi.org/10.1021/ja01539a017.

Marcano DC, Kosynkin DV, Berlin JM, Sinitskii A, Sun Z, Slesarev A, Alemany LB, Lu W, Tour JM. Improved synthesis of graphene oxide. ACS Nano. 2010. https://doi.org/10.1021/nn1006368.

Fernández-Merino MJ, Guardia L, Paredes JI, Villar-Rodil S, Solís-Fernández P, Martínez-Alonso A, Tascón JMD. Vitamin C is an ideal substitute for hydrazine in the reduction of graphene oxide suspensions. J Phys Chem C. 2010. https://doi.org/10.1021/jp100603h.

Bertóti I, Farah S, Bulátkó A, Farkas A, Madarász J, Mohai M, Sáfrán G, László K. Nitrogen implantation into graphene oxide and reduced graphene oxides using radio frequency plasma treatment in microscale. Carbon. 2022;31(199):415–23. https://doi.org/10.1016/j.carbon.2022.08.024.

Allen FH. The Cambridge structural database: a quarter of a million crystal structures and rising. Acta Cryst. 2002. https://doi.org/10.1107/S0108768102003890.

Macrae CF, Bruno IJ, Chisholm JA, Edgington PR, McCabe P, Pidcock E, Rodriguez-Monge L, Taylor R, van de Streek J, Wood PA. Mercury CSD 20—new features for the visualization and investigation of crystal structures. J Appl Cryst. 2008. https://doi.org/10.1107/S0021889807067908.

Brunauer S, Emmett PH, Teller E. Adsorption of gases in multimolecular layers. J Am Chem Soc. 1938. https://doi.org/10.1021/ja01269a023.

Dubinin MM, Radushkevich LV. The Equation of the characteristic curve of activated charcoal. Dokl Akad Nauk SSSR. 1947;55:327–9.

Barret EP, Joyner LG, Halenda PP. The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J Am Chem Soc. 1951. https://doi.org/10.1021/ja01145a126.

Parker WJ, Jenkins RJ, Butler CP, Abbott GL. Flash method of determining thermal diffusivity, heat capacity, and thermal conductivity. J Appl Phys. 1961. https://doi.org/10.1063/1.1728417.

James HM. Some extensions of the flash method of measuring thermal diffusivity. J Appl Phys. 1980. https://doi.org/10.1063/1.328337.

Both S, Czél B, Fülöp T, Gróf G, Gyenis Á, Kovács R, Ván P, Verhás J. Deviation from the Fourier law in room-temperature heat pulse experiments. J Non-Equilib Thermodyn. 2016;41(1):41–8.

Wee LH, Lohe MR, Janssens N, Kaskelb S, Martens JA. Fine tuning of the metal–organic framework Cu3(BTC)2 HKUST-1 crystal size in the 100 nm to 5 micron range. J Mater Chem. 2012. https://doi.org/10.1039/C2JM31536J.

Yang A, Li P, Zhong J. Facile preparation of low-cost HKUST-1 with lattice vacancies and high-efficiency adsorption for uranium. RSC Adv. 2019. https://doi.org/10.1039/C9RA01427F.

Bragg WH, Bragg WL. The reflexion of X-rays by crystals. Proc R Soc Lond. 1913. https://doi.org/10.1098/rspa.1913.0040.

Scherrer P. Bestimmung der Größe und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Göttinger Nachrichten Math Phys. 1918;2:98–100.

Langford JI, Wilson AJC. Scherrer after sixty years: A survey and some new results in the determination of crystallite size. J Appl Cryst. 1978. https://doi.org/10.1107/S0021889878012844.

Todaro M, Alessi A, Sciortino L, Agnello S, Cannas M, Gelardi FM, Buscarino G. Investigation by Raman spectroscopy of the decomposition process of HKUST-1 upon exposure to air. J Spectrosc. 2016. https://doi.org/10.1155/2016/8074297.

Prestipino C, Regli L, Vitillo JG, Bonino F, Damin A, Lamberti C, Zecchina A, Solari PL, Kongshaug KO, Bordiga S. Local Structure of Framework Cu(II) in HKUST-1 Metallorganic Framework: Spectroscopic Characterization upon Activation and Interaction with Adsorbates. Chem Mater. 2006. https://doi.org/10.1021/cm052191g.

Gentile FS, Pannico M, Causá M, Mensitieri G, Palma GD, Scherillo G, Musto P. Metal defects in HKUST-1 MOF revealed by vibrational spectroscopy: a combined quantum mechanical and experimental study. J Mater Chem A. 2020. https://doi.org/10.1039/D0TA01760D.

Acknowledgements

We extend our warm thanks to G. Bosznai (BME) for the invaluable technical assistance. This work was performed in the frame of the 2020‐3.1.1‐ZFR‐KVG‐2020‐00006 project, implemented with the support provided from the National Research, Development and Innovation Fund of Hungary, financed under the 2020‐3.1.2‐ZFR‐KVG funding scheme. This research was also funded by the Hungarian grants OTKA K143571 and FK134277. The research is part of project no Project no. TKP‐6‐6/PALY‐2021 has been implemented with the support provided by the Ministry of Culture and Innovation of Hungary from the National Research, Development and Innovation Fund, financed under the TKP2021‐NVA funding scheme. The research was also funded by the Sustainable Development and Technologies National Programme of the Hungarian Academy of Sciences (FFT NP FTA). SKSA is grateful to the Stipendium Hungaricum scholarship program of the Hungarian Government.

Funding

Open access funding provided by Budapest University of Technology and Economics.

Author information

Authors and Affiliations

Contributions

MG contributed to the sample preparation, investigation, and data evaluation; SKS Andrade was involved in the writing—review and editing; AF assisted in the experiments evaluations and data acquisition; AF and JM assisted in the investigation; LH contributed to the synthesis; PG was involved in the investigation; RK contributed to the resources and supervision. KL was involved in the conceptualization, methodology, resources, and writing—original draft preparation.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gál, M., Andrade, S.K.S., Fehér, A. et al. Thermal diffusity in copper benzene-1,3,5-tricarboxylate–reduced graphite oxide mechanical composites. J Therm Anal Calorim (2024). https://doi.org/10.1007/s10973-024-13021-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10973-024-13021-x