Abstract

India has an abundance of solar energy resources. Nearly 90% of the urban dwellers in different parts of India used electricity for heating water. Using electricity for resident water heating not only contributes to negative environment impact via the emission of a substantial quantity of carbon dioxide but also places a financial burden on households. The examination of solar irradiance, economic feasibility, and hot water demands is crucial in assessing the potential of solar thermal collector (STC) to fulfill hot water requirement. In order to enhance the value of the STC, it is essential for the collector to effectively manage operations with a focus on minimizing cost. To get an optimal heating effect, the present STC is fastened with an obstruction inside the tube. The collector is examined in three distinct seasons to observe temperature variations and the appropriate use of the device during non-operational hours. The recommended average temperatures for summer, rainy season, and winter are 68, 57, and 47 °C, respectively. Additionally, a thorough examination of the economic analysis and payback period for STC was also conducted.

Similar content being viewed by others

Introduction

One of the significant impediments to any nation's growth is the issue of global warming, which is worsening due to dangerous gas emissions generated by the extensive use of conventional fuels. The only way to solve this issue is by using unconventional energy sources. Solar energy (SE) is one of the most prominent resources of energy that helps overcome this problem. It is observed that around 35% of the energy is utilized by the building section for different applications. It is observed by [1] that 75% of the total energy is used for solar water heating applications in the building sector. Therefore, an initiative is considered to place SWH in building areas. Evacuated tube collectors (ETC) and S-FPC are good options available for water heating applications [2, 3]. It is observed that the S-FPC is excessively used for heating applications due to its simple design and low maintenance cost. However, due to heat waste from the solar collector and low thermal efficiency, scientists are continuously working to increase the TP of the system. There are different ways to enhance the TP of the system. The researcher works on the design geometry of the system to create turbulence along the flow of the fluids. Different types of turbulators are used to augment the system's TP. In the current work, the author used delta obstacle to augment the TP of the system. SWHS has a few drawbacks, the most vital being that they rely on the weather and take a significant amount of time to function [4]. The drawbacks raise the question of how one can efficiently create hot water in various settings. One option is to make use of energy; however, this solution may be expensive, and there is no guarantee that reliable access will always be available in more distant locations [5, 6]. Another contributor is the use of fossil fuels, which, unfortunately, has a negative impact on the natural world. On the other hand, solar radiation provides an effective alternative to traditional means of heating water, and this alternative is known as a SWH [7, 8]. Several groups of researchers in a wide range of countries and regions throughout the globe have used SWHS with great success. Some countries have an abundance of solar energy, such as India, which has an average of 300 sunny days per year with daily insolation levels ranging from 3 to 5 kWh/m2. Using SWHS as a water heating method is a highly efficient option in these places. The techniques used by modern solar energy harvesting devices are analogous to those used by heat absorber surfaces. Examples of these techniques include SWHSs, solar air heating systems, solar cookers [9,10,11]. Figure 1 depicts a classification of STC.

Solar thermal collectors have been of great importance for the last few decades. The researcher has replaced fossil fuels with renewable energy sources due to their unexhausted nature. The SE is also the prime energy source and is available in abundance. The researcher used solar energy in different ways to enhance the performance of the STC. Water heating is also one of the significant resources from STC because it can reduce the electricity bills used for water heating. Nowadays, most people utilize SWHS in both commercial and industrial applications. To increase the HT rate of SHWS, researchers are investigating several methods. India has great potential for producing clean energy sources, including hydropower, wind, and solar. This ability is recognized, demonstrating India's knowledge of the necessity for a growing nation to decrease its carbon impact. In January 2010, the Indian government attempted to encourage clean energy awareness under the Jawaharlal Nehru National Solar Mission, among the 8th goal under the National Action Plan on Climate Change (NAPCC-2008) [12]. Nevertheless, once they started paying attention and started with 1 MWh in 1995, it increased to 6134 MWh by the conclusion of the fiscal year 2020. By 2030, it is anticipated that the growth rate will have increased by about 40 times, reaching 746 GW. India has a considerable solar power capacity of 750 GW, a characteristic that may be ascribed to its demographic factors (MNRE, 2017). As a result, SE will fulfill the country's energy demands. Figure 2 illustrates the distribution of solar energy installation capacity among different Indian states.

India receives enough sunlight throughout the year due to its favorable geographical location. The solar radiation in India differs from 3 to 7 kWh/m2/day [13]. The optimum solar radiation is attained in June to July and December to January. A 2012 study found that the time spent outside in the sun decreased by 54% to account for rain, clouds, and fog. Therefore, solar energy can ensure an environmentally favorable environment for future growth. The Indian government has already taken steps to yield 10% of overall electricity production from clean energy sources such as solar, wind, and waste by 2020. Figure 3 shows the research area's geographical position on a map.

Research area's geographical position on a map [14]

Different F-SWHs are offered with various design setups. Direct flow, thermosiphon, and heat pipe types are some of these. Numerous academics have recently published their findings after aggressively working to improve F-SWH technology. The geographical location of the concerned area is Latitude: 30.9090° N, Longitude: 77.1219° E. Solan, Himachal Pradesh, India. Different studies have been done so far related to S-FPC. García et al. [15] explored the impact of three TT and three wire coil specimens within a solar collector tube on the thermal performance of S-FPC via experimental study. To ascertain if inserts may successfully augment HT in STCs, researchers examine the axial and longitudinal temperature development within the riser and absorber in addition to the f data. It describes the effects of f on heat transmission results and finds a consistent link between f and flow patterns. Legitimate criteria are provided to help choose the appropriate insert device for actual flat plate solar collectors based on their operating properties. Utilizing a compound parabolic concentrator (CPC) collector, Devanarayanan and Murugavel [16] offer the most recent advancements in integrated collector storage solar water heaters (ICSSWH). Many elements, including water tank placement and arrangement, absorber surface types, reflector types, glazing, and other design characteristics, influence the TP of the integrated compound parabolic concentrator storage solar water heater (ICPCSSWH). An overview of the performance analysis and several designs of ICPCSSWHs are given. As a dependable heat source for water heating applications, solar energy consumption is a promising design in recent advancements in CPC-based ICSSWH. Nevertheless, during non-collection times, in particular, the communal collection and storage function experiences considerable heat losses to the ambient (Table 1).

Nowadays, the accessible number of energy/sources is vigorously acceptable defunct in the world, and the scientists have been acknowledge the way of proliferate new systems, resettling present ones, and conclusively decline energy consumption/costs. The aspect of energy saving inspires the expansion of technique by reducing the cost. The distinct type of heat augmentation methods is utilized for heating purpose that includes active and passive [23]. In order to enhance the heating effect, various types of obstacles such as twisted tape, helical spring, coil spring, rib have been tested by the researcher [1, 4, 18]. The outcomes from these shapes are to have some different reactions to the hindrance promoter. Raymond Bliss [24] works on the design parameter of plate-efficiency factors of solar heat collector. A discussion on the physical mechanisms that are responsible for the spectrum selectivity of solar absorber coatings was given by Hutchins [25]. The article provides an overview of some examples of coatings that have shown to be useful and have found widespread use in solar heating systems. The criteria for endurance of coatings are evaluated, and an overview of procedures for surface examination is provided. Promvonge [26] carried out an investigation via experimentation that sought into the features of HT and \(f\) in a circular tube equipped with TT and coiled wire turbulators for the turbulent regime, Re = 3000–18,000. According to the findings, using wire coils in addition to TTs increase HT by twice as much as using only wire coils or TT alone. In the same circumstances, a TT and wire coil with a lower twist and coil pitch ratio have an advanced HT rate than one with a larger ratio. In addition, performance assessment standards for determining the true advantages of using the upgraded tube's TT and wire coil are provided. Sarma et al. [27] studied the combined approach of friction coefficient and HT characteristics using TT with a wide range of Re and PR. A generalize correlation between the \(f\) and the \({h}_{{\text{c}}}\) is analyzed by using the TT turbulator inside the tube and \(Re\) varies from 3000 to 22,000. The physical appearance shows that by inserting the turbulator inside the AT create swirl. Samruaisin et al. [28] studied the influence of convective \({h}_{{\text{c}}}\) in HE by using the TT turbulator. TT works as the swirl generator for increasing the TP of the system. In this work, the author also examined the combined effect of twisted tube and TT on \({h}_{{\text{c}}}\), pressure drop and TP of the system. The experiment is conducted utilizing trapezoidal shaped TT with different parameters such as \(y/w\)= 2.0–5.0, \(Re\)= 4500–16,000. The outcomes revel that the TP is increased by reducing the \(y/w\) and \(Re\). The TT with lower \(y/w\) of 2.0 yields the higher TP. Sable [29] studied the economic analysis of concrete SC by using the dimple tube. The author studied the utilization of SWHS in geographical region of Pune, India. In this experimental work, concrete slab is used in the wooden box. The author studied the SWHS in three different seasons, i.e., summer, rainy and winter seasons. Testing result revels that the average collector water temperature varies in the range from 59 to 69 °C. It is also examined that by utilizing dimple, the temperature is increased by 2.5 °C. Jaisankar et al. [30] experimentally examine the influence of HT and \(f\) characteristics in SWHS fitted with helically TT turbulator. The experiment is conducted with \(y/w\) of 3–6 and \(Re\) varies from 3000 to 23,000. The result demonstrates that the greatest TP is found for lower \(y/w\) of 3. Bhattacharyya et al. [31] numerically examine the effectiveness of TT insertion in SWHS for increasing \({h}_{{\text{c}}}\). The experiment is conducted with different entrance angle of 140°–180° and \(Re\) of 100–20,000. The examination shows that the greater entrance angle of 180° and smaller \(y/w\) can efficiently enhance the HT rate. Feizabadi et al. [32] experimentally evaluate the TP of TT fitted in U-tube HE. The various geometrical parameters that are used in this work are \(Re\) varies from 3843 to 11,436 and \(y/w\) of 2 and 6. It is conclude that in U-shaped tube fitted with TT, the \(Nu\) and \(f\) show significant increases of 122.4 and 78.4%, respectively, when compared to the smooth U-tube. Mohammad et al. [33] examined the TP of rib-groove channel with nano-fluids. Nine different shapes of groove are studied in this experimental work. In this study, nine distinct combinations of rib and groove shapes were examined, with three different rib designs, three distinct groove designs that including rectangular, triangular, and trapezoidal, with various parametric range. The outcomes revel that the rectangular and triangular rib groove as the optimum \(Nu\) among the other grooves. Ibrahim [34] works on the HT in laminar flow by fitted helical screw tape inside the flat tube. The geometrical parameters that are used in this work are S = 0–400 and \(y/w\)= 2.17–5. The outcomes show that the HT rate is optimum with geometrical parameter of \(y/w\) of 2.17 and S = 0. Tang and Zhu [35] experimentally and numerically studied the HT characteristics of rectangular channel with crossed rib and groove. The experimental outcomes demonstrate that the combined thermal and hydraulic performance of ribbed-grooved channels exhibits a 10–13.6% improvement in comparison with ribbed channels. Silva et al. [36] worked on the longitudinal vortex generator for enhancing the HT rate in S-FPC. The result shows that the optimum HT occurs for attack angle of 45° for both types of swirl generator. The geometrical parameters with \(Re\) of 300–900 and attack angle of 15–45° are taken for experimental examination. The outcomes revels that the optimum HT is attain at an angle of 45°. Yao et al. [37] investigate, via experimentation, the impact of TT inserted in ET-SWH. The geometrical parameters include \(y/w\) of 2.5–4. It is concluded from the experimental examination that the higher HT rate occurs at \(y/w\) of 4.

The researcher finds out different ways for enhancing the TP of the SWHS. There are numerous types of obstacles that are used in the prior research by different authors and are discussed in the literature above with their importance. In this work, the author used delta shaped obstacles for enhancing the efficiency of the STC. The reason for choosing that geometrical shape is their physical importance. The surface area of delta obstacle has larger so that when fluid is allowed to contact with the surface of winglet, it creates more swirl as compared to other and alternatively, the heating effect of system is also higher.

Hindrance promoter and their geometrical parameters

The main purpose of using a SWHS is to harvest solar energy that is renewable and useful for many domestic uses. The main objective of the design of such systems is to optimize the use of already available SE. It is possible that the performance of traditional SWHS systems will be limited, which will make designers consider incorporating vortex generators into the tube system. These techniques are utilized to increase the swirling flow within the system by putting a swirl generator into the AT. The addition of a swirl generator increases system efficiency as well as HT rates [38, 39]. Figure 4a and b shows the schematic and actual view of hindrance promoter inserted into the AT. The obstacle made of copper is fixed inside the circular AT for creating the vortex along their face that helps to generate the translation motion of the fluids. The length of the AT is 1160 mm, and the inside and outside diameter of pipe are 50 and 54 mm, respectively. As water enters the AT, delta-winglets disrupt the boundary layer along the tube's wall, generating more eddies and enhancing the thermal conductivity of the water [40, 41].

Experimental setup

In this study, the AT of the STC was equipped with a delta-type obstacle. The AT measures 1160 mm in length, with an inner diameter of 50 mm and an outer diameter of 54 mm. The system's basic working concept is as follows: when solar radiation strikes the collector's surface, it efficiently collects a substantial quantity of heat energy, increasing the water's temperature.

A delta-type heat enhancer is installed inside the AT of an experimental copper tube STC. To help the hot water flow to the storage tank, the header and footer tubes are joined to a vertical pipe. To guarantee its dependability, the STC system was developed and built in compliance with ASME requirements. The lower and side components of the experimental setup are effectively insulated to reduce heat losses.

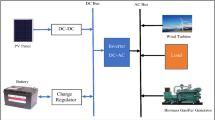

The lower header is where the cold water first enters the collector after leaving the tank, where it is then distributed to the riser tubes. The fluid is then heated by the convective HT process. The top header is where the hot water is gathered before being put into the storage tank. The difference in water densities acts as the driving force behind this circulation. The driving force stops working when the temperatures at the water's input and outflow reach equilibrium levels. Sensors are strategically positioned within the riser tube to measure the water's temperature at the entrance and output. A flow meter is used to measure the water flow rate. A single 4 mm thick clear glass cover transmits solar energy to the AP. At the locations where the collector and tubes meet, efficient insulation is used to reduce heat losses. The physical model of the STC is depicted visually in Fig. 5.

Diagrammatical arrangement of STC. [41]

Every day, for a total of five hours, the collector runs continuously under various operational and geometrical circumstances. For data gathering, a variety of measuring devices are used, such as thermocouples, flow rate meters, and pyranometers to detect radiation intensity. The storage tank is totally drained at the end of each day's data gathering and is replenished with new water the following morning (Fig. 6).

Validation of the experimental setup

The experimental setup's validity was investigated via a series of validation tests, which also included a comparison of the experimental conditions with the outcomes of HT and \(f\) calculations found in previously published studies. The findings of the experiment are analyzed and compared to the correlations that have been established in the existing literature. Experimental determinations of the \(Nu\) and \(f\) of plain tubes devoid of heat enhancers have been made, and they have been compared with the Dittus–Boelter [42] and modified Blasius equations [43].

Dittus–Bolter equation:

Modified Blasius equation:

Figure 7 shows the comparison of the experimental and predicted values of \({Nu}_{{\text{p}}}\) and \({f}_{{\text{p}}}\) as a function of \(Re\).The standard equation is used to validate the experimental setup, and if is found that the deviation is within 2–4%.

Result and discussion

The experiment was performed in the months of the summer, rainy, and winter seasons. The working period of the collector is 5 h from 11 a.m. to 4 p.m. for a fixed flow rate. A low single-tempered glass cover is used for the transmission of solar radiation, which is about 95%, and the thickness of the glass is 4 mm. The collector is provided with insulation in order to provide the minimum heat loss. The material of the tube used is copper. The Resistance Temperature Detector is used for the measurement of inlet and outlet temperatures with ± 0.1 °C accuracy. The \({I}_{SR}\) is measured by a pyranometer.

After setting the flow rate at a particular value over the course of the day, the inlet and outlet temperatures of the water are measured. Firstly, the temperature of the water increased, then again decreased, followed by an increase at 1.00 pm (peak sunshine hours), and then finally decreased due to a reduction in the sun’s rays. On account of its storage capacity for heat, it continuously delivered hot water even though there was fluctuation in solar radiation. The heat inside the collector is not utilized until the water is flowing through it, so at 11:00 a.m., the temperature of the water is higher, carried by a speedy decrease due to the flowing water, and then decrease until it gains heat, and the highest peak of temperature is obtained at 1:00 p.m. (maximum solar intensity), and then lastly, it goes on reducing with the reduction in time. Due to the collector property of heat storage capacity, the STC continuously delivered hot water even at lower \({I}_{SR}\).

In Fig. 7, it is observed that the influence of the delta obstacle plays a crucial role in enhancing the TP of the STC. During the start-up phase of the experiment, the water inside the collector gains instant heat between 11:00 a.m. and 12:00 p.m. It absorbs conductive heat from the solar intensity during the summer season due to the dry air. The excessively low moisture content during the summer season agitates the dry air particles and increases the conduction rate of water. At peak sunshine hours around 1.00 a.m., the water molecules gain excessive heat from the surface of the water tank and warm up the water temperature to its optimum temperature. After the afternoon hours, the solar intensity goes on decreasing, and the efficiency of the STC declines continuously.

The experiment is also conducted in the winter and rainy seasons, as shown in Figs. 8 and 9. In Fig. 8, it is shown that the outlet temperature is lower as compared to the summer season. The delta obstacle that is used in this experiment is also responsible for the higher conduction rate. During these seasons of winter and rain, the intensity of solar radiation is also lower. But due to the presence of a delta obstacle, the creation of eddy formation is maximum, and the efficiency of the STC is good enough as compared to the conventional one. From Figs. 8, 9, it is seen that the water attains its peak temperature at 1.00 p.m. and goes down as the solar radiation continues to decrease. The main technical background behind this study involves utilizing the obstacle inside the tube. It is observed that when the water flows along the pipes, the water particles that strike on the front face of the delta obstacle create swirls and gain more heat. The repeated swirl on the full length of the tape results in a higher temperature at the outlet.

Cost and the payback period

The payback period is the length of time (in years) needed to recover an initial investment. The comparison is made between the cost of heating water using STC and electric heating. Assuming a STC of 50L tank capacity, which costs around Rs. 20,000. This STC is daily adequate for a four-person family. The price of electricity is Rs. 5.82 per kilowatt-hour.

Payback period in years = Capital investment/Annual saving.

Annual saving = 365 \(\times CE\times {Q}_{{\text{Load}}}\)

\({Q}_{{\text{L}}}\)= \({G}_{{\text{w}}}\times {C}_{{\text{p}}}\) (\({T}_{{\text{h}}}\)-\({T}_{{\text{c}}}\)).

where

\(CE\): the cost of electricity needed per hour.

\({Q}_{{\text{Load}}}\)= the daily amount of electricity required.

(\({T}_{{\text{h}}}\) -\({T}_{{\text{c}}}\)): difference of final and initial temperature of heated water = 41 °C

\({G}_{{\text{w}}}\): daily amount of water required = 50L = 50 kg/day.

\({C}_{{\text{p}}}\): Water specific heat 4.184 kJ kg−1 \(^\circ{\rm C}^{-1}\)

\({Q}_{{\text{Load}}}\)= 50 \(\times\) 4.184 \(\times\) 41 = 8577 kJ/day or 2.38 kWh/day.

The yearly saving cost is computed using the data above:

Savings amount annually = 365 \(\times\) 5.82 \(\times\) 2.38 = Rs 5055.83/-

Payback period = 20,000/5055.83 = 3.9 years.

Conclusions

In order to investigate the performance assessment of STC using a delta-type heat enhancer, an experimental study was conducted and the findings were afterward assessed. Using a delta-type heat enhancer introduces additional perturbations in the fluid flow, enhancing the system's thermal efficiency. Furthermore, a comprehensive evaluation of STC's economic analysis and payback time is also conducted. The following is an overview of the main conclusions drawn from the investigation:

-

1.

The manufacture of STC, which is used to heat water, is quite simple; it can be made locally using simple, feasible materials and without skilled workers or a special workshop. Additionally, the price of this STC is lower than that of other collectors.

-

2.

The recommended average storage temperature for 50L of water throughout the summer, rainy, and winter seasons is 68, 57, and 47 °C, respectively. Because of this, this STC meets the need for hot water for domestic uses throughout the year, even on cloudy and foggy days.

-

3.

The financial analysis demonstrates that the payback period of 3.9 years is relatively short due to the high efficiency of the proposed STC.

Abbreviations

- SWHS:

-

Solar water heating system

- S-FPC:

-

Solar flat plate collector

- HT:

-

Heat transfer

- \(y/w\) :

-

Twist ratio

- \(Nu\) :

-

Nusselt number

- \(Re\) :

-

Reynolds number

- \({Nu}_{{\text{p}}}\) :

-

Plain tube Nusselt number

- HE:

-

Heat exchanger

- TP:

-

Thermal performance

- S:

-

Spacer length, mm

- AT:

-

Absorber tube

- m w :

-

Mass flow rate, Kg/s

- PR:

-

Pitch ratio

- \({\alpha }_{{\text{w}}}\) :

-

Angle of attack

- b :

-

Height of delta obstacle, mm

- P :

-

Distance between two delta obstacles, mm

- \({f}_{{\text{p}}}\) :

-

Plain tube friction factor

- \(f\) :

-

Friction factor

- \({h}_{{\text{c}}}\) :

-

Heat transfer coefficient

- TT:

-

Twisted tape

- SC:

-

Solar collector

- AP:

-

Absorber plate

- \({I}_{{\text{SR}}},\) :

-

Intensity of solar radiation, W/m2

- SWH:

-

Solar water heater

References

Wang Z, Yang W, Qiu F, Zhang X, Zhao X. Solar water heating: from theory, application, marketing and research. Renew Sustain Energy Rev. 2015;41:68–84.

Bhowmik M, Muthukumar P, Patil A. Analysis of heat transfer characteristics and optimization of U-tube based solar evacuated tube collector system with different flow conditioning inserts. Therm Sci and Eng Prog. 2023;39:101709.

Al-Madani H. The performance of a cylindrical solar water heater. Renew Energy. 2006;11:1751–63.

Agrawal Y, Bhagoria JL, Gautam A, Sharma A, Yadav AS, Alam T, Kumar R, Goga G, Chakroborty S, Kumar R. Investigation of thermal performance of a ribbed solar air heater for sustainable built environment. Sustain Energy Technol Assess. 2023;57:103288.

Kallioğlu MA, Yılmaz A, Sharma A, Mohamed A, Dobrotă D, Alam T, Khargotra R, Singh T. Optimal insulation assessment, emission analysis, and correlation formulation for Indian region. Buildings. 2023;13:13020569.

Alam T, Saini RP, Saini JS. Experimental investigation on heat transfer enhancement due to V-shaped perforated blocks in a rectangular duct of solar air heater. Energy Convers Manage. 2014;81:374–83.

Patel A. Experimental evaluation of twisted tube solar water heater. Int J Eng Res Technol. 2023;12:30–4.

Shrivastava RL, Kumar V, Untawale SP. Modeling and simulation of solar water heater: a TRNSYS perspective. Renew Sustain Energy Rev. 2017;67:126–43.

Patel A. Thermal performance analysis conical solar water heater. World J Adv Eng Technol Sci. 2023;9:276–83.

Patel A. Comparative thermal performance investigation of the straight tube and square tube solar water heater. World J Adv Res Rev. 2023;19:727–35.

Li T, Wang Z, Yu J, Mao Q. Experimental and simulation on night heat dissipation characteristics and freezing process of evacuated tube solar water heaters. Int J Therm Sci. 2023;192:108455.

Kumar A, Kumar K, Kaushik N, Sharma S, Mishra S. Renewable energy in India: current status and future potentials. Renew Sustain Energy Rev. 2010;14:2434–42.

Khare V, Khare CJ, Bhuiyan MA. Design, optimization, and data analysis of solar-tidal hybrid renewable energy system for Hurawalhi. Maldives Clean Energy Syst. 2023;28:100088.

Awasthi A, Kallioğlu MA, Sharma A, Mohan A, Chauhan R, Singh T. Solar collector tilt angle optimization for solar power plant setup-able sites at Western Himalaya and correlation formulation. J Therm Anal Calorim. 2022;147:11417–31.

García A, Herrero-Martin R, Solano JP, Pérez-García J. The role of insert devices on enhancing heat transfer in a flat-plate solar water collector. Appl Therm Eng. 2018;132:479–89.

Devanarayanan K, Murugavel KK. Integrated collector storage solar water heater with compound parabolic concentrator–development and progress. Renew Sustain Energy Rev. 2014;39:51–64.

Eiamsa-ard S, Pethkool S, Thianpong C, Promvonge P. Turbulent flow heat transfer and pressure loss in a double pipe heat exchanger with louvered strip inserts. Int Commun Heat Mass Transfer. 2008;35:120–9.

Naphon P, Nuchjapo M, Kurujareon J. Tube side heat transfer coefficient and friction factor characteristics of horizontal tubes with helical rib. Energy Convers Manage. 2006;47:3031–44.

Li XW, Meng JA, Guo ZY. Turbulent flow and heat transfer in discrete double inclined ribs tube. Int J Heat Mass Transf. 2009;52:962–70.

Deshmukh K, Karmare S, Patil P. Experimental investigation of convective heat transfer inside tube with stable plasmonic TiN nanofluid and twisted tape combination for solar thermal applications. Heat Mass Transf. 2023;23:1–8.

Wongcharee K, Eiamsa-Ard S. Friction and heat transfer characteristics of laminar swirl flow through the round tubes inserted with alternate clockwise and counter-clockwise twisted-tapes. Int Commun Heat Mass Transfer. 2011;38:348–52.

Eiamsa-ard S, Wongcharee K, Eiamsa-Ard P, Thianpong C. Heat transfer enhancement in a tube using delta-winglet twisted tape inserts. Appl Therm Eng. 2010;30:310–8.

Kanojiya NC, Shahare AS, Sambare RK. Productivity, thermal, and exergy efficiency analyses of tubular solar still integrated with solar water heater. Energy Sour Part A: Recov Util Environ Effects. 2023;45:3584–601.

Bliss RW Jr. The derivations of several plate-efficiency factors useful in the design of flat-plate solar heat collectors. Sol Energy. 1959;3:55–64.

Hutchins MG. Spectrally selective solar absorber coatings. Appl Energy. 1979;5:251–62.

Promvonge P. Thermal augmentation in circular tube with twisted tape and wire coil turbulators. Energy Convers Manage. 2008;49:2949–55.

Sarma PK, Kishore PS, Rao VD, Subrahmanyam T. A combined approach to predict friction coefficients and convective heat transfer characteristics in a tube with twisted tape inserts for a wide range of Re and Pr. Int J Therm Sci. 2005;44:393–8.

Samruaisin P, Kunlabud S, Kunnarak K, Chuwattanakul V, Eiamsa-ard S. Intensification of convective heat transfer and heat exchanger performance by the combined influence of a twisted tube and twisted tape. Case Stud Thermal Eng. 2019;14:100489.

Sable A. Experimental and economic analysis of concrete absorber collector solar water heater with use of dimpled tube. Resour Eff Technol. 2017;13:483–90.

Jaisankar S, Radhakrishnan TK, Sheeba KN. Experimental studies on heat transfer and friction factor characteristics of forced circulation solar water heater system fitted with helical twisted tapes. Sol Energy. 2009;183:1943–52.

Bhattacharyya S, Chattopadhyay H, Haldar A. Design of twisted tape turbulator at different entrance angle for heat transfer enhancement in a solar heater. Beni-Suef Univ J Basic Appl Sci. 2018;17:118–26.

Feizabadi A, Khoshvaght-Aliabadi M, Rahimi AB. Experimental evaluation of thermal performance and entropy generation inside a twisted U-tube equipped with twisted-tape inserts. Int J Therm Sci. 2019;1145:106051.

Mohammed HA, Al-Shamani AN, Sheriff JM. Thermal and hydraulic characteristics of turbulent nanofluids flow in a rib–groove channel. Int Commun Heat Mass Trans. 2012;139:1584–94.

Ibrahim EZ. Augmentation of laminar flow and heat transfer in flat tubes by means of helical screw-tape inserts. Energy Convers Manage. 2011;152:250–7.

Xinyi TA, Dongsheng ZH. Experimental and numerical study on heat transfer enhancement of a rectangular channel with discontinuous crossed ribs and grooves. Chin J Chem Eng. 2012;120:220–30.

Da Silva FA, Dezan DJ, Pantaleão AV, Salviano LO. Longitudinal vortex generator applied to heat transfer enhancement of a flat plate solar water heater. Appl Therm Eng. 2017;158:113790.

Yao K, Li T, Tao H, Wei J, Feng K. Performance evaluation of all-glass evacuated tube solar water heater with twist tape inserts using CFD. Energy Procedia. 2015;170:332–9.

Arunprasad V, Jaisankar S. Effects of left and right screw tapes in natural circulation solar water heating system. Energy Sour Part A: Recov Util Environ Effects. 2023;45:2540–52.

Ananth J, Jaisankar S, Arumugam B. Design and experimentation on domestic solar water heaters using kenics twist inserts. J Therm Anal Calorim. 2023;148:943–53.

Khargotra R, Kumar R, Sharma A, Singh T. Design and performance optimization of solar water heating system with perforated obstacle using hybrid multi-criteria decision-making approach. J Energy Stor. 2023;63:107099.

Khargotra R, Kumar R, András K, Fekete G, Singh T. Thermo-hydraulic characterization and design optimization of delta-shaped obstacles in solar water heating system using CRITIC-COPRAS approach. Energy. 2022;261:125236.

Dittus FW. Heat transfer in automobile radiators of the tubular type. Univ Calif Pub Eng. 1930;2:443–61.

Blasius H. The boundary layers in fluids with little friction. National Advisory Committee for Aeronautics; 1950; 1:56.

Funding

Open access funding provided by University of Pannonia.

Author information

Authors and Affiliations

Contributions

Rohit Khargotra was contributed to methodology, writing—original draft preparation. Raj Kumar was contributed to writing—review and editing, investigation, methodology. András Kovács was contributed to writing—review and editing, supervision, methodology. Tej Singh was contributed to writing—review and editing, methodology.

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Khargotra, R., Kumar, R., Kovács, A. et al. Techno-economic analysis of solar thermal collector for sustainable built environment. J Therm Anal Calorim 149, 1175–1184 (2024). https://doi.org/10.1007/s10973-023-12775-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12775-0