Abstract

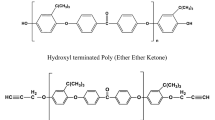

In this paper, we report detailed cure kinetics of epoxy and polyetheramine (Jeffamine) systems. Three cured epoxy networks were prepared by using three types of Jeffamines having different molecular masses and polyether segment in the chain. The effect of epoxy to Jeffamine stoichiometric and sub-stoichiometric ratios and molecular mass of Jeffamines on curing behaviour, mechanical properties and thermal behaviour of the resulting networks were investigated. The results were explained using Fourier transform infrared (FTIR) spectroscopic analysis. The epoxy systems with optimised epoxy/amine ratios were studied for their cure behaviour using temperature modulated differential scanning colorimetric (MDSC) analysis. Isoconversion kinetics was studied to find out activation energy, pre-exponential factor. The conversion function, f(a) was found to be fitting as Sestak–Berggren model. Thermal behaviour of the epoxy networks was determined by a non-isothermal thermogravimetric analysis (TGA) both in nitrogen and air envelop. The thermal stability of the rubbery epoxy systems is observed to be much better than the conventional rubbers having unsaturation.

Similar content being viewed by others

References

Ratna D. Handbook of thermoset resins. London: Smithers and Rapra Technology; 2009.

Pascault JP. Thermosetting polymers. New York: Marcel Dekker; 2002.

Ellis B. Chemistry and technology of epoxy resins. London: Chapman & Hall; 1993.

Bouer RS. Epoxy resin chemistry, advances in chemistry series 114. Washington, DC: American Chemical Society; 1979.

Potter WG. Epoxide resins. New York: Springer; 1970.

Ratna D, Varley R, Raman RKS, Simon GP. Studies on blends of epoxy-functionalized hyperbranched polymer and epoxy resin. J Mater Sci. 2003;38:147–54. https://doi.org/10.1023/A:1021182320285.

Riew CK. Rubber toughened plastic, advances in chemistry, series 222. Washington, DC: American Chemical Society; 1989.

Cheng J, Li J, Zhang JY. Curing behavior and thermal properties of trifunctional epoxy resin cured by 4, 4’-diaminodiphenyl sulfone. Express Polym Lett. 2009;3:501–9. https://doi.org/10.3144/expresspolymlett.2009.62.

Bonnaud L, Pascault JP, Sautereau H. Kinetic of a thermoplastic-modified epoxy-aromatic diamine formulation: modeling and influence of a trifunctional epoxy prepolymer. Eur Polym J. 2000;36:1313–21. https://doi.org/10.1016/S0014-3057(99)00197-4.

Amdouni N, Sautereau H, Gerard JF, Pascault JP. Epoxy networks based on dicyandiamide: effect of the cure cycle on viscoelastic and mechanical properties. Polymer. 1990;31:1245–53. https://doi.org/10.1016/0032-3861(90)90215.

Calventus Y, Montserrat S, Hutchinson JM. Enthalpy relaxation of non-stoichiometric epoxy-amine resins. Polymer. 2001;42:7081–93. https://doi.org/10.1016/S0032-3861(01)00133-1.

Heux L, Lauprêtre F, Halary JL, Monnerie L. Dynamic mechanical and 13C NMR analyses of the effects of antiplasticization on the β secondary relaxation of aryl-aliphatic epoxy resins. Polymer. 1998;39:1269–78. https://doi.org/10.1016/S0032-3861(97)00423-0.

Charlesworth JM. Effect of crosslink density on the molecular relaxations in diepoxide-diamine network polymers. Part 1. The glassy region. Polym Eng Sci. 1988;28:221–9. https://doi.org/10.1002/PEN.760280405.

Yang G, Fu SY, Yang JP. Preparation and mechanical properties of modified epoxy resins with flexible diamines. Polymer. 2007;48:302–10. https://doi.org/10.1016/j.polymer.2006.11.031.

Hallary JL, Cukierman S, Monnerie L. Relations entre structure chimique Et propriétés mécaniques dans les réseaux epoxydes. Bull Soc Chim Belg. 1989;98:623–34. https://doi.org/10.1002/bscb.19890980903.

De Nograro FF, Llano-Ponte R, Mondragaon I. Dynamic and mechanical properties of epoxy networks obtained with PPO based amines/mPDA mixed curing agents. Polymer. 1996;37:1589–600. https://doi.org/10.1016/0032-3861(96)83707-4.

Lin JJ, Tseng FP, Chang FC (2000) Electrostatic dissipation and flexibility of poly (oxyalkylene) amine segmented epoxy derivatives, Polym Int, 49:387–394. http://hdl.handle.net/11536/30593.

Ratna D, Manoj NR, Chandrasekhar L, Chakraborty BC. Novel epoxy compositions for vibration damping applications. Polym Adv Technol. 2004;15:583–6. https://doi.org/10.1002/pat.513.

May CA. Epoxy resins, chemistry and technology. New York: Marcel Dekker; 1988.

Lin JJ, Speranza GP, Waddill HG. Aromatic polyoxyalkylene amidoamines as curatives for epoxy resins—derivatives from t-butyl isophthalic acid. J Polym Res. 1996;3:97–104. https://doi.org/10.1007/BF01492900.

Vyazovkin S, Mitielu A, Sbirrazzuoli N. Kinetics of epoxy-amine curing accompanied by the formation of liquid crystalline structure. Macromol Rapid Commun. 2003;24:1060–5. https://doi.org/10.1002/marc.200300023.

Morgan RJ, Kong FM, Walkup CM. Structure-property relations of polyethertriamine cured bisphenol A diglycidyl ether epoxies. Polymer. 1984;25:375–86. https://doi.org/10.1016/0032-3861(84)90291-X.

Gupta VB, Drzal LT, Lee CYC, Rich MJ. The effects of stoichiometry and structure on the dynamic torsional properties of a cured epoxy resin system. J Macromol Sci Part B. 1984;23:435–66. https://doi.org/10.1080/00222348408219470.

Palmese GR, McCullough RL. Effect of epoxy–amine stoichiometry on cured resin material properties. J Appl Polym Sci. 1992;46:1863–73. https://doi.org/10.1002/app.1992.070461018.

Nograro FF, Valea A, Ponte RL, Mondragon I. Dynamic and mechanical properties of DGEBA/poly (propylene oxide) amine based epoxy resins as a function of stoichiometry. Eur Polym J. 1996;32:251–66. https://doi.org/10.1016/0014-3057(95)00122-0.

Oleinik EF. Epoxy-aromatic amine networks in the glassy state structure and properties. In: Dušek K, editor. Epoxy resins and composites IV. Berlin: Springer; 1986. p. 49–99. https://doi.org/10.1007/3-540-16423-5_12.

Matejka L. Amine cured epoxide networks: formation, structure, and properties. Macromolecules. 2000;33:3611–9. https://doi.org/10.1021/ma991831w.

Chiou PL, Letton A. Modelling the chemorheology of an epoxy resin system exhibiting complex curing behaviour. Polymer. 1992;33:3925–31. https://doi.org/10.1016/0032-3861(92)90384-9.

Ivanov DA, Chuvaev VF, Kiselev MR. Thermoanalytical studies on the curing of epoxy resin under the action of aqueous solutions of heteropolyacids of tungsten and molybdenum. J Therm Anal. 1992;38:1061–70. https://doi.org/10.1007/bf01979169.

Verchere D, Sauterau H, Pascault JP. Build-up of epoxy cycloaliphatic amine networks. Kinetics, vitrification, and gelation. Macromolecules. 1990;23:725–31. https://doi.org/10.1021/ma00205a006.

Deng Y, Martin GC. Diffusion and diffusion-controlled kinetics during epoxy-amine cure. Macromolecules. 1994;27:5147–53. https://doi.org/10.1021/ma00096a043.

Ran Z, Liu X, Jiang X, Wu Y, Liao H. Study on curing kinetics of epoxy-amine to reduce temperature caused by the exothermic reaction. Thermochim Acta. 2020;692: 178735. https://doi.org/10.1016/j.tca.2020.178735.

Pramanik M, Fowler EW, Rawlins JW. Cure kinetics of several epoxy–amine systems at ambient and high temperatures. J Coat Technol Res. 2014;11:143–57. https://doi.org/10.1007/s11998-013-9565-4.

Guan DB, Cai ZY, Zhai XJ, Yao WG, Wang SJ, Hui A, Qiu AX. Studies on curing kinetics of epoxy resin/modified amine system. Adv Mater Res. 2013;652–654:121–6. https://doi.org/10.4028/www.scientific.net/AMR.652-654.121.

Cai H, Li P, Sui G, Yu Y, Li G, Yang X, Ryu S. Curing kinetics study of epoxy resin/flexible amine toughness systems by dynamic and isothermal DSC. Thermochim Acta. 2008;473:101–5. https://doi.org/10.1016/j.tca.2008.04.012.

Wisanrakkit G, Gillham JK. The glass transition temperature (Tg) as an index of chemical conversion for a high-Tg amine/epoxy system: chemical and diffusion-controlled reaction kinetics. J Appl Polym Sci. 1990;41:2885–929. https://doi.org/10.1002/app.1990.070411129.

Vyazovkin S, Linert W. Evaluation and application of isokinetic relationships: the thermal decomposition of solids under nonisothermal conditions. J Chem Inf Comput Sci. 1994;34:1273–8. https://doi.org/10.1021/ci00022a008.

Doyle CD. Estimating isothermal life from thermogravimetric data. J Appl Polym Sci. 1962;6:639–42. https://doi.org/10.1002/APP.1962.070062406.

Toop DJ. Theory of life testing and use of thermogravimetric analysis to predict the thermal life of wire enamels. IEEE Trans Electr Insul. 1971. https://doi.org/10.1109/TEI.1971.299128.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Japan. 1965;38:1881–6. https://doi.org/10.1246/bcsj.38.1881.

Lee JY, Shim MJ, Kim SW. Thermal decomposition kinetics of an epoxy resin with rubber-modified curing agent. J Appl Polym Sci. 2001;81:479–85. https://doi.org/10.1002/app.1460.

Xia L, Zuo L, Wang X, Lu D, Guan R. Non-isothermal kinetics of thermal degradation of DGEBA/TU-DETA epoxy system. J Adhes Sci Technol. 2014;28:1792–807. https://doi.org/10.1080/01694243.2014.922454.

Gonzalez M, Cabanelas JC, Baselga J. Infrared spectroscopy–Materials Science, engineering and technology, Prof. Theophanides Theophile (Ed.), ISBN: 2012; 978-953-51-0537-4. https://doi.org/10.5772/2055.

Zhong M, Wang R, Kawamoto K, Olsen BD, Johnson JA. Quantifying the impact of molecular defects on polymer network elasticity. Science. 2016;353:1264–8. https://doi.org/10.1126/science.aag0184.

Karkanas PI, Partridge IK. Cure modeling and monitoring of epoxy/amine resin systems i cure kinetics modelling. J Appl Polym Sci. 2000;77:1419–31. https://doi.org/10.1002/1097-4628(20000815)77:7%3c1419::AID-APP3%3e3.0.CO;2-N.

Flynn JH. The isoconversional method for determination of energy of activation at constant heating rates. J Thermal Anal. 1983;27:95–102. https://doi.org/10.1007/BF01907325.

Vyazovkin S. Alternative description of process kinetics. Thermochem Acta. 1992;211:181–7. https://doi.org/10.1016/0040-6031(92)87018-6.

Vyazovkin S, Lesnikovich AI. Practical application of isoconversional methods. Thermochi Acta. 1992;203:177–85. https://doi.org/10.1016/0040-6031(92)85194-Z.

Vyazovkin S, Dollimore D. Linear and nonlinear procedures in iso-conversional computations of the activation energy of nonisothermal reactions in solids. J Chem Inf Comput Sci. 1996;36:42–5. https://doi.org/10.1021/ci950062m.

Vyazovkin S, Wight CA. Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta. 1999;340–341:53–68. https://doi.org/10.1016/S0040-6031(99)00253-1.

Khawam A, Flanagan DR. Role of isoconversional methods in varying activation energies of solid-state kinetics: II. Nonisothermal kinetic studies, Thermochim Acta. 2005;436:101–12. https://doi.org/10.1016/j.tca.2005.05.015.

Stanko M, Stommel M. Kinetic prediction of fast curing polyurethane resins by model-free isoconversional methods. Polymers. 2018;10:698. https://doi.org/10.3390/polym10070698.

Vyazovkina S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochimica Acta. 2011;520:1–19. https://doi.org/10.1016/j.tca.2011.03.034.

Sestak J, Berggren G. Study of the kinetics of the mechanism of solid-state reactions at increased temperature. Thermochim Acta. 1971;3:1–12. https://doi.org/10.1016/0040-6031(71)85051-7.

Friedman HL. New methods for evaluating kinetic parameters from thermal analysis data. J Polym Sci Part B Polym Lett. 1969;7:41–6. https://doi.org/10.1002/pol.1969.110070109.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404:163–76. https://doi.org/10.1016/S0040-6031(03)00144-8.

Vyazovkin S, Sbirrazzuoli N. Mechanism and kinetics of epoxy-amine cure studied by differential scanning calorimetry. Macromolecules. 1996;29:1867–73. https://doi.org/10.1021/MA951162W.

Hao W, Hu J, Chen L, Zhang J, Xing L, Yang W. Isoconversional analysis of non-isothermal curing process of epoxy resin/epoxide polyhedral oligomeric silsesquioxane composites. Polym Test. 2011;30:349–55. https://doi.org/10.1016/j.polymertesting.2011.02.005.

Vyazovkin S, Lesnikovich AI. Estimation of the pre-exponential factor in the isoconversional calculation of effective kinetic parameters. Thermochim Acta. 1988;128:297–300. https://doi.org/10.1016/0040-6031(88)85372-3.

Søren H, Andreas TE. A practical approach for data gathering for polymer cure simulations. Appl Sci. 2018;8:2227. https://doi.org/10.3390/app8112227.

Senum GI, Yang RT. Rational approximations of the integral of the Arrhenius function. J Therm Anal. 1977;11:445–7. https://doi.org/10.1007/BF01903696.

Author information

Authors and Affiliations

Contributions

DR contributed to conceptualization, data analysis, manuscript writing. SBJ FTIR contributed to mechanical testing and data analysis. RN DSC contributed to analysis. BCC contributed to Kinetics and model analysis, manuscript writing.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ratna, D., Jagtap, S.B., Nimje, R. et al. Cure kinetics and thermal degradation characteristics of epoxy/polyetheramine systems. J Therm Anal Calorim 149, 1073–1087 (2024). https://doi.org/10.1007/s10973-023-12737-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12737-6