Abstract

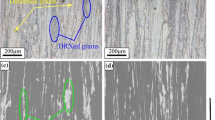

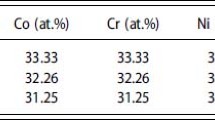

In this work, the impacts of shallow cryogenic (−40 °C) and natural ageing treatments on the precipitation of the second phases in a 7xxx alloy were investigated. Using the differential scanning calorimetry (DSC) analysis technique, transformation temperatures of the phases both in standard natural aged and naturally aged after cryogenic treatment were determined. As a result of the analyses made, the activation energies of the precipitates formed in the material were calculated with the Kissinger, Takhor and Augis-Bennett equations and their effects on diffusion were considered. With DSC analysis, nucleation characteristics of the η′ phase (MgZn2) were determined by the Avrami parameter from the Ozawa equation. Also, features and distributions of different types of precipitates were analysed by means of scanning electron microscopy (SEM), energy-dispersive X-ray spectrometry (EDS) and X-ray diffraction (XRD) techniques, respectively. Particularly, during the cryogenic and natural ageing processes, dislocation densities, strain values of the planes, texture coefficients and so subsequent after effects on the crystal structure were assessed. It was anticipated that excess dislocations generated during sub-zero treatment preferably settled on suitable planes to subside the strain energy. Finally, it was noticed that compared to natural aged samples, application of the cryogenic treatment before ageing upsurged the hardness of the material on the average by15%. This was possibly because of the η′ precipitates nucleated mainly on dislocations.

Graphical abstract

Similar content being viewed by others

References

Hirsch J. Recent development in aluminium for automotive applications. Trans Nonferrous Met Soc China. 2014;24(7):1995–2002. https://doi.org/10.1016/S1003-6326(14)63305-7.

Kodetová V, Vlach M, Kudrnová H, Leibner M, Málek J, Cieslar M, Neubert V. Annealing effects in commercial aluminium hot-rolled 7075 (–Sc–Zr) alloys. J Therm Anal Calorim. 2020;142(5):1613–23. https://doi.org/10.1007/s10973-020-10249-1.

Zhao H, Gault B, Ponge D, Raabe D. Reversion and re-aging of a peak aged Al–Zn–Mg–Cu alloy. Scr Mater. 2020;188:296–273. https://doi.org/10.1016/j.scriptamat.2020.07.049.

Omer K, Abolhasani A, Kim S, Nikdejad T, Butcher C, Wells M, Worswick M. Process parameters for hot stamping of AA7075 and D-7xxx to achieve high performance aged products. J Mater Process Technol. 2018;257:170–9. https://doi.org/10.1016/j.jmatprotec.2018.02.039.

Liu S, Li C, Han S, Deng Y, Zhang X. Effect of natural aging on quench-induced inhomogeneity of microstructure and hardness in high strength 7055 aluminum alloy. J Alloy Compd. 2015;625:34–43. https://doi.org/10.1016/j.jallcom.2014.10.195.

Erhard H. Hundred years of precipitation hardening. J Light Met. 2001;1(2):127–32. https://doi.org/10.1016/S1471-5317(01)00006-2.

Leacock AG, Howe C, Brown D, Lademo OG, Deering A. Evolution of mechanical properties in a 7075 Al-alloy subject to natural ageing. Mater Des. 2013;49:160–7. https://doi.org/10.1016/j.matdes.2013.02.023.

Ayer R, Koo JY, Steeds JW, Park BK. Microanalytical study of the heterogeneous phases in commercial Al–Zn–Mg–Cu alloys. Metall Trans A. 1985;16(11):1925–36. https://doi.org/10.1007/BF02662393.

Deschamps A, Bley F, Livet F, Fabregue D, David L. In-situ small-angle X-ray scattering study of dynamic precipitation in an Al–Zn–Mg–Cu alloy. Philos Mag. 2003;83(6):677–92. https://doi.org/10.1080/0141861021000051091.

Dehghani K, Nekahi A, Mirzaie MAM. Optimizing the bake hardening behavior of Al7075 using response surface methodology. Mater Des. 2010;31(4):1768–75. https://doi.org/10.1016/j.matdes.2009.11.014.

Dlubek G, Krause R, Brümmer O, Plazaola F. Study of formation and reversion of Guinier-Preston zones in Al-4.5 at % Zn-x at % Mg alloys by positrons. J Mater Sci. 1986;21(3):853–858. https://doi.org/10.1007/BF01117364.

Berg LK, Gjønnes J, Hansen VX, Li XZ, Knutson-Wedel M, Schryvers D, Wallenberg LR. GP-zones in Al–Zn–Mg alloys and their role in artificial aging. Acta Mater. 2001;49(17):3443–51. https://doi.org/10.1016/S1359-6454(01)00251-8.

Chung TF, Yang YL, Huang BM, Shi Z, Lin J, Ohmura T, Yang JR. Transmission electron microscopy investigation of separated nucleation and in-situ nucleation in AA7050 aluminium alloy. Acta Mater. 2018;149:377–87. https://doi.org/10.1016/j.actamat.2018.02.045.

Löffler H, Kovács I, Lendvai J. Decomposition processes in Al-Zn-Mg alloys. J Mater Sci. 1983;18(8):2215–40. https://doi.org/10.1007/BF00541825.

Hou S, Zhang D, Ding Q, Zhang J, Zhuang L. Solute clustering and precipitation of Al-5.1 Mg-0.15 Cu-xZn alloy. Mater Sci Eng A. 2019;759:465–478. https://doi.org/10.1016/j.msea.2019.05.066

Ozer M, Dalli K, Ozer A. Effect of ball-burnishing on surface integrity and fatigue behaviour of 7175–T6 AA. Mater Sci Technol. 2023;39(2):248–57. https://doi.org/10.1080/02670836.2022.2142744.

Inoue H, Sato T, Kojima Y, Takahashi T. The temperature limit for GP zone formation in an Al-Zn-Mg alloy. Metall Mater Trans A. 1981;12(8):1429–34. https://doi.org/10.1007/BF02643687.

Chen J, Zhen L, Yang S, Shao W, Dai S. Investigation of precipitation behavior and related hardening in AA 7055 aluminum alloy. Mater Sci Eng A. 2009;500(1–2):34–42. https://doi.org/10.1016/j.msea.2008.09.065.

Lin YC, Jiang YQ, Zhang JL, Chen XM. Influence of stress-aging processing on precipitates and mechanical properties of a 7075 aluminum alloy. Adv Eng Mater. 2018;20(1):1700583. https://doi.org/10.1002/adem.201700583.

Xu X, Zheng J, Li Z, Luo R, Chen B. Precipitation in an Al-Zn-Mg-Cu alloy during isothermal aging: atomic-scale HAADF-STEM investigation. Mater Sci Eng A. 2017;691:60–70. https://doi.org/10.1016/j.msea.2017.03.032.

Hansen V, Karlsen OB, Langsrud Y, Gjønnes J. Precipitation and strengthening in aluminium alloys. Mater Sci Technol. 2004;20(2):185–93. https://doi.org/10.1179/026708304225010424.

Lendvai J. Precipitation and strengthening in aluminium alloys. Mater Sci Forum. 1996;217:43–56. https://doi.org/10.4028/www.scientific.net/MSF.217-222.43.

Sha G, Cerezo A. Early-stage precipitation in Al–Zn–Mg–Cu alloy (7050). Acta Mater. 2004;52(15):4503–16. https://doi.org/10.1016/j.actamat.2004.06.025.

Liu J, Hu R, Zheng J, Zhang Y, Ding Z, Liu W, Sha G. Formation of solute nanostructures in an Al–Zn–Mg alloy during long-term natural aging. J Alloy Compd. 2020;821:153572. https://doi.org/10.1016/j.jallcom.2019.153572.

Chatterjee A, Qi L, Misra A. In situ transmission electron microscopy investigation of nucleation of GP zones under natural aging in Al-Zn-Mg alloy. Scr Mater. 2022;207:114319. https://doi.org/10.1016/j.scriptamat.2021.114319.

Khalfallah A, Raho AA, Amzert S, Djemli A. Precipitation kinetics of GP zones, metastable η′ phase and equilibrium η phase in Al—5.46 wt.% Zn—1.67 wt.% Mg alloy. Trans Nonferrous Met Soc China. 2019;29(2):233–241. https://doi.org/10.1016/S1003-6326(19)64932-0

Schneider R, Heine B, Grant RJ, Zouaoui Z. Mechanical behaviour of aircraft relevant aluminium wrought alloys at low temperatures. Proc Inst Mech Eng Part L J Mater Des Appl. 2015;229(2):126–36. https://doi.org/10.1177/1464420713501734.

Yuan S, Cheng W, Liu W, Xu Y. A novel deep drawing process for aluminum alloy sheets at cryogenic temperatures. J Mater Process Technol. 2020;284:116743. https://doi.org/10.1016/j.jmatprotec.2020.116743.

Yin X, Deng W, Zou Y, Zhang J. Ultrafine grained Al 7075 alloy fabricated by cryogenic temperature large strain extrusion machining combined with aging treatment. Mater Sci Eng A. 2019;762:138106. https://doi.org/10.1016/j.msea.2019.138106.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29(11):1702–6.

Takhor RL. Advances in nucleation and crystallization of glasses. Am Ceram Soc Columb. 1971;166:10–2.

Augis JA, Bennett JE. Calculation of the avrami parameters for heterogeneous solid state reactions using a modification of the kissinger method. J Therm Anal. 1978;13(2):283–92. https://doi.org/10.1007/BF01912301.

Hulett JR. Deviations from the arrhenius equation. Q Rev Chem Soc. 1964;18(3):227–42. https://doi.org/10.1039/QR9641800227.

Taskesen A, Aksoz S, Ozdemir A. The effect of cryogenic treatment on ageing behaviour of B4C reinforced 7075 aluminium composite. Kovove Mater-Met Mater. 2017;55(1):57–67. https://doi.org/10.4149/km_2017_1_57.

Davis JR. Aluminum and aluminum alloys. ASM International. 1993;3:534–642.

Warren BE. X-ray diffraction. Courier Corporation. 1990;1:7–10.

Harris GBX. Quantitative measurement of preferred orientation in rolled uranium bars. The Lond Edinb Dublin Philos Mag J Sci. 1952;43(336):113–23. https://doi.org/10.1080/14786440108520972.

Smallman RE. Modern physical metallurgy. 2016;4:385–491.

Holzwarth U, Gibson N. The Scherrer equation versus the ’Debye-Scherrer equation. Nat Nanotechnol. 2011;6(9):534–534. https://doi.org/10.1038/nnano.2011.145.

Williamson GK, Hall WH. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953;1(1):22–31. https://doi.org/10.1016/0001-6160(53)90006-6.

Hansen N. Hall-Petch relation and boundary strengthening. Scr Mater. 2004;51(8):801–6. https://doi.org/10.1016/j.scriptamat.2004.06.002.

Martin JW. Micromechanisms in particle-hardened alloys. Cambridge: Cambridge University; 1980.

Ozawa T. Kinetic analysis of derivative curves in thermal analysis. J Therm Anal. 1970;2(3):301–24. https://doi.org/10.1007/BF01911411.

Papazian JM. Calorimetric studies of precipitation and dissolution kinetics in aluminum alloys 2219 and 7075. Metall Trans A. 1982;13(5):761–9. https://doi.org/10.1007/BF02642389.

Fanfoni M, Tomellini M. The johnson-mehl-avrami-kohnogorov model: a brief review. Il Nuovo Cimento D. 1998;20(7):1171–82. https://doi.org/10.1007/BF03185527.

Callister JR, William D, David G. Rethwisch. Fundamentals of materials science and engineering an integrated approach. 2020;261–79.

Altuntaş G, Altuntaş O, Bostan B. Characterization of Al-7075/T651 alloy by RRA heat treatment and different pre-deformation effects. Trans Indian Inst Met. 2021;74(12):3025–33. https://doi.org/10.1007/s12666-021-02369-5.

Altuntaş G, Bostan B. Metallurgical characterization of natural aging effects on pre-deformed Al 7075/T651 alloy during retrogression and re-aging heat treatment. Kovove Mater-Met Mater. 2022;60(4):209–222. https://doi.org/10.31577/km.2022.4.209.

Guo W, Guo J, Wang J, Yang M, Li H, Wen X, Zhang. Evolution of precipitate microstructure during stress aging of an Al–Zn–Mg–Cu alloy. J Mater Sci Eng A. 2015;634:167–175. https://doi.org/10.1016/j.msea.2015.03.047.

Gao M, Feng CR, Wei RP. An analytical electron microscopy study of constituent particles in commercial 7075–T6 and 2024–T3 alloys. Metall Mater Trans A. 1998;29(4):1145–51. https://doi.org/10.1007/s11661-998-0240-9.

Acknowledgements

This study has been financially supported by the Gazi University Scientific Research Projects Coordination Unit [under Project Number FGA-2023-8195].

Funding

This study was funded by Gazi Üniversitesi, FDK-2023-7620, Bülent Bostan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors report no potential conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Altuntaş, G., Özdemir, A.T. & Bostan, B. A survey of the effect of cryogenic treatment and natural ageing on structural changes and second-phase precipitation in Al–Zn–Mg–Cu alloy. J Therm Anal Calorim 148, 10713–10725 (2023). https://doi.org/10.1007/s10973-023-12414-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12414-8