Abstract

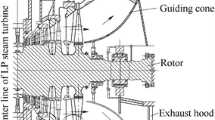

Ejector is a simple device which is used in gas turbine and steam power plants. It is used to pump or compress a low-pressure fluid with the help of a high-pressure fluid without any moving parts. The performance of an ejector is a function of entrainment ratio (ω) and pressure lift ratio (rp). The work aims to perform a parametric study and propose the optimized geometry parameters of a steam ejector, such as mixing chamber length (Lm) and diameter (Dm), for getting maximum ω and rp. A 3D turbulent model was developed to investigate these geometry parameters. Realizable k–ε turbulence model was chosen for considering the turbulence effects. Lm was varied from 0.6 to 1.2 m and Dm from 0.1 to 0.14 m. Mach number, temperature, pressure and density profiles inside the steam ejector were estimated and analyzed. It was found that Lm has shown less influence on ω and rp. A minimum Lm of 1 m was required to get a uniform, non-fluctuated and symmetric profile of Mach number, temperature, pressure and density inside the system, especially at the diffuser section. Dm has shown a significant effect on ω, and it increased from 1.12 to 1.64 when Dm was varied from 0.1 to 0.13 m. Any further increase in Dm caused a decrease in ω. From the parametric study, it is concluded that Lm and Dm of 1 m and 0.13 m, respectively, gave a better flow uniformity, non-fluctuated flow and maximum ω.

Similar content being viewed by others

Abbreviations

- NXP:

-

Nozzle exit position

- CFD:

-

Computational fluid dynamics

- COP:

-

Coefficient of performance

- A t :

-

Area of nozzle throat (m2)

- C :

-

Specific heat (J kg−1 K−1)

- D m :

-

Diameter of mixing chamber (m)

- D t :

-

Diameter of nozzle throat (m)

- k :

-

Thermal conductivity (W m−1 K−1)

- L m :

-

Length of mixing chamber (m)

- M :

-

Mach number

- m :

-

Mass flow rate (kg s−1)

- p :

-

Pressure (bar)

- R:

-

Gas constant (J kg−1 K−1)

- r p :

-

Pressure ratio

- T :

-

Temperature (K)

- u :

-

Velocity (m s−1)

- μ t :

-

Turbulent viscosity (m2 s−1)

- p:

-

Primary fluid

- s:

-

Secondary fluid

- t:

-

Nozzle throat

- 1:

-

Nozzle exit

- 2:

-

Diffuser exit

- m:

-

Mixing chamber

- ω :

-

Entrainment ratio

- θ :

-

Suction chamber convergence angle (°)

- µ :

-

Dynamic viscosity (kg m−1 s−1)

- ρ :

-

Density (kg m−3)

- ε :

-

Rate of dissipation of turbulent energy (m2 s−3)

- γ :

-

Ratio of specific heats

References

Keenan JH, Neumann EP, Lustwerk F. A simple air ejector. J Appl Mech-T ASME. 1942;64:75–81.

Munday JT, Bagster DF. A new ejector theory applied to steam jet refrigeration. Ind Eng Chem Process Des Dev. 1997;16:442–9. https://doi.org/10.1021/i260064a003.

Ruangtrakoon N, Aphornratana S. Design of steam ejector in a refrigeration application based on thermodynamic performance analysis. Sustain Energy Technol Assess. 2019;31:369–82. https://doi.org/10.1016/j.seta.2018.12.014.

Huang BJ, Chang JM, Wang CP, Petrenko VA. A 1-D analysis of ejector performance. Int J Refrig. 1999;22(5):354–64. https://doi.org/10.1016/S0140-7007(99)00004-3.

Eames IW. A new prescription for the design of supersonic jet-pumps: the constant rate of momentum change method. Appl Therm Eng. 2009;22(2):121–31. https://doi.org/10.1016/S1359-4311(01)00079-5.

Chandra VV, Ahmed MR. Experimental and computational studies on a steam jet refrigeration system with constant area and variable area ejectors. Energy Convers Manag. 2015;79:377–86. https://doi.org/10.1016/j.enconman.2013.12.035.

Wu H, Liu Z, Han B, Li Y. Numerical investigation of the influences of mixing chamber geometries on steam ejector performance. Desalination. 2015;353:15–20. https://doi.org/10.1016/j.desal.2014.09.002.

Foroozesh F, Khoshnevis AB, Lakzian E. Investigation on the effects of water steam ejector geometry in the refrigeration systems using entropy generation assessment. J Therm Anal Calorim. 2020;141:1399–411. https://doi.org/10.1007/s10973-019-09128-1.

Yuan Y, Tan L, Xu Y, Yuan Y. Three-dimensional CFD modelling and simulation on the performance of steam ejector heat pump for dryer section of the paper machine. Vacuum. 2015;122:168–78. https://doi.org/10.1016/j.vacuum.2015.09.016.

Buttsworth D, Al-Doori G, Sharifi N. Mixing layer effects on the entrainment ratio in steam ejectors through ideal gas computational simulations. Energy. 2016;95:380–92. https://doi.org/10.1016/j.energy.2015.12.027.

Chen H, Lu W. Design of cylindrical mixing chamber ejector according to performance analyses. Energy. 2018;56:32–48. https://doi.org/10.1016/j.energy.2018.09.025.

Ramesh AS, Sekhar SJ. Experimental and numerical investigations on the effect of suction chamber angle and nozzle exit position of a steam-jet ejector. Energy. 2018;48:256–68. https://doi.org/10.1016/j.energy.2018.09.010.

Shovon MKB, Raman SK, Suryan A, et al. Performance of ejector refrigeration cycle based on solar energy working with various refrigerants. J Therm Anal Calorim. 2020;141:301–12. https://doi.org/10.1007/s10973-020-09319-1.

Wu Y, Zhao H, Zhang C, Wang L, Han J. Optimization analysis of structure parameters of steam ejector based on CFD and orthogonal test. Energy. 2018;151:79–93. https://doi.org/10.1016/j.energy.2018.03.041.

Foroozesh F, Khoshnevis AB, Lakzian E. Improvement of the wet steam ejector performance in a refrigeration cycle via changing the ejector geometry by a novel EEC (Entropy generation, Entrainment ratio, and Coefficient of performance) method. Int J Refrig. 2020;110:248–61. https://doi.org/10.1016/j.ijrefrig.2019.11.006.

Hemidi A, Henry F, Leclaire S, Seynhaeve JM, Bartosiewicz Y. CFD analysis of a supersonic air ejector. Part I: experimental validation of single-phase and two-phase operation. Appl Therm Eng. 2014;29(8–9):1523–31. https://doi.org/10.1016/j.applthermaleng.2008.07.003.

Thongtip T, Aphornratana S. An experimental analysis of the impact of primary nozzle geometries on the ejector performance used in R141b ejector refrigerator. Appl Therm Eng. 2016;110:89–101. https://doi.org/10.1016/j.applthermaleng.2016.08.100.

Varga S, Oliveira AC, Diaconu B. Influence of geometrical factors on steam ejector performance—a numerical assessment. Int J Refrig. 2009;32(7):1694–701. https://doi.org/10.1016/j.ijrefrig.2009.05.009.

Mohammadi A. An investigation of geometrical factors of multi-stage steam ejectors for air suction. Energy. 2019;180:115808. https://doi.org/10.1016/j.energy.2019.07.138.

Hakkaki-Fard A, Aidoun Z, Ouzzane M. A computational methodology for ejector design and performance maximisation. Energy Convers Manag. 2015;105:1291–302. https://doi.org/10.1016/j.enconman.2015.08.070.

Sheikholeslami M, Jafaryar M, Said Z, Alsabery AI, Babazadeh H, Shafee A. Modification for helical turbulator to augment heat transfer behavior of nanomaterial via numerical approach. Appl Therm Eng. 2021;182:115935. https://doi.org/10.1016/j.applthermaleng.2020.115935.

Sheikholeslami M, Farshad SA, Ebrahimpour Z, Said Z. Recent progress on flat plate solar collectors and photovoltaic systems in the presence of nanofluid: a review. J Clean Prod. 2021;293: 126119. https://doi.org/10.1016/j.jclepro.2021.126119.

Dong J, Yu M, Wang W, Song H, Li C, Pan X. Experimental investigation on low-temperature thermal energy driven steam ejector refrigeration system for cooling application. Appl Therm Eng. 2017;123:167–76. https://doi.org/10.1016/j.applthermaleng.2017.05.061.

Al-Shamani AN. Evaluation of solar-assisted absorption refrigeration cycle by using a multi-ejector. J Therm Anal Calorim. 2020;142:1477–81. https://doi.org/10.1007/s10973-020-09560-8.

Wang L, Yan J, Wang C, Li X. Numerical study on optimization of ejector primary nozzle geometries. Int J Refrig. 2017;76:219–29. https://doi.org/10.1016/j.ijrefrig.2017.02.010.

Mazzelli F, Little AB, Garimella S, Bartosiewicz Y. Computational and experimental analysis of supersonic air ejector: turbulence modeling and assessment of 3D effects. Int J Heat Fluid Flow. 2015;56:305–16. https://doi.org/10.1016/j.ijheatfluidflow.2015.08.003.

Tsegelskii VG, Akimov MV, Safargaliev TD. Experimental study of the effect the basic geometrical parameter and the active gas nozzle expansion ratio have on the performance characteristics of supersonic gas ejectors fitted with a conical mixing chamber. Therm Eng. 2018;65(1):27–38. https://doi.org/10.1134/S0040601518010081.

Lin C, He M. A numerical study on the supersonic steam ejector use in steam turbine system. Math Probl Eng. 2013;651483:1–9. https://doi.org/10.1155/2013/651483.

Sheikholeslami M, Farshad SA, Said Z. Analyzing entropy and thermal behavior of nanomaterial through solar collector involving new tapes. Int Commun Heat Mass Transf. 2021;123:105190. https://doi.org/10.1016/j.icheatmasstransfer.2021.105190.

Sheikholeslami M, Farshad SA. Investigation of solar collector system with turbulator considering hybrid nanoparticles. Renew Energy. 2021;171:1128–58. https://doi.org/10.1016/j.renene.2021.02.137.

Soham J. Design of supersonic ejector using computational fluid dynamics. Master’s thesis. Pilani: Birla Institute of Technology & Science; 2017.

Ramesh AS, Sekhar SS. Analytical and numerical studies of a steam ejector on the effect of nozzle exit position and suction chamber angle to fluid flow and system performance. J Appl Fluid Mech. 2017;10(1):369–78. https://doi.org/10.18869/acadpub.jafm.73.238.26027.

Sparrow EM, Abraham JP, Minkowycz WJ. Flow separation in a diverging conical duct: effect of Reynolds number and divergence angle. Int J Heat Mass Transf. 2009;52(13–14):3079–83. https://doi.org/10.1016/j.ijheatmasstransfer.2009.02.010.

Acknowledgements

The authors acknowledge the working environment provided by GE India Industrial Private Limited, Bangalore, India-560066, under the Internship program given to the first author of the manuscript (Ref: Mail dated 17th April 2019). The authors also acknowledge the support received by way of proofreading from Dr. M. Raja Vishwanathan, Assistant Professor, Humanities and Social Science Department, NIT Warangal, India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kakkirala, V., Velayudhan Parvathy, C. Optimized mixing chamber length and diameter of a steam ejector for the application of gas turbine power plant: a computational approach. J Therm Anal Calorim 147, 8881–8894 (2022). https://doi.org/10.1007/s10973-021-11190-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11190-7