Abstract

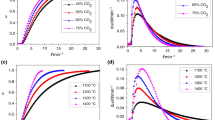

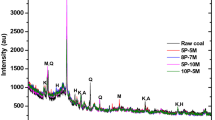

The ash fusion characteristics of bamboo and coal co-firing process were determined by a thermogravimetric analyzer, X-ray fluorescence and X-ray diffraction. The results showed that the ash of bamboo and coal co-firing process had similar chemical compositions with coal ash. Ash components occurred to synergistic interaction during co-firing process of bamboo and coal. Bamboo increased ash fusion temperatures of blends. The ash fusion process included moisture evaporation, oxidation of organic matters, removal and reaction of inorganic matters. The transformation of chemical compositions resulted in mass loss of ash. Fusion mechanism included G–B model, Mampel power model, second-order reaction and the Avrami–Erofeev model. The optimum blend ratio of bamboo and coal was suggested as 30%:70%. The results will be helpful to provide a scientific guidance to use bamboo residues for energy products.

Similar content being viewed by others

References

Contreras ML, Javier García- Frutos F, Bahillo A. Study of the thermal behaviour of coal/biomass blends during oxy-fuel combustion by thermogravimetric analysis. J Therm Anal Calorim. 2015;123:1643–55.

Kocaba-Atakl ZO, Okyay-ONer F, Yürüm Y. Combustion characteristics of Turkish hazelnut shell biomass, lignite coal, and their respective blends via thermogravimetric analysis. J Therm Anal Calorim. 2015;119:1723–9.

Xiao R, Chen X, Wang F, Yu G. The physicochemical properties of different biomass ashes at different ashing temperature. Renew Energy. 2011;36:244–9.

Ma X, Li F, Ma M, Fang Y. Investigation on blended ash fusibility characteristics of biomass and coal with high silica-alumina. Energy Fuels. 2017;31:7941–51.

Namkung H, Lee YJ, Park JH, Song GS, Choi JW, Choi YC, Park SJ, Kim JG. Blending effect of sewage sludge and woody biomass into coal on combustion and ash agglomeration behavior. Fuel. 2018;225:266–76.

Xiong QA, Li JZ, Guo S, Li G, Zhai JT, Fang YT. Ash fusion characteristics during co-gasification of biomass and petroleum coke. Bioresour Technol. 2018;257:1–6.

Li F, Xu M, Tao W, Fang Y, Ma M. An investigation on the fusibility characteristics of low-rank coals and biomass mixtures. Fuel. 2015;158:884–90.

Abreu P, Casaca C, Costa M. Ash deposition during the co-firing of bituminous coal with pine sawdust and olive stones in a laboratory furnace. Fuel. 2010;89:4040–8.

Manton NL, Williamson J, Riley GS. A laboratory assessment of the slagging propensity of blended coals. Prepr Pap Am Chem Soc Div Fuel Chem. 1996;41:1113–7.

Obernberger I, Brunner T, Bärnthaler G, Kaltschmitt M. Chemical properties of solid biofuels-significance and impact. Biomass Bioenergy. 2006;30:973–82.

Niu Y, Tan H, Hui SE. Ash-related issues during biomass combustion: Alkali-induced slagging, silicate melt-induced slagging (ash fusion), agglomeration, corrosion, ash utilization, and related countermeasures. Prog Energy Combust Sci. 2016;52:1–61.

Wang X, Liu Y, Tan H, Lin M, Xu T. Mechanism research on the development of ash deposits on the heating surface of biomass furnaces. J Guangdong Ocean Univ. 2012;30:86–90.

Mu L, Zhao L, Liu L, Yin H. Elemental distribution and mineralogical composition of ash deposits in a large-scale wastewater incineration plant: a case study. Ind Eng Chem Res. 2012;51:8684–94.

Wu H, Glarborg P, Frandsen FJ, Dam-Johansen K, Jensen PA, Bo S. Co-combustion of pulverized coal and solid recovered fuel in an entrained flow reactor: general combustion and ash behaviour. Fuel. 2011;90:1980–91.

Rousset P, Aguiar C, Labbé N, Commandré JM. Enhancing the combustible properties of bamboo by torrefaction. Bioresour Technol. 2011;102:8225–31.

Liu Z, Hu W, Jiang Z, Mi BB, Fei BH. Investigating combustion behaviors of bamboo, torrefied bamboo, coal and their respective blends by thermogravimetric analysis. Renew Energy. 2016;87:346–52.

Mi BB, Liu ZJ, Hu WH, Wei PL, Jiang ZH, Fei BH. Investigating pyrolysis and combustion characteristics of torrefied bamboo, torrefied wood and their blends. Bioresour Technol. 2016;209:50–5.

Mi BB, Yang XM, Liang F, Zhang T, Hu WH, Liu ZJ. Investigating synergistic interaction of bamboo and torrefied bamboo with coal during co-combustion. Wood Fiber Sci. 2017;49:1–11.

Liu ZJ, Zhang T, Zhang J, Xiang HZ, Yang XM, Hu WH, Liang F, Mi BB. Ash fusion characteristics of bamboo, wood and coal. Energy. 2018;161:517–22.

Zhu Y, Hu J, Yang W, Zhang W, Zeng K, Yang H, Du SL, Chen HP. Ash fusion characteristics and transformation behaviors during bamboo combustion in comparison with straw and poplar. Energy Fuels. 2018;32:5244–51.

Chen M, Dong Y, Wei Y. Evaluation on ash fusion behavior of eucalyptus bark/lignite blends. Powder Technol. 2015;286:39–47.

Pourmortazavi SM, Kohsari I, Teimouri MB, Hajimirsadeghi SS. Thermal behaviour kinetic study of dihydroglyoxime and dichloroglyoxime. Mater Lett. 2007;61:4670–3.

Vlaev LT, Markovska IG, Lyubchev LA. Non-isothermal kinetics of pyrolysis of rice husk. Thermochim Acta. 2003;406:1–7.

Magdziarz A, Dalai AK, Koziński JA. Chemical composition, character and reactivity of renewable fuel ashes. Fuel. 2016;176:135–45.

Niu Y, Zhu Y, Tan H, Wang X, Hui SE, Du W. Experimental study on the coexistent dual slagging in biomass-fired furnaces: alkali- and silicate melt-induced slagging. Proc Combust Inst. 2014;35:2405–13.

Zheng Y, Jensen PA, Jensen AD, Bo S, Junker H. Ash transformation during co-firing coal and straw. Fuel. 2007;86:1008–20.

Dayton DC, Belle-Oudry D, Nordin A. Effect of coal minerals on chlorine and alkali metals released during biomass/coal cofiring. Energy Fuels. 1999;13:1203–11.

Haykiri-Acma H, Yaman S, Kucukbayrak S. Effect of biomass on temperatures of sintering and initial deformation of lignite ash. Fuel. 2010;89:3063–8.

Acknowledgements

This research was financially supported by the “13th Five Years Plan-Study on Manufacturing Technology of Bamboo Wastes and its Mechanism” (Grant No. 2016YFD0600906) and the “Basic Scientific Research Funds of International Centre for Bamboo and Rattan-Manufacturing Technology of Biochar from Mixture of Bamboo and Wood” (Grant No. 1632018020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Z., Feng, Z., Xiang, H. et al. The ash fusion characteristics of bamboo and coal co-firing process. J Therm Anal Calorim 146, 461–468 (2021). https://doi.org/10.1007/s10973-020-09970-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09970-8