Abstract

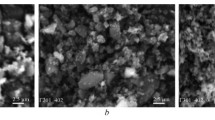

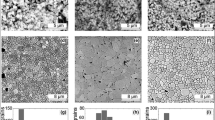

Using the method of dilatometry, kinetic characteristics of compacts shrinkage manufactured from ultrafine plasmochemical ZrO2 (Y) powders and commercial Tosoh’s powders are investigated. The shrinkage curves are constructed with a DIL 402 C high-sensitivity dilatometer in a non-isothermal heating mode at different heating rates (1, 2, 5 and 10 °C min−1). It is shown that the plasmochemical powders are characterized by a lower sintering efficiency than the Tosoh’s powders. The kinetic results are processed using a Netzsch Thermokinetics license software program developed for those who make use of devices manufactured by the Netzsch-Geratebau GmbH. The kinetic characteristics of compact shrinkage are determined as a function of partial length variation using Friedman’s analysis. Considerable differences are found between the values of apparent shrinkage activation energy for plasmochemical and Tosoh’s powders in the initial and final shrinkage stages. We attribute the mentioned differences in phase composition of the powders and their degree of agglomeration. In the intermediate shrinkage stage, the values of the apparent activation energy obtained for both types of powders have only marginal differences.

Similar content being viewed by others

References

Gusev AI. Nanomaterials, nanostructures, nanotechnology. Moscow: Fizmatlit; 2007 (in Russian).

Lange FF. Transformation toughening. Part 3: experimental observation in the ZrO2–Y2O3 system. Mater Sci. 1982;17(1):240–6.

Bowen P, Carry C. From powder to sintered pieces: formation, transformation and sintering of nanostructured ceramic oxides. Powder Technol. 2002;128:248–55.

Chevalier J, Gremillard L, Virkar AV, Clarke DL. The tetragonal–monoclinic transformation in zirconia: lessons learned and future trends. J Am Ceram Soc. 2009;92(9):1901–20.

Subaro ES. Science and technology of zirconia: advanced in ceramics. Kansas: ACERS Publisher; 1981.

Cottom BA, Mayo MJ. Fracture toughness of nanocrystalline ZrO2-3 mol% Y2O3 determined by Vickers indentation. Scr Mater. 1996;34:809–14.

Dychton K, Drajewicz M, Pytel M, Rokicki P, Nowotnik A. Yttria-stabilized zirconia–alumina composite sintering temperature effect on thermal diffusivity. J Therm Anal Calorim. 2016;126:1–7.

Ryczkowski R, Niewiadomski M, Michalkiewicz B, Skiba E, Ruppert AM, Grams J. Effect of alkali and alkaline earth metals addition on Ni/ZrO2 catalyst activity in cellulose conversion. J Therm Anal Calorim. 2016;126:103–10.

Ruppert AM, Niewiadomski M, Grams J, Kwapiński W. Optimization of Ni/ZrO2 catalytic performance in thermochemical cellulose conversion for enhanced hydrogen production. Appl Catal B Environ. 2014;145:5–90.

Caproni E, Carvalho FMS, Muccillo R. Development of zirconia–magnesia/zirconia–yttria composite solid electrolytes. Solid State Ion. 2008;179(27–23):1652–4.

Wakai F, Sakaguchi S, Matsuno Y. Superplasticity of Yttria—stabilized tetragonal ZrO2 polycrystalls. Adv Ceram Mater. 1986;1:259–63.

Opfermann J, Blumm J, Emmerich W-D. Simulation of sintering behavior of ceramic green body using advanced thermokinetic analysis. Thermochim Acta. 1998;318:213–20.

Blumm J, Opfermann J. Simulation of the sintering behavior of high-tech ceramics by means of dilatometry and thermokinetic analysis. High Temp High Press. 2000;32:567–72.

Larin VK, Kondakov VM, Malui EN, Matykha VA, Dedov NV, et al. A Plasmochemical process for production of ultrafine (nano) powders of metal oxides and their promising applications. Izv Vyschikh Uchebn Zaved Tsvetn Metall. 2003;5:59–64 (in Russian).

Surzhikov AP, Ghyngazov SA, Frangulyan TS. A dilatometric study of the effect of pressing on the kinetics of compression of ultrafine zirconium doxide powders under thermal annealing. Rus Phys J. 2012;55(4):345–52.

Theunissen GSA, Winnubst AJA, Burggraaf AJ. Surface and grain boundary analysis of doped zirconia ceramics by AES and XPS. J Mater Sci. 1992;27:5057–66.

Surzhikov AP, Ghyngazov SA, Frangulyan TS, Vasil’ev IP. Thermal transformations in ultrafine plasmochemical zirconium dioxide powders. J Therm Anal Calorim. 2015;119:1603–9.

Shi JL, Gao JH, Lin ZH, Yan DS. Effect of agglomerates in ZrO2 powder compacts on microstructural development. J Mater Sci. 1993;28:342–8.

Luo J, Adak S, Steven R. Microstructure evolution and grain growth in the sintering of 3Y-TZP ceramics. J Mater Sci. 1998;33:5301–9.

Friedman HL. J Polym Sci (1965); C6:175.

Batista RM, Muccillo ENS. Dilatometry analysis of the sintering process of nanostructured gadolinia-doped ceria. J Therm Anal Calorim. 2016;. doi:10.1007/s10973-016-5674-5.

Rankin J, Sheldon BW. In suti TEM sintering of nano-sized ZrO2 particles. Mater Sci Eng A. 1995;204:48–53.

Wakai F, Nagono T. The role of interface-controlled diffusion creep on superplasticity of yttria-stabilized tetragonal ZrO2 polycrystals. J Mater Sci Lett. 1988;7:607–9.

Panda PC, Wang J, Raj R. Sinter-forging characteristics of fine-grained zirconia. J Am Ceram Soc. 1988;71:507–9.

Ashby MF, Verrall RA. Diffusion-accommodated flow and superplasticity. Acta Metal. 1973;21:149–63.

Nieh TG, McNally CN, Wadsworth J. Superplastic properties of a fine-grained yttria-stabilized tetragonal polycrystal of zirconia. Scr Metall. 1988;22:1297–300.

Shojai F, Mantyla TA. Effect of Sintering temperature and holding time on the properties of 3 Y-ZrO2 microfiltration members. J Mater Sci. 2001;36:1–10.

Maca K, Trunec M, Doback P. Bulk zirconia nanoceramics prepared by cold isostatic pressing and pressureless sintering. Rev Adv Mater Sci. 2005;10:84–8.

Mazaheri M, Simchi A, Dourandish M, Golestani-Fard F. Master sintering curves of a nanoscale 3Y-TZP powder compacts. Ceram Int. 2009;35(2):547–54.

Teng M-H, Lai Y-C, Chen Y-T. A computer program of master sintering curve model to accurately predict sintering results. West Pac Earth Sci. 2002;2:171–80.

Acknowledgements

This work was supported by The Ministry of Education and Science of the Russian Federation in part of the “Science” program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Surzhikov, A.P., Ghyngazov, S.A., Frangulyan, T.S. et al. Investigation of sintering behavior of ZrO2 (Y) ceramic green body by means of non-isothermal dilatometry and thermokinetic analysis. J Therm Anal Calorim 128, 787–794 (2017). https://doi.org/10.1007/s10973-016-5966-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5966-9