Abstract

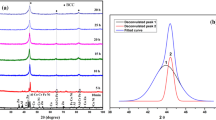

In the present study, experimental and thermodynamic analysis of phase transformation in hypoeutectic Fe–24Cr–11Ni–4Mo–0.64C alloy is presented. The investigated alloy was synthesized in an arc furnace in high-purity argon atmosphere using suction-casting unit. Chemical composition of the alloy was determined using an optical emission spectrometer. The microstructure was characterized by scanning electron microscopy. Phase composition in as-cast state was analysed by X-ray diffraction and compared with thermodynamic calculations for equilibrium state using Thermo-Calc software. The analysis of phase transformations was conducted by dilatometry and differential scanning calorimetry investigations. It was found that phase composition of the alloy after non-equilibrium solidification (cooling rate ~30 °C s−1) differs significantly from equilibrium state. Critical temperatures of phase transformations in the alloy were determined.

Similar content being viewed by others

References

Plaut R, Herrera C, Escriba D. A short review on wrought austenitic stainless steels at high temperatures: processing, microstructure, properties and performance. Mater Res. 2007;. doi:10.1590/S1516-14392007000400021.

Totten GE. Steel heat treatment, metallurgy and technologies. Boca Raton: Taylor & Francis Group; 2007.

Venkatraman M, Neumann JP. The C–Cr (carbon-chromium) system. Bull Alloy Phase Diagr. 1990;. doi:10.1007/BF02841701.

Goldschmidt HJ. Interstitial alloys. New York: Springer; 1967.

Sohar CR, Betzwar-Kotas A, Gierl C, Weiss B, Danninger H. Gigacycle fatigue behavior of a high chromium alloyed cold work tool steel. Int J Fatigue. 2008;. doi:10.1016/j.ijfatigue.2007.09.012.

Doğan ÖN, Hawk JA, Laird G. Solidification structure and abrasion resistance of high chromium white irons. Metall Mater Trans A. 1997;. doi:10.1007/s11661-997-0267-3.

Svensson L-E, Gretoft B, Ulander B, Bhadeshia HKDH. Fe–Cr–C hardfacing alloys for high-temperature applications. J Mater Sci. 1986;21:1015–9.

Fan C, Chen MC, Chang CM, Wu W. Microstructure change caused by (Cr, Fe)23C6 carbides in high chromium Fe–Cr–C hardfacing alloys. Surf Coat Technol. 2006;. doi:10.1016/j.surfcoat.2006.01.010.

Kopyciński D, Kawalec M, Szczęsny A, Gilewski R, Piasny S. Analysis of the structure and abrasive wear resistance of white cast iron with precipitates of carbides. Arch Metall Mater. 2013;. doi:10.2478/amm-2013-0113.

Yang Z, Lang Y, Liu Z, Chen H, Liang J. The benefit of molybdenum in stainless steel. In: International seminar applications of Mo steels June 27th–28th, 2010:27–45.

Tabrett CP, Sare IR, Ghomashchi MR. Microstructure-property relationships in high chromium white iron alloys. Int Mater Rev. 1996;. doi:10.1179/095066096790326075.

Imurai S, Thanachayanont C, Pearce JTH, Chairuangsri T. Microstructure and erosion-corrosion behaviour of as-cast high chromium white irons containing molybdenum in aqueous sulfuric-acid slurry. Arch Metall Mater. 2015;. doi:10.1515/amm-2015-0230.

Palcut M, Vach M, Cicka R, Janovec J. Compositional changes in carbide M7C3 upon annealing. Arch Metall Mater. 2008;53:1157–64.

Gulyaev AP. Carbide transformations in alloy steels. Metal Sci Heat Treat Met 1959;1(11):53–60.

Wieczerzak K, Bala P, Stepien M, Cios G, Koziel T. Microstructural aspects of cast Fe–Cr–Mo–C alloy. In: Met. 2015, June 3rd–5th, Brno, 2015; 1–6.

Lo KH, Shek CH, Lai JKL. Recent developments in stainless steels. Mater Sci Eng R Rep. 2009;. doi:10.1016/j.mser.2009.03.001.

Padilha AF, Rios PR. Decomposition of austenite in austenitic stainless steels. ISIJ Int. 2002;. doi:10.2355/isijinternational.42.325.

Bechtoldt CJ, Vacher HC. Phase-diagram study of alloys in the iron-chromium-molybdenum-nickel system. J Res Natl Bur Stand. 1957;. doi:10.6028/jres.058.002.

Kim SJ, Lee TH. Precipitation sequences in austenitic Fe–22Cr–21Ni–6Mo–(N) stainless steels. Mater Sci Forum. 1999;. doi:10.4028/www.scientific.net/MSF.318-320.109.

Stoter LP. Thermal ageing effects in AISI type 316 stainless steel. J Mater Sci. 1981;. doi:10.1007/BF00542750.

Liu S, Hamaguchi Y, Kuwano H. Intermetallic compounds and their formation reactions in system Fe–Cr–Mo at high-temperatures. Acta Metall Sin (Engl Lett). 1989;2:321–8.

Filho AI, Cardoso WS, Gontijo LC, Silva RV, Casteletti LC. Austenitic–ferritic stainless steel containing niobium. Metall Mater. 2013;66:467–71.

Nilsson JO. Super duplex stainless steels. Mater Sci Technol. 1992;. doi:10.1179/mst.1992.8.8.685.

Kim SH, Kim H, Kim NJ. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Nature. 2015;. doi:10.1038/nature14144.

Kosec L, Šavli Š, Kožuh S, Holjevac Grgurić T, Nagode A, Kosec G, et al. Transformation of austenite during isothermal annealing at 600–900 C for heat-resistant stainless steel. J Alloys Compd. 2013;. doi:10.1016/j.jallcom.2013.03.102.

Weiss B, Stickler R. Phase instabilities during high temperature exposure of 316 austenitic stainless steel. Metall Trans. 1972;. doi:10.1007/BF02647659.

Kozieł T. Estimation of cooling rates in suction casting and copper-mould casting processes. Arch Metall Mater. 2015;. doi:10.1515/amm-2015-0204.

Durand-Charre M. Microstructure of steels and cast irons. Berlin: Springer; 2003.

Seiser B, Drautz R, Pettifor DG. TCP phase predictions in Ni-based superalloys: structure maps revisited. Acta Mater. 2011;. doi:10.1016/j.actamat.2010.10.013.

Inoue A, Masumoto T. Carbide reactions (M3C–M7C3–M23C6–M6C) during tempering of rapidly solidified high carbon Cr–W and Cr–Mo steels. Metall Trans A. 1980;. doi:10.1007/BF02661203.

Diószegi A, Diaconu VL, Fourlakidis V. Prediction of volume fraction of primary austenite at solidification of lamellar graphite cast iron using thermal analyses. J Therm Anal Calorim. 2016;. doi:10.1007/s10973-015-5158-z.

Guerra-Fuentes L, Deaquino Lara R, Hernandez-Rodriguez MAL, Salinas-Rodriguez A. Garcia-Sanchez1 E. Thermal stability and phase transformations of a FV535 steel. J Therm Anal Calorim. 2016;. doi:10.1007/s10973-015-4948-7.

Klančnik G, Medved J, Nagode A, Novak G, Steiner Petrovič D. Influence of Mn on the solidification of Fe–Si–Al alloy for non-oriented electrical steel. J Therm Anal Calorim. 2014;. doi:10.1007/s10973-013-3536-y.

Maehara Y, Fujino N, Kunitake T. Effects of plastic deformation and thermal history on σ phase precipitation in duplex phase stainless steels. Trans Iron Steel Inst Japan. 1983;. doi:10.2355/isijinternational1966.23.247.

Acknowledgements

This work was supported by the AGH UST Grant No. 15.11.110.430.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wieczerzak, K., Bała, P., Cios, G. et al. Experimental study of phase transformation in non-equilibrium hypoeutectic alloy from the Fe–Cr–Ni–Mo–C system. J Therm Anal Calorim 127, 449–455 (2017). https://doi.org/10.1007/s10973-016-5943-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5943-3