Abstract

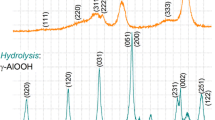

In situ techniques were used to investigate the hierarchical porous structure of alumina monoliths formed by the combined processes of sol–gel transition and spinodal phase separation. The addition of low molecular weight poly(ethylene oxide) (PEO) in the sol–gel reaction of aluminum chloride induced phase separation between aluminate gel and PEO solvent. In situ time-resolved small-angle X-ray scattering (SAXS) measurements revealed that structural evolution during gelation of a sample without PEO was dominated by Ostwald ripening. With PEO addition, this coarsening mechanism, occurring during a short intermediate stage (6 min), was followed by the aggregative coalescence of phase separating domains during the late stage of spinodal decomposition. The effect of PEO in the gelation mechanism also influenced the porous structure formed by calcination of the alumina monoliths. During calcination for PEO removal and conversion from xerogel to ceramic, in situ SAXS monitoring evidenced that the formation of mesopores followed the spinodal decomposition mechanism proposed by Cahn’s theory. Alumina with well-defined meso- and macropore families, high specific pore volume (2.0 cm3 g−1), and high surface area (252 m2 g−1) was obtained as a result of spinodal decomposition during the sol–gel transition followed by heat treatment.

Highlights

-

Elucidation of the structure formation process of hierarchical porous alumina with high pore volume.

-

In situ SAXS used to probe the gelation mechanism and coarsening of phase-separated domains.

-

Mesoporosity evolution during heat treatment followed Cahn’s model for spinodal decomposition.

Similar content being viewed by others

References

Pélisson CH, Nakanishi T, Zhu Y, Morisato K, Kamei T, Maeno A, Kaji H, Muroyama S, Tafu M, Kanamori K, Shimada T, Nakanishi K (2017) Grafted polymethylhydrosiloxane on hierarchically porous silica monoliths: a new path to monolith-supported palladium nanoparticles for continuous flow catalysis applications. ACS Appl Mater Interfaces 9:406–412. https://doi.org/10.1021/acsami.6b12653

Moitra N, Kanamori K, Ikuhara YH, Gao X, Zhu Y, Hasegawa G, Takeda K, Shimada T, Nakanishi K (2014) Reduction on reactive pore surfaces as a versatile approach to synthesize monolith-supported metal alloy nanoparticles and their catalytic applications. J Mater Chem A 2:12535–12544. https://doi.org/10.1039/C4TA01767F

Passos AR, Martins L, Pulcinelli SH, Santilli CV, Briois V (2017) Correlation of sol-gel alumina-supported cobalt catalyst processing to cobalt speciation, ethanol steam reforming activity, and stability. ChemCatChem 9:3918–3929. https://doi.org/10.1002/cctc.201700319

Guo X, Ding L, Kanamori K, Nakanishi K, Yang H (2017) Functionalization of hierarchically porous silica monoliths with polyethyleneimine (PEI) for CO2 adsorption. Microporous Mesoporous Mater 245:51–57. https://doi.org/10.1016/j.micromeso.2017.02.076

Tokudome Y, Tarutani N, Nakanishi K, Takahashi M (2013) Layered double hydroxide (LDH)-based monolith with interconnected hierarchical channels: enhanced sorption affinity for anionic species. J Mater Chem A 1:7702–7708. https://doi.org/10.1039/c3ta11110e

Nakanishi K, Tanaka N (2007) Sol-gel with phase separation. Hierarchically porous materials optimized for high-performance liquid chromatography separations. Acc Chem Res 40:863–873. https://doi.org/10.1021/ar600034p

Hu Y, Giret S, Meinusch R, Han J, Fontaine FG, Kleitz F, Larivière D (2019) Selective separation and preconcentration of Th(iv) using organo-functionalized, hierarchically porous silica monoliths. J Mater Chem A 7:289–302. https://doi.org/10.1039/C8TA07952H

Hasegawa G, Kanamori K, Kiyomura T, Kurata H, Nakanishi K, Abe T (2015) Hierarchically porous Li4Ti5O12 anode materials for Li- and Na-ion batteries: effects of nanoarchitectural design and temperature dependence of the rate capability. Adv Energy Mater 5:1400730. https://doi.org/10.1002/aenm.201400730

Gong J, Zhao G, Feng J, Wang G, An Y, Zhang L, Li B (2019) Novel method of fabricating free-standing and nitrogen-doped 3D hierarchically porous carbon monoliths as anodes for high-performance sodium-ion batteries by supercritical CO2 foaming. ACS Appl Mater Interfaces 11:9125–9135. https://doi.org/10.1021/acsami.8b21660

Tokudome Y, Fujita K, Nakanishi K, Miura K, Hirao K (2007) Synthesis of monolithic Al2O3 with well-defined macropores and mesostructured skeletons via the sol-gel process accompanied by phase separation. Chem Mater 19:3393–3398. https://doi.org/10.1021/cm063051p

Lu X, Hasegawa G, Kanamori K, Nakanishi K (2020) Hierarchically porous monoliths prepared via sol–gel process accompanied by spinodal decomposition. J Sol-Gel Sci Technol 95:530–550. https://doi.org/10.1007/s10971-020-05370-4

Sachse A, Galarneau A, Coq B, Fajula F (2011) Monolithic flow microreactors improve fine chemicals synthesis. New J Chem 35:259–264. https://doi.org/10.1039/c0nj00965b

Nakanishi K (1997) Pore structure control of silica gels based on phase separation. J Porous Mater 4:67–112. https://doi.org/10.1023/a:1009627216939

Passos AR, Pulcinelli SH, Briois V, Santilli CV (2016) High surface area hierarchical porous Al2O3 prepared by the integration of sol-gel transition and phase separation. RSC Adv 6:57217–57226. https://doi.org/10.1039/C6RA11477F

Kido Y, Nakanishi K, Miyasaka A, Kanamori K (2012) Synthesis of monolithic hierarchically porous iron-based xerogels from iron(III) salts via an epoxide-mediated sol–gel process. Chem Mater 24:2071–2077. https://doi.org/10.1021/cm300495j

Fukumoto S, Nakanishi K, Kanamori K (2015) Direct preparation and conversion of copper hydroxide-based monolithic xerogels with hierarchical pores. New J Chem 39:6771–6777. https://doi.org/10.1039/c5nj00479a

Tokudome Y, Miyasaka A, Nakanishi K, Hanada T (2011) Synthesis of hierarchical macro/mesoporous dicalcium phosphate monolith via epoxide-mediated sol–gel reaction from ionic precursors. J Sol-Gel Sci Technol 57:269–278. https://doi.org/10.1007/s10971-010-2184-y

Nakanishi K, Soga N (1991) Phase separation in gelling silica-organic polymer solution: systems containing poly(sodium styrenesulfonate). J Am Ceram Soc 74:2518–2530. https://doi.org/10.1111/j.1151-2916.1991.tb06794.x

Cahn JW (1961) On spinodal decomposition. Acta Met 9:795–801. https://doi.org/10.1016/0001-6160(61)90182-1

Gao Y, Kim J, Helgeson ME (2015) Microdynamics and arrest of coarsening during spinodal decomposition in thermoreversible colloidal gels. Soft Matter 11:6360–6370. https://doi.org/10.1039/c5sm00851d

Gommes C, Goderis B, Pirard J (2007) Relevance of spinodal decomposition for support formation and metal dispersion in cogelled Pd/SiO2 catalysts. J Phys Chem C 111:11150–11156. https://doi.org/10.1021/jp070648z

Tokudome Y, Nakanishi K, Kanamori K, Hanada T (2010) In situ SAXS observation on metal-salt-derived alumina sol-gel system accompanied by phase separation. J Colloid Interface Sci 352:303–308. https://doi.org/10.1016/j.jcis.2010.08.041

Zinn T, Sharpnack L, Narayanan T (2020) Phoretic dynamics of colloids in a phase separating critical liquid mixture. Phys Rev Res 2:033177. https://doi.org/10.1103/physrevresearch.2.033177

Cahn JW (1965) Phase separation by spinodal decomposition in isotropic systems. J Chem Phys 42:93–99. https://doi.org/10.1063/1.1695731

Nakanishi K, Kanamori K, Tokudome Y, Hasegawa G, Zhu Y (2017) Sol–gel processing of porous materials. In: Handbook of solid state chemistry. Wiley-VCH, Weinheim.

Passos AR, Martins L, Pulcinelli SH, Santilli CV (2011) Construction of a chamber for in situ monitoring of the drying process of gels and porous solids. Quim Nova 34:1455–1458. https://doi.org/10.1590/S0100-40422011000800027

Gregg SJ, Sing KSW (1997) Adsorption, surface area and porosity. Academic Press, London

Gash AE, Tillotson TM, Satcher JH, Poco JF, Hrubesh LW, Simpson RL (2001) Use of epoxides in the sol−gel synthesis of porous iron(III) oxide monoliths from Fe(III) salts. Chem Mater 13:999–1007. https://doi.org/10.1021/cm0007611

Pawar N, Bohidar HB (2010) Spinodal decomposition and phase separation kinetics in nanoclay–biopolymer solutions. J Polym Sci Part B Polym Phys 48:555–565. https://doi.org/10.1002/polb.21922

Guinier A, Fournet G (1995) Small-angle scattering of X-rays. Wiley, New York, NY

Porod G (1982) Small angle X-ray scattering. Academic Press, London.

Vollet DR, Donatti DA, Ibãez Ruiz A, De Vicente FS (2010) Dynamical scaling in fractal structures in the aggregation of tetraethoxysilane-derived sonogels. J Appl Crystallogr 43:949–954. https://doi.org/10.1107/S0021889810025161

Vollet DR, Donatti DA, Awano CM, Chiappim W, de Vicente FS (2011) Dynamic scaling and growth kinetics of 3-glycidoxypropyltrimethoxysilane-derived organic/silica hybrids. Macromolecules 44:6849–6855. https://doi.org/10.1021/ma1028483

Awano CM, de Vicente FS, Donatti DA, Vollet DR (2012) Structure and growth kinetics of 3-glycidoxypropyltrimethoxysilane-derived organic/silica hybrids at different temperatures. J Phys Chem C 116:24274–24280. https://doi.org/10.1021/jp305222z

Ostwald WZ (1901) Blocking of Ostwald ripening allowing long-term stabilization. Phys Chem 37:385

Passos AR, Martins L, Pulcinelli SH, Santilli CV (2012) Design of hierarchical porous aluminas by using one-pot synthesis and different calcination temperatures. J Sol-Gel Sci Technol 63:242–250. https://doi.org/10.1007/s10971-011-2674-6

Santilli CV, Pulcinelli SH, Craievich AF (1995) Porosity evolution in SnO2 xerogels during sintering under isothermal conditions. Phys Rev B 51:8801–8809. https://doi.org/10.1103/PhysRevB.51.8801

Sudarsanam P, Peeters E, Makshina EV, Parvulescu VI, Sels BF (2019) Advances in porous and nanoscale catalysts for viable biomass conversion. Chem Soc Rev 48:2366–2421. https://doi.org/10.1039/c8cs00452h

Liu L, Milas N, Mukai AHC, Resende XR, De Sá FH (2014) The sirius project. J Synchrotron Radiat 21:904–911. https://doi.org/10.1107/S1600577514011928

Shpyrko OG (2014) X-ray photon correlation spectroscopy. J Synchrotron Radiat 21:1057–1064. https://doi.org/10.1107/S1600577514018232

Acknowledgements

This work was supported by the Brazilian agencies CAPES (project number 17515/12-2), CNPq (project numbers 482176/2013-0, 163588/2015-5, and 147402/2019-0), and FAPESP (project numbers 2007/53073-4 and 2011/08673-9). The authors thank SOLEIL (France) for synchrotron beamtime at the SWING beamline.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Passos, A.R., Pulcinelli, S.H. & Santilli, C.V. Relevance of sol–gel transition and spinodal decomposition for hierarchical porosity structure of monolithic alumina. J Sol-Gel Sci Technol 102, 6–17 (2022). https://doi.org/10.1007/s10971-021-05620-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-021-05620-z