Abstract

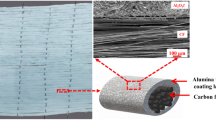

The extrusion impregnation method is used to prepare carbon fiber felt/portland cement (CFF/PC) composite materials. The samples are placed into muffle furnace for ablation, but carbon fiber is oxidized at around 450 °C. To improve the oxidation resistance of carbon fiber, Al2O3 sol–gel (AS) is prepared to coat the surface of carbon fiber. The extrusion impregnation method is also used to prepare AS–CFF/PC composite materials. The samples are also ablated into muffle furnace at different temperatures. The results indicate that carbon fiber is uniformly dispersed and closely arranged in the matrix, presenting a three-dimensional network distribution. The bending and compressive strengths of CFF/PC composite materials are increased by 200% and 12% when compared with that of PC material at room temperature. The AS coating layer can effectively improve the antioxidant capacity of carbon fiber at high temperatures. The comparison reveals that AS–CFF/PC composite materials exhibit improved high-temperature resistance performance.

Highlights

-

CFF/PC and AS–CFF/PC composites were prepared by extrusion impregnation method.

-

Sol–gel method was used to prepare different concentrations of Al2O3 sol–gel (AS).

-

AS coating layer can improve the antioxidant capacity of carbon fiber.

-

AS–CFF/PC composites exhibit improved high-temperature resistance.

Similar content being viewed by others

References

Mohanty RM (2013) Climate based performance of carbon-carbon disc brake for high speed aircraft braking system. Def Sci J 63(5):531–538

Li SZ, Luo C (2000) Present state of non-asbestic friction materials for the use of automobiles in china. Powder Metall Ind 10(2):38–41

Wang Y, Zhou YK, Nie HW (2016) Study on the friction factor and high-temperature friction resistance of semi-metal frictional materials. Key Eng Mater 693:629–637

Jang H, Ko K, Kim SJ, Fash JW (2004) The effect of metal fibers on the friction performance of automotive brake friction materials. Wear 256(3–4):406–414

Kwon DJ, Shin PS, Kim JH, Devries KL, Park JM (2016) Evaluation of dispersion and damage sensing of carbon fiber/polypropylene (PP)-polyamide (PA) composites using 2 dimensional electrical resistance mapping. Compos Part A 90:417–423

Chauhan S, Kumar A, Patnaik A, Satapathy A, Singh I (2009) Mechanical and wear characterization of GF reinforced vinylester resin composites with different comonomers. J Reinf Plast Compos 28(21):2675–2684

Xu LX, Guan HB, Yang ZW, Hao XZ (2015) Preparation and mechanical property of C/SiC composite by vacuum infusion method. J Mater Eng 43(12):10–16

Talijan NM, Trifunović DS, Trifunović DD (2000) The influence of different iron powders on the friction properties of sintered friction materials based on iron. Mater Lett 46(5):255–260

Magnier V, Roubin E, Colliat JB, Dufrénoy P (2017) Methodology of porosity modeling for friction pad: Consequence on squeal. Tribol Int 109:78–85

Ertan R (2016) Synergistic effect of organic- and ceramic-based ingredients on the tribological characteristics of brake friction materials. Mater Tehnol 50(2):223–228

Wang FH, Liu Y (2012) Effectcs of mullite fiber content on friction and wear properties of ceramic-based friction material. J Mater Eng 12:61–65

Hoshino S, Tadokoro C, Sasaki S (2016) Effect of surface texturing on friction transition of C/C composite material. Tribol Online 11(2):426–431

Wei K, Cheng X, He R, Pei Y, Fang D (2014) Heat transfer mechanism of the C/SiC ceramics pyramidal lattice composites. Compos Part B 63(5):8–14

Krenkel W, Berndt F (2005) C/C–SiC composites for space applications and advanced friction systems. Mater Sci Eng A 412(1–2):177–181

Farzadnia N, Ali AAA, Demirboga R (2013) Characterization of high strength mortars with nano alumina at elevated temperatures. Cem Concr Res 54:43–54

Pernites RB, Santra AK (2016) Portland cement solutions for ultra-high temperature wellbore applications. Cem Concr Compos 72:89–103

Madej D, Szczerba J (2017) Detailed studies on microstructural evolution during the high temperature corrosion of SiC-containing andalusite refractories in the cement kiln preheater. Ceram Int 43:1988–1996

Wang YL, Zhun BQ, Li XC, Chen PA (2016) Effect of dispersants on the hydrate morphologies of spinel-containing calcium aluminate cement and on the properties of refractory castables. Ceram Int 42(1):711–720

Ouedraogo E, Roosefid M, Prompt N, Deteuf C (2011) Refractory concretes uniaxial compression behaviour under high temperature testing conditions. J Eur Ceram Soc 31(15):2763–2774

Ranade R, Zhang J, Lynch JP, Li VC (2014) Influence of micro-cracking on the composite resistivity of engineered cementitious composites. Cem Concr Res 58:1–12

Laukaitis A, Kerienė J, Kligys M, Mikulskis D, Lekūnaitė L (2012) Influence of mechanically treated carbon fibre additives on structure formation and properties of autoclaved aerated concrete. Constr Build Mater 26(1):362–371

Düzgün OA, Gül R, Aydin AC (2005) Effect of steel fibers on the mechanical properties of natural lightweight aggregate concrete. Mater Lett 59(27):3357–3363

Xu LX, Jiang AX, Yang ZW, Guan HB, Jia H, Min MY (2017) Mechanical properties of CFF/MC/SF composite prepared using vacuum infusion impregnation method. Results Phys 7:1016–1021

Wang C, Jiao GS, Li BL, Peng L, Feng Y, Gao N, Li KZ (2017) Dispersion of carbon fibers and conductivity of carbon fiber-reinforced cement-based composites. Ceram Int 43:15122–15132

Jiang AX, Xu LX, Guan HB, Yang ZW, Jia H (2017) Effect of silica fume content on tribological property of carbon felt/cement composite. Mater Mech Eng 41(5):74–78

Min MY, Xu LX, Jiang AX, Yang ZW, Zhu RY (2017) Effect of graphite on friction properties of carbon felt/cement composites. Non-Met Mines 40(6):101–103

Cairo CAA, Graça MLA, Silva CRM, Bressiani JC (2001) Functionally gradient ceramic coating for carbon–carbon antioxidation protection. J Eur Ceram Soc 21(3):325–329

Morales A, Duran A (1997) Sol–gel protection of front surface silver and aluminum mirrors. J Sol–Gel Sci Technol 8:451–457

EI-Didamony H, EI-Rahman EA, Osman RM (2012) Fire resistance of fired clay bricks–fly ash composite cement pastes. Ceram Int 38(1):201–209

Silva FDA, Butler M, Hempel S, Filho RDT, Mechtcherine V (2014) Effects of elevated temperatures on the interface properties of carbon textile-reinforced concrete. Cem Concr Compos 48(4):26–34

Rashad AM, Bai Y, Basheer PAM, Collier NC, Milestone NB (2012) Chemical and mechanical stability of sodium sulfate activated slag after exposure to elevated temperature. Cem Concr Res 42(2):333–343

Xu WT, Dai JG, Ding Z, Wang YS (2017) Polyphosphate-modified calcium aluminate cement under normal and elevated temperatures: phase evolution, microstructure, and mechanical properties. Ceram Int 43:15525–15536

Hafiane YE, Smith A, Abouliatim Y, Chartier T, Nibou L, Bonnet JP (2014) Calcium aluminate cement tapes—Part I: structural and microstructural characterizations. J Eur Ceram Soc 34(4):1017–1023

Bayramli E, Toppare L, Erinc NK (2001) Investigations on the electrochemical surface treatment of carbon fibers. Turk J Chem 25(3):251–258

Aleš N, Kaja J, Ivan J, Daniel V, Milan B, Borut K, Blaž K, Borut Z (2018) The effect of sol–gel boehmite coatings on the corrosion and decarburization of C45 steel. J Sol–Gel Sci Technol 86:1–12

Ghasemi-Kahrizsangi S, Dehsheikh HG, Karamian E, Ghasemi-Kahrizsangi A, Hosseini SV (2017) The influence of Al2O3 nanoparticles addition on the microstructure and properties of bauxite self–flowing low-cement castables. Ceram Int 43:8813–8818

Potong R, Rianyoi R, Ngamjarurojana A, Yimnirun R, Guo R, Bhalla AS, Chaipanich A (2017) Thermal expansion behaviors of 0–3 connectivity lead-free barium zirconate titanate-portland cement composites. Ceram Int 43:S129–S135

Nematollahi B, Qiu JS, Yang EH, Sanjayan J (2017) Microscale investigation of fiber-matrix interface properties of strain-hardening geopolymer composite. Ceram Int 43:15616–15625

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51236003) and the Natural Science Foundation of Gansu Province (1506RJZA076).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, L., Min, M., Yang, S. et al. Improvement of high-temperature resistance on carbon fiber felt/portland cement composite friction material by Al2O3 sol–gel coating. J Sol-Gel Sci Technol 91, 471–484 (2019). https://doi.org/10.1007/s10971-019-05050-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-019-05050-y