Abstract

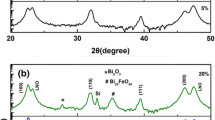

The high-concentration precursor solution of Bi0.9La0.1FeO3 (BLFO) was fabricated and stored under the different temperatures (40, 20, 0 °C). After 10 days, the solution at the temperature of 40 °C generated both bismuth acetate precipitation and nitrogen dioxide gas and at the temperature of 20 °C generated nitrogen dioxide gas, while the solution still maintains stability and transparency at the temperature of 0 °C. These results show that low temperature is an important way to improve the stability of high-concentration precursor solution in sol–gel method. Furthermore, the stability precursor solution is adopted to prepare BLFO thick film on indium tin oxide/glass substrate by spin coating combined with sequential layer annealing. The film exhibits a perovskite structure without impurity phase; especially, a comparatively high remanent polarization (P r) of 42.85 μC/cm2 can be obtained, which may be related to lanthanum doping, preferred (110) orientation and relatively compact microstructure.

Graphical Abstract

XRD patterns and cross-sectional structure of Bi0.9La0.1FeO3 thick film, polarization–electric field (P–E) loops at various voltages.

Similar content being viewed by others

References

Zhou Q, Lau S, Wu D, Shung KK (2011) Piezoelectric films for high frequency ultrasonic transducers in biomedical applications. Prog Mater Sci 56:139–174

Enrico T, Maria LDV, Silvia L (2000) Sol–Gel nanosized semiconducting titania-based powders for thick-film gas sensors. J Sol Gel Sci Technol 19:193–196

Vittorio F, Daniele M, Andrea T, Elisabetta R (2000) Multisensor array of mass microbalances for chemical detection based on resonant piezo-layers of screen-printed PZT. Sens Actuators B 68:81–87

White NM, Glynne-Jones P, Beeby SP (2001) A novel thick-film piezo-electric micro-generator. Smart Mater Struct 10:850–852

Darko B, Marko H, Janez H, Marina SZ, Marija K, Marko P (2007) The application of thick-film technology in C-MEMS. J Electroceram 19:363–368

Khomyakova E, Pavlic J, Makarovic M, Ursic H, Walker J, Rojac T, Malic B, Bencan A (2015) Integration of BiFeO3 thick films onto ceramic and metal substrates by screen printing. J Eur Ceram Soc 35:4163–4171

Zhao Y, Hao XH, Li ML (2014) Dielectric properties and energy-storage performance of (Na0.5Bi0.5)TiO3 thick films. J Alloys Compd 601:112–115

Du P, Yang F, Zang X, Qiu C (2014) Effect of excess Bi Content on the electrical properties of Bi0.95La0.05FeO3 thick films. J Mater Sci Mater Electron 25:5316–5321

Takaaki T, Shuichi O, Satoshi W (2003) Preparation pf PZT thick films by an interfacial polymerization method. J Sol Gel Sci Technol 26:1037–1040

Liu YM, Lam KH, Shung KK, Li JY, Zhou QF (2013) Enhanced piezoelectric performance of composite sol–gel thick films evaluated using piezoresponse force microscopy. J Appl Phys 113:187205

Ringgaard E, Wurlitzer T (2005) Lead-free piezoceramics based on alkali niobates. J Eur Ceram Soc 25:2701–2706

Gaur A, Singh P, Choudhary N, Kumar D, Shariq M, Singh K (2011) Structural, optical and magnetic properties of Nd-doped BiFeO3 thin films prepared by pulsed laser deposition. Phys B 406:1877–1882

Ali Z, Atta A, Abbas Y, Sedeek K, Adam A, Abdeltweb E (2015) Multiferroic BiFeO3 thin films: structural and magnetic characterization. Thin Solid Film 577:124–127

Riaz S, Shah SMH, Akbar A, Atiq S, Naseem S (2015) Effect of Mn doping on structural, dielectric and magnetic properties of BiFeO3 thin film. J Sol Gel Sci Technol 74:329–339

Ryu J, Baek CW, Park DS, Jeong DY (2010) Multiferroic BiFeO3 thick film fabrication by aerosol deposition. Met Mater Int 16:639–642

Si HY, Lu WL, Chen JS, Chow GM, Sun XG, Zhao JJ (2013) Hydrothermal epitaxial multiferroic BiFeO3 thick film by addition of the PVA. J Alloys Compd 577:44–48

Karpinsky DV, Troyanchuk IO, Tovar M, Sikolenko V, Emov V, Kholkin AL (2013) Evolution of crystal structure and ferroic properties of La-doped BiFeO3 ceramics near the rhombohedral-orthorhombic phase boundary. J Alloys Compd 555:101–107

Saxena A, Sharma P, Saxena A, Verma V, Saxena RS (2014) Effects of La doping on dielectric properties of BiFe0.95Mn0.05O3 multiferroics. Ceram Int 40:15065–15072

Yokoyama S, Honda Y, Morioka H, Okamoto S, Funakubo H, Iijima T, Matsuda TH, Saito K, Yamamoto T, Okino H, Sakata O, Kimura S (2005) Dependence of electrical properties of epitaxial Pb(Zr, Ti)O3 thick films on crystal orientation and Zr/(Zr + Ti) ratio. J Appl Phys 98:094106

Yao K, He XJ, Xu Y, Chen MM (2005) Screen-printed piezoelectric ceramic thick films with sintering additives introduced through a liquid-phase approach. Sens Actuator A Phys 118:342–348

Navarro A, Alcock JR, Whatmore RW (2004) Aqueous colloidal processing and green sheet properties of lead zirconate titanate (PZT) ceramics made by tape casting. J Eur Ceram Soc 24:1073–1076

Singha A, Khan ZR, Vilarinho PM, Gupta V, Katiyar RS (2014) Influence of thickness on optical and structural properties of BiFeO3 thin films: PLD grown. Mater Res Bull 49:531–536

Chen MJ, Ding JN, Qiu JH, Yuan NY (2015) Effect of film thickness and bottom electrode material on the ferroelectric and photovoltaic properties of sputtered polycrystalline BiFeO3 films. Mater Lett 15:325–328

Teruyuki S, Kazutaka K (2008) Preparation of thick and hard coating films via sol–gel process with a low temperature treatment. J Sol Gel Sci Technol 46:180–189

Kojima T, Sakai T, Watanabe T, Funakubo H, Saito K, Osada M (2002) Large remanent polarization of (Bi, Nd)4Ti3O12 epitaxial thin films grown by metalorganic chemical vapor deposition. Appl Phys Lett 80:2746

Wang J, Neaton JB, Zheng H, Nagarajan V, Ogale SB, Liu B, Viehland D, Vaithyanathan V, Schlom DG, Waghmare UV, Spaldin NA, Rabe KM, Wuttig M, Ramesh R (2003) Epitaxial BiFeO3 Multiferroic thin film heterostructures. Science 299:1719–1722

Li JF, Wang JL, Wuttig M, Ramesh R, Wang NG, Ruette B, Pyatakov AP, Zvezdin AK, Viehland D (2004) Dramatically enhanced polarization in (001), (101), and (111) BiFeO3 thin films due to epitaxial-induced transitions. Appl Phys Lett 84:5261–5263

Zhang ST, Zhang Y, Lu MH, Du CL, Chen YF, Liu ZG, Zhu YY, Ming NB (2006) Substitution-induced phase transition and enhanced multiferroic properties of Bi1−xLaxFeO3 ceramics. Appl Phys Lett 88:162901

Yan F, Zhu TJ, Lai MO, Lu L (2010) Enhanced multiferroic properties and domain structure of La-doped BiFeO3 thin films. Scr Mater 63:780–783

Damodaran AR, Lee S, Jambunathan K, Macclaren S, Martin LW (2012) Temperature and thickness evolution and epitaxial breakdown in highly strained BiFeO3 thin film. Phys Rev B 85:024113

Yan J, Hu GD, Chen XM (2008) Ferroelectric properties, morphologies, and leakage currents of Bi0.97La0.03FeO3 thin films deposited on indium tin oxide/glass substrates. J Appl Phys 104:076103

Rao TD, Asthana S (2014) Evidence of improved ferroelectric phase stabilization in Nd and Sc co-substituted BiFeO3. J Appl Phys 116:164102

Liu JJ, Yin ZM, Zhang HY, Sun W, Jiang B, Hu GD (2012) Elimination of domain backswitching in BiFe0.95Mn0.05O3 thin films by lowering the layer thickness. J Appl Phys 111:006107

Dho JH, Qi XD, Haekwon K, Judith MMD, Blamire M (2006) Large electric polarization and exchange bias in multiferroic BiFeO3. Adv Mater 18:1445–1448

Cui SG, Hu GD, Wu WB, Yang CH, Jiao LL, Wen Z (2009) Aging-induced double ferroelectric hysteresis loops and asymmetric coercivity in as-deposited BiFe0.95Zn0.05O3 thin film. J Am Ceram Soc 92:1610–1612

Abazari M, Safari A, Bharadwaja SSN, Trolier-Mckinstry S (2010) Dielectric and piezoelectric properties of lead-free (Bi, Na)TiO3-based thin film. Appl Phys Lett 96:082903

Li WL, Chi QG, Fei WD (2011) Microstructures and electric properties of highly (111)-oriented Nb-doped Pb(Zr0.2, Ti0.8)O3 films with Pb0.8La0.1Ca0.1Ti0.975O3 seed layer. J Am Ceram Soc 94:1503–1508

Yang CH, Sui HT, Wu HT, Hu GD (2015) Na0.5Bi0.5(Ti0.98Zr0.02)O3 thin film with improved performance by modifying annealing atmosphere and Zr doping content. J Alloys Compd 637:315–320

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Nos. 51172094 and 51372100).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Guo, S.J., Yang, C.H., Jiang, X.M. et al. High ferroelectric performance of Bi0.9La0.1FeO3 thick film by optimizing preparation precursor solution. J Sol-Gel Sci Technol 80, 174–179 (2016). https://doi.org/10.1007/s10971-016-4059-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-016-4059-3