Abstract

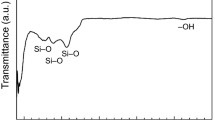

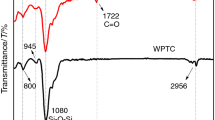

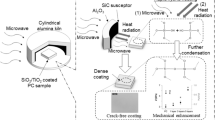

SiO2 anti-reflective (AR) layers have been prepared via sol–gel dip-coating technique and the mechanism study of crack formation has been then carried out. It is found that thermal expansion difference between substrate and layer, in combination with capillary tension caused by water vapor, was responsible for the production of considerable stress inside the sol–gel coating. Initial crack would be generated once this combined stress exceeded the self-relaxation and self-reconstruction capability of this sol–gel AR layer. It is also found that the morphology of most cracks exhibited to be a ridged edge accompanied with a collapse dent. This deformation was also assigned to the combination effect of capillary tension and expansion strain. In addition, a surface barrier was formed on the section of crack, owing to the incorporation between numerous hydroxyl groups and water vapor molecules. Such barrier would result in aggravation of initial cracks, in order to release the internal stress further.

Similar content being viewed by others

References

Vicente GS, Bayon R, German N et al (2011) Surface modification of porous antireflective coatings for solar glass covers. Sol Energy 85:676–680

Huang MCY, Zhou Y, Chang-Husnain CJ (2007) A surface-emitting laser incorporating a high-index-contrast subwavelength grating. Nat Photonics 1:119–122

Sobahan KMA, Park YJ, Kim JJ et al (2011) Nanostructured porous SiO2 films for antireflection coatings. Opt Commun 284:873–876

Mammeri F, Bourhis EL, Rozesa L et al (2005) Mechanical properties of hybrid organic–inorganic materials. J Mater Chem 15:3787–3811

Vicente GS, Morales A, Gutierrez MT (2002) Sol–gel TiO2 antireflective films for textured monocrystalline silicon solar cells. Thin Solid Films 403–404:335–338

Fu Y, Zhang XC, Xuan FZ et al (2013) Multiple cracking of thin films due to residual stress combined with bending stress. Comp Mater Sci 73:113–119

Wang X, Chen Z, Atkinson A (2013) Crack formation in ceramic films used in solid oxide fuel cells. J Eur Ceram Soc 33:2539–2547

Kondo T, Imaoka T, Hirakata H et al (2013) Effects of stress ratio on fatigue crack propagation properties of submicron-thick free-standing copper films. Acta Mater 61:6310–6327

Islam S, Rahman RA, Othaman Z et al (2013) Preparation and characterization of crack-free sol–gel based SiO2–TiO2 hybrid nanoparticle film. J Sol–Gel Sci Technol 68:162–168

Shen HH, Zu HY, Peng SM et al (2013) On the study of the oriented cracks formed in ErD2 thin film. Mater Lett 106:259–262

Doi T, Soyama N, Sakurai H (2013) Effect of poly(vinylpyrrolidone) as a stress-relaxing additive in fabrication of PbZrxTi1-xO3 thin films using sol–gel route. Jpn J Appl Phys 52:09KA05

Zhu W, Leto A, Hashimoto KY et al (2013) Evaluation of critical stress intensity for crack initiation and rising R-curve behavior in wurtzitic AlN film grown on (001) Si substrate. Thin Solid Films 537:176–179

Dutton R, Nuttall K, Puls MP, Simpson LA (1977) Mechanisms of hydrogen induced delayed cracking in hydride forming materials. Metall Trans A 8:1553–1562

Song J, Curtin WA (2013) Atomic mechanism and prediction of hydrogen embrittlement in iron. Nat Mater 12:145–151

Takemori M (2009) Crack formation, exfoliation, and ridge formation in 500 °C annealed sol–gel silica coatings on stainless steel SUS304: part II spectroscopic and mechanical analyses and insights into mechanisms controlling coating characteristics. Ceram Int 35:1747–1755

Zhang Q, Wang J, Ma H et al (2009) Modification of porous silica antireflective coating with Fluorine-containing organosilicon. Acta Opt Sinica 29:1719–1723

Takemori M (2009) Crack formation, exfoliation, and ridge formation in 500 °C annealed sol–gel silica coatings on stainless steel SUS304: part I Microscopic observations and elemental analyses. Ceram Int 35:1731–1746

Bautista MC, Morales A (2003) Silica antireflective films on glass produced by the sol–gel method. Sol Energy Mater Sol Cells 80:217–225

Vicente GS, Bayon R, German N et al (2009) Long-term durability of sol–gel porous coatings for solar glass covers. Thin Solid Films 517:3157–3160

Schmidt H (1994) Inorganic–organic composites by sol–gel techniques. J Sol–Gel Sci Technol 1:217–231

Acknowledgments

This work was supported by the Major National Science and Technology Project (2013ZX04006011-101).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, XR., Zhang, QH., Lei, XY. et al. Study on the crack mechanism of SiO2 anti-reflective layer prepared by sol–gel method. J Sol-Gel Sci Technol 73, 242–249 (2015). https://doi.org/10.1007/s10971-014-3523-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-014-3523-1