Abstract

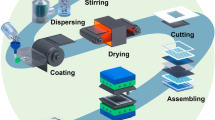

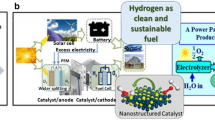

Nafion membranes are commercially available for the application of direct methanol fuel cells (DMFCs) due to their unique nano-porous structure, high wettability, high ion exchange capacity due to sulfonic groups and high mechanical strength. However, its high cost and high swelling in water result in high methanol crossover, low chemical stability and low ion conductivity at elevated temperatures that limit its usage. Moreover, in commercial membranes when the thickness increases, the ion conductivity compromises and when the thickness decreases, the fuel crossover increases which disrupts the performance of the fuel cell. The modification of pre-existing Nafion membrane such as Nafion 115, Nafion 117, Nafion 212, Nafion 112 and laboratory recasted Nafion membrane is a promising requirement for their future applications. Additives such as organic, inorganic nanoparticles and polymers apply to the Nafion membrane that not only tune the physical aspects of the membrane but also improve the electrochemical properties of the membrane. This review article focuses on advances in different Nafion commercial membranes and laboratory recasted non-commercial Nafion membrane that make under special conditions after modifications. This paper provides challenges, advantages, and disadvantages, as well as future advances in the application of composite membranes in direct methanol fuel cells.

Similar content being viewed by others

Data availability

All of the data created or analyzed during the study is contained in this publication and the files with extra information attached.

Abbreviations

- GO:

-

Graphene Oxide

- SGO:

-

Sulfonated Graphene Oxide

- PCM:

-

Phase change material

- Sc-Co2 :

-

Super critical carbon dioxide

- EBL:

-

Electron beam laser

- PFA:

-

Polyfurfuryl alcohol

- PEG:

-

Polyethylene glycol

- PVDF:

-

Poly (vinylidene fluoride)

- PVDF-HFP:

-

Poly (vinylidene fluoride-co-hexafluoropropylene)

- SPVDF:

-

Sulfonated Poly (vinylidene fluoride)

- SPVDF-HFP:

-

Sulfonated Poly (vinylidene fluoride-co-hexafluoropropylene)

- PBI:

-

Polybenzimidazole

- Pd:

-

Palladium

- FEP:

-

Poly(tetrafluoroethylene-co-hexafluoropropylene)

- PGMA:

-

Poly(glycidyl methacrylate)

- Ar:

-

Argon

- EB:

-

Electron Beam

- PVA:

-

Polyvinyl alcohol (PVA)

- P4VP:

-

Poly(4-vinyl pyridine)

- PEDT:

-

3,4-polyethylenedioxythiophene

- PPy:

-

Polypyrrole

- PANi:

-

Polyaniline

- BMPyr:

-

1-Butyl-1-methylpyrrolidinium bis (trifluoromethylsulfonyl)imide

- PAH:

-

Poly (allylamine hydrochloride)

- CO2 :

-

Carbon Dioxide

- TiO2 :

-

Titanium Dioxide

- SiO2 :

-

Silicon Dioxide

- CS:

-

Chitosan

- SiWA:

-

Silicotungstic acid

- TPA Hydroxide:

-

Tetrapropylammonium hydroxide

- PSU:

-

Polysulfone

- SPAEK:

-

Poly(arylene ether ketone)

- SPANi:

-

Sulfonated Polyaniline

- PC:

-

Polycarbonate

- PPO:

-

Polyphenylene oxide

- SPEEK:

-

Sulfonated poly(ether ether ketone)

- PEEK:

-

poly(ether ether ketone)

- CF4 :

-

Carbon tetrafluoride

- SDF:

-

Spirodifluorenyl

- PAI:

-

Polyacrylamide

- PI:

-

Polyimide

- PSSf:

-

Poly(styrene sulfone)

- PEI:

-

polyethylenimine

- F-silica:

-

Functionalized silica

- (SN-b-CD):

-

β-cyclodextrin (β-CD) modified silica nanoparticles

- MSN:

-

Mesoporous silica nanoparticles

- Bio-SiO2-sys:

-

Bioinspired silica cysteine

- SZO:

-

Zirconyl oxalate

- ZrO2 :

-

Zirconia

- Zr(HPO4)2 :

-

Zirconium phosphate

- ZrP:

-

Zirconium phosphate

- BN:

-

Boron Nitride

- S-graphene:

-

Sulfonated graphene

- CP:

-

Calcium phosphate

- CHP:

-

Calcium hydroxyphosphate

- H-ZSM:

-

Hierarchically porous zeolite

- NAFB:

-

Acid functionalized zeolite Beta

- HA:

-

Hydroxyapatite

- BMMT:

-

Benzyltrimethylammonium chloride modified montmorillonite

- MMT:

-

Montmorillonite

- MOR:

-

Mordenite

- MPTPS:

-

3-Mercaptopropyl)trimethoxysilane

- Al-MCM:

-

Acid-functionalized mesostructured aluminosilicate

- MOF:

-

Metal-organic framework

- UiO-66:

-

Zirconium based metal organic framework

- Na2Ti3O:

-

Sodium titanate

- PtRu:

-

Platinum rubidium

- CQDs:

-

Carbon quantum dots

- CNT:

-

Carbon nanotube

- MWCNT:

-

Multi-walled Carbon nanotubes

- GDY:

-

Graphdiyne

- GCN:

-

Graphitic Carbon Nitride

- s-GCN:

-

Sulfonated Graphitic Carbon Nitride

- γ-Fe2O3 :

-

Iron oxide gamma

- PSS:

-

Polystyrene sulfonic acid

- ORMOSIL:

-

Organically modified silica

- SPBI:

-

sulfonated poly(benzobisimidazole)

- P2VP:

-

Poly(2-vinylpyridine)

- CH3OH:

-

Methanol

- PTFE:

-

Poly(tetrafluoroethylene)

- CO2 :

-

Carbon dioxide

- H2O:

-

Water

- PEM:

-

Proton exchange membrane

- Pd(NH3)4Cl2 :

-

TetraamMinepalladium (II) Chloride

References

Asghar MR, Anwar MT, Xia G, Zhang J (2020) Cellulose/Poly(vinylidene fluoride hexafluoropropylene) composite membrane with titania nanoparticles for lithium-ion batteries. Mater Chem Phys 252:123122. https://doi.org/10.1016/j.matchemphys.2020.123122

Asghar MR, Zhang Y, Wu A et al (2018) Preparation of microporous cellulose/poly(vinylidene fluoride-hexafluoropropylene) membrane for lithium ion batteries by phase inversion method. J Power Sources 379:197–205. https://doi.org/10.1016/j.jpowsour.2018.01.052

Asghar MR, Anwar MT, Naveed A, Zhang J (2019) A review on inorganic nanoparticles modified composite membranes for lithium-ion batteries: recent progress and prospects. Membranes (Basel) 9:78. https://doi.org/10.3390/membranes9070078

Asghar MR, Anwar MT, Rasheed T et al (2019) Lithium salt doped poly(vinylidene fluoride)/cellulose acetate composite gel electrolyte membrane for lithium ion battery. IOP Conf Ser Mater Sci Eng 654:012017. https://doi.org/10.1088/1757-899X/654/1/012017

Guan L, Yu W, Rehman Asghar M et al (2024) Effect of graphene aerogel as a catalyst layer additive on performance of direct methanol fuel cell. Fuel 360:130503. https://doi.org/10.1016/j.fuel.2023.130503

Anwar MT, Yan X, Asghar MR et al (2019) MoS2-rGO hybrid architecture as durable support for cathode catalyst in proton exchange membrane fuel cells. Chinese J Catal 40:1160–1167. https://doi.org/10.1016/S1872-2067(19)63365-6

Anwar MT, Yan X, Asghar MR et al (2019) Recent advances in hybrid support material for Pt-based electrocatalysts of proton exchange membrane fuel cells. Int J Energy Res 43:2694–2721. https://doi.org/10.1002/er.4322

Cheng X, Wei G, Luo L et al (2023) Application of solid catalysts with an ionic liquid layer (SCILL) in PEMFCs: from half-cell to full-cell. Electrochem Energy Rev 6:32. https://doi.org/10.1007/s41918-023-00195-5

Kirubakaran A, Jain S, Nema RK (2009) A review on fuel cell technologies and power electronic interface. Renew Sustain Energy Rev 13:2430–2440. https://doi.org/10.1016/j.rser.2009.04.004

Zou S, Li Y, Jin H et al (2022) Highly safe, durable, adaptable, and flexible fuel cell using gel/sponge composite material. Adv Energy Mater. https://doi.org/10.1002/aenm.202103178

Jin H, Zou S, Wen Q et al (2023) Performance improvement of air-breathing proton exchange membrane fuel cell (PEMFC) with a condensing-tower-like curved flow field. Chinese Chem Lett 34:107441. https://doi.org/10.1016/j.cclet.2022.04.039

Souzy R, Ameduri B (2005) Functional fluoropolymers for fuel cell membranes. Prog Polym Sci 30:644–687. https://doi.org/10.1016/j.progpolymsci.2005.03.004

Xu P, Wen Q, Zou S et al (2023) A 3D printed alveolus-inspired flow field for direct methanol fuel cells with enhanced performance and durability. J Mater Chem A 11:8845–8857. https://doi.org/10.1039/D2TA09709E

Li Z, Zhou X, Singh S et al (2023) Degradation of platinum electrocatalysts for methanol oxidation by lead contamination. Chinese Chem Lett 34:107230. https://doi.org/10.1016/j.cclet.2022.02.035

Wycisk R, Pintauro PN, Park JW (2014) New developments in proton conducting membranes for fuel cells. Curr Opin Chem Eng 4:71–78. https://doi.org/10.1016/j.coche.2014.01.012

Zhang L, Chae S-R, Hendren Z et al (2012) Recent advances in proton exchange membranes for fuel cell applications. Chem Eng J 204–206:87–97. https://doi.org/10.1016/j.cej.2012.07.103

Zakil FA, Kamarudin SK, Basri S (2016) Modified Nafion membranes for direct alcohol fuel cells: An overview. Renew Sustain Energy Rev 65:841–852. https://doi.org/10.1016/j.rser.2016.07.040

Cele N, Ray SS (2009) Recent progress on Nafion-based nanocomposite membranes for fuel cell applications. Macromol Mater Eng 294:719–738. https://doi.org/10.1002/mame.200900143

Yin C, Li J, Zhou Y et al (2018) Enhancement in proton conductivity and thermal stability in nafion membranes induced by incorporation of sulfonated carbon nanotubes. ACS Appl Mater Interfaces 10:14026–14035. https://doi.org/10.1021/acsami.8b01513

Frühwirt P, Kregar A, Törring JT et al (2020) Holistic approach to chemical degradation of Nafion membranes in fuel cells: modelling and predictions. Phys Chem Chem Phys 22:5647–5666. https://doi.org/10.1039/C9CP04986J

Xu T (2005) Ion exchange membranes: State of their development and perspective. J Memb Sci 263:1–29. https://doi.org/10.1016/j.memsci.2005.05.002

Zhu L-Y, Li Y-C, Liu J et al (2022) Recent developments in high-performance Nafion membranes for hydrogen fuel cells applications. Pet Sci 19:1371–1381. https://doi.org/10.1016/j.petsci.2021.11.004

Ahmad S, Nawaz T, Ali A et al (2022) An overview of proton exchange membranes for fuel cells: Materials and manufacturing. Int J Hydrogen Energy 47:19086–19131. https://doi.org/10.1016/j.ijhydene.2022.04.099

Berretti E, Osmieri L, Baglio V et al (2023) Direct Alcohol Fuel Cells: A Comparative Review of Acidic and Alkaline Systems. Electrochem Energy Rev 6:30. https://doi.org/10.1007/s41918-023-00189-3

Halim J, Büchi FN, Haas O et al (1994) Characterization of perfluorosulfonic acid membranes by conductivity measurements and small-angle x-ray scattering. Electrochim Acta 39:1303–1307. https://doi.org/10.1016/0013-4686(94)E0051-Z

Lourenssen K, Williams J, Ahmadpour F et al (2019) Vanadium redox flow batteries: A comprehensive review. J Energy Storage 25:100844. https://doi.org/10.1016/j.est.2019.100844

Röschenthaler G-V, Storzer W (1982) A Stable Tetraalkoxy(hydroxy)phosphorane and Phosphorane Oxide Anion by Hydrolysis of Tetraalkoxy(halogen)phosphoranes. Angew Chemie Int Ed English 21:208–208. https://doi.org/10.1002/anie.198202081

Vilčiauskas L, Kreuer K-D (2011) Comment on “Mixed Grotthuss and Vehicle Transport Mechanism in Proton Conducting Polymers from Ab initio Molecular Dynamics Simulations.” Chem Mater 23:3377–3378. https://doi.org/10.1021/cm200865v

Alberti G, Casciola M (2003) composite membranes for medium-temperature PEM fuel cells. Annu Rev Mater Res 33:129–154. https://doi.org/10.1146/annurev.matsci.33.022702.154702

Kreuer KD (2001) On the development of proton conducting polymer membranes for hydrogen and methanol fuel cells. J Memb Sci 185:29–39. https://doi.org/10.1016/S0376-7388(00)00632-3

Zhang H, Shen PK (2012) Recent Development of Polymer Electrolyte Membranes for Fuel Cells. Chem Rev 112:2780–2832. https://doi.org/10.1021/cr200035s

Yang L, Nik-Ghazali N-N, Ali MAH et al (2023) A review on thermal management in proton exchange membrane fuel cells: Temperature distribution and control. Renew Sustain Energy Rev 187:113737. https://doi.org/10.1016/j.rser.2023.113737

Chen Q, Zhang G, Zhang X et al (2021) Thermal management of polymer electrolyte membrane fuel cells: A review of cooling methods, material properties, and durability. Appl Energy 286:116496. https://doi.org/10.1016/j.apenergy.2021.116496

Mo S, Du L, Huang Z et al (2023) Recent Advances on PEM Fuel Cells: From Key Materials to Membrane Electrode Assembly. Electrochem Energy Rev 6:28. https://doi.org/10.1007/s41918-023-00190-w

Qiu D, Peng L, Lai X et al (2019) Mechanical failure and mitigation strategies for the membrane in a proton exchange membrane fuel cell. Renew Sustain Energy Rev 113:109289. https://doi.org/10.1016/j.rser.2019.109289

Xu K, Pei S, Zhang W et al (2022) Chemical stability of proton exchange membranes synergistically promoted by organic antioxidant and inorganic radical scavengers. J Memb Sci 655:120594. https://doi.org/10.1016/j.memsci.2022.120594

Xu F, Chen Y, Li J et al (2022) Robust poly(alkyl–fluorene isatin) proton exchange membranes grafted with pendant sulfonate groups for proton exchange membrane fuel cells. J Memb Sci 664:121045. https://doi.org/10.1016/j.memsci.2022.121045

Li H-Y, Liu Y-L (2014) Nafion-functionalized electrospun poly(vinylidene fluoride) (PVDF) nanofibers for high performance proton exchange membranes in fuel cells. J Mater Chem A 2:3783–3793. https://doi.org/10.1039/C3TA14264G

Aricò AS, Srinivasan S, Antonucci V (2001) DMFCs: from fundamental aspects to technology development. Fuel Cells 1:133–161. https://doi.org/10.1002/1615-6854(200107)1:2%3c133::AID-FUCE133%3e3.3.CO;2-X

Wan N (2023) Durability study of direct methanol fuel cell under accelerated stress test. J Power Sources 556:232470. https://doi.org/10.1016/j.jpowsour.2022.232470

Mehmood A, An M-G, Ha HY (2014) Physical degradation of cathode catalyst layer: A major contributor to accelerated water flooding in long-term operation of DMFCs. Appl Energy 129:346–353. https://doi.org/10.1016/j.apenergy.2014.05.016

Zainoodin AM, Kamarudin SK, Masdar MS et al (2014) Investigation of MEA degradation in a passive direct methanol fuel cell under different modes of operation. Appl Energy 135:364–372. https://doi.org/10.1016/j.apenergy.2014.08.036

Neburchilov V, Martin J, Wang H, Zhang J (2007) A review of polymer electrolyte membranes for direct methanol fuel cells. J Power Sources 169:221–238. https://doi.org/10.1016/j.jpowsour.2007.03.044

Peighambardoust SJ, Rowshanzamir S, Amjadi M (2010) Review of the proton exchange membranes for fuel cell applications. Int J Hydrogen Energy 35:9349–9384. https://doi.org/10.1016/j.ijhydene.2010.05.017

Abouzari-Lotf E, Nasef MM, Ghassemi H et al (2015) Improved methanol barrier property of nafion hybrid membrane by incorporating nanofibrous interlayer self-immobilized with high level of phosphotungstic acid. ACS Appl Mater Interfaces 7:17008–17015. https://doi.org/10.1021/acsami.5b02268

Lin CW, Lu YS (2013) Highly ordered graphene oxide paper laminated with a Nafion membrane for direct methanol fuel cells. J Power Sources 237:187–194. https://doi.org/10.1016/j.jpowsour.2013.03.005

Ruhkopf J, Plachetka U, Moeller M et al (2023) Graphene Coating of Nafion Membranes for Enhanced Fuel Cell Performance. ACS Appl Eng Mater 1:947–954. https://doi.org/10.1021/acsaenm.2c00234

Kim D, Scibioh MA, Kwak S et al (2004) Nano-silica layered composite membranes prepared by PECVD for direct methanol fuel cells. Electrochem commun 6:1069–1074. https://doi.org/10.1016/j.elecom.2004.07.006

Liu J, Wang H, Cheng S, Chan K-Y (2004) Nafion–polyfurfuryl alcohol nanocomposite membranes with low methanol permeation. Chem Commun 4:728–729. https://doi.org/10.1039/B315742C

Liu J, Wang H, Cheng S, Chan K-Y (2005) Nafion–polyfurfuryl alcohol nanocomposite membranes for direct methanol fuel cells. J Memb Sci 246:95–101. https://doi.org/10.1016/j.memsci.2004.08.016

Lin CW, Fan KC, Thangamuthu R (2006) Preparation and characterization of high selectivity organic–inorganic hybrid-laminated Nafion 115 membranes for DMFC. J Memb Sci 278:437–446. https://doi.org/10.1016/j.memsci.2005.11.040

Liu D, Xie Y, Zhao Z et al (2023) Structural optimization and performance trade-off strategies for semi-crystalline sulfonated poly(arylene ether ketone) membranes in high-concentration direct methanol fuel cells. J Energy Chem 85:67–75. https://doi.org/10.1016/j.jechem.2023.05.049

Bagus Pambudi A, Priyangga A, Hartanto D, Atmaja L (2021) Fabrication and characterization of modified microcrystalline cellulose membrane as proton exchange membrane for direct methanol fuel cell. Mater Today Proc 46:1855–1859. https://doi.org/10.1016/j.matpr.2021.01.431

Altaf F, Ahmed S, Dastan D et al (2022) Novel sepiolite reinforced emerging composite polymer electrolyte membranes for high-performance direct methanol fuel cells. Mater Today Chem 24:100843. https://doi.org/10.1016/j.mtchem.2022.100843

Liu D, Xie Y, Zhong J et al (2022) High methanol resistance semi-crystalline sulfonated poly(ether ketone) proton exchange membrane for direct methanol fuel cell. J Memb Sci 650:120413. https://doi.org/10.1016/j.memsci.2022.120413

Mališ J, Mazúr P, Paidar M et al (2016) Nafion 117 stability under conditions of PEM water electrolysis at elevated temperature and pressure. Int J Hydrogen Energy 41:2177–2188. https://doi.org/10.1016/j.ijhydene.2015.11.102

Alberti G, Casciola M, Massinelli L, Bauer B (2001) Polymeric proton conducting membranes for medium temperature fuel cells (110–160°C). J Memb Sci 185:73–81. https://doi.org/10.1016/S0376-7388(00)00635-9

Cho K, Jung H, Choi N et al (2005) A coated Nafion membrane with a PVdF copolymer/Nafion blend for direct methanol fuel cells (DMFCs). Solid State Ionics 176:3027–3030. https://doi.org/10.1016/j.ssi.2005.09.048

Mondal S, Soam S, Kundu PP (2015) Reduction of methanol crossover and improved electrical efficiency in direct methanol fuel cell by the formation of a thin layer on Nafion 117 membrane: Effect of dip-coating of a blend of sulphonated PVdF-co-HFP and PBI. J Memb Sci 474:140–147. https://doi.org/10.1016/j.memsci.2014.09.023

Lefaux CJ, Kim B-S, Venkat N, Mather PT (2015) Molecular composite coatings on Nafion using layer-by-layer self-assembly. ACS Appl Mater Interfaces 7:10365–10373. https://doi.org/10.1021/acsami.5b01371

Kim Y, Choi W, Woo S, Hong W (2004) Proton conductivity and methanol permeation in Nafion™/ORMOSIL prepared with various organic silanes. J Memb Sci 238:213–222. https://doi.org/10.1016/j.memsci.2004.04.005

Sha Wang L, Nan Lai A, Xiao Lin C et al (2015) Orderly sandwich-shaped graphene oxide/Nafion composite membranes for direct methanol fuel cells. J Memb Sci 492:58–66. https://doi.org/10.1016/j.memsci.2015.05.049

Iwai Y, Ikemoto S, Haramaki K et al (2014) Influence of ligands of palladium complexes on palladium/Nafion composite membranes for direct methanol fuel cells by supercritical CO2 impregnation method. J Supercrit Fluids 94:48–58. https://doi.org/10.1016/j.supflu.2014.06.015

Choi WC, Kim JD, Woo SI (2001) Modification of proton conducting membrane for reducing methanol crossover in a direct-methanol fuel cell. J Power Sources 96:411–414. https://doi.org/10.1016/S0378-7753(00)00602-9

Lue SJ, Shih T-S, Wei T-C (2006) Plasma modification on a Nafion membrane for direct methanol fuel cell applications. Korean J Chem Eng 23:441–446. https://doi.org/10.1007/BF02706747

Tsuchida R, Hiraiwa S, Tsukamoto A et al (2014) Fabrication of function-graded proton exchange membranes for direct methanol fuel cells using electron beam-grafting. Fuel Cells 14:284–290. https://doi.org/10.1002/fuce.201200226

Hobson LJ, Ozu H, Yamaguchi M et al (2002) Nafion®117 modified by low dose EB irradiation: surface structure and physical properties. J Mater Chem 12:1650–1656. https://doi.org/10.1039/b108898j

Zhang X, Zhang Y, Nie L et al (2012) Modification of Nafion membrane by Pd-impregnation via electric field. J Power Sources 216:526–529. https://doi.org/10.1016/j.jpowsour.2012.06.036

Chai BZ, Wang C, Zhang H et al (2010) Nafi on – carbon nanocomposite membranes prepared using hydrothermal carbonization for proton-exchange- membrane fuel cells. 4394–4399. https://doi.org/10.1002/adfm.201001412

Eldin MSM, Elzatahry AA, El-Khatib KM et al (2011) Novel grafted nafion membranes for proton-exchange membrane fuel cell applications. J Appl Polym Sci 119:120–133. https://doi.org/10.1002/app.32613

Nataraj SK, Wang C, Huang H et al (2012) Highly proton-selective biopolymer layer-coated ion-exchange membrane for direct methanol fuel cells. Chemsuschem 5:392–395. https://doi.org/10.1002/cssc.201100366

Shao ZG, Wang X, Hsing IM (2002) Composite Nafion/polyvinyl alcohol membranes for the direct methanol fuel cell. J Memb Sci 210:147–153. https://doi.org/10.1016/S0376-7388(02)00386-1

Woong JC, Venkataramani S, Kim SC (2006) Modification of Nafion membrane using poly(4-vinyl pyridine) for direct methanol fuel cell. Polym Int 55:491–499. https://doi.org/10.1002/pi.1986

Awuzie CI (2017) Conducting Polymers Mater Today Proc 4:5721–5726. https://doi.org/10.1016/j.matpr.2017.06.036

Elschner A, Kirchmeyer S, Lovenich W et al (2010) PEDOT: Principles and applications of an intrinsically conductive polymer. CRC Press 1st Ed.: 377. https://doi.org/10.1201/b10318

Kaloni TP, Giesbrecht PK, Schreckenbach G, Freund MS (2017) Polythiophene: From fundamental perspectives to applications. Chem Mater 29:10248–10283. https://doi.org/10.1021/acs.chemmater.7b03035

Li L, Drillet JF, Mácová Z et al (2006) Poly(3,4-ethylenedioxythiophene)-modified nafion membrane for direct methanol fuel cells. Russ J Electrochem 42:1193–1201. https://doi.org/10.1134/S102319350611005X

Smit MA, Ocampo AL, Espinosa-Medina MA, Sebastián PJ (2003) A modified Nafion membrane with in situ polymerized polypyrrole for the direct methanol fuel cell. J Power Sources 124:59–64. https://doi.org/10.1016/S0378-7753(03)00730-4

Wang C-H, Chen C-C, Hsu H-C et al (2009) Low methanol-permeable polyaniline/Nafion composite membrane for direct methanol fuel cells. J Power Sources 190:279–284. https://doi.org/10.1016/j.jpowsour.2008.12.125

Escudero-Cid R, Montiel M, Sotomayor L et al (2015) Evaluation of polyaniline-Nafion® composite membranes for direct methanol fuel cells durability tests. Int J Hydrogen Energy 40:8182–8192. https://doi.org/10.1016/j.ijhydene.2015.04.130

Huang QM, Zhang QL, Huang HL et al (2008) Methanol permeability and proton conductivity of Nafion membranes modified electrochemically with polyaniline. J Power Sources 184:338–343. https://doi.org/10.1016/j.jpowsour.2008.06.013

Schmidt C, Glück T, Schmidt-Naake G (2008) Modification of Nafion Membranes by Impregnation with Ionic Liquids. Chem Eng Technol 31:13–22. https://doi.org/10.1002/ceat.200700054

Deligöz H, Yılmaztürk S, Karaca T et al (2009) Self-assembled polyelectrolyte multilayered films on Nafion with lowered methanol cross-over for DMFC applications. J Memb Sci 326:643–649. https://doi.org/10.1016/j.memsci.2008.10.055

Guerrero-Gutiérrez EMA, Suleiman D (2013) Supercritical fluid CO 2 processing and counter ion substitution of nafion® membranes. J Appl Polym Sci 129:73–85. https://doi.org/10.1002/app.38689

Suo C, Zhang W, Wang H, Yang F (2012) Modified Nafion polymer electrolyte membranes by γ-ray irradiation used in direct methanol fuel cells. J Shanghai Jiaotong Univ 17:579–585. https://doi.org/10.1007/s12204-012-1328-3

Muhmed SA, Jaafar J, Daud SS et al (2021) Improvement in properties of nanocrystalline cellulose/poly (vinylidene fluoride) nanocomposite membrane for direct methanol fuel cell application. J Environ Chem Eng 9:105577. https://doi.org/10.1016/j.jece.2021.105577

Kim Y-M, Park K-W, Choi J-H et al (2003) A Pd-impregnated nanocomposite Nafion membrane for use in high-concentration methanol fuel in DMFC. Electrochem commun 5:571–574. https://doi.org/10.1016/S1388-2481(03)00130-9

Kim M, Ha D, Choi J (2019) Nanocellulose-modified Nafion 212 membrane for improving performance of vanadium redox flow batteries. Bull Korean Chem Soc 40:533–538. https://doi.org/10.1002/bkcs.11725

Liang D, Wu C, Liu L et al (2023) High methanol tolerant proton exchange membranes based on novel coupling-type sulfonated poly(phenylquinoxaline) for direct methanol fuel cells. J Memb Sci 685:121920. https://doi.org/10.1016/j.memsci.2023.121920

Wu J, Wang F, Fan X et al (2023) Phosphoric acid-doped Gemini quaternary ammonium-grafted SPEEK membranes with superhigh proton conductivity and mechanical strength for direct methanol fuel cells. J Memb Sci 672:121431. https://doi.org/10.1016/j.memsci.2023.121431

Yan XH, Wu R, Xu JB et al (2016) A monolayer graphene – Nafion sandwich membrane for direct methanol fuel cells. J Power Sources 311:188–194. https://doi.org/10.1016/j.jpowsour.2016.02.030

Li J, Xu G, Cai W et al (2018) Non-destructive modification on Nafion membrane via in-situ inserting of sheared graphene oxide for direct methanol fuel cell applications. Electrochim Acta 282:362–368. https://doi.org/10.1016/j.electacta.2018.06.072

Li J, Fan K, Cai W et al (2016) An in-situ nano-scale swelling-filling strategy to improve overall performance of Nafion membrane for direct methanol fuel cell application. J Power Sources 332:37–41. https://doi.org/10.1016/j.jpowsour.2016.09.108

Xu G, Li J, Ma L et al (2017) Performance dependence of swelling-filling treated Nafion membrane on nano-structure of macromolecular filler. J Memb Sci 534:68–72. https://doi.org/10.1016/j.memsci.2017.04.016

Zhang Y, Li J, Ma L et al (2015) Recent developments on alternative proton exchange membranes: strategies for systematic performance improvement. Energy Technol 3:675–691. https://doi.org/10.1002/ente.201500028

Byun SC, Jeong YJ, Park JW et al (2006) Effect of solvent and crystal size on the selectivity of ZSM-5/Nafion composite membranes fabricated by solution-casting method. Solid State Ionics 177:3233–3243. https://doi.org/10.1016/j.ssi.2006.09.014

Li J, Yang X, Tang H, Pan M (2010) Durable and high performance Nafion membrane prepared through high-temperature annealing methodology. J Memb Sci 361:38–42. https://doi.org/10.1016/j.memsci.2010.06.016

Vengatesan S, Cho E, Kim H-J, Lim T-H (2009) Effects of curing condition of solution cast Nafion® membranes on PEMFC performance. Korean J Chem Eng 26:679–684. https://doi.org/10.1007/s11814-009-0113-y

Li L, Su L, Zhang Y (2012) Enhanced performance of supercritical CO2 treated Nafion 212 membranes for direct methanol fuel cells. Int J Hydrogen Energy 37:4439–4447. https://doi.org/10.1016/j.ijhydene.2011.11.110

Zhang Yi, Jian Lu, Zhou H et al (2008) Application of nanoimprint technology in MEMS-based micro direct-methanol fuel cell (μ-DMFC). J Microelectromechanical Syst 17:1020–1028. https://doi.org/10.1109/JMEMS.2008.926979

Yildirim MH, te Braake J, Aran HC et al (2010) Micro-patterned Nafion membranes for direct methanol fuel cell applications. J Memb Sci 349:231–236. https://doi.org/10.1016/j.memsci.2009.11.050

Omosebi A, Besser RS (2011) Electron beam assisted patterning and dry etching of Nafion membranes. J Electrochem Soc 158:D603. https://doi.org/10.1149/1.3615938

Omosebi A, Besser RS (2013) Electron beam patterned Nafion membranes for DMFC applications. J Power Sources 228:151–158. https://doi.org/10.1016/j.jpowsour.2012.11.076

Cai Z, Li L, Su L, Zhang Y (2012) Supercritical carbon dioxide treated Nafion 212 commercial membranes for direct methanol fuel cells. Electrochem commun 14:9–12. https://doi.org/10.1016/j.elecom.2011.09.022

Lin H-L, Yeh S-H, Yu TL, Chen L-C (2009) Silicate and zirconium phosphate modified Nafion/PTFE composite membranes for high temperature PEMFC. J Polym Res 16:519–527. https://doi.org/10.1007/s10965-008-9255-6

Ling J, Savadogo O (2004) Comparison of methanol crossover among four types of Nafion membranes. J Electrochem Soc 151:A1604. https://doi.org/10.1149/1.1789394

Okonkwo PC, Ben Belgacem I, Emori W, Uzoma PC (2021) Nafion degradation mechanisms in proton exchange membrane fuel cell (PEMFC) system: A review. Int J Hydrogen Energy 46:27956–27973. https://doi.org/10.1016/j.ijhydene.2021.06.032

Lu GQ, Liu FQ, Wang C-Y (2005) Water Transport Through Nafion 112 Membrane in DMFCs. Electrochem Solid-State Lett 8:A1. https://doi.org/10.1149/1.1825312

Liu Z, Guo B, Huang J et al (2006) Nano-TiO2-coated polymer electrolyte membranes for direct methanol fuel cells. J Power Sources 157:207–211. https://doi.org/10.1016/j.jpowsour.2005.07.070

Zhang H, Huang H, Shen PK (2012) Methanol-blocking Nafion composite membranes fabricated by layer-by-layer self-assembly for direct methanol fuel cells. Int J Hydrogen Energy 37:6875–6879. https://doi.org/10.1016/j.ijhydene.2012.01.066

Ben Jadi S, El Guerraf A, Bazzaoui EA et al (2019) Synthesis, characterization, and transport properties of Nafion-polypyrrole membrane for direct methanol fuel cell (DMFC) application. J Solid State Electrochem 23:2423–2433. https://doi.org/10.1007/s10008-019-04355-w

Gribov EN, Krivobokov IM, Parkhomchuk EV et al (2009) Transport properties of Nafion membranes modified with tetrapropylammonium ions for direct methanol fuel cell application. Russ J Electrochem 45:199–207. https://doi.org/10.1134/S1023193509020116

Kang S, Bae G, Kim S-K et al (2018) Performance of a MEA using patterned membrane with a directly coated electrode by the bar-coating method in a direct methanol fuel cell. Int J Hydrogen Energy 43:11386–11396. https://doi.org/10.1016/j.ijhydene.2018.04.086

Siroma Z, Fujiwara N, Ioroi T et al (2004) Dissolution of Nafion® membrane and recast Nafion® film in mixtures of methanol and water. J Power Sources 126:41–45. https://doi.org/10.1016/j.jpowsour.2003.08.024

Elham OSJ, Kamarudin SK, Shaari N et al (2023) Development of low-cost Nafion-Lignin composite conductive membranes for application in direct methanol fuel cells. J Environ Chem Eng 111514. https://doi.org/10.1016/j.jece.2023.111514

Lin H-L, Wang S-H (2014) Nafion/poly(vinyl alcohol) nano-fiber composite and Nafion/poly(vinyl alcohol) blend membranes for direct methanol fuel cells. J Memb Sci 452:253–262. https://doi.org/10.1016/j.memsci.2013.09.039

Ng WW, Thiam HS, Pang YL et al (2023) Facile synthesis of nafion based self-healable proton exchange membranes for direct methanol fuel cells. Mater Today Proc 1–5. https://doi.org/10.1016/j.matpr.2023.01.407

Ng WW, Thiam HS, Pang YL et al (2023) Freeze‐Thawed Nafion‐Poly(vinyl alcohol) self‐healing membranes for direct methanol fuel cells. Chem Eng Technol 1–9. https://doi.org/10.1002/ceat.202300099

DeLuca NW, Elabd YA (2006) Direct methanol fuel cell performance of Nafion®/poly(vinyl alcohol) blend membranes. J Power Sources 163:386–391. https://doi.org/10.1016/j.jpowsour.2006.09.009

Yuan C, Li Q, Dong Y et al (2023) Click chemistry-based azide-substituted polysulfone/alkynyl-substituted sulfonated polyvinyl alcohol/nafion blend membranes for direct methanol fuel cells. J Polym Sci 1–11. https://doi.org/10.1002/pol.20230509

Ru C, Gu Y, Duan Y et al (2019) Enhancement in proton conductivity and methanol resistance of Nafion membrane induced by blending sulfonated poly(arylene ether ketones) for direct methanol fuel cells. J Memb Sci 573:439–447. https://doi.org/10.1016/j.memsci.2018.12.030

Wang S-H, Lin H-L (2014) Poly (vinylidene fluoride-co-hexafluoropropylene)/polybenzimidazole blend nanofiber supported Nafion membranes for direct methanol fuel cells. J Power Sources 257:254–263. https://doi.org/10.1016/j.jpowsour.2014.01.104

Lin J-C, Ouyang M, Fenton JM et al (1998) Study of blend membranes consisting of NafionR and vinylidene fluoride-hexafluoropropylene copolymer. J Appl Polym Sci 70:121–127. https://doi.org/10.1002/(SICI)1097-4628(19981003)70:1%3c121::AID-APP12%3e3.0.CO;2-A

Dutta K, Das S, Kundu PP (2016) Highly methanol resistant and selective ternary blend membrane composed of sulfonated PVdF - HFP, sulfonated polyaniline and nafion. J Appl Polym Sci 133:1–10. https://doi.org/10.1002/app.43294

Hasani-Sadrabadi MM, Dashtimoghadam E, Nasseri R et al (2014) Cellulose nanowhiskers to regulate the microstructure of perfluorosulfonate ionomers for high-performance fuel cells. J Mater Chem A 2:11334. https://doi.org/10.1039/c4ta00635f

Yang Z, Peng H, Wang W, Liu T (2010) Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J Appl Polym Sci 116:2658–2667. https://doi.org/10.1002/app

Gloukhovski R, Tsur Y, Freger V (2017) A Nafion-filled Polycarbonate Track-Etched Composite Membrane with Enhanced Selectivity for Direct Methanol Fuel Cells. Fuel Cells 17:56–66. https://doi.org/10.1002/fuce.201600154

Ma C-CM, Hsiao Y-H, Lin Y-F et al (2008) Effects and properties of various molecular weights of poly(propylene oxide) oligomers/Nafion® acid–base blend membranes for direct methanol fuel cells. J Power Sources 185:846–852. https://doi.org/10.1016/j.jpowsour.2008.06.089

Li J, Bu F, Ru C et al (2020) Enhancing the selectivity of Nafion membrane by incorporating a novel functional skeleton molecule to improve the performance of direct methanol fuel cells. J Mater Chem A 8:196–206. https://doi.org/10.1039/c9ta10215a

Lu J, Tang H, Xu C, Jiang SP (2012) Nafion membranes with ordered mesoporous structure and high water retention properties for fuel cell applications. J Mater Chem 22:5810. https://doi.org/10.1039/c2jm14838b

Cai W, Fan K, Li J et al (2016) A bi-functional polymeric nano-sieve Nafion composite membrane: Improved performance for direct methanol fuel cell applications. Int J Hydrogen Energy 41:17102–17111. https://doi.org/10.1016/j.ijhydene.2016.07.128

Shen L, Sun Z, Chu Y et al (2015) Novel sulfonated Nafion®-based composite membranes with pillararene as selective artificial proton channels for application in direct methanol fuel cells. Int J Hydrogen Energy 40:13071–13079. https://doi.org/10.1016/j.ijhydene.2015.07.073

Nguyen T, Wang X (2010) Multifunctional composite membrane based on a highly porous polyimide matrix for direct methanol fuel cells. J Power Sources 195:1024–1030. https://doi.org/10.1016/j.jpowsour.2009.08.049

Choi J, Kim IT, Kim SC, Hong YT (2005) Nafion-sulfonated poly(arylene ether sulfone) composite membrane for direct methanol fuel cell. Macromol Res 13:514–520. https://doi.org/10.1007/BF03218489

Wu W, Zhou Z, Wang Y et al (2022) Manipulating the ionic nanophase of Nafion by in-situ precise hybridization with polymer quantum dot towards highly enhanced fuel cell performances. Nano Res 15:4124–4131. https://doi.org/10.1007/s12274-022-4073-4

Kang DH, Kim D (2007) Modification of Nafion membranes by incorporation of cationic polymers for reduction of methanol permeability. Korean J Chem Eng 24:1101–1105. https://doi.org/10.1007/s11814-007-0128-1

Chen WF, Shen YC, Hsu HM, Kuo PL (2012) Continuous channels created by self-assembly of ionic cross-linked polysiloxane-Nafion nanocomposites. Polym Chem 3:1991–1995. https://doi.org/10.1039/c2py20203d

Zhang H, Xia H, Zhao Y (2012) Poly(vinyl alcohol) Hydrogel Can Autonomously Self-Heal. ACS Macro Lett 1:1233–1236. https://doi.org/10.1021/mz300451r

Thiam HS, Daud WRW, Kamarudin SK et al (2013) Performance of direct methanol fuel cell with a palladium-silica nanofibre/Nafion composite membrane. Energy Convers Manag 75:718–726. https://doi.org/10.1016/j.enconman.2013.08.009

Li J, Xu G, Luo X et al (2018) Effect of nano-size of functionalized silica on overall performance of swelling-filling modified Nafion membrane for direct methanol fuel cell application. Appl Energy 213:408–414. https://doi.org/10.1016/j.apenergy.2018.01.052

Wang H, Li X, Zhuang X et al (2017) Modification of Nafion membrane with biofunctional SiO2 nanofiber for proton exchange membrane fuel cells. J Power Sources 340:201–209. https://doi.org/10.1016/j.jpowsour.2016.11.072

Garnica Rodriguez JI, Dicks AL, Duke MC, Diniz Da Costa JC (2006) Silica nafion modified composite membranes for direct methanol fuel cells. Dev Chem Eng Miner Process 14:119–131. https://doi.org/10.1002/apj.5500140109

Jia W, Feng K, Tang B, Wu P (2015) β-Cyclodextrin modified silica nanoparticles for Nafion based proton exchange membranes with significantly enhanced transport properties. J Mater Chem A 3:15607–15615. https://doi.org/10.1039/C5TA03381K

Yang CW, Chen KH, Cheng S (2016) Effect of pore-directing agents and silanol groups in mesoporous silica nanoparticles as Nafion fillers on the performance of DMFCs. RSC Adv 6:111666–111680. https://doi.org/10.1039/C6RA24210C

Cozzi D, de Bonis C, D’Epifanio A et al (2014) Organically functionalized titanium oxide/Nafion composite proton exchange membranes for fuel cells applications. J Power Sources 248:1127–1132. https://doi.org/10.1016/j.jpowsour.2013.10.070

Ercelik M, Ozden A, Devrim Y, Colpan CO (2017) Investigation of Nafion based composite membranes on the performance of DMFCs. Int J Hydrogen Energy 42:2658–2668. https://doi.org/10.1016/j.ijhydene.2016.06.215

Sigwadi R, Mokrani T, Dhlamini MS et al (2019) Nafion®/ sulfated zirconia oxide-nanocomposite membrane: the effects of ammonia sulfate on fuel permeability. J Polym Res 26:108. https://doi.org/10.1007/s10965-019-1760-2

Sigwadi R, Mokrani T, Dhlamini S, Msomi PF (2021) Nafion® reinforced with polyacrylonitrile/ ZrO2 nanofibers for direct methanol fuel cell application. J Appl Polym Sci. https://doi.org/10.1002/app.49978

Nicotera I, Khalfan A, Goenaga G et al (2008) NMR investigation of water and methanol mobility in nanocomposite fuel cell membranes. Ionics (Kiel) 14:243–253. https://doi.org/10.1007/s11581-007-0178-8

Hou H, Sun G, Wu Z et al (2008) Zirconium phosphate/Nafion115 composite membrane for high-concentration DMFC. Int J Hydrogen Energy 33:3402–3409. https://doi.org/10.1016/j.ijhydene.2008.03.060

Casciola M, Bagnasco G, Donnadio A et al (2009) Conductivity and Methanol Permeability of Nafion-Zirconium Phosphate Composite Membranes Containing High Aspect Ratio Filler Particles. Fuel Cells 9:394–400. https://doi.org/10.1002/fuce.200800135

Jia W, Tang B, Wu P (2017) Novel Composite Proton Exchange Membrane with Connected Long-Range Ionic Nanochannels Constructed via Exfoliated Nafion-Boron Nitride Nanocomposite. ACS Appl Mater Interfaces 9:14791–14800. https://doi.org/10.1021/acsami.7b00858

Choi BG, Huh YS, Park YC et al (2012) Enhanced transport properties in polymer electrolyte composite membranes with graphene oxide sheets. Carbon N Y 50:5395–5402. https://doi.org/10.1016/j.carbon.2012.07.025

Gagliardi GG, El-Kharouf A, Borello D (2023) Assessment of innovative graphene oxide composite membranes for the improvement of direct methanol fuel cells performance. Fuel 345:128252. https://doi.org/10.1016/j.fuel.2023.128252

Chien H-C, Tsai L-D, Huang C-P et al (2013) Sulfonated graphene oxide/Nafion composite membranes for high-performance direct methanol fuel cells. Int J Hydrogen Energy 38:13792–13801. https://doi.org/10.1016/j.ijhydene.2013.08.036

Prapainainar P, Pattanapisutkun N, Prapainainar C, Kongkachuichay P (2019) Incorporating graphene oxide to improve the performance of Nafion-mordenite composite membranes for a direct methanol fuel cell. Int J Hydrogen Energy 44:362–378. https://doi.org/10.1016/j.ijhydene.2018.08.008

Ng WW, Thiam HS, Pang YL et al (2023) Self-sustainable, self-healable sulfonated graphene oxide incorporated nafion/poly(vinyl alcohol) proton exchange membrane for direct methanol fuel cell applications. J Environ Chem Eng 11:111151. https://doi.org/10.1016/j.jece.2023.111151

Parthiban V, Akula S, Peera SG et al (2016) Proton Conducting Nafion-Sulfonated Graphene Hybrid Membranes for Direct Methanol Fuel Cells with Reduced Methanol Crossover. Energy Fuels 30:725–734. https://doi.org/10.1021/acs.energyfuels.5b02194

Feng K, Tang B, Wu P (2014) Sulfonated graphene oxide–silica for highly selective Nafion-based proton exchange membranes. J Mater Chem A 2:16083–16092. https://doi.org/10.1039/C4TA03207A

Park Y-S, Yamazaki Y (2005) Low methanol permeable and high proton-conducting Nafion/calcium phosphate composite membrane for DMFC. Solid State Ionics 176:1079–1089. https://doi.org/10.1016/j.ssi.2004.12.012

Park Y-S, Yamazaki Y (2006) Low water/methanol permeable Nafion/CHP organic–inorganic composite membrane with high crystallinity. Eur Polym J 42:375–387. https://doi.org/10.1016/j.eurpolymj.2005.07.018

Hamid NSA, Kamarudin SK, Karim NA (2021) Potential of Nafion/eggshell composite membrane for application in direct methanol fuel cell. Int J Energy Res 45:2245–2264. https://doi.org/10.1002/er.5917

Yildirim MH, Curòs AR, Motuzas J et al (2009) Nafion®/H-ZSM-5 composite membranes with superior performance for direct methanol fuel cells. J Memb Sci 338:75–83. https://doi.org/10.1016/j.memsci.2009.04.009

Zhang Z, Désilets F, Felice V et al (2011) On the proton conductivity of Nafion-Faujasite composite membranes for low temperature direct methanol fuel cells. J Power Sources 196:9176–9187. https://doi.org/10.1016/j.jpowsour.2011.07.009

Chen Z, Holmberg B, Li W et al (2006) Nafion/Zeolite Nanocomposite Membrane by in Situ Crystallization for a Direct Methanol Fuel Cell. Chem Mater 18:5669–5675. https://doi.org/10.1021/cm060841q

Park Y-S, Yamazaki Y (2005) Novel Nafion/Hydroxyapatite composite membrane with high crystallinity and low methanol crossover for DMFCs. Polym Bull 53:181–192. https://doi.org/10.1007/s00289-004-0310-0

Hasani-Sadrabadi MM, Dashtimoghadam E, Majedi FS et al (2010) Novel high-performance nanohybrid polyelectrolyte membranes based on bio-functionalized montmorillonite for fuel cell applications. Chem Commun 46:6500. https://doi.org/10.1039/c0cc01125h

Hasani-Sadrabadi MM, Ghaffarian SR, Renaud P (2013) Nafion/benzotriazole functionalized montmorillonite nanocomposites: novel high-performance proton exchange membranes. RSC Adv 3:19357. https://doi.org/10.1039/c3ra42142b

Rhee CH, Kim HK, Chang H, Lee JS (2005) Nafion/Sulfonated Montmorillonite Composite: A New Concept Electrolyte Membrane for Direct Methanol Fuel Cells. Chem Mater 17:1691–1697. https://doi.org/10.1021/cm048058q

Felice C, Ye S, Qu D (2010) Nafion−Montmorillonite Nanocomposite Membrane for the Effective Reduction of Fuel Crossover. Ind Eng Chem Res 49:1514–1519. https://doi.org/10.1021/ie901600a

Bae G-N, Kim H-W, Jung E-M et al (2023) Effects on the electrochemical performance of surface-modified mordenite in a PTFE Nafion composite membrane for direct methanol fuel cells. Int J Hydrogen Energy 48:18879–18889. https://doi.org/10.1016/j.ijhydene.2023.02.001

Prapainainar P, Du Z, Kongkachuichay P et al (2017) Mordenite/Nafion and analcime/Nafion composite membranes prepared by spray method for improved direct methanol fuel cell performance. Appl Surf Sci 421:24–41. https://doi.org/10.1016/j.apsusc.2017.02.004

Prapainainar P, Theampetch A, Kongkachuichay P et al (2015) Effect of solution casting temperature on properties of nafion composite membrane with surface modified mordenite for direct methanol fuel cell. Surf Coatings Technol 271:63–73. https://doi.org/10.1016/j.surfcoat.2015.01.021

Meenakshi S, Sahu AK, Bhat SD et al (2013) Mesostructured-aluminosilicate-Nafion hybrid membranes for direct methanol fuel cells. Electrochim Acta 89:35–44. https://doi.org/10.1016/j.electacta.2012.11.003

Wang Z, Ren J, Sun Y et al (2022) Fluorinated strategy of node structure of Zr-based MOF for construction of high-performance composite polymer electrolyte membranes. J Memb Sci 645:120193. https://doi.org/10.1016/j.memsci.2021.120193

Rao Z, Tang B, Wu P (2017) Proton Conductivity of Proton Exchange Membrane Synergistically Promoted by Different Functionalized Metal-Organic Frameworks. ACS Appl Mater Interfaces 9:22597–22603. https://doi.org/10.1021/acsami.7b05969

Rao Z, Feng K, Tang B, Wu P (2017) Construction of well interconnected metal-organic framework structure for effectively promoting proton conductivity of proton exchange membrane. J Memb Sci 533:160–170. https://doi.org/10.1016/j.memsci.2017.03.031

Wei Y, Matar S, Shen L et al (2012) A novel membrane for DMFC – Na 2 Ti 3 O 7 Nanotubes/Nafion® composite membrane: Performances studies. Int J Hydrogen Energy 37:1857–1864. https://doi.org/10.1016/j.ijhydene.2011.08.107

Li L, Zhang Y, Drillet J-F et al (2007) Preparation and characterization of Pt direct deposition on polypyrrole modified Nafion composite membranes for direct methanol fuel cell applications. Chem Eng J 133:113–119. https://doi.org/10.1016/j.cej.2007.02.008

Park H, Kim Y, Choi YS et al (2008) Surface chemistry and physical properties of Nafion/polypyrrole/Pt composite membrane prepared by chemical in situ polymerization for DMFC. J Power Sources 178:610–619. https://doi.org/10.1016/j.jpowsour.2007.08.050

Kim D, Sauk J, Byun J et al (2007) Palladium composite membranes using supercritical CO2 impregnation method for direct methanol fuel cells. Solid State Ionics 178:865–870. https://doi.org/10.1016/j.ssi.2007.02.034

Brandão L, Rodrigues J, Madeira LM, Mendes A (2010) Methanol crossover reduction by Nafion modification with palladium composite nanoparticles: Application to direct methanol fuel cells. Int J Hydrogen Energy 35:11561–11567. https://doi.org/10.1016/j.ijhydene.2010.04.096

Thiam HS, Daud WRW, Kamarudin SK et al (2013) Nafion/Pd–SiO2 nanofiber composite membranes for direct methanol fuel cell applications. Int J Hydrogen Energy 38:9474–9483. https://doi.org/10.1016/j.ijhydene.2012.11.141

Jung E, Jung U, Yang T et al (2007) Methanol crossover through PtRu/Nafion composite membrane for a direct methanol fuel cell. Int J Hydrogen Energy 32:903–907. https://doi.org/10.1016/j.ijhydene.2006.12.014

Parthiban V, Panda SK, Sahu AK (2018) Highly fluorescent carbon quantum dots-Nafion as proton selective hybrid membrane for direct methanol fuel cells. Electrochim Acta 292:855–864. https://doi.org/10.1016/j.electacta.2018.09.193

Parthiban V, Akula S, Sahu AK (2017) Surfactant templated nanoporous carbon-Nafion hybrid membranes for direct methanol fuel cells with reduced methanol crossover. J Memb Sci 541:127–136. https://doi.org/10.1016/j.memsci.2017.06.081

Hasani-Sadrabadi MM, Dashtimoghadam E, Majedi FS et al (2013) Nafion/chitosan-wrapped CNT nanocomposite membrane for high-performance direct methanol fuel cells. RSC Adv 3:7337–7346. https://doi.org/10.1039/c3ra40480c

Tohidian M, Ghaffarian SR (2018) Surface modified multi-walled carbon nanotubes and Nafion nanocomposite membranes for use in fuel cell applications. Polym Adv Technol 29:1219–1226. https://doi.org/10.1002/pat.4232

Jia W, Tang B, Wu P (2018) Carbon dots with multi-functional groups and the application in proton exchange membranes. Electrochim Acta 260:92–100. https://doi.org/10.1016/j.electacta.2017.11.047

Wang F, Zuo Z, Li L et al (2019) Large-Area Aminated-Graphdiyne Thin Films for Direct Methanol Fuel Cells. Angew Chemie Int Ed 58:15010–15015. https://doi.org/10.1002/anie.201910588

Velayutham P, Sahu AK (2018) Graphitic Carbon Nitride Nanosheets—Nafion as a Methanol Barrier Hybrid Membrane for Direct Methanol Fuel Cells. J Phys Chem C 122:21735–21744. https://doi.org/10.1021/acs.jpcc.8b06042

Chang CM, Li HY, Lai JY, Liu YL (2013) Nanocomposite membranes of Nafion and Fe3O4-anchored and Nafion-functionalized multiwalled carbon nanotubes exhibiting high proton conductivity and low methanol permeability for direct methanol fuel cells. RSC Adv 3:12895–12904. https://doi.org/10.1039/c3ra40438b

Hasanabadi N, Ghaffarian SR, Hasani-Sadrabadi MM (2013) Nafion-based magnetically aligned nanocomposite proton exchange membranes for direct methanol fuel cells. Solid State Ionics 232:58–67. https://doi.org/10.1016/j.ssi.2012.11.015

Liang ZX, Shi JY, Liao SJ, Zeng JH (2010) Noble metal nanowires incorporated Nafion® membranes for reduction of methanol crossover in direct methanol fuel cells. Int J Hydrogen Energy 35:9182–9185. https://doi.org/10.1016/j.ijhydene.2010.06.054

Cao L, Wang X, Meziani MJ et al (2007) Carbon dots for multiphoton bioimaging. J Am Chem Soc 129:11318–11319. https://doi.org/10.1021/ja073527l

Dong Y, Shao J, Chen C et al (2012) Blue luminescent graphene quantum dots and graphene oxide prepared by tuning the carbonization degree of citric acid. Carbon N Y 50:4738–4743. https://doi.org/10.1016/j.carbon.2012.06.002

Dong Y, Wang R, Li H et al (2012) Polyamine-functionalized carbon quantum dots for chemical sensing. Carbon N Y 50:2810–2815. https://doi.org/10.1016/j.carbon.2012.02.046

Reed D, Thomsen E, Wang W et al (2015) Performance of Nafion® N115, Nafion® NR-212, and Nafion® NR-211 in a 1 kW class all vanadium mixed acid redox flow battery. J Power Sources 285:425–430. https://doi.org/10.1016/j.jpowsour.2015.03.099

Karimi MB, Mohammadi F, Hooshyari K (2019) Recent approaches to improve Nafion performance for fuel cell applications: A review. Int J Hydrogen Energy 44:28919–28938. https://doi.org/10.1016/j.ijhydene.2019.09.096

Zhou J, Cao J, Zhang Y et al (2021) Overcoming undesired fuel crossover: Goals of methanol-resistant modification of polymer electrolyte membranes. Renew Sustain Energy Rev 138:110660. https://doi.org/10.1016/j.rser.2020.110660

Acknowledgements

This work is fully supported by the grants from Jiangsu Natural Science Foundation (No. BK20231323), State Key Laboratory of Engines at Tianjin University (No. K2020–14), and High-Tech Research Key Laboratory of Zhenjiang City (No. SS2018002). We also want to thank Professor Weiqi Zhang, Professor Huaneng Su, Dr. Divya Kumar, Professor Huiyuan Liu [Jiangsu University], Professor Lei Xing [University of Surrey] and Professor Xiaohui Yan [Shanghai Jiao Tong University] for their supports.

Funding

Jiangsu Natural Science Foundation, BK20231323, Qian Xu; State Key Laboratory of Engines at Tianjin University, K2020–14, Qian Xu; High-Tech Research Key Laboratory of Zhenjiang, SS2018002, Qian Xu.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• New advancements in Nafion-based commercial and non-commercial membranes are reviewed.

• Additives application in these membranes and their connections with Nafion are given.

• The future prospects for the improvement of Nafion membranes are discussed.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Asghar, M., Xu, Q. A review of advancements in commercial and non-commercial Nafion-based proton exchange membranes for direct methanol fuel cells. J Polym Res 31, 125 (2024). https://doi.org/10.1007/s10965-024-03964-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-024-03964-y