Abstract

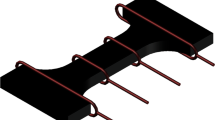

The possibility of making strain gauges with high sensitivity to changes in mechanical stress based on hard elastic films of isotactic polypropylene, with thixotropic polymer softening during cyclic deformation (Patrikeev-Mullins effect) and the “dry crazing” effect, is studied. Three options of rigid elastic film preparation using isotactic polypropylene for successive deposition of an adhesive layer of a solution of macromolecular compounds and an electrically conductive layer of a graphite dispersion are proposed. The optimal order of operations for manufacturing electrical sensors with high sensitivity to changes in mechanical stress has been established, including preliminary cyclic deformation in the air to form open micropores as a result of “dry crazing”. A mathematical model has been developed, which predicts the mechanical stress and/or the change in mechanical stress of film strain gauges based on the change in the electrical resistance of the conductive layer in the 6–35% strain range with up to 700 relative strain sensitivity.

Similar content being viewed by others

References

Cannon SL, McKenna GB, Statton WO (1976) J Polym Sci 11:209

Ren W (1992) Colloid Polym Sci 270:943

Garcia-Leiner M, Song J, Lesser AJ (2003) J Polym Sci 41(12):1375

Park IK, Noether HD (1975) Colloid Polym Sci 253:824

Flynn C, Taberner A, Nielsen P (2011) Biomech Model Mechanobiol 10:27

Zhang L, Li H, Lai X, Gao T, Yang J, Zeng X, Appl ACS (2018) Mater Interfaces 10:41784–41792

Ding G, Jiao W, Wang R, Chu Z, Huang Y (2019) J Mater Chem A 19:712333–12342

Liu Y, Pharr M, Salvatore GA (2017) ACS Nano 10:9614

Hu Z, Xin Y, Fu Q (2021) J Polym Res 28:134

Yang H, Kim D, Abhishek KS et al (2011) MRS Online Proc Libr 1312:407

Wu J, Li H, Lai X, Chen Z, Zeng X (2020) Mater Lett 280:128591

Hu Y, Zhao T, Zhu P et al (2018) Nano Res 11:1938–1955

Wu Z, Yang F, Yang J, Yang P, Zhang X, Zhang T, Lu M (2022) Macromol Mater Eng 307:2100502

Lee K, Ju B (2012) Appl Mater Sci 5(209):2082–2086

Palza H, Reznik B, Wilhelm M, Arias O (2012) Electrical. Macromol Mater Eng 297:474–480

Zhou C, Zhang Y, Hu C, Meng Y, Yu D (2022) J Polym Res 7:29

Sokolov AK, Garishin OK, Svistkov AL (2018) Mech Adv Mater Mod Process 4:7

Garishin OK, Shadrin VV, Kornev YuV (2019) Mater Phys Mech 42:445–454

Diani J, Fayolle B, Gilormini P (2009) Eur Polymer J 45:601

Lin Y, Li X, Chen X, An M, Zhang Q, Wang D, Chen W, Sun L, Yin P, Meng L, Li L (2019) Polymer 184:121930

Marchenko ES, Yasenchuk YF, Bajgonakova GA, Gunter SV, Shishelova AA (2020) Russ Phys J 63:1243

Yasenchuk Y, Marchenko E, Baigonakova G, Gunther S, Kokorev O, Gunter V, Chekalkin T, Topolnitskiy E, Obrosov A, Kang J (2021) Biomed Mater 16:021001

Monogenov AN, Gunther VE, Anikeev SG, Marchenko ES, Khodorenko VN, Fatyushin MY (2020) Russ Metall 10:1116

Luo RK, Wu X, Mortel WJ (2014) Mullins effect modelling and experiment for anti-vibration systems. Polym Test 40:304–312

Yasenchuk YF, Marchenko ES, Gunter SV, Baigonakova GA, Kokorev OV, Volinsky AA, Topolnitsky EB (2021) Materials 14:6256

Luo RK, Peng L, Wu X, Mortel WJ (2014) Polym Testing 40:304–312

Kondratov AP, Cherkasov EP, Nagornova IV (2019) AIP Conf Proc 2141:050006

Hu J, Zhu Y, Huang H, Lu J (2012) Prog Polymer Sci 37:1720

Kondratov AP, Volinsky AA, Chen J (2018) Polymer Technol 37:668

Jiang ZC, Xiao Y, Kang Y, Pan M, Li B-J, Zhang S, Appl ACS (2017) Mater Interfaces 9(24):20276

Kondratov AP, Volinsky AA, Chen J (2016) J Appl Polym Sci 133:43691

Zare MT, Prabhakaran MP, Parvin N, Ramakrishna S (2019) Chem Eng J 374:706

Rubinstein M, Panyukov S (2002) Macromolecules 35:6670–6686

Estevez R, Tijssens MGA, Giessen E (2000) J Mech Phys Solids 48:2585–2617

Rakkapao N, Vao-Soongnern V (2014) J Polym Res 21:12

Gao C, Lu H, Ni H, Chen J (2018) J Polym Res 25(1):6

Juan L (2017) J Nanomater 5:2171356

Funding

There was no funding received to conduct the reported research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests or conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kondratov, A.P., Lozitskaya, A.V., Samokhin, V.N. et al. Mullins effect in polymer large deformation strain gauges. J Polym Res 30, 36 (2023). https://doi.org/10.1007/s10965-022-03372-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03372-0