Abstract

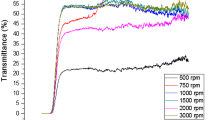

In this work, a novel cerium-based anti-ultraviolet fiber (CAUF) was prepared by masterbatch method for the first time. A pigment material, nano-cerium phosphate (nano-CePO4) was modified by aluminate coupling agent and then applied as the cerium-based anti-ultraviolet agent (CAUA) in the preparation of masterbatch. The characteristics of anti-ultraviolet agent, masterbatch and fibers were investigated by Fourier transform infrared spectroscopy, electron microscopy, differential scanning calorimeter, X-ray diffractometer, contact angle meter and ultraviolet spectrophotometer. The results indicated that masterbatch with the CAUA content of 10 wt.% could achieve the excellent dispersion of nanoparticles in PET matrix and improve the compatibility between nanoparticles and PET matrix, which was chosen for spinning. As the content of masterbatch (CAUA) in fibers reached to 15 wt.% (1.5 wt.%), not only the good physical–mechanical properties of fibers were achieved, but also the ultraviolet transmittance of fibers in UVA and UVB bands decreased to 2.27% and 0.57%, which presented the better anti-ultraviolet property than nano-titanium dioxide. Therefore, surface modified nano-CePO4 is a promising inorganic anti-ultraviolet agent with great chemical inertia, low photocatalytic activity and high absorption in the UV region, which could endow fibers with excellent protection properties in both UVA and UVB bands.

Similar content being viewed by others

Change history

05 February 2021

A Correction to this paper has been published: https://doi.org/10.1007/s10965-021-02423-2

References

Zou JP, Zhao Y, Yang MJ, Dan Y (2008) UV-resistant performance of polystyrene/TiO2 composite particles containing organic UV-stabiliser groups. PolymPolym Compos16: 209–216. https://doi.org/10.1177/096739110801600306.

RenF, Wang F, Pan Y, Sun HX, Zhu ZQ, Ma CH, Xiao CH, Liang WD, Chen LH, Li A (2018) Flexible and UV Resistant Films Based on Thiophene-Substituted Conjugated Microporous Polymers Bearing Alkyl Chains: Tuning of Rigidity into Soft. Macromol Mater Eng 303: 152–157. https://doi.org/10.1002/mame.201700619.

Yang HY, Yu ZW, Li K, Jiang L, Liu X, Deng B, Xiao CH, Cheng FX, XuWL (2019) Facile and Effective Fabrication of Highly UV-Resistant Silk Fabrics with Excellent Laundering Durability and Thermal and Chemical Stabilities. AcsAppl Mater Inter 11: 27426–27434. https://doi.org/10.1021/acsami.9b07646.

Paul CL, Paul Ft, Girgis A, Brozek I, Baird H, Hughes J (2005) Solaria compliance in an unregulated environment: the Australian experience. Eur J Cancer 41: 1178-1184. https://doi.org/10.1016/j.ejca.2005.01.019.

Saraiya M, GlanzK, Briss PA, Nichols P, White C, Das D, Smith SJ, Tannor B, Hutchinson AB, Wilson KM, Gandhi N, Lee NC, Rimer B, Coates RC, Kerner JF, Hiatt RA, Buffler P, Rochester P (2004) Interventions to prevent skin cancer by reducing exposure to ultraviolet radiation: a systematic review. Am J Prev Med 27: 482–483. https://doi.org/10.1016/j.amepre.2004.08.009.

Balakrishnan P, Gopi S, Sreekala MS, Thomas S (2018) UV resistant transparent bionanocomposite films based on potato starch/cellulose for sustainable packaging. Starch-Staerke 70: 1–2. https://doi.org/10.1002/star.201700139.

Zhang SS, Li J, Guo XP, Liu LH, Wei H, Zhang YW (2016) Nanostructured composite films of ceria nanoparticles with anti-UV and scratch protection properties constructed using a layer-by-layer strategy. Appl Surf Sci 382:316–322. https://doi.org/10.1016/j.apsusc.2016.04.151

Zhang GY, Lin H, Morikawa H, Mikihiko M (2013) In-situ growth of ZnO particles on bamboo pulp fabric and its anti-UV property. Fiber Polym 14: 1803–1807. https://doi.org/10.1007/s12221-013-1803-y.

Wang YZ, Dong SB, Yue CG, Ma D, Chen GL (2017) Study on anti-UV aging mechanism of PP-g-AN in the PP/PP-g-AN blend.PolymSciSer B+ 59: 354–361. https://doi.org/10.1134/S1560090417030174.

Seyed S, Seyed I, Kong JH, Lu XH (2017) Aqueous-Only, Green Route to Self-Healable, UV-Resistant, and Electrically Conductive Polyurethane/Graphene/Lignin Nanocomposite Coatings. Acs Sustain ChemEng 5:3148–3157. https://doi.org/10.1021/acssuschemeng.6b02941

Zink A (2019) Trends in the treatment and prevention of keratinocyte carcinoma (non-melanoma skin cancer). CurrOpinPharmacol 46: 19–23. https://doi.org/10.1016/j.coph.2018.12.002.

Surdu S (2014) Non-melanoma skin cancer: occupational risk from UV light and arsenic exposure. Rev Environ Health 29:255–264. https://doi.org/10.1515/reveh-2014-0040

Didona D, Paolino G, Bottoni U (2018) Non melanoma skin cancer pathogenesis overview. Biomedicines 6: 6. https://doi.org/10.3390/biomedicines6010006.

Abbas M, Kalia S (2015) Trends in Non-Melanoma Skin Cancer (Basal Cell Carcinoma and Squamous Cell Carcinoma) in Canada: A Descriptive Analysis of Available Data. J Cutan Med Surg20: 66–75. https://doi.org/10.1177/1203475415610106.

Zhang HD, Huang Y, Wang CL, wangLL, Shang JZ, (2016) Properties of anti-UV-finished cotton fabrics cured by blue light irradiation. Fiber Polm 17:396–401. https://doi.org/10.1007/s12221-016-5648-z

Li RX, Shen XL, Zhang XY, Xiao XF, Jiang S, Yin WW (2016) Study on anti-UV property of cotton fibers by in-situ generation of TiO2. Indian J Fiber Text37: 78–81. https://doi.org/10.13475/j.fzxb.20150103804.

Gallagher RP, Lee TK (2006) Adverse effects of ultraviolet radiation: a brief review. ProgBiophysMolBiol92: 119–131. https://doi.org/10.1016/j.pbiomolbio.2006.02.011.

Lisby S, Gniadecki R, Wulf HC (2005) UV-induced DNA damage in human keratinocytes: quantitation and correlation with long-term survival. ExpDermatol 14: 349–355. https://doi.org/10.1111/j.0906-6705.2005.00282.x.

Aslzadeh MM, Abdouss M, Shoushtari AM, Ghanbari F (2016) A comparative study on anti-UV non-spherical methacrylate polymer particles and anti-UV PVA nanofibers. Iran Polym J 25: 145–156. https://doi.org/10.1007/s13726-015-0409-1.

Saraiya M, Glanz K, Briss P (2004) Interventions to prevent skin cancer by reducing exposure to ultraviolet radiation systematic review. Am J Prev Med 27: 422–466. https://doi.org/10.1016/s0749-3797(04)00205-3.

Zhao Y, Xu Z, Wang X (2013)Super hydrophobic and UV-blocking cotton fabrics prepared by layer-by-layer assembly of organic UV absorber intercalated layered double hydroxides. Appl Surf Sci 286: 364–370. https://doi.org/10.1016/j.apsusc.2013.09.092.

Abidi N, Cabrales L, Hequet E (2019) Functionalization of a cotton fabric surface with titaniananosols: applications for self-cleaning and UV-protection properties. AcsAppl Mater Inter 1: 2141–2146. https://doi.org/10.1021/am900315t.

Zheng Y, Xiao M, Jiang S (2013) Coating fabrics with gold nanorods for colouring, UV-protection, and antibacterial functions. Nanoscale 5: 788–795. https://doi.org/10.1039/C2NR33064D.

Zhang XD, Cai YB, Teng X, Nan BH, Xu SA (2019) Application of polybenzimidazole as a panchromatic ultraviolet absorber in poly(vinyl chloride) film. Constr Build Mater 194: 171–178. https://doi.org/10.1016/j.conbuildmat.2018.10.152.

Feng Y, Li D, Zhang F, Zhang G (2017)A novel reactive anti-ultraviolet finishing of cotton fabric based on N-dihydroxy ethylene cyanoguanidine. Text Res J 87: 1722–1729. https://doi.org/10.1177/0040517516658515.

Baaka N, Ticha MB, Haddar W (2018) Upgrading of UV Protection Properties of Several Textile Fabrics by Their Dyeing with Grape Pomace Colorants. Fiber Polym 19:307–312. https://doi.org/10.1007/s12221-018-7327-0

Kurokl K, Hayashi T, Sato K, Asai T, Okano M, Kominami Y, Takahashi Y, Kawai T (2010) Effect of self-cured acrylic resin added with an inorganic antimicrobial agent on streptococcus mutans. Dent Mater J29: 277–285. https://doi.org/10.4012/dmj.2009-076.

Fang M, Chai F, Chen JH, Neut C, Jia M, Liu Y, Zhao SJ, Hildebrand HF (2007) Antimicrobial functionalization of an experimental self-etching primer by inorganic agents: microbiological and biocompatibility evaluations. BiomolEng 24: 483–488. https://doi.org/10.1016/j.bioeng.2007.07.013.

J H He, W S Ma, S Z Tan, J Q Zhao (2015) Study on surface modification of ultrafine inorganic antimicrobial particles. Appl Surf Sci 241: 279–286. https://doi.org/10.1016/j.apsusc.2004.06.161.

Justin G, William CE, Platten WE, Baumann EJ, Andrew R, Steve M, Harmona CL, Bennett S, Treye A, Thomas, Luxtona TP (2018) Dermal transfer and environmental release of CeO2 nanoparticles used as UV inhibitors on outdoor surfaces: Implications for human and environmental health. Sci Total Environ 12: 714–723. https://doi.org/10.1016/j.scitotenv.2017.09.050.

Mohammadi MA, Abdouss M, Mousavi AS, Ghanbari F (2016) Indirect effect of polyvinylpyrrolidone and cetyltrimethylammonium bromide on UV‐blocking efficiency of TiO2@PVP‐CTAB@SiO2 core‐shell nanohybrid particles. ApplPolymSci 133: 44148. https://doi.org/10.1002/app.44148.

Marcos Z, Pilar GP, David L (2007) Preventing of UV-light damage of light sensitive materials using a highly protective UV-absorbing coating. ChemSoc Rev 36: 1270–1281. https://doi.org/10.1039/B608888K.

Wan CC, Jiao Y, Li J (2015) In situ deposition of graphenenanosheets on wood surface by one-pot hydrothermal method for enhanced UV-resistant ability. Appl Sur Sci 347: 891–897. https://doi.org/10.1016/j.apsusc.2015.04.178.

Habibi MH, Nasr-Esfahani M, Emtiazi G, Hosseinkhani B (2010) Nanostructure Thin Films of Titanium Dioxide Coated on Glass and Its Anti UV Effect for Living Organism. CurrNanosci 6: 324–329. https://doi.org/10.2174/157341310791171180.

Bai Y, Li Z, Cheng B, Zhang M, Su K (2017) Higher UV-shielding ability and lower photocatalytic activity of TiO2@SiO2/APTES and its excellent performance in enhancing the photostability of poly(p-phenylene sulfide). RscAdv 7: 21758–21767. https://doi.org/10.1039/C6RA28098F.

Ju H, Jiang YS, Xue B, Xu YJ, Guo HG (2018) UV shielding performance of illite/TiO2nanocomposites. New J Chem 42: 9260–9268. https://doi.org/10.1039/c7nj04740a.

Wang CX, Lv JC, Ren Y, Zhou QQ, Chen JY, Zhi T, Lu ZQ, Gao DW, Ma ZP, Jin LM (2016) Cotton fabric with plasma pretreatment and ZnO/Carboxymethyl chitosan composite finishing for durable UV resistance and antibacterial property. CarbohydPolym 138: 106–113. https://doi.org/10.1016/j.carbpol.2015.11.046.

Huang XJ, Zeng XF, Wang JX (2019) Synthesis of monodispersed ZnO@SiO2 nanoparticles for anti-UV aging application in highly transparent polymer-based nanocomposites. J Mater Sci 54: 8581. https://doi.org/10.1007/s10853-019-03393-z.

Nick S, Daniele D, Angelo A (2007) Inorganic and organic UV filters: their role and efficacy in sunscreens and suncare products. InorgChimActa 360: 794–802. https://doi.org/10.1016/j.ica.2005.12.057.

Stefano L, Ingrid C, Cristin PM (2010) Decreasing the oxidative potential of TiO2 nanoparticles through modification of the surface with carbon: a new strategy for the production of safe UV filters. ChemCommun 46: 8478–8480. https://doi.org/10.1039/c0cc02537b.

Yabe S, Yamashita M, Momose S, Tahira K, Yoshida S (2001) Synthesis and UV-shielding properties of metal oxide doped ceria via soft chemical route. Int J Inorg Mater 3: 1003–1008. https://doi.org/10.1016/S1466-6049(01)00198-2.

Li RX, Yabe S, Yamashita M, Momose S, Yoshida S, Yin S (2002) UV shielding properties of zinc oxide-doped ceria fine powders derived via soft solution chemical routes. Mater ChemPhys 75: 39–44. https://doi.org/10.1016/S0254-0584(02)00027-5.

Zhang WW, Zhang DS, Chen YY, Lin H (2015)Hyperbranched Polymer Functional TiO2 Nanoparticles: Synthesis and Its Application for the anti-UV Finishing of Silk. Fiber Polym 16: 503–509. https://doi.org/10.1007/s12221-015-0503-1.

Bayan R, Karak N (2017) Renewable resource modified polyol derived aliphatic hyperbranched polyurethane as a biodegradable and UV-resistant smart material. PolymInt 66:839–850. https://doi.org/10.1002/pi.5323

Lima JFD, Serra OA (2013) Cerium phosphate nanoparticles with low photocatalytic activity for UV light absorption application in photoprotection. Dyes and Pigments 97: 291–296. https://doi.org/10.1016/j.dyepig.2012.12.020.

Imanaka N, Masui T, Hirai H, Adachi GY (2003) Amorphous cerium-titanium solid solution phosphate as a novel family of band gap tunable sunscreen materials. Chem Mater 34: 2289–2291. https://doi.org/10.1021/cm034200w.

Wu W, Fan YJ, Wu XH, Liao S, Huang XF, Li XH (2009) Preparation of nano-sized cerium and titanium pyrophosphates via solid-state reaction at room temperature. Rare Met 28: 33–38. https://doi.org/10.1007/s12598-009-0007-5.

Masui T, Hirai H, Imanaka N, Adachi GY (2006) New sunscreen materials based on amorphous cerium and titanium phosphate. J Alloy Compd 408–412: 1141–1144. https://doi.org/10.1016/j.jallcom.2004.12.136.

Buccella M, Dorigato A, Rizzola F (2016) Influence of the Processing Parameters on the Dispersion and Coloration Behavior of a Halogenated Copper Phthalocyanine-Based Masterbatch. AdvPolym Tech 37: 21–29. https://doi.org/10.1002/adv.21721.

Antoniadis G, Paraskevopoulos KM, Vassilioub AA, Papageorgioub GZ, Bikiaris D, Chrissafis K (2011)Nonisothermal melt-crystallization kinetics for in situ prepared poly(ethyleneterephthalate)/monmorilonite (PET/OMMT). ThermochimActa 521: 161–169. https://doi.org/10.1016/j.tca.2011.04.019.

Erdem N, Erdogan UH, Cireli AA, Onar N (2010) Structural and Ultraviolet-Protective Properties of Nano-TiO2-Doped Polypropylene Filaments. J ApplPolymSci 27: 152–157. https://doi.org/10.1002/app.30950.

Chen LL, Zhang Y (2009) Wet Surface modification of light calcium carbonate powder by aluminate coupling agent. Adv Mater Res 79: 1967–1970. https://doi.org/10.4028/www.scientific.net/AMR.79-82.1967

Cammarata RC (1997) Surface and interface stress effects on interfacial and nanostructured Materials. Mat SciEng A-Struct237: 180–184. https://doi.org/10.1016/s0921-5093(97)00128-7 .

Minakov AA, Mordvintsev DA, SchickC. Melting and reorganization of poly(ethylene terephthalate) on fast heating (1000 K/s). Polymer 11:3755–3763. https://doi.org/10.1016/j.polymer.2004.03.072.

Zhang X, Zhao S, Mohamed MG, KuoSW, Xin Z (2020) Crystallization behaviors of poly(ethylene terephthalate) (PET) with monosilane isobutyl-polyhedral oligomericsilsesquioxanes (POSS). J Mater Sci55:14642–14655. https://doi.org/10.1007/s10853-020-05003-9.

Xu QW, Meng XK (2014) Effect of nucleating agent on the structure and mechanical properties of oriented PET. Adv Mater Res 914: 445–455. https://doi.org/10.4028/www.scientific.net/AMR.912-914.445.

Acknowledgments

This study was funded by The National Key Research and Development Program of China (2016YFB0302801).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, K., Hu, D., Wang, S. et al. Application of cerium phosphate in preparing anti-ultraviolet PET fibers with masterbatch method. J Polym Res 27, 361 (2020). https://doi.org/10.1007/s10965-020-02324-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02324-w