Abstract

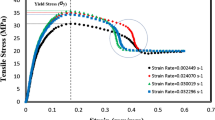

The mechanical behavior of polypropylene polymer was investigated under the effect of various temperatures. Mechanical properties of polymer were carried out through uniaxial tensile tests for low and high temperatures respectively. The results showed that both yield stress and the elastic modulus of the material decrease with the increase of temperature. Similarly, the post-yielding behavior of the material can be clearly observed at low temperature, and this behavior gradually disappears as the temperature increases. A phenomenological constitutive model is proposed in order to understand the mechanical behavior of polymer by combining the hyperbolic and multi-linear relationships. It is based on the experiments, and the proposed constitutive model is successfully validated by the excellent agreement between model prediction and experimental results.

Similar content being viewed by others

References

Grala M, Bartczak Z, Morphology RA (2016) Thermal and mechanical properties of polypropylene/SiO 2, nanocomposites obtained by reactive blending. J Polym Res 23:1–19

Chiu HT, Hsiao YK (2006) Compatibilization of poly(ethylene terephthalate)/polypropylene blends with maleic anhydride grafted polyethylene-Octene elastomer. J Polym Res 13:153–160

Gamonpilas C, Mccuiston R, Mccuiston R (2012) A non-linear viscoelastic material constitutive model for polyurea. Polymer 53:3655–3658

Haward RN, Thackray G (1968) The use of a mathematical model to describe isothermal stress-strain curves in glassy thermoplastics. Proc R Soc Math Phys Eng Sci 302:453–472

Ree T, Eyring H (1955) Theory of non-Newtonian flow. I. Solid plastic system. J Appl Phys 26:793–800

Boyce MC, Parks DM, Argon AS (1988) Large inelastic deformation of glassy polymers. Part I: rate dependent constitutive model. Mech Mater 7:15–33

De Focatiis DSA, Embery J, Buckley CP (2010) Large deformations in oriented polymer glasses: experimental study and a new glass-melt constitutive model. J Polym Sci B Polym Phys 48:1449–1463

Govaert LE, Tervoort TA (2000) Strain hardening of polycarbonate in the glassy state: influence of temperature and molecular weight. J Rheol 44:1263–1277

Duan Y, Saigal A, Greif R, et al. (2001) A uniform phenomenological constitutive model for glassy and Semicrystalline polymers. Polym Eng Sci 41:1322–1328

Yang L, Wang L, Zhu Z (1994) A micromechanical analysis of the nonlinear elastic and viscoelastic constitutive relation of a polymer filled with rigid particles. Acta Mech Sinica 10:176–185

Drozdov AD (2010) Linear thermo-viscoelasticity of polypropylene. Mech Res Commun 37(8):690–695

Cao K, Wang Y, Wang Y (2014) Experimental investigation and modeling of the tension behavior of polycarbonate with temperature effects from low to high strain rates. Int J Solids Struct 51:2539–2548

Li G, Chen Y, Ruan B, et al. (2016) A constitutive model of polymer at different temperature. Aust J Mech Eng 52:67–73

Zhou Y, Mallick PK (2002) Effects of temperature and strain rate on the tensile behavior of unfilled and talc-filled polypropylene Part II: constitutive equation. Polym Eng Sci 42:2461–2470

Mahieux CA, Reifsnider KL (2001) Property modeling across transition temperatures in polymers: a robust stiffness-temperature model. Polymer 42:3281–3291

Richeton J, Ahzi S, Vecchio KS, et al. (2006) Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: characterization and modeling of the compressive yield stress. Int J Solids Struct 43:2318–2335

Sardon H, Irusta L, Santamaría P, et al. (2012) Thermal and mechanical behaviour of self-curable waterborne hybrid polyurethanes functionalized with (3-aminopropyl) triethoxysilane (APTES). J Polym Res 19:1–9

Gibson AG, Torres MEO, Browne TNA, et al. (2010) High temperature and fire behavior of continuous glass fibre/polypropylene laminates. Compos A Appl Sci Manuf 41:1219–1231

Dar UA, Zhang W, Xu Y, et al. (2014) Thermal and strain rate sensitive compressive behavior of polycarbonate polymer - experimental and constitutive analysis. J Polym Res 21:1–10

Acknowledgements

This work is supported by the Research Program of Shanghai Science and Technology Committee (NO.14DZ1204203).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, G., Wang, J., Feng, J. et al. Experimental investigation and modeling of the tension behavior of polypropylene at different temperature. J Polym Res 24, 223 (2017). https://doi.org/10.1007/s10965-017-1356-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-017-1356-7