Abstract

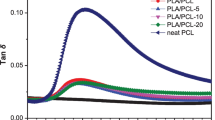

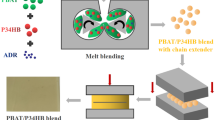

Biodegradable polymer blends of high-molecular-weight poly(3-hydroxybutyrate) (PHB) and poly(lactic acid) (PLA) are not miscible in general. Yet, by decreasing the molecular weight of PHB, the low-molecular-weight PHB could have improved miscibility with the PLA. In this study, a melt-induced degradation process of PLA/PHB blends was therefore implemented, termed the in-situ self-compatibilization approach, to produce low-molecular-weight PHB during melt blending process. The solution blends of PLA and oligomer PHB (PLA/OPHB) were also prepared as a basis to understand the role of low-molecular-weight PHB to improve its miscibility with PLA in PLA/PHB blends. Only one single glass transition temperature (Tg) was found for the resulting PLA/PHB blends at compositions of 95/05 to 80/20, proving that the miscibility was greatly improved by decreasing molecular weight of PHB. Because the degraded PHB had a relatively lower Tg, it thus provided plasticization effect to the PLA and resulted in the decreased crystallization temperature. Moreover, with increasing PHB content to 20% in the blend, the elongation at break increased significantly from 7.2% to 227%, more than 30-fold. The extensive shear yielding and necking behavior were observed during tensile testing for the blend of 80/20. The localized plasticization within PLA/PHB matrix with the reduction of local yield stress and the well-dispersed PHB crystallites were the major contributing factors to trigger shear yielding phenomenon. Moreover, initial modulus decreased only 20%, from 1.68 to 1.35 GPa. A common problem of severely reduced stiffness from the added plasticizer encountered in the plasticized PLA blends was therefore not perceived here.

Similar content being viewed by others

References

Lim LT, Auras R, Rubino M (2008) Processing technologies for poly(lactic acid). Prog Polym Sci (Oxford). doi:10.1016/j.progpolymsci.2008.05.004

Auras RA, Lim LT, Selke SEM, Tsuji H (2010) Poly(lactic acid): synthesis, structures, properties, processing, and applications. John Wiley & Sons, New Jersey

Lee SY, J-i C, Wong HH (1999) Recent advances in polyhydroxyalkanoate production by bacterial fermentation: mini-review. Int J Biol Macromol. doi:10.1016/S0141-8130(99)00012-4

Lenz RW, Marchessault RH (2005) Bacterial polyesters: biosynthesis, biodegradable plastics and biotechnology. Biomacromolecules. doi:10.1021/bm049700c

Murariu M, Da Silva FA, Pluta M, Bonnaud L, Alexandre M, Dubois P (2008) Polylactide (PLA)-CaSO4 composites toughened with low molecular weight and polymeric Ester-like plasticizers and related performances. Eur Polym J. doi:10.1016/j.eurpolymj.2008.07.055

Ma P, Hristova-Bogaerds DG, Goossens JGP, Spoelstra AB, Zhang Y, Lemstra PJ (2012) Toughening of poly(lactic acid) by ethylene-co-vinyl acetate copolymer with different vinyl acetate contents. Eur Polym J. doi:10.1016/j.eurpolymj.2011.10.015

Oyama HT (2009) Super-tough poly(lactic acid) materials: reactive blending with ethylene copolymer. Polymer 50(3):747–751. doi:10.1016/j.polymer.2008.12.025

Zhang C, Wang W, Huang Y, Pan Y, Jiang L, Dan Y, Luo Y, Peng Z (2013) Thermal, mechanical and rheological properties of polylactide toughened by expoxidized natural rubber. Mater Des. doi:10.1016/j.matdes.2012.09.024

Hao Y, Liang H, Bian J, Sun S, Zhang H, Dong L (2013) Toughening of polylactide with epoxy-functionalized methyl methacrylate-butadiene copolymer. Polym Int. doi:10.1002/pi.4561

Xiu H, Huang C, Bai H, Jiang J, Chen F, Deng H, Wang K, Zhang Q, Fu Q (2014) Improving impact toughness of polylactide/poly(ether)urethane blends via designing the phase morphology assisted by hydrophilic silica nanoparticles. Polymer. doi:10.1016/j.polymer.2014.01.057

Dogan SK, Reyes EA, Rastogi S, Ozkoc G (2014) Reactive compatibilization of PLA/TPU blends with a diisocyanate. J Appl Polym Sci. doi:10.1002/app.40251

Hong H, Wei J, Yuan Y, Chen F-P, Wang J, Qu X, Liu C-S (2011) A novel composite coupled hardness with flexibleness-polylactic acid toughen with thermoplastic polyurethane. J Appl Polym Sci. doi:10.1002/app.33675

Lai S-M, Lan Y-C, Wu W-L, Wang Y-J (2015) Compatibility improvement of poly(lactic acid)/thermoplastic polyurethane blends with 3-aminopropyl triethoxysilane. J Appl Polym Sci. doi:10.1002/app.42322

Vilay V, Mariatti M, Ahmad Z, Pasomsouk K, Todo M (2009) Characterization of the mechanical and thermal properties and morphological behavior of biodegradable poly(L-lactide)/poly(ε-caprolactone) and poly(L-lactide)/poly(butylene succinate-co-L-lactate) polymeric blends. J Appl Polym Sci. doi:10.1002/app.30683

Pai F-C, Chu H-H, Lai S-M (2011) Reactive compatibilization of poly(lactic acid)/polyethylene octene copolymer blends with ethylene-glycidyl methacrylate copolymer. J Polym Eng. doi:10.1515/POLYENG.2011.091

Lin K-W, Lan C-H, Sun Y-M (2016) Poly[(R)3-hydroxybutyrate] (PHB)/poly(L-lactic acid) (PLLA) blends with poly(PHB/PLLA urethane) as a compatibilizer. Polym Degrad Stab. doi:10.1016/j.polymdegradstab.2016.09.017

Martin O, Avérous L (2001) Poly(lactic acid): plasticization and properties of biodegradable multiphase systems. Polymer. doi:10.1016/S0032-3861(01)00086-6

Kulinski Z, Piorkowska E (2005) Crystallization, structure and properties of plasticized poly(L-lactide). Polymer. doi:10.1016/j.polymer.2005.07.101

Armentano I, Fortunati E, Burgos N, Dominici F, Luzi F, Fiori S, Jiménez A, Yoon K, Ahn J, Kang S, Kenny JM (2015) Bio-based PLA_PHB plasticized blend films: Processing and structural characterization. LWT - Food Sci Technol. doi:10.1016/j.lwt.2015.06.032

Ljungberg N, Wesslén B (2005) Preparation and properties of plasticized poly(lactic acid) films. Biomacromolecules. doi:10.1021/bm050098f

Zhang L, Xiong C, Deng X (1996) Miscibility, crystallization and morphology of poly(ß-hydroxybutyrate)/poly(d,l-lactide) blends. Polymer. doi:10.1016/0032-3861(96)81093-7

Zhang M, Thomas NL (2011) Blending polylactic acid with polyhydroxybutyrate: the effect on thermal, mechanical, and biodegradation properties. Adv Polym Technol. doi:10.1002/adv.20235

Furukawa T, Sato H, Murakami R, Zhang J, Duan YX, Noda I, Ochiai S, Ozaki Y (2005) Structure, dispersibility, and crystallinity of poly(hydroxybutyrate)/poly(L-lactic acid) blends studied by FT-IR microspectroscopy and differential scanning calorimetry. Macromolecules. doi:10.1021/ma0504668

Park JW, Doi Y, Iwata T (2004) Uniaxial drawing and mechanical properties of poly[(R)-3-hydroxybutyrate]/poly(L-lactic acid) blends. Biomacromolecules. doi:10.1021/bm049905l

Koyama N, Doi Y (1997) Miscibility of binary blends of poly[(R)-3-hydroxybutyric acid] and poly[(S)-lactic acid]. Polymer. doi:10.1016/S0032-3861(96)00685-4

Zhang J, Sato H, Furukawa T, Tsuji H, Noda I, Ozaki Y (2006) J Phys Chem B 110:24463–24471. doi:10.1021/jp065233c

Focarete ML, Ceccorulli G, Scandola M, Kowalczuk M (1998) Further evidence of crystallinity-induced biodegradation of synthetic atactic poly(3-hydroxybutyrate) by PHB-depolymerase a from Pseudomonas lemoignei. Blends of atactic poly(3-hydroxybutyrate) with crystalline polyesters. Macromolecules. doi:10.1021/ma981115e

Ohkoshi I, Abe H, Doi Y (2000) Miscibility and solid-state structures for blends of poly[(S)-lactide] with atactic poly[(R,S)-3-hydroxybutyrate]. Polymer. doi:10.1016/S0032-3861(99)00781-8

Nguyen S, Yu G-e, Marchessault RH (2002) Thermal degradation of poly(3-hydroxyalkanoates): preparation of well-defined oligomers. Biomacromolecules. doi:10.1021/bm0156274

Fisher EW, Sterzel HJ, Wegner G (1973) Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Kolloid Z.u.Z. Polymers 251:980. doi:10.1007/BF01498927

Barham PJ, Keller A, Otun EL, Holmes PA (1984) Crystallization and morphology of a bacterial thermoplastic: poly-3-hydroxybutyrate. J Mater Sci. doi:10.1007/BF01026954

Don T-M, Chen CW, Chan T-H (2006) Preparation and characterization of poly(hydroxyalkanoate) from the fermentation of Haloferax mediterranei. J Biomater Sci Polym Ed. doi:10.1163/156856206778937208

Liu Q, Shyr T-W, Tung C-H, Liu Z, Shan G, Zhu M, Deng B (2012) Particular thermal properties of poly(3-hydroxybutyrateco-3-hydroxyvalerate) oligomers. J Polym Res. doi:10.1007/s10965-011-9756-6

Lai S-M, Sun W-W, Don T-M (2015) Preparation and characterization of biodegradable polymer blends from poly(3-hydroxybutyrate)/poly(vinyl acetate)-modified corn starch. Polym Eng Sci. doi:10.1002/pen.24071

Xu J, Guo B-H, Yang R, Wu Q, Chen G-Q, Zhang Z-M (2002) In situ FTIR study on melting and crystallization of polyhydroxyalkanoates. Polymer. doi:10.1016/S0032-3861(02)00615-8

Focarete ML, Scandola M, Dobrzynski P, Kowalczuk M (2002) Miscibility and mechanical properties of blends of (L)-lactide copolymers with atactic poly(3-hydroxybutyrate). Macromolecules. doi:10.1021/ma020940z

Acknowledgements

The authors wish to thank the Ministry of Science and Technology (MOST) in Taiwan for financial support under the contract number NSC 101-2221-E-032-002-MY3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lai, SM., Liu, YH., Huang, CT. et al. Miscibility and toughness improvement of poly(lactic acid)/poly(3-Hydroxybutyrate) blends using a melt-induced degradation approach. J Polym Res 24, 102 (2017). https://doi.org/10.1007/s10965-017-1253-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-017-1253-0