Abstract

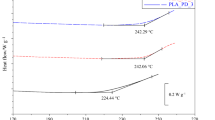

Dynamic mechanical thermal analysis was used to investigate the thermal transitions and modulus/temperature behavior of thermoformable carrier films, and to relate the information obtained to carrier film behavior during the thermoforming process. In this study the glass transition temperatures (T g) and the temperatures at which crystallization occurred during heating (T c) of four thermoformable carrier films were measured by using a dynamic mechanical thermal analyzer (DMTA). These films are good candidates for the automotive process, which uses painted carrier films as moldable automotive coatings (MAC). The modulus/temperature behavior of the films was also observed over a wide temperature range, which included thermoforming temperatures. Although films of PETG and PCTG 5445, co-polyesters based on poly(1,4-cyclohexylene dimethylene terephthalate), are thermoformable, their T g values, 92 and 99 °C, respectively, are not high enough to allow current paint systems (with bake temperature of 100–110 °C) to cure on the films without causing severe film deformation.

Similar content being viewed by others

References

Jones V, Kuivinen E, Sloat D, Wilson J (2002) US Patent 6,426,130

Spain P, Trung K, Robrbacher F (2005) US Patent 6,966,962 B2

Benedek I (2004) Pressure sensitive adhesives and application, 2nd edn, ISBN 0-8247-5059-4. Mercel Dekker, New York 10016

Winget LJ, Preisley DJ, Murar JT (1988) US Patent 4,251,291

Grujicic AM, Sellappan V, Omar M, Seyr N, Obieglo A, Erdmann M, Holzleitner J (2008) An overview of the polymer-to-metal direct adhesion hybrid technologies for load bearing automotive components. J Mater Process Technol 197:263–373

Robert W, Lenz (1967) Organic chemistry ofsynthetic high polymers. Interscience, New York, Chap 2

Billmeyer FW Jr (1971) Textbook of polymer science. Wiley-Interscience, New York, Chap 7

Sadighi M, Zadeh E, Saravi F (2008) Effects of laminate sequencing on thermoforming of thermoplastic matrix complex. J Mater Process Technol 201:725–730

Mark M, Eisenberg A, Graessley W, Mandelkern M, Koenig J (1984) Physical properties of polymers. American Chemical Society, Washington, pp 64–66

Aklonis J, Macknight W, Shen W (1972) Introduction to polymer viscoelasticity. Wiley-Interscience, New York, Chap 3

Tessier-Doyen N, Glandus J, Hugo M (2006) Untypical Young’s modulus evolution of model refractories at high temperature. J Eur Ceram Soc 26:289–295

Lipson R, Overdorf RJ (1994) US Patent 5,282,145

Paul D, Newman S (1978) Polymer Blends, vol 1. Academic, New York

Paul D, Barlow J (1980) Macromol Sci Rev Macromol Chem C18(1):109, 241–273

Schroeder J (1983) PhD dissertation, University of Massachusetts

PL-DMTA Operators Manual, Polymer Laboratories, Loughborough, UK (1982).

Evans S, Haines P, Skinner G (1996) The effects of structure on the thermal degradation of polyester resins. J Thermochim Acta 278:77–89

Kint DP, Munoz-Guerra S (2003) Modification of the thermal properties and crystallization behavior of poly(ethylene terephthalate) by copolymerization. Polym Int 52:321–336

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jodeh, S. Carrier films behavior during thermoforming process studied using dynamic mechanical thermal analysis (DMTA). J Polym Res 18, 939–944 (2011). https://doi.org/10.1007/s10965-010-9491-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9491-4