Abstract

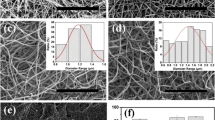

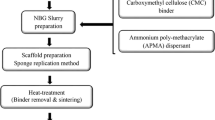

Cellulose nano fibril (CNF) aerogel, which is provided with high porosity, ultralow density and biodegradable ability, is a promising material for tissue engineering scaffold. Restricted by its poor mechanical properties, common CNF aerogel is unable to make scaffold with customized 3D structures. In order to make it useful in tissue engineering, the synthetic polymer Poly(ethylene glycol) diacrylate (PEGDA) has been chosen to mix with CNF solution to form a kind of composite bio-resin, which is ready for stereolithography. Our former study has proved the printability of the bio-resin and the biocompatibility of the CNF aerogel scaffold. But the relationship among its properties, material component and manufacturing condition has not been systematically studied. Thus an attempt is made to study and optimize the process factors that govern the aerogel scaffold’s property by using Taguchi experiment design in this work, where four main factors of material and fabrication process: the content of PEGDA, the content of CNF, the size of CNF and the pre-freeze temperature have been chosen to make a discussion of their effect on the aerogel scaffold’s properties including its porosity, mechanical property, micro-structure and so on. An orthogonal array of experiment is developed. It has the least number of experimental runs with desired process factor settings. The results analyzed by the tool of Analysis of Variance (ANOVA) show that different factor has various degrees of effect on different properties. Finally the optimized factors are acquired by screening the experiments data.

Similar content being viewed by others

References

M.P. Lutolf, J.A. Hubbell, Synthetic biomaterials as instructive extracellular microenvironments for morphogenesis in tissue engineering. Nat. Biotechnol. 23(1), 47–55 (2005)

W.J. Li, C.T. Laurencin, E.J. Caterson, R.S. Tuan, F.K. Ko, Electrospun nanofibrous structure: a novel scaffold for tissue engineering. J. Biomed. Mater. Res. 60(4), 613–621 (2002)

M. Bhattacharya, M.M. Malinen, P. Lauren, Y.R. Lou, S.W. Kuisma, L. Kanninen, M. Lille, A. Corlu, C. Guguen-Guillouzo, O. Ikkala, Nanofibrillar cellulose hydrogel promotes three-dimensional liver cell culture. J Control. Release Off. J. Control. Release Soc. 164(3), 291–298 (2012)

F.J. O’Brien, B.A. Harley, I.V. Yannas, L.J. Gibson, The effect of pore size on cell adhesion in collagen-GAG scaffolds. Biomaterials 26(4), 433–441 (2005)

X. Liu, X. Jin, P.X. Ma, Nanofibrous hollow microspheres self-assembled from star-shaped polymers as injectable cell carriers for knee repair. Nat. Mater. 10(5), 398–406 (2011)

S. Wang, A. Lu, L. Zhang, Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 53, 169–206 (2016)

C. Jiménez-Saelices, B. Seantier, Y. Grohens, I. Capron, Thermal superinsulating materials made from nanofibrillated cellulose-stabilized Pickering emulsions. ACS Appl. Mater. Interfaces. 10(18), 16193–16202 (2018)

H.C. Bi, X. Xie, K.B. Yin, Y.L. Zhou, S. Wan, L.B. He, F. Xu, F. Banhart, L.T. Sun, R.S. Ruoff, Spongy graphene as a highly efficient and recyclable sorbent for oils and organic solvents. Adv. Func. Mater. 22(21), 4421–4425 (2012)

S.C. Liao, T.L. Zhai, H.S. Xia, Highly adsorptive graphene aerogel microspheres with center-diverging microchannel structures. J. Mater. Chem. A 4(3), 1068–1077 (2016)

C. Hongli, S. Sudhir, L. Wenying, M. Wei, L. Wei, Z. Xiaodan, D. Yulin, Aerogel microspheres from natural cellulose nanofibrils and their application as cell culture scaffold. Biomacromol 15(7), 2540–2547 (2014)

J. Stergar, U. Maver, Review of aerogel-based materials in biomedical applications. J. Sol-Gel. Sci. Technol. 77(3), 738–752 (2016)

C. Zhang, T. Zhai, L.S. Turng, Aerogel microspheres based on cellulose nanofibrils as potential cell culture scaffolds. Cellulose 24(7), 2791–2799 (2017)

C. Wenshuai, L. Qing, W. Youcheng, Y. Xin, Z. Jie, Y. Haipeng, L. Yixing, L. Jian, Comparative study of aerogels obtained from differently prepared nanocellulose fibers. Chemsuschem 7(1), 154–161 (2014)

H. Sehaqui, M. Salajková, Z. Qi, L.A. Berglund, Mechanical performance tailoring of tough ultra-high porosity foams prepared from cellulose I nanofiber suspensions. Soft Matter 6(8), 1824–1832 (2010)

K. Yuri, S. Tsuguyuki, I. Akira, Aerogels with 3D ordered nanofiber skeletons of liquid-crystalline nanocellulose derivatives as tough and transparent insulators. Angew. Chem. Int. Ed. 53(39), 10253–10253 (2015)

Z.Q. Yang, J.H. Si, Z.X. Cui, J.H. Ye, X.F. Wang, Q.T. Wang, K.P. Peng, W.Z. Chen, S.C. Chen, Biomimetic composite scaffolds based on surface modification of polydopamine on electrospun poly(lactic acid)/cellulose nanofibrils. Carbohydr. Polym. 174, 750–759 (2017). https://doi.org/10.1016/j.carbpol.2017.07.010

H. Alenezi, M.E. Cam, M. Edirisinghe, Experimental and theoretical investigation of the fluid behavior during polymeric fiber formation with and without pressure. Appl. Phys. Rev. 6(4), 13 (2019). https://doi.org/10.1063/1.5110965

V.C.F. Li, A. Mulyadi, C.K. Dunn, Y. Deng, H.J. Qi, Direct Ink Write (DIW) 3D printed cellulose nanofiber aerogel structures with highly deformable, shape recoverable and functionalizable properties. ACS Sustain. Chem. Eng. 6(2), 2011–2022 (2017)

A. Rees, L.C. Powell, G. Chingacarrasco, D.T. Gethin, K. Syverud, K.E. Hill, D.W. Thomas, 3D Bioprinting of carboxymethylated-periodate oxidized nanocellulose constructs for wound dressing applications. Biomed Res. Int. 2015(2), 925757 (2015)

A.K. Mohanty, M. Misra, L.T. Drzal, Surface modifications of natural fibers and performance of the resulting biocomposites: an overview. Compos. Interfaces 8(5), 313–343 (2001)

O.N. Khlebnikov, V.E. Silantev, Y.A. Shchipunov, Dimensionally stable aerogels from cellulose mechanically treated to a moderate microfibrillar degree. Mendeleev Commun. 28(2), 214–215 (2018)

Y. Li, L. Xu, B. Xu, Z. Mao, H. Xu, Y. Zhong, L. Zhang, B. Wang, X. Sui, Cellulose sponge supported palladium nanoparticles as recyclable cross-coupling catalysts. ACS Appl. Mater. Interfaces. 9(20), 17155–17162 (2017)

X. Ge, Y. Shan, W. Lin, X. Mu, P. Hui, Y. Jiang, High-strength and morphology-controlled aerogel based on carboxymethyl cellulose and graphene oxide. Carbohyd. Polym. 197, 277–283 (2018)

S. Kalia, A. Dufresne, B.M. Cherian, B.S. Kaith, L. Averous, J. Njuguna, E. Nassiopoulos, Cellulose-based bio- and nanocomposites: a review. Int. J. Polym. Sci. 2011, 1–35 (2011)

J.K. Pandey, S.H. Ahn, C.S. Lee, A.K. Mohanty, M. Misra, Recent Advances in the application of natural fiber based composites. Macromol. Mater. Eng. 295(11), 975–989 (2010)

B. Deepa, S.S. Pillai, L.A. Pothan, S. Thomas, Mechanical properties of cellulose-based bionanocomposites. Biopolym. Nanocomp. Process. Proper. App. 177(1), 20–36 (2009)

R. Cancedda, B. Dozin, P. Giannoni, R. Quarto, Tissue engineering and cell therapy of cartilage and bone. Matrix Biol. 22(1), 81–91 (2004)

C. Cha, P. Soman, W. Zhu, M. Nikkhah, G. Camci-Unal, S. Chen, A. Khademhosseini, Structural reinforcement of cell-laden hydrogels with microfabricated three dimensional scaffolds. Biomater. Sci. 2(5), 703–709 (2014)

W.L. Jin, P. Soman, J.H. Park, S. Chen, D.W. Cho, A tubular biomaterial construct exhibiting a negative Poisson’s ratio. PLoS ONE 11(5), e0155681 (2016)

Y. Huang, X.F. Zhang, G. Gao, T. Yonezawa, X. Cui, 3D bioprinting and the current applications in tissue engineering. Biotechnol. J. 12(8), 1600734 (2017)

A. Tang, Q. Wang, S. Zhao, W. Liu, Fabrication of nanocellulose/PEGDA hydrogel by 3D printing. Rapid Prototyping J. 24(8), 1265–1271 (2018)

A.M. Tang, J. Li, J. Li, S. Zhao, W.Y. Liu, T.T. Liu, J.F. Wang, Y.Y. Liu, Nanocellulose/PEGDA aerogel scaffolds with tunable modulus prepared by stereolithography for three-dimensional cell culture. J. Biomater. Sci.-Polym. Ed. 30(10), 797–814 (2019)

R. Langer, J.P. Vacanti, Tissue engineering. Science 260(5110), 920–926 (1993)

A.J. Svagan, P. Jensen, S.V. Dvinskikh, I. Furó, L.A. Berglund, Towards tailored hierarchical structures in cellulose nanocomposite biofoams prepared by freezing/freeze-drying. J. Mater. Chem. 20(32), 6646–6654 (2010)

P.R. Nelson, Design and analysis of experiments, 3rd Ed. J. Quality Technol. 23(4), 375–375 (1991)

C.S. Bahney, T.J. Lujan, C.W. Hsu, M. Bottlang, J.L. West, B. Johnstone, Visible light photoinitiation of mesenchymal stem cell-laden bioresponsive hydrogels. Eur. Cell Mater. 22(7), 43–55 (2011)

D. Sun, W. Liu, A. Tang, F. Guo, W. Xie, A new PEGDA/CNF aerogel-wet hydrogel scaffold fabricated by two-step method. Soft Matter (2019). https://doi.org/10.1039/C9SM00899C

E.C. Beck, M. Barragan, M.H. Tadros, S.H. Gehrke, M.S. Detamore, Approaching the compressive modulus of articular cartilage with a decellularized cartilage-based hydrogel. Acta Biomater. 38, 94–105 (2016)

Acknowledgements

The study was supported by the National Natural Science Foundation of China (Grant Nos. 51875214 & 11972161), Science and Technology Program of Guangzhou, China (Grant No. 201804010452).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, D., Liu, W., Zhou, F. et al. Optimizing material and manufacturing process for PEGDA/CNF aerogel scaffold. J Porous Mater 27, 1623–1637 (2020). https://doi.org/10.1007/s10934-020-00938-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-020-00938-5