Abstract

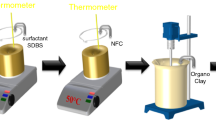

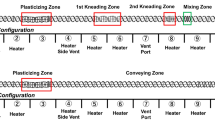

This study aims to develop fully bio-based barrier membranes from polylactic acid (PLA) and cellulose microfibers (CMF) to control the transmission of water vapor through the building envelope. To improve the dispersibility of CMF in the PLA matrix, lactic acid (LA) monomer or oligomer was grafted onto the surface of CMF by a simple esterification reaction. Based on the morphological analysis, the LA-modified CMF (CMF-LA) showed excellent dispersion in the PLA matrix due to the improved interfacial adhesion between modified fibers and PLA. The results of thermal analyses indicated that the glass transmission temperature and thermal decomposition temperatures of materials enhanced after the addition of bio-fillers. According to the tensile test results, the PLA-based composites incorporated with the different content of CMF-LA (1–20 wt%) and dicumyl peroxide (PLALCD composites) showed higher values of tensile strength and Young’s modulus compared to the neat PLA. Moreover, the PLALCD composites displayed superior vapor barrier properties than the PLA/untreated CMF composites, and there was no significant decrement in the barrier performance of PLALCD composites when the CMF-LA content was up to 15 wt%. Additionally, the environmental impact of the prepared composite was studied by the life cycle assessment tool and results demonstrated that the incorporation of cellulose fibers into PLA reduced the global warming potential of materials. The obtained results suggest that the modification of CMF with LA can be considered a simple, cost-effective, and sustainable method to fabricate a PLA-based membrane for the building envelope application.

Similar content being viewed by others

References

Ascione F, Bianco N, De Masi RF et al (2015) Design of the building envelope: a novel multi-objective approach for the optimization of energy performance and thermal comfort. Sustainability 7:10809–10836

Iwaro J, Mwasha A (2013) The impact of sustainable building envelope design on building sustainability using integrated performance model. Int J Sustain Built Environ 2:153–171

Kamel E, Memari AM (2022) Residential building envelope energy retrofit methods, simulation tools, and example projects: a review of the literature. Buildings 12:954

Huynh A, Dias Barkokebas R, Al-Hussein M et al (2021) Energy-efficiency requirements for residential building envelopes in cold-climate regions. Atmos (Basel) 12:405

Boudreaux P, Pallin S, Accawi G et al (2018) A rule-based expert system applied to moisture durability of building envelopes. J Build Phys 42:416–437

Zhou X, Carmeliet J, Derome D (2018) Influence of envelope properties on interior insulation solutions for masonry walls. Build Environ 135:246–256

Rasmussen TV, Hansen TK, Shashoua Y et al (2022) Performance of polyethylene vapor barrier systems in temperate climates. Buildings 12:1768

El-Sherif DM, Eloffy MG, Elmesery A et al (2022) Environmental risk, toxicity, and biodegradation of polyethylene: a review. Environ Sci Pollut Res 29:81166–81182

Pellis A, Malinconico M, Guarneri A, Gardossi L (2021) Renewable polymers and plastics: performance beyond the green. N Biotechnol 60:146–158

Balart R, Garcia-Garcia D, Fombuena V et al (2021) Biopolymers from natural resources. Polym (Basel) 13:2532

Naser AZ, Deiab I, Darras BM (2021) Poly (lactic acid)(PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: a review. RSC Adv 11:17151–17196

Chomachayi MD, Jalali-arani A, Beltrán FR et al (2020) Biodegradable nanocomposites developed from PLA/PCL blends and silk fibroin nanoparticles: study on the microstructure, thermal behavior, crystallinity and performance. J Polym Environ 28:1252–1264

Taib N-AAB, Rahman MR, Huda D et al (2022) A review on poly lactic acid (PLA) as a biodegradable polymer. Polym Bull 6:1–35

Madival S, Auras R, Singh SP, Narayan R (2009) Assessment of the environmental profile of PLA, PET and PS clamshell containers using LCA methodology. J Clean Prod 17:1183–1194

Wang H, Zhang X, Guo S, Liu T (2021) A review of coextruded wood–plastic composites. Polym Compos 42:4174–4186

Bashir ASM, Manusamy Y (2015) Recent developments in biocomposites reinforced with natural biofillers from food waste. Polym Plast Technol Eng 54:87–99

Chopra Lothers (2022) Extraction of cellulosic fibers from the natural resources: a short review. Mater Today Proc 48:1265–1270

Schwarzkopf MJ, Burnard MD (2016) Wood-plastic composites—performance and environmental impacts. Environ impacts Tradit Innov Bioprod. https://doi.org/10.1007/978-981-10-0655-5_2

Venkatarajan S, Athijayamani A (2021) An overview on natural cellulose fiber reinforced polymer composites. Mater Today Proc 37:3620–3624

Ng H-M, Sin LT, Bee S-T et al (2017) Review of nanocellulose polymer composite characteristics and challenges. Polym Plast Technol Eng 56:687–731

Mohit H, Arul Mozhi Selvan V (2018) A comprehensive review on surface modification, structure interface and bonding mechanism of plant cellulose fiber reinforced polymer based composites. Compos Interfaces 25:629–667

Fazeli M, Florez JP, Simão RA (2019) Improvement in adhesion of cellulose fibers to the thermoplastic starch matrix by plasma treatment modification. Compos Part B 163:207–216

Zhou L, Ke K, Yang M-B, Yang W (2021) Recent progress on chemical modification of cellulose for high mechanical-performance poly (lactic acid)/Cellulose composite: a review. Compos Commun 23:100548

Wang Y, Wang X, Xie Y, Zhang K (2018) Functional nanomaterials through esterification of cellulose: a review of chemistry and application. Cellulose 25:3703–3731

El-Gendy A, Abou-Zeid RE, Salama A et al (2017) TEMPO-oxidized cellulose nanofibers/polylactic acid/TiO2 as antibacterial bionanocomposite for active packaging. Egypt J Chem 60:1007–1014

Yin Y, Ma J, Tian X et al (2018) Cellulose nanocrystals functionalized with amino-silane and epoxy-poly (ethylene glycol) for reinforcement and flexibilization of poly (lactic acid): material preparation and compatibility mechanism. Cellulose 25:6447–6463

Loganathan TM, Sultan MTH, Ahsan Q et al (2020) Characterization of alkali treated new cellulosic fibre from Cyrtostachys renda. J Mater Res Technol 9:3537–3546

Boulos L, Foruzanmehr MR, Tagnit-Hamou A et al (2017) Wetting analysis and surface characterization of flax fibers modified with zirconia by sol-gel method. Surf Coat Technol 313:407–416

Hussain A, Blanchet P (2021) Preparation of breathable cellulose based polymeric membranes with enhanced water resistance for the building industry. Mater (Basel) 14:4310

Johari AP, Kurmvanshi SK, Mohanty S, Nayak SK (2016) Influence of surface modified cellulose microfibrils on the improved mechanical properties of poly (lactic acid). Int J Biol Macromol 84:329–339

Chomachayi MD, Blanchet P, Hussain A (2022) Development of bio-based membranes for building envelope applications from poly (lactic acid) and cellulose microfibers. BioResources 17:5707–5727

Sethi J, Farooq M, Sain S et al (2018) Water resistant nanopapers prepared by lactic acid modified cellulose nanofibers. Cellulose 25:259–268

Wu H, Nagarajan S, Shu J et al (2018) Green and facile surface modification of cellulose nanocrystal as the route to produce poly (lactic acid) nanocomposites with improved properties. Carbohydr Polym 197:204–214

ASTM D882-10 (2010) Standard test method for tensile properties of thin plastic sheeting. ASTM International, West Conshohocken

ASTM standard E 96/E96M-16 (Method B) (2016) Standard test methods for water vapor transmission of materials. ASTM International, West Conshohocken

ISO 14040 (2006) Environmental management-life cycle assessment-principles and framework. ASTM International, West Conshohocken

Hospodarova V, Singovszka E, Stevulova N (2018) Characterization of cellulosic fibers by FTIR spectroscopy for their further implementation to building materials. Am J Anal Chem 9:303–310

Dhar P, Tarafder D, Kumar A, Katiyar V (2016) Thermally recyclable polylactic acid/cellulose nanocrystal films through reactive extrusion process. Polym (Guildf) 87:268–282

Zheng T, Clemons CM, Pilla S (2019) Comparative study of direct compounding, coupling agent-aided and initiator-aided reactive extrusion to prepare cellulose nanocrystal/PHBV (CNC/PHBV) nanocomposite. ACS Sustain Chem Eng 8:814–822

Dadras Chomachayi M, Jalali-arani A, Martínez Urreaga J (2021) A comparison of the effect of silk fibroin nanoparticles and microfibers on the reprocessing and biodegradability of PLA/PCL Blends. J Polym Environ 29:2585–2597

Mokhena TC, Sefadi JS, Sadiku ER et al (2018) Thermoplastic processing of PLA/cellulose nanomaterials composites. Polym (Basel) 10:1363

Monika, Pal AK, Bhasney SM et al (2018) Effect of dicumyl peroxide on a poly (lactic acid)(PLA)/poly (butylene succinate)(PBS)/functionalized chitosan-based nanobiocomposite for packaging: a reactive extrusion study. Acs Omega 3:13298–13312

Botta L, Scaffaro R, Sutera F, Mistretta MC (2018) Reprocessing of PLA/graphene nanoplatelets nanocomposites. Polym (Basel) 10:18

Yasir M, Ahmad F, Megat-Yusoff PSM et al (2019) Quantifying the effects of basalt fibers on thermal degradation and fire performance of epoxy-based intumescent coating for fire protection of steel substrate. Prog Org Coatings 132:148–158

Rieger J (2001) The glass transition temperature tg of polymers—comparison of the values from differential thermal analysis (DTA, DSC) and dynamic mechanical measurements (torsion pendulum). Polym Test 20:199–204

Liu Q, Shaw MT, Parnas RS, McDonnell A-M (2006) Investigation of basalt fiber composite mechanical properties for applications in transportation. Polym Compos 27:41–48

Wang K, Abdala AA, Khraisheh MK (2017) Mechanical characterization of membranes. In: Hilal N, Ismail AF (eds) Membrane characterization. Elsevier, Amsterdam, pp 259–306

Shi X, Burnett E (2008) Mechanics and test study of flexible membranes ballooning in three dimensions. Build Environ 43:1871–1881

Knight KD, Boyle BJ (2002) Guidelines for Delivering Effective Air Barrier Systems. Canada Mortgage and Housing Corporation. Ottawa, Ontario, pp 1–36

Riahinezhad M, Hallman M, Masson JF (2021) Critical review of polymeric building envelope materials: degradation, durability and service life prediction. Buildings 11:299

Singha S, Hedenqvist MS (2020) A review on barrier properties of poly (lactic acid)/clay nanocomposites. Polym (Basel) 12:1095

NRCC (1995) National Building Code of Canada. Associate Committee on the National Building Code, National Research Council of Canada, Ottawa, ON. Part 9, Article 9.25.4.2

Jose AJ, Kappen J, Alagar M (2018) Polymeric membranes: classification, preparation, structure physiochemical, and transport mechanisms. In: Thomas S, Balakrishnan P (eds) Fundamental biomaterials: polymers. Elsevier, Amsterdam, pp 21–35

Heidari MD, Mathis D, Blanchet P, Amor B (2019) Streamlined life cycle assessment of an innovative bio-based material in construction: a case study of a phase change material panel. Forests 10:160

Humbert S, Rossi V, Margni M et al (2009) Life cycle assessment of two baby food packaging alternatives: glass jars vs. plastic pots. Int J Life Cycle Assess 14:95–106

Acknowledgements

The authors are thankful to the Natural Sciences and Engineering Research Council (NSERC) of Canada for the financial support through its IRC and CRD programs (IRCPJ 461745-18 and RDCPJ 524504-18) as well as the industrial partner, Kruger Inc., of the NSERC industrial chair on eco-responsible wood construction (CIRCERB).

Author information

Authors and Affiliations

Contributions

Conceptualization, MDC, PB, and AH; methodology, MDC and PB; formal analysis, MDC.; investigation, MDC.; resources, PB; writing-original draft preparation, MDC; writing-review and editing, MDC, PB, AH, SP; visualization, MDC; supervision, PB; project administration, PB; funding acquisition, PB All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, and interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dadras Chomachayi, M., Blanchet, P., Hussain, A. et al. Vapor Barrier Membranes Based on Polylactic acid and Cellulose Microfibers for the Building Envelope Application. J Polym Environ 31, 5309–5325 (2023). https://doi.org/10.1007/s10924-023-02946-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-023-02946-3