Abstract

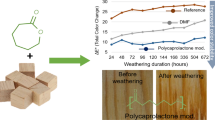

In this study, spruce wood was modified by ring-opening polymerization of ε-caprolactone to graft poly (ε-caprolactone) into wood cell wall by impregnation of 30%, 50%, and 70% monomer concentrations and further polymerization in DMF solution. The biodegradability of the modified wood by the wood-decaying fungi was investigated by means of weight losses, and the chemical and morphological background of the degradation process was analyzed through FTIR and SEM analysis, respectively. For this purpose, modified samples were exposed to brown rot fungi Coniophora puteana and Postia placenta, and white rot fungi Trametes versicolor and Pleurotus ostreatus attacks to determine the optimum concentration level of ε-caprolactone monomer for sufficient decay resistance on media inoculated with malt-extract agar and soil, according to principles of CEN EN 113 and ASTM D 1413, respectively. A leaching test was conducted in order to evaluate any loss in effectiveness in decay resistance. Results showed that all concentrations of PCL exhibited superior decay resistance in samples after the decay test was conducted on agar media. However, modified samples gave high weight losses in soil contact decay testing. P. placenta and P. ostreatus attacks were found to be more aggressive in modified samples than other fungi attacks. 70% ε-caprolactone concentration was found more efficacious in suppressing brown rot fungi attacks than lower concentrations, whilst lower concentration levels were found to be more efficacious in suppressing white rot fungi attacks than 70% concentration level. SEM and FTIR findings proved that weight losses were due to both cell wall degradations and polymer digestion by fungal enzymes. SEM study revealed that cell wall modification inhibits the consumption of cell wall polymers compared to controls.

Similar content being viewed by others

References

Berglund LA, Burgert I (2018) Bioinspired wood nanotechnology for functional materials. Adv Mater 30(19):1704285

Sandberg D, Kutnar A, Mantanis G (2017) Wood modification technologies-a review. iForest 10:895–908. https://doi.org/10.3832/ifor2380-010

Goldhahn C, Cabane E, Chanana M (2021) Sustainability in wood materials science: an opinion about current material development techniques and the end of lifetime perspectives. Phil Trans R Soc A 379:20200339. https://doi.org/10.1098/rsta.2020.0339

Singh T, Singh AP (2012) A review on natural products as wood protectant. Wood Sci Technol 46(5):851–870

Demirel GK, Temiz A, Jebrane M, Terziev N, Gezer ED (2018) Micro-distribution, water absorption, and dimensional stability of wood treated with epoxidized plant oils. BioResources 13:5124–5138

Jebrane M, Fernández-Cano V, Panov D, Terziev N, Daniel G (2015) Novel hydrophobization of wood by epoxidized linseed oil. Part 1. Process description and anti-swelling efficiency of the treated wood. Holzforschung 69(2):173–177

Lee SH, Ashaari Z, Lum WC, Halip JA, Ang AF, Tahir TLP, PM, (2018) Thermal treatment of wood using vegetable oils: a review. Constr Build Mater 181:408–419

Tomak ED, Viitanen H, Yildiz UC, Hughes M (2011) The combined effects of boron and oil heat treatment on the properties of beech and Scots pine wood. Part 2: Water absorption, compression strength, color changes, and decay resistance. J Mater Sci 46:608–615

Tomak ED (2022) Surface wettability of boron and oil-treated wood. Cerne 28:e-103058. https://doi.org/10.1590/01047760202228013058

Jebrane M, Cai S, Sandström C, Terziev N (2017) The reactivity of linseed and soybean oil with different epoxidation degree towards vinyl acetate and impact of the resulting copolymer on the wood durability. Express Polymer Lett 11:383–395. https://doi.org/10.3144/expresspolymlett.2017.37

Cabane E, Keplinger T, Merk V, Hass P, Burgert I (2014) Renewable and functional wood materials by grafting polymerization within cell walls. Chemsuschem 7:1020–1025. https://doi.org/10.1002/cssc.201301107

Can A, Sivrikaya H, Hazer B, Palanti S (2022) Beech (Fagus orientalis) wood modification through the incorporation of polystyrene-ricinoleic acid copolymer with Ag nanoparticles. Cellulose 29(2):1149–1161

Ermeydan MA, Babacan M, Tomak ED (2020) Evaluation of dimensional stability, weathering and decay resistance of modified pine wood by in-situ polymerization of styrene. J Wood Chem Technol 40(5):294–305. https://doi.org/10.1080/02773813.2020.1786127

Keplinger T, Cabane E, Chanana M, Hass P, Merk V, Gierlinger N, Burgert I (2015) A versatile strategy for grafting polymers to wood cell walls. Acta Biomater 11:256–263. https://doi.org/10.1016/j.actbio.2014.09.016

Li X, Wang D, Zhao L, Hou X, Liu L, Feng B, Li M, Zheng P, Zhao X, Wei S (2021) UV LED curable epoxy soybean-oil-based waterborne PUA resin for wood coatings. Prog Org Coat 151:105942

Zaborniak I, Macior A, Chmielarz P, Smenda J, Wolski K (2021) Hydrophobic modification of fir wood surface via low ppm ATRP strategy. Polymer 228:123942

Montanari C, Olsen P, Berglund LA (2021) Sustainable wood nanotechnologies for wood composites processed by in-situ polymerization. Front Chem 9:483

Noel M, Fredon E, Mougel E, Masson D, Masson E, Delmotte L (2009) Lactic acid/wood-based composite material. Part 1: synthesis and characterization. Bioresour Technol 100(20):4711–4716. https://doi.org/10.1016/j.biortech.2009.04.040

Noel M, Mougel E, Fredon E, Masson D, Masson E (2009) Lactic acid/wood-based composite material. Part 2: physical and mechanical performance. Bioresour Technol 100(20):4717–4722. https://doi.org/10.1016/j.biortech.2009.04.042

Noel M, Grigsby WJ, Volkmer T (2015) Evaluating the extent of bio-polyester polymerization in solid wood by thermogravimetric analysis. J Wood Chem Technol 35(5):325–336. https://doi.org/10.1080/02773813.2014.962154

Ermeydan MA, Cabane E, Hass P, Koetz J, Burgert I (2014) Fully biodegradable modification of wood for improvement of dimensional stability and water absorption properties by poly(ε-Caprolactone) grafting into the cell walls. Green Chem 16(6):3313. https://doi.org/10.1039/c4gc00194j

Ermeydan MA, Babacan M, Tomak ED (2021) Poly(ε-caprolactone) grafting into scots pine wood: improvement on the dimensional stability, weathering and decay resistance. Cellulose 28(9):5827–5841. https://doi.org/10.1007/s10570-021-03895-7

Dong Y, Wang K, Yan Y, Zhang S, Li J (2016) Grafting polyethylene glycol dicrylate (PEGDA) to cell walls of poplar wood in two steps for improving dimensional stability and durability of the wood polymer composite. Holzforschung 70(10):919–926. https://doi.org/10.1515/hf-2015-0239

Jeremic D, Cooper P, Brodersen P (2007) Penetration of poly(ethylene glycol) into wood cell walls of red pine. Holzforschung 61(3):272–278. https://doi.org/10.1515/HF.2007.068

Trey SM, Netrval J, Berglund L, Johansson M (2010) Electron-beam-initiated polymerization of poly(ethylene glycol)-based wood impregnants. ACS Appl Mater Interfaces 2(11):3352–3362. https://doi.org/10.1021/am100778q

Ermeydan MA (2018) Modification of spruce wood by UV-crosslinked PEG hydrogels inside wood cell walls. React Funct Polym 131:100–106. https://doi.org/10.1016/j.reactfunctpolym.2018.07.013

Cambazoglu M, Tomak ED, Ermeydan MA (2022) Natural weathering of spruce wood chemically modified by re-used ε-caprolactone solution. Color Technol. https://doi.org/10.1111/cote.12645

Ermeydan MA, Cambazoğlu M, Tomak ED (2022) A methodological approach to ε-caprolactone modification of wood. J Wood Chem Technol 42(4):286–296. https://doi.org/10.1080/02773813.2022.2085747

Ermeydan MA, Kartal ZN, Tomak ED (2019) Effect of process variations of polycaprolactone modification on wood durability, dimensional stability and boron leaching. Holzforschung 73(9):847–858. https://doi.org/10.1515/hf-2018-0231

CEN EN 113-1 (2020) Durability of wood and wood-based products-Test method against wood destroying basidiomycetes-Part 1: Assessment of biocidal efficacy of wood preservatives. European Committee For Standardization, Brussels

ASTM D 1413 (2007) Standard test method for wood preservatives by laboratory soil-block cultures. ASTM International, West Conshohocken, Pennsylvania, USA

Elzein T, Nasser-Eddine M, Delaite C, Bistac S, Dumas P (2004) FTIR study of polycaprolactone chain organization at interfaces. J Colloid Interface Sci 273(2):381–387

Rowell RM (2012) Chemical modification of wood. In: Rowell RM (ed) Handbook of wood chemistry and composites, 2nd edn. CRC Press, Boca Raton, p 62

EN 84 (2020) Durability of wood and wood-based products. Accelerated ageing of treated wood prior to biological testing. Leaching procedure. European Committee For Standardization, Brussels

Irbe I, Andersons B, Chirkova J, Kallavus U, Andersone I, Faix O (2006) On the changes of pinewood (Pinus sylvestris L.) chemical composition and ultrastructure during the attack by brown-rot fungi Postia placenta and Coniophora puteana. Int Biodeterior Biodegrad 57(2):99–106

Raberg U, Hafren J (2008) Biodegradation and appearance of plastic treated solid wood. Int Biodeterior Biodegrad 62(2):210–213

Eichlerova I, Homolka L, Žifčáková L, Lisá L, Dobiášová P, Baldrian P (2015) Enzymatic systems involved in decomposition reflects the ecology and taxonomy of saprotrophic fungi. Fungal Ecol 13:10–22

Pathak VM (2017) Review on the current status of polymer degradation: a microbial approach. Bioresour Bioprocess 4(1):1–31

Shimao M (2001) Biodegradation of plastics. Curr Opin Biotechnol 12(3):242–247

Tan T (2005) The biodegradation of a synthetic co-polyester by hydrolase-producing microorganisms. Master’s Thesis, Department of Chemical Engineering, McGiII University Montréal, Québec, Canada

Moosavinejad SM, Madhoushi M, Vakili M, Rasouli D (2019) Evaluation of degradation in chemical compounds of wood in historical buildings using FT-IR and FT-Raman vibrational spectroscopy. Maderas-Cienc Tecnol 21(3):381–392. https://doi.org/10.4067/S0718

Zabel RA, Morrell JJ (1992) Wood deterioration agents. Wood Microbiology: Decay and its Prevention. Academic Press, San Diego, CL

Alfaro M, Majcherczyk A, Kües U, Ramírez L, Pisabarro AG (2020) Glucose counteracts wood dependent induction of lignocellulolytic enzyme secretion in monokaryon and dikaryon submerged cultures of the white-rot basidiomycete Pleurotus ostreatus. Sci Rep 10(1):1–10

Bari E, Nazarnezhad N, Kazemi SM, Ghanbary MAT, Mohebby B, Schmidt O, Clausen CA (2015) Comparison between degradation capabilities of the white rot fungi Pleurotus ostreatus and Trametes versicolor in beech wood. Int Biodeterior Biodegrad 104:231–237

Leviu L, Castro MA (1998) Anatomical study of the decay caused by the white-rot fungus Trametes trogii (Aphyllophorales) in wood of Salix and Populus. IAWA J 19(2):169–180

Schmidt O (2006) Wood and tree fungi: biology, damage, protection, and use. Springer-Verlag, Germany

Camarero S, Galletti GC, Martinez AT (1994) Preferential degradation of phenolic lignin units by two white rot fungi. Appl Environ Microbiol 60:4509–4516

Martínez AT, Speranza M, Ruiz-Dueñas FJ, Ferreira P, Camarero S, Guillén F, Martínez MJ, Gutiérrez A, del Río JC (2005) Biodegradation of lignocellulosics: microbial, chemical, and enzymatic aspects of the fungal attack of lignin. Int Microbiol 8:195–204

Boddy L, Frankland J, Van West P (2008) Ecology of saprotrophic basidiomycetes. Academic press Elsevier, UK

Kubicek CP (2013) Fungi and lignocellulosic biomass. John Wiley & Sons Inc, India

Leja K, Lewandowicz G (2010) Polymer biodegradation and biodegradable polymers–a review. Polish J Environ Stud 19:255–266

Hakala T (2007) Characterization of lignin-modifying enzymes of the selective white-rot fungus Physisporinus rivulosus. Doctoral dissertation, Department of Applied Chemistry and Microbiology, University of Helsinki, Finland

Nakagame S, Minagawa H, Motegi N (2022) Purification and characterization of class III lipase from a white-rot fungus Pleurotus ostreatus. Appl Biochem Biotechnol. https://doi.org/10.1007/s12010-022-04211-0

Piscitelli A, Tarallo V, Guarino L, Sannia G, Birolo L, Pezzella C (2017) New lipases by mining of Pleurotus ostreatus genome. PLoS ONE 12(9):e0185377

Singh D, Zeng J, Laskar DD, Deobald L, Hiscox WC, Chen S (2011) Investigation of wheat straw biodegradation by Phanerochaete chrysosporium. Biomass Bioenerg 35(3):1030–1040

Funding

This work was supported by the Bursa Technical University Research Funding (Grant no. BTU-BAP 211N001), Bursa, Türkiye.

Author information

Authors and Affiliations

Contributions

EDT: funding acquisition, project administration, conceptualization, methodology, investigation, data curation, visualization, writing–original draft. AC: methodology, investigation, data curation, visualization, writing–review & editing. MAE: conceptualization, data curation, visualization, writing–review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The manuscript was approved by all authors for publication.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tomak, E.D., Can, A. & Ermeydan, M.A. Biodegradability of Poly (Ɛ-Caprolactone) Modified Wood by Decaying Fungi. J Polym Environ 31, 4097–4111 (2023). https://doi.org/10.1007/s10924-023-02839-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-023-02839-5