Abstract

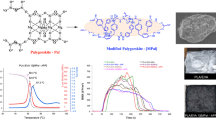

Poly (lactic acid) (PLA) is a bio-based polymer that is derived from renewable plant resources, such as corn, cassava, and other crops. It has a wide range of potential applications. However, currently, the PLA produced on an industrial scale is a thermoplastic polymer, which has poor mechanical strength and poor flame retardancy. These mediocre properties limit its potential uses in housings, structural interior of automotives, and packaging. The present study aimed to overcome the limitations of thermoplastic PLA by developing a synthesis route for producing thermosetting PLA with improved flame retardancy. The synthesis involved reacting 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) with itaconic acid (IA), polymerizing the product with pentaerythritol (PENTA) and lactic acid (LA) oligomer, and end-functionalizing with methacrylic anhydride (MAAH). The success of the synthesis was confirmed by analyzing the results of Fourier transform infrared spectroscopy (FTIR) and proton nuclear magnetic resonance (1 H NMR) analysis. The curing kinetics is elaborated by Kissinger’s and Crane’s methods with outstanding fitting. Increasing the LA-to-PENTA ratio results in higher molecular weight and larger arm length, leading to less crosslinking density and lower phosphorus content. A 10:1 LA-to-PENTA mole ratio contributes to UL-94 V1 ranking, 24% limit oxygen index (LOI), 183 kJ/g heat release capacity (HRC), and 21.4 kJ/g total heat release (THR) indicating the admirable flame retardancy. The development of flame-retardant thermosetting PLA could be a significant step forward in expanding its potential applications and improving its properties.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Kim Y-h, Murakami R-i, Park S-j (2021) Advanced Composites Engineering and its Nano-bridging Technology. Applied Research For Polymer Composites And Nanocomposites, World Scientific

Summerscales J (2021) A review of bast fibres and their composites: part 4 ~ organisms and enzyme processes. Compos Part A: Appl Sci Manufac 140:106149

Tavares TD, Antunes JC, Ferreira F, Felgueiras HP (2020) Biofunctionalization of natural fiber-reinforced biocomposites for biomedical applications. Biomolecules 10(1):148

Zhang L, Li Z, Pan Y-T, Yáñez AP, Hu S, Zhang X-Q, Wang R, Wang D-Y (2018) Polydopamine induced natural fiber surface functionalization: a way towards flame retardancy of flax/poly (lactic acid) biocomposites. Compos Part B: Eng 154:56–63

Saba N, Tahir PM, Jawaid M (2014) A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 6(8):2247–2273

Kuang X, Guo E, Chen K, Qi HJ (2019) Extraction of biolubricant via chemical recycling of thermosetting polymers. ACS Sustain Chem Eng 7(7):6880–6888

Babu RP, O’connor K, Seeram R (2013) Current progress on bio-based polymers and their future trends. Prog Biomater 2(1):1–16

Bhardwaj R, Mohanty AK (2007) Advances in the properties of polylactides based materials: a review. J Biobased Mater Bioenergy 1(2):191–209

Zhao X, Li K, Wang Y, Tekinalp H, Larsen G, Rasmussen D, Ginder RS, Wang L, Gardner DJ, Tajvidi M (2020) High-strength polylactic acid (PLA) biocomposites reinforced by epoxy-modified pine fibers. ACS Sustain Chem Eng 8(35):13236–13247

Jia Y-W, Zhao X, Fu T, Li D-F, Guo Y, Wang X-L, Wang Y-Z (2020) Synergy effect between quaternary phosphonium ionic liquid and ammonium polyphosphate toward flame retardant PLA with improved toughness. Compos Part B: Eng 197:108192

Gardella L, Calabrese M, Monticelli O (2014) PLA maleation: an easy and effective method to modify the properties of PLA/PCL immiscible blends. Colloid Polym Sci 292(9):2391–2398

Jiang P, Zhang S, Bourbigot S, Chen Z, Duquesne S, Casetta M (2019) Surface grafting of sepiolite with a phosphaphenanthrene derivative and its flame-retardant mechanism on PLA nanocomposites. Polym Degrad Stab 165:68–79

Yeo JCC, Muiruri JK, Tan BH, Thitsartarn W, Kong J, Zhang X, Li Z, He C (2018) Biodegradable PHB-rubber copolymer toughened PLA green composites with ultrahigh extensibility. ACS Sustain Chem Eng 6(11):15517–15527

Quirino RL, Monroe K, Fleischer CH III, Biswas E, Kessler MR (2021) Thermosetting polymers from renewable sources. Polym Int 70(2):167–180

Kaczmarek H, Nowicki M, Vuković-Kwiatkowska I, Nowakowska S (2013) Crosslinked blends of poly (lactic acid) and polyacrylates: AFM, DSC and XRD studies. J Polym Res 20(3):1–12

Gürler N, Paşa S, Temel H (2021) Silane doped biodegradable starch-PLA bilayer films for food packaging applications: mechanical, thermal, barrier and biodegradability properties. J Taiwan Inst Chem Eng 123:261–271

Åkesson D, Skrifvars M, Seppälä J, Turunen M, Martinelli A, Matic A (2010) Synthesis and characterization of a lactic acid-based thermoset resin suitable for structural composites and coatings. J Appl Polym Sci 115(1):480–486

Chang S, Zeng C, Li J, Ren J (2012) Synthesis of polylactide-based thermoset resin and its curing kinetics. Polym Int 61(10):1492–1502

Wan J, Gan B, Li C, Molina-Aldareguia J, Li Z, Wang X, Wang D-Y (2015) A novel biobased epoxy resin with high mechanical stiffness and low flammability: synthesis, characterization and properties. J Mater Chem A 3(43):21907–21921

Xiong Z, Zhang Y, Du X, Song P, Fang Z (2019) Green and scalable fabrication of core–shell biobased flame retardants for reducing flammability of polylactic acid. ACS Sustain Chem Eng 7(9):8954–8963

Attia NF, Saleh BK (2020) Novel synthesis of renewable and green flame-retardant, antibacterial and reinforcement material for styrene–butadiene rubber nanocomposites. J Therm Anal Calorim 139(3):1817–1827

Attia NF, Hegazi EM, Abdelmageed A (2018) Smart modification of inorganic fibers and flammability mechanical and radiation shielding properties of their rubber composites. J Therm Anal Calorim 132(3):1567–1578

Xia L, Lv Y, Miao Z, Luo L, Luo W, Xu Y, Yuan C, Zeng B, Dai L (2022) A flame retardant fabric nanocoating based on nanocarbon black particles@ polymer composite and its fire-alarm application. Chem Eng J 433:133501

Xia L, Miao Z, Dai J, Zhu A, Xu H, Zhong J, Chen Y, Luo W, Xu Y, Yuan C (2022) Facile fabrication of multifunctional flame retardant epoxy resin by a core–shell structural AgNC@ boronate polymer. Chem Eng J 438:135402

Xia L, Dai J, Wang X, Xue M, Xu Y, Yuan C, Dai L (2022) Facile fabrication of multifunctional cotton fabric by AgNC@ boronate polymer/crosslinked chitosan. Carbohydr Polym 288:119384

Xia L, Wang X, Guo C, Miao Z, Dai J, Li D, Xu Y, Luo W, Yuan C, Zeng B (2022) Core-shell structured ZnO nanorods enable flame-retardant, smoke suppressed and mechanically reinforced epoxy resin composites. Compos Commun 35:101311

Xia L, Wang X, Ren T, Luo L, Li D, Dai J, Xu Y, Yuan C, Zeng B, Dai L (2022) Green construction of multi-functional fire resistant epoxy resins based on boron nitride with core-shell structure. Polym Degrad Stab 203:110059

Attia NF, Abd El-Aal N, Hassan M (2016) Facile synthesis of graphene sheets decorated nanoparticles and flammability of their polymer nanocomposites. Polym Degrad Stab 126:65–74

Tawiah B, Yu B, Fei B (2018) Advances in flame retardant poly (lactic acid). Polymers 10(8):876

Liu T, Jing J, Zhang Y, Fang Z (2018) Synthesis of a novel polyphosphate and its application with APP in flame retardant PLA. RSC Adv 8(8):4483–4493

Chen C, Gu X, Jin X, Sun J, Zhang S (2017) The effect of chitosan on the flammability and thermal stability of polylactic acid/ammonium polyphosphate biocomposites. Carbohydr Polym 157:1586

Li Y, Sun XS (2010) Preparation and characterization of polymer – inorganic nanocomposites by in situ melt polycondensation of l-lactic acid and surface-hydroxylated mgo. Biomacromolecules 11(7):1847–1855

Wang D-Y, Song Y-P, Lin L, Wang X-L, Wang Y-Z (2011) A novel phosphorus-containing poly (lactic acid) toward its flame retardation. Polymer 52(2):233–238

Wen X, Liu Z, Li Z, Zhang J, Wang D-Y, Szymańska K, Chen X, Mijowska E, Tang T (2020) Constructing multifunctional nanofiller with reactive interface in PLA/CB-g-DOPO composites for simultaneously improving flame retardancy, electrical conductivity and mechanical properties. Compos Sci Technol 188:107988

Petit T, Puskar L (2018) FTIR spectroscopy of nanodiamonds: methods and interpretation. Diam Relat Mater 89:52–66

Van Hove AH, Wilson BD, Benoit DS (2013) Microwave-assisted functionalization of poly (ethylene glycol) and on-resin peptides for use in chain polymerizations and hydrogel formation. JoVE (Journal of Visualized Experiments) 80:e50890

Chang SK, Zeng C, Li J, Ren J (2012) Synthesis of polylactide-based thermoset resin and its curing kinetics. Polym Int 61(10):1492–1502

Matsuda H, Goto S, DIFFERENTIAL THERMAL-ANALYSIS OF REACTION-KINETICS IN (1984) PSEUDO-ISOTHERMAL STATE.1. SIMPLE REACTION. Can J Chem Eng 62(1):103–107

Tranchida D, Gloger D, Gahleitner M (2017) A critical approach to the Kissinger analysis for studying non-isothermal crystallization of polymers. J Therm Anal Calorim 129(2):1057–1064

Peyser P, Bascom WD, ANALYSIS OF CURING KINETICS IN POLYMER COMPOSITES - COMMENT (1975) J Polym Sci Part C-Polymer Lett 13(3):129–130

Acknowledgements

This research was supported by National Natural Science Foundation of China (11872279, 12172258 and 11625210).

Author information

Authors and Affiliations

Contributions

Zixuan Chen: Data interpretation, Writing and Revising. Fei Sun: Experiment, Data collection. Tao Yu: Conceptualization, Methodology, Supervision. Huakun Zhao, Weidong Yang, Qian Li, Yan Li: Reviewing, Validation.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Z., Sun, F., Zhao, H. et al. Development of Flame-retardant Thermosetting Poly (Lactic acid) (PLA) and Its Curing Kinetics. J Polym Environ 31, 3573–3584 (2023). https://doi.org/10.1007/s10924-023-02834-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-023-02834-w