Abstract

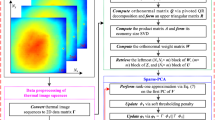

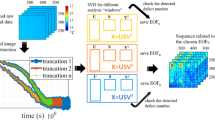

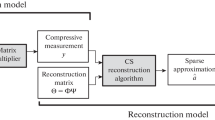

Statistical methods, such as Principal component thermography (PCT) and Sparse Principal component thermography (SPCT) have been widely used for signal enhancement of subsurface defects in pulsed thermographic (PT) detection of composite materials. However, PCT and SPCT mainly focus on the temporal variation of thermographic data while leaving the structural variation un-modeled. In this paper, a method of sparse structural principal component thermography (S2PCT) is proposed. In S2PCT, the operation of shift-sampling is first conducted to augment the original thermographic matrix and capture the structural relationships inside the original thermal images. After that, the sparse trick is applied to extract features for defects and reduce signals of noise and non-uniform background. In the case study, two carbon fiber reinforced polymer (CFRP) specimens are detected with PT and the proposed S2PCT is evaluated for visualization enhancing purpose. The results of the experiments have revealed the proposed method helps to highlight the defect signals during the augmentation process, thus showing higher flexibility in reducing interference from background signals. As a conclusion, compared to the original statistical methods, S2PCT has better performance in visualization enhancing of defects.

Similar content being viewed by others

References

Moskovchenk, A.I., Vavilov, V.P., Bernegger, R., Maierhofer, C., Chulko, A.O.: Detecting delaminations in semitransparent glass fiber composite by using pulsed infrared thermography. J. Nondestruct. Eval. 39(3), 1–10 (2020). https://doi.org/10.1007/s10921-020-00717-x

Tran, G.H., Huh, J., Kang, C., Lee, B.Y., Kim, I.T., Ahn, J.H.: Detectability of subsurface defects with different width-to-depth ratios in concrete structures using pulsed thermography. J. Nondestruct. Eval. 37(2), 32 (2018). https://doi.org/10.1007/s10921-018-0489-x

Liu, L., Wang, L., Guo, C., Mei, H., Zhao, C.: Detecting defects in porcelain postinsulator coated with room temperature vulcanized silicone rubber by Pulsed Thermography. IEEE Trans. Instrum. Meas. 68(1), 225–233 (2019). https://doi.org/10.1109/TIM.2018.2834157

Burghold, E.M., Frekers, Y., Kneer, R.: Transient contact heat transfer measurements based on high-speed IR-thermography. Int. J. Therm. Sci. 115(1), 169–175 (2017). https://doi.org/10.1016/j.ijthermalsci.2017.01.019

Plasser, H., Günther, M., Gregor, T., Günther, H., Major, Z.: Photothermal porosity estimation in CFRP by the time-of-flight of virtual waves. J. Nondestruct. Eval. (2020). https://doi.org/10.1007/s10921-020-00722-0

Sirikham, A., Zhao, Y.F., Nezhad, H.Y., Du, W.X., Roy, R.: Estimation of damage thickness in fiber-reinforced composites using pulsed thermography. IEEE Trans. Ind. Inf. 15(1), 445–453 (2019). https://doi.org/10.1109/TII.2018.2878758

Saeed, N., Abdulrahman, Y., Amer, S., Omar, M.A.: Experimentally validated defect depth estimation using artificial neural network in pulsed thermography. Infrared Phys. Technol. 98, 192–200 (2019). https://doi.org/10.1016/j.infrared.2019.03.014

Wang, F., Wang, Y., Liu, J., Wang, Y.: The feature recognition of CFRP subsurface defects using low-energy chirp-pulsed radar thermography. IEEE Trans. Ind. Inf. 16(8), 5160–5168 (2020). https://doi.org/10.1109/TII.2019.2954718

Zheng, K.Y., Chang, Y.S., Wang, K.H., Yao, Y.: Improved non-destructive testing of carbon fiber reinforced polymer (CFRP) composites using pulsed thermograph. Polym. Test. 46, 26–32 (2015). https://doi.org/10.1016/j.polymertesting.2015.06.016

Usamentiaga, R., Venegas, P., Guerediaga, J., Vega, L., Lopez, I.: Automatic detection of impact damage in carbon fiber composites using active thermography. Infrared Phys. Technol. 58, 36–46 (2013). https://doi.org/10.1016/j.infrared.2013.01.004

Barbara, S., Unnikrishnakurup, S., Balasubramaniam, K.: Background removal methods in thermographic non-destructive testing of composite materials. In: NDE 2014 (2014)

Hiasa, S., Birgul, R., Catbas, F.N.: Effect of defect size on subsurface defect detectability and defect depth estimation for concrete structures by infrared thermography. J. Nondestruct. Eval. 36(3), 57 (2017). https://doi.org/10.1007/s10921-017-0435-3

Balageas, D.L., Roche, J.M., Leroy, F.H., Liu, W.M., Gorhach, A.M.: The thermographic signal reconstruction method: a powerful tool for the enhancement of transient thermographic images. Biocybernet. Biomed. Eng. 35(1), 1–9 (2015). https://doi.org/10.1016/j.bbe.2014.07.002

Benitez, H., Castanedo, C.I., Bendada, A.: Modified differential absolute contrast using thermal quadrupoles for the nondestructive testing of finite thickness specimens by infrared thermography. In: Conference on Electrical and Computer Engineering IEEE (2006)

Guo, X.W., Liu, Y.T.: Pulsed phase thermography and its application in the NDT of composite materials. J. Beijing Univ. Aeronaut Astronaut 31(10), 1049–1053 (2005). https://doi.org/10.1016/j.cej.2014.10.016

Gry, S.: Filtered thermal contrast based technique for testing of material by infrared thermography. Opto-Electron. Rev. 19(2), 234–241 (2011). https://doi.org/10.2478/s11992-011-0009-3

Giron, R., Andres, D., Correa, H.L.: Background thermal compensation by filtering for contrast enhancement in active thermography. J. Nondestruct. Eval. 35(1), 1–11 (2016). https://doi.org/10.1007/s10921-016-0336-x

Rajic, N.: Principal component thermography for flaw contrast enhancement and flaw depth characterisation in composite structures. Compos. Struct. 58(4), 521–528 (2002). https://doi.org/10.1016/S0263-8223(02)00161-7

Zheng, K.Y., Chang, Y.S., Yao, Y.: Defect detection in CFRP structures using pulsed thermographic data enhanced by penalized least squares methods. Compos. B Eng. 79(9), 351–358 (2015). https://doi.org/10.1016/j.compositesb.2015.04.049

Liu, Y., Wu, Y., Liu, K.X., Wen, H.L., Yao, Y., et al.: Independent component thermography for non-destructive testing of defects in polymer composites. Meas. Sci. Technol. (2019). https://doi.org/10.1088/1361-6501/ab02db

Liu, Y., Liu, K., Yang, J., Yao, Y.: Spatial-neighborhood manifold learning for nondestructive testing of defects in polymer composites. IEEE Trans. Ind. Inf. 99, 1–1 (2019). https://doi.org/10.1109/TII.2019.2949358

Zhou, D., Chi, M.: Pulse-coupled neural network and its optimization for segmentation of electrical faults with infrared thermography. Appl. Soft Comput. (2019). https://doi.org/10.1016/j.asoc.2018.10.056

Wu, J.Y., Sfarra, S., Yao, Y.: Sparse principal component thermography for subsurface defect detection in composite products. IEEE Trans. Ind. Inf. 99(3), 1 (2018). https://doi.org/10.1109/TII.2018.2817520

Wen, C.M., Sfarra, S., Gargiulo, G., Yao, Y.: Edge-group sparse principal component thermography for defect detection in an ancient marquetry sample. Proceedings 27(1), 34 (2019)

Liu, K., Li, Y., Yang, J., Liu, Y., Yao, Y.: Generative principal component thermography for enhanced defect detection and analysis. IEEE Trans. Instrum. Meas. 99, 1–1 (2020). https://doi.org/10.1109/TIM.2020.2992873

Jie, J., Dai, S., Hou, B., Zhang, M., Zhou, L.: Defect detection in composite products based on sparse moving window principal component thermography. Adv. Polym. Technol. 2020(2), 1–12 (2020). https://doi.org/10.1155/2020/4682689

Abdi, H., Williams, L.J.: Principal component analysis. Comput. Stat. 2(4), 433–459 (2002). https://doi.org/10.2307/3172953

Zou, H., Hastie, T.: Regularization and variable selection via the elastic net. J. R. Stat. Soc. B 67(2), 301–320 (2005). https://doi.org/10.1111/j.1467-9868.2005.00527.x

Zou, H., Hastie, T., Tibshirani, R.: Sparse principal component analysis. J. R. Stat. Soc. Ser. B 15, 265–286 (2006). https://doi.org/10.1198/106186006X113430

Liu, Q., Mo, Z.W., Wu, Y.H., Ma, J.B., Tsui, G., Hui, D.: Crush response of CFRP square tube filled with aluminum honeycomb. Compos. Part B Eng. 98, 406–414 (2016). https://doi.org/10.1016/j.compositesb.2016.05.048

Taljsten, B., Carolin, A., Nordin, H.: Concrete structures strengthened with near surface mounted reinforcement of CFRP. Adv. Struct. Eng. 6(3), 201–213 (2016). https://doi.org/10.1260/136943303322419223

Liu, S.F., Cheng, X.Q., Zhang, Q., Zhang, J.: An investigation of hygrothermal effects on adhesive materials and double lap shear joints of CFRP composite laminates. Compos. Part B Eng. 91(15), 431–440 (2016). https://doi.org/10.1016/j.compositesb.2016.01.051

Artner, G., Langwieser, R., Mecklenbrauker, C.F.: Concealed CFRP vehicle chassis antenna cavity. IEEE Antennas Wirel. Propag. Lett. 16, 1415–1418 (2016). https://doi.org/10.1109/LAWP.2016.2637560

Feng, B., Pasadas, D.J., Ribeiro, A.L., Ramos, H.G.: Locating defects in anisotropic CFRP plates using ToF-based probability matrix and neural networks. IEEE Trans. Instrum. Meas. 68(5), 1252–1260 (2019). https://doi.org/10.1109/TIM.2019.2893701

Moskovchenko, A.I., Vavilov, V.P., Chulkov, A.O.: Comparing the efficiency of defect depth characterization algorithms in the inspection of CFRP by using one-sided pulsed thermal NDT. Infrared Phys. Technol. 107, 103289 (2020). https://doi.org/10.1016/j.infrared.2020.103289

Foudazi, A., Edwards, C.A., Ghasr, M.T., Donnell, K.M.: Active microwave thermography for defect detection of CFRP-strengthened cement-based materials. IEEE Trans. Instrum. Meas. 65(11), 2612–2620 (2016). https://doi.org/10.1109/TIM.2016.2596080

Acknowledgements

This work has been supported by Zhejiang Provincial Natural Science Foundation of China (LY19F030003), Educational Commission Research Program of Zhejiang Province (Y202044842) and National Natural Science Foundation of China (62003306)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, W., Hou, B., Wang, Y. et al. Sparse Structural Principal Component Thermography for Defect Signal Enhancement in Subsurface Defects Detection of Composite Materials. J Nondestruct Eval 41, 8 (2022). https://doi.org/10.1007/s10921-021-00838-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-021-00838-x