Abstract

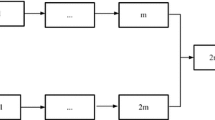

In production scheduling with assembly operations, after processing jobs in the first stage, in the second one, assembly operations are performed. Making these two decisions is very important because optimizing the scheduling of jobs in one stage of production without considering the parameters and capacities of the next stage in the assembly stage will not guarantee the shortening of the total production time and the optimal use of machines. In this study, a mathematical model has been developed for a flexible job-shop scheduling problem with assembly operation. In the first stage, the scheduling is performed according to the job release times and machine breakdowns. Then, jobs enter the assembly stage in a flow-shop environment, and finally, the assembled products are sent to customers in batches. Here, three objective functions must be minimized simultaneously, including (i) the costs of tardiness, earliness, fuzzy transportation, and makespan, (ii) the fuzzy emission of CO2, and (iii) the noise pollution. In this research, after linearization of the proposed model, using the ε-constraint methods and Lagrangian relaxation algorithm, its complexity was reduced. The comparison results of the proposed algorithm and the model that was solved with the GAMS show that the Lagrangian relaxation algorithm is quite efficient.

Similar content being viewed by others

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Afsar S, Palacios J, Puente J, Vela RC, González-Rodríguez I (2022) Multi-objective enhanced memetic algorithm for green job shop scheduling with uncertain times. Swarm Evol Comput 68:1–14

Baptiste P, Flamini M, Sourd F (2008) Lagrange bounds for just-in-time job-shop scheduling. Comput Oper Res 35(3):906–915

Chen H, Luh PB (2003) An alternative framework to Lagrangian relaxation approach for job shop scheduling. Eur J Oper Res 149(3):499–512

Du Y, Li J-Q, Chen X-L, Duan P-Y, Pan Q-K (2022) Knowledge-based reinforcement learning and estimation of distribution algorithm for flexible job shop scheduling problem. IEEE Trans Emerg Topics Comput Intell. https://doi.org/10.1109/TETCI.2022.3145706

Esfahani MS, Heidary MH, Jaberi S (2014) A simulated annealing algorithm for fuzzy reliability optimization model in series-parallel and standby systems. Int J Ind Eng 24(4):413–422

Fattahi P, Daneshamooz F (2017) Hybrid algorithms for job shop scheduling problem with lot streaming and a parallel assembly stage. J Ind Syst Eng 10(3):92–112

Glover F, Woolsey E (1974) Converting the 0–1 polynomial programming problem to a 0–1 linear program. Oper Res 22(1):180–182

Gong G, Deng Q, Gong X, Liu W, Ren Q (2018) A new double flexible job-shop scheduling problem integrating processing time, green production, and human factor indicators. J Clean Prod 174:560–576

Held M, Carp R (1971) The travelling salesman problem and minimum spanning trees: part II. Math Prog 1:6–25

Hosseini SMH (2019) Modelling and solving the job shop scheduling Problem followed by an assembly stage considering maintenance operations and access restrictions to machines. J Optim Ind Eng 12(1):63–78

Jeong I-J, Yim S-B (2009) A job shop distributed scheduling based on Lagrangian relaxation to minimise total completion time. Int J Prod Res 47(24):6783–6805

Jiang T, Zhang C, Sun Q (2019) Green job shop scheduling problem with discrete whale optimization algorithm. IEEE Access 7:1–14

Jiang T, Zhu H, Deng G (2020) Improved African buffalo optimization algorithm for the green flexible job shop scheduling problem considering energy consumption. J Intell Fuzzy Syst 38:4573–4589

Jiang Z, Le Z (2014) Study on multi-objective flexible job-shop scheduling problem considering energy consumption. J Ind Eng Manag (JIEM) 7(3):589–604

Kaizhou G (2015) Meta-heuristics for scheduling flexible job-shop problems with constraints. Phd, School of Electrical and Electronic Engineering, Nanyang Technological University, Nanyang

Kaskavelis CA, Caramanis MC (1998) Efficient Lagrangian relaxation algorithms for industry size job-shop scheduling problems. IIE Trans 30(11):1085–1097

Lei D (2010) A genetic algorithm for flexible job-shop scheduling with fuzzy processing time. Int J Prod Res 48(10):2995–3013

Li M, Lei D (2021) An imperialist competitive algorithm with feedback for energy-efficient flexible job shop scheduling with transportation and sequence-dependent setup times. Eng Appl Artif Intell 103:1–13

Li J-Q, Chen X-L, Duan P-Y, Mou J-H (2022) KMOEA: a knowledge-based multiobjective algorithm for distributed hybrid flow shop in a prefabricated system. IEEE Trans Industr Inf 18(8):5318–5329

Lu Y, Jiang T (2019) Bi-population based discrete bat algorithm for the low-carbon job shop scheduling problem. IEEE Access 7:14513–14522

Lu C, Zhang B, Gao L, Yi J, Mou J (2021) A knowledge-based multi-objective memetic algorithm for green job shop scheduling with variable machining speeds. IEEE Syst J 16(1):1–12

Luh PB, Zhao X, Wang Y, Thakur LS (2000) Lagrangian relaxation neural networks for job shop scheduling. IEEE Trans Robot Autom 16(1):78–88

Mokhtari H, Hasani A (2017) A multi-objective model for cleaner production-transportation planning in manufacturing plants via fuzzy goal programming. J Manuf Syst 44:230–242

Namazi A, Golmakani H (2013) Multiple route job shop scheduling with maintenance activity constraints. IJIEPM 23(4):459–470

Norouzi N, Tavakkoli-Moghaddam R, Ghazanfari M, Alinaghian M, Salamatbakhsh A (2012) A new multi-objective competitive open vehicle routing problem solved by particle swarm optimization. Netw Spat Econ 12(4):609–633

Rasi R (2021) Optimization of the multi-objective flexible job shop scheduling model by applying NSGAII and NRGA algorithms. J Ind Eng Manag Stud 8(1):45–71

Rakovitis N, Li D, Zhang N, Li J, Zhang L, Xiao X (2022) Novel approach to energy-efficient flexible job- shop scheduling problems. Energy 238:1–16

Ren W, Wen J, Yan Y, Hu Y, Guan Y, Li J (2021) Multi-objective optimisation for energy-aware flexible job-shop scheduling problem with assembly operations. Int J Prod Res 59(23):1–17

Sarkodie SA, Strezov V (2018) Assessment of contribution of Australia’s energy production to CO2 emissions and environmental degradation using statistical dynamic approach. Sci Total Environ 639:888–899

Shen L, Dauzère-Pérès S, Neufeld JS (2018) Solving the flexible job shop scheduling problem with sequence-dependent setup times. Eur J Oper Res 265(2):503–516

Shi F, Zhao S, Meng Y (2020) Hybrid algorithm based on improved extended shifting bottleneck procedure and GA for assembly job shop scheduling problem. Int J Prod Res 58(9):2604–2625

Sun L, Gen M, Li H (2019) A hybrid cooperative co-evolution algorithm for fuzzy flexible job-shop scheduling. IEEE Trans Fuzzy Syst 27(5):1–16

Parchami Afra A, Behnamian J (2021) Lagrangian heuristic algorithm for green multi-product production routing problem with reverse logistics and remanufacturing. J Manuf Syst 58(A):33–43

Thomalla C (2001) Job shop scheduling with alternative process plans. Int J Prod Econ 74:125–134

Wang H, Jiang Z, Wang Y, Zhang H, Wang Y (2018) A two-stage optimization method for energy-saving flexible job-shop scheduling based on energy dynamic characterization. J Clean Prod 188:575–588

Wang J, Luh PB (1997) Scheduling job shops with batch machines using the Lagrangian relaxation technique. Eur J Control 3(4):268–279

Wang H, Sheng B, Lu Q, Yin X, Zhao X, Lu X, Luo R, Fu G (2021) A novel multi-objective optimization algorithm for the integrated scheduling of flexible job shops considering preventive maintenance activities and transportation processes. Soft Comput 25:2863–2889

Wang Y, van Stein B, Bäck T, Emmerich M (2020) A tailored NSGA-III for multi-objective flexible job shop scheduling. In: 2020 IEEE symposium series on computational intelligence, pp 2746–2753

Wu X, Liu X, Zhao N (2019) An improved differential evolution algorithm for solving a distributed assembly flexible job shop scheduling problem. Memetic Comput 11(4):335–355

Zadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353

Zhang L, Xu X, Tao L (2013) Some similarity measures for triangular fuzzy number and their applications in multiple criteria group decision-making. J Appl Math 3:1–7

Zhang S, Wang S (2018) Flexible assembly job-shop scheduling with sequence-dependent setup times and part sharing in a dynamic environment: constraint programming model, mixed-integer programming model, and dispatching rules. IEEE Trans Eng Manag 65(3):487–504

Zhang H, Xu G, Pan R, Ge H (2021) A novel heuristic method for the energy-efficient flexible job-shop scheduling problem with sequence-dependent set-up and transportation time. Eng Optim 54:1646–1667

Zhu H, Deng Q, Zhang L, Hu X, Lin W (2020) Low carbon flexible job shop scheduling problem considering worker learning using a memetic algorithm. Optim Eng 21(2):1–26

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hajibabaei, M., Behnamian, J. Fuzzy cleaner production in assembly flexible job-shop scheduling with machine breakdown and batch transportation: Lagrangian relaxation. J Comb Optim 45, 112 (2023). https://doi.org/10.1007/s10878-023-01046-1

Accepted:

Published:

DOI: https://doi.org/10.1007/s10878-023-01046-1