Abstract

Natural cartilage surfaces were macroscopically curved with multi-porous viscoelastic biologic materials with extremely high water, but whether curved surface configuration could play an important role on the contact and frictional properties of natural cartilages fails to be completely understood up to now. In this current study, cartilage samples came from the 18–24 month-old bovine femora. Contact characteristic and frictional properties at two cartilage configurations were investigated using the UMT-2 testing rig and the five-point sliding average method would be adopted to analyze these tested data. These results indicated the surface displacement was extremely associated with the plate cartilage surface and seemed to be a representative of cartilage surface configuration. The summit of the surface load lagged behind that of the surface displacement at the same condition. Coefficient of friction showed obviously different variation with time at two cartilage surface configurations due to the fact that these two surface displacements had different amplitudes and opposite directions as a function of the sliding length. Therefore, surface configuration played the main role on these variables of contact displacement, contact load and coefficient of friction due to the direction and magnitude of the surface displacement while applied load and sliding velocity had a secondary role.

Graphical Abstract

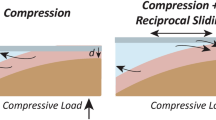

Natural cartilage surfaces were macroscopically curved with multi-porous viscoelastic biologic materials with extremely high water, but whether curved surface configuration could play an important role on the contact and frictional properties of natural cartilages fails to be completely understood up to now. In this study, two different cartilage configurations were adopted to investigate natural cartilage properties, and the five-point sliding average method would be used to analyze these tested data. These results indicated the contact displacement was consisted of cartilage deformation and surface displacement while contact load was composed of steady load and surface load (as shown in the figure, panels (a) and (b)). Surface displacement was greatly associated with the plate cartilage surface and seemed to be a representative of cartilage surface configuration. These two surface displacements had different amplitudes and opposite directions as a function of the sliding length (as shown in panel (c)). The summit of the surface load lagged behind that of the surface displacement at the same condition (as shown in panel (d)). Surface displacement and surface load in the contact characteristic of natural cartilages were extremely related with the cartilage configurations. and their correlation coefficients varied periodically with the moving time (as shown in panel (e)). Coefficient of friction showed obviously different variation with time (as shown in panel (f)). Therefore, surface configuration played the main role on these variables of contact displacement, contact load and coefficient of friction due to the direction and magnitude of the surface displacement while applied load and sliding velocity had a secondary role.  Variation in contact and frictional properties of natural cartilage at two different surface configurations (a) Contact displacement and its parts varied with time; (b) Contact load and its parts varied with time; (c) Surface displacement varied with the sliding length at two CPSTs; (d) Surface load and surface displacement varied with time; (e) Variation in the relation coefficient with the moving time; (f) Coefficient of friction varied with time at two CPSTs.

Variation in contact and frictional properties of natural cartilage at two different surface configurations (a) Contact displacement and its parts varied with time; (b) Contact load and its parts varied with time; (c) Surface displacement varied with the sliding length at two CPSTs; (d) Surface load and surface displacement varied with time; (e) Variation in the relation coefficient with the moving time; (f) Coefficient of friction varied with time at two CPSTs.

Similar content being viewed by others

References

Sakai N, Hagihara Y, Furusawa T, Hosoda N, Sawae Y, Murakami T. Analysis of biphasic lubrication of articular cartilage loaded by cylindrical indenter. Tribol Int. 2012;46:225–36.

Jin ZM, Dowson D. Bio-friction. Friction. 2013;1(2):100–13.

Swann DA, Silver FH, Slayter HS, Stafford W, Shore E. The molecular-structure and lubricating activity of lubricin isolated from bovine and human synovial-fluids. J Biochem. 1985;225:195–201.

Forster H, Fish J. The influence of loading time and lubricant on the friction of articular cartilage. Proc Inst Mech Eng. 1996;210:109–19.

Forster H, Fisher J. The influence of continuous sliding and subsequent surface wear on the friction of articular cartilage. Proc Inst Mech Eng H J Eng Med. 1999;213(H4):329–45.

Jin ZM, Pickard JE, Forster H, Ingham E, Fisher J. Frictional behavior of bovine articular cartilage. Biorheology. 2000;37(1-2):57–63.

Ateshian GA, Soltz MA, Mauck RL, Basalo IM, Hung CT, Lai WM. The role of osmotic pressure and tension-compression nonlinearity in the frictional response of articular cartilage. Transport Porous Med. 2003;50:5–33.

Krishnan R, Kopacz M, Ateshian GA. Experimental verification of the role of interstitial fluid pressurization in cartilage lubrication. J Ortho Res. 2004;22:565–70.

Krishnan R, Caligaris M, Mauck RL, Hung CT, Costa KD, Ateshian GA. Removal of the superficial zone of bovine articular cartilage does not increase its frictional coefficient. Osteoarthr Cartil. 2004;12(12):947–55.

Ozturk HE, Stoffel KK, Jones CF, Stachowiak GW. The effect of surface-active phospholipids on the lubrication of osteoarthritic sheep knee joints. Tribol Lett. 2004;16(4):283–9.

Naka MH, Hattori K, Ohashi T, Ikeuchi K. Evaluation of the effect of collagen network degradation on the frictional characteristics of articular cartilage using a simultaneous analysis of the contact condition. Clin Biomech. 2005;20(10):1111–8.

Naka MH, Morita Y, Keuchi KI. Influence of proteoglycan contents and of tissue hydration on the frictional characteristics of articular cartilage. Proc Inst Mech Eng H J Eng Med. 2005;219(H3):175–82.

Naka MH, Hattori K, Ikeuchi K. Evaluation of the superficial characteristics of articular cartilage using evanescent waves in the friction tests with intermittent sliding and loading. J Biomech. 2006;39(12):2164–70.

Katta J, Pawaskar S, Jin Z, Ingham E, Fisher J. Effect of load variation on the friction properties of articular cartilage. Proc I MECH E Part J J Eng Tribol. 2007;221:175–81.

Gleghorn JP, Bonassar LJ. Lubrication mode analysis of articular cartilage using Stribeck surfaces. J Biomech. 2008;41(9):1910–8.

Qian SH, Ge SR. Friction behavior of coupling motion for natural articular cartilage by reciprocating rotation. Chinese Sci Bull. 2009;54(4):576–83.

Bonnevie ED, Baro VJ, Wang L, Burris DL. In situ studies of cartilage microtribology: roles of speed and contact area. Tribol Lett. 2011;41(1):83–95.

Pan YS, Xiong DS, Gao F. Viscoelastic behavior of nano-hydroxyapatite reinforced poly(vinyl alcohol) gel biocomposites as an articular cartilage. J Mater Sci-Mater Med. 2008;19(5):1963–9.

Li F, Su YL, Wang JP, Wu G, Wang CT. Influence of dynamic load on friction behavior of human articular cartilage, stainless steel and polyvinyl alcohol hydrogel as artificial cartilage. J Mater Sci-Mater Med. 2010;21:147–54.

Mamada K, Fridrici V, Kosukegawa H, Kapsa P, Ohta M. Friction properties of poly(vinyl alcohol) hydrogel: effects of degree of polymerization and saponification value. Tribol Lett. 2011;42(2):241–51.

Kosukegawa H, Fridrici V, Kapsa P, Sutou Y, Adachi K, Ohta M. Friction properties of medical metallic alloys on soft tissue–mimicking poly(vinyl alcohol) hydrogel biomodel. Tribol Lett. 2013;51(3):311–21.

Shi Y, Xiong DS, Zhang JF. Effect of irradiation dose on mechanical and biotribological properties of PVA/PVP hydrogels as articular cartilage. Tribol Int. 2014;78:60–67.

Shokrgozar MA, Bonakdar S, Dehghan MM, Emami SH, Montazeri L, Azari S, Rabbani M. Biological evaluation of polyvinyl alcohol hydrogel crosslinked by polyurethane chain for cartilage tissue engineering in rabbit model. J Mater Sc-Mater Med. 2013;24(10):2449–60.

Parkes M, Myant C, Dini D, Cann P. Tribology-optimised silk protein hydrogels for articular cartilage repair. Tribol Int. 2015;89:9–18.

Murakami T, Sakai N, Yamaguchi T, Yarimitsu S, Nakashima K, Sawae Y, Suzuki A. Evaluation of a superior lubrication mechanism with biphasic hydrogels for artificial cartilage. Tribol Int. 2015;89:19–26.

Li F, Wang AM, Wang CT. Analysis of friction between articular cartilage and polyvinyl alcohol hydrogel artificial cartilage. J Mater Sci-Mater Med. 2016;27:87–8.

Caligaris M, Ateshian GA. Effects of sustained interstitial fluid pressurization under migrating contact area, and boundary lubrication by synovial fluid, on cartilage friction. Osteoarthr Cartil. 2008;16:1220–7.

Bostan L, Trunfio-Sfarghiu AM, Verestiuc L, Popa MI, Munteanu F, Rieu JP, Berthier Y. Mechanical and tribological properties of poly (hydroxyethyl methacrylate) hydrogels as articular cartilage substitutes. Tribol Int. 2012;46:215–24.

Maroudas A, Bullough P, Swanson SAV. The permeability of articular cartilage. J Bone Joint Surg. 1968;50b:166–77.

Wang J, Hu X. Application of MATLAB in the processing of vibrational signal. Beijing: China Water Power Press; 2006. p. 73–82.

Pickard J, Ingham E, Fisher J. Investigation into the effect of proteoglycan molecules on the tribological properties of cartilage joint tissues. Proc Inst Mech Eng J Eng Med. 2008;212(3):177–82.

Qian SH, Ge SR. The frictional coefficient of bovine knee articular cartilage. J Bionic Eng. 2006;3(2):79–85.

Wen SZ, Huang PT. 4th edn. Beijing: Tsinghua University Press; 2012. p. 282–4.

Acknowledgements

The work was financially sponsored by the Natural Science Foundation of Jiangsu Province (BK20161123) and the Foundation of Jiangsu Key Laboratory of Advanced Food Manufacturing Equipment and Technology(Jiangnan University)(FM201502) and Jiangsu Key Laboratory of Large Engineering Equipment Detection and Control (Xuzhou Institute of Technology) (JSKLEDC201504).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Qian, S., Zhang, L., Ni, Z.f. et al. Investigation of contact characteristics and frictional properties of natural articular cartilage at two different surface configurations. J Mater Sci: Mater Med 28, 84 (2017). https://doi.org/10.1007/s10856-017-5895-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-017-5895-6