Abstract

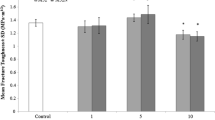

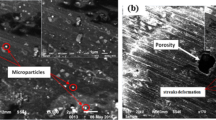

The initial composition of acrylic bone cement along with the mixing and delivery technique used can influence its final properties and therefore its clinical success in vivo. The polymerisation of acrylic bone cement is complex with a number of processes happening simultaneously. Acrylic bone cement mixing and delivery systems have undergone several design changes in their advancement, although the cement constituents themselves have remained unchanged since they were first used. This study was conducted to determine the factors that had the greatest effect on the final properties of acrylic bone cement using a pre-filled bone cement mixing and delivery system. A design of experiments (DoE) approach was used to determine the impact of the factors associated with this mixing and delivery method on the final properties of the cement produced. The DoE illustrated that all factors present within this study had a significant impact on the final properties of the cement. An optimum cement composition was hypothesised and tested. This optimum recipe produced cement with final mechanical and thermal properties within the clinical guidelines and stated by ISO 5833 (International Standard Organisation (ISO), International standard 5833: implants for surgery—acrylic resin cements, 2002), however the low setting times observed would not be clinically viable and could result in complications during the surgical technique. As a result further development would be required to improve the setting time of the cement in order for it to be deemed suitable for use in total joint replacement surgery.

Similar content being viewed by others

References

http://www.njrcentre.org.uk/njrcentre/Portals/0/Documents/England/Reports/9th_annual_report/NJR%209th%20Annual%20Report%202012.pdf. Accessed 4 July 2014.

Dang K, Pelletier MH, Walsh WR. Factors affecting flexural strength in cement within cement revisions. J Arthroplast. 2011;26(8):1540–8.

Kane RJ, Yue W, Mason JJ, Roeder RK. Improved fatigue life of acrylic bone cements reinforced with zirconia fibers. J Mech Behav Biomed Mater. 2010;3(7):504–11.

Dunne N, Orr J. Influence of mixing techniques on the physical properties of acrylic bone cement. Biomaterials. 2001;22(13):1819–26.

Lidgren L, Drar H, Möller J. Strength of polymethylmethacrylate increased by vacuum mixing. Acta Orthop. 1984;55(5):536–41.

Dunne N, Orr J, Mushipe M, Eveleigh R. The relationship between porosity and fatigue characteristics of bone cements. Biomaterials. 2003;24(2):239–45.

Hasenwinkel JM, Lautenschlager EP, Richard WL, Gilbert JL. Effect of initiation chemistry on the fracture toughness, fatigue strength, and residual monomer content of a novel high-viscosity, two-solution acrylic bone cement. J Biomed Mater Res. 2002;59:411–21.

Hoey D, Taylor D. Quantitative analysis of the effect of porosity on the fatigue strength of bone cement. Acta Biomater. 2009;5(2):719–26.

Eriksson AR, Albrektsson T. Temperature threshold levels for heat-induced bone tissue injury: a vital-microscopic study in the rabbit. J Prosthet Dent. 1983;50(1):101–7.

Dunne N, Orr J. Thermal characteristics of curing acrylic bone cement. ITBM-RBM. 2001;22(2):88–97.

Kuehn K, Ege W, Gopp U. Acrylic bone cements: composition and properties. Orthop Clin N Am. 2005;36(1):17–28.

International Standard Organisation (ISO). International standard 5833: implants for surgery—acrylic resin cements. ISO; 2002.

Meyer PR, Lautenschlager EP, Moore BK. On the setting properties of acrylic bone cement. J Bone Joint Surg. 1973;55(1):149–56.

Turner RC, White FB, Park JB. The effect of initial temperature on free radical decay in PMMA bone cement. J Biomed Mater Res. 1982;16(5):639–46.

Turner RE, Atkins PE, Ackley MA, Park JB. Molecular and macroscopic properties of PMMA bone cement: free-radical generation and temperature change versus mixing ratio. J Biomed Mater Res. 1981;15:425–32.

Vallo CI, Montemartini PE, Cuadrado TR. Effect of residual monomer content on some properties of a poly (methyl methacrylate)-based bone cement. J Appl Polym Sci. 1998;69(7):1367–83.

Orr J, Dunne N, Quinn J. Shrinkage stresses in bone cement. Biomaterials. 2003;24(17):2933–40.

Gilbert J, Hasenwinkel J, Wixson R, Lautenschlager E. A theoretical and experimental analysis of polymerization shrinkage of bone cement: a potential major source of porosity. J Biomed Mater Res. 2000;52(1):210–8.

López A, Unosson E, Engqvist H, Persson C. Direct and interactive effects of three variables on properties of PMMA bone cement for vertebral body augmentation. J Mater Sci Mater Med. 2011;22(6):1599–606.

Werdofa DMI, Lewis G. Direct and interactive influence of explanatory variables on properties of a calcium phosphate cement for vertebral body augmentation. J Mater Sci Mater Med. 2014;25(1):55–66.

O’Hara RM, Dunne NJ, Orr JF, Buchanan FJ, Wilcox RK, Barton DC. Optimisation of the mechanical and handling properties of an injectable calcium phosphate cement. J Mater Sci Mater Med. 2010;21(8):2299–305.

Harper EJ, Bonfield W. Tensile characteristics of ten commercial acrylic bone cements. J Biomed Mater Res. 2000;53:605–16.

Dunne NJ, Orr JF. Curing characteristics of acrylic bone cement. J Mater Sci Mater Med. 2002;13(1):17–22.

Haas SS, Brauer GM, Dickson G. A characterization of polymethylmethacrylate bone cement. J Bone Joint Surg Am. 1975;57(3):380–391.

Lewis G. Relative roles of cement molecular weight and mixing method on the fatigue performance of acrylic bone cement: Simplex®P versus Osteopal®. J Biomed Mater Res. 2000;53(1):119–30.

Harper EJ, Braden M, Bonfield W, Dingeldein E, Wahlig H. Influence of sterilisation upon a range of properties of experimental bone cements. J Mater Sci Mater Med. 1997;8:849–53.

Walker GM, Daly C, Dunne NJ, Orr JF. Liquid monomer—powder particle interaction in acrylic bone cement. Chem Eng J. 2008;139(3):489–494.

Lelovics H, Liptakova T. Time and mixing technique dependent changes in bone cement smartset. Acta Bioeng Biomech. 2010;12(4):63–7.

Lennon A, Prendergast P. Residual stress due to curing can initiate damage in porous bone cement: experimental and theoretical evidence. J Biomech. 2002;35(3):311–21.

Lewis G, Xu J, Madigan S, Towler M. Influence of two changes in the composition of an acrylic bone cement on its handling, thermal, physical, and mechanical properties. J Mater Sci Mater Med. 2007;18(8):1649–58.

Hasenwinkel JM, Lautenschlager EP, Wixson RL, Gilbert JL. A novel high-viscosity, two-solution acrylic bone cement: Effect of chemical composition on properties. J Biomed Mater Res. 1999;47(1):36–45.

Kuhn K. Bone cements—up to date comparison of physical and chemical properties of commercial materials. Berlin: Springer; 2000.

Rehman I, Harper EJ, Bonfield W. In situ analysis of the degree of polymerization of bone cement by using FT-Raman spectroscopy. Biomaterials. 1996;17(16):1615–9.

Pascual B, Vázquez B, Gurrachaga M, Goñi I, Ginebra MP, Gil FJ, Planell JA, Levenfeld B, Román JS. New aspects of the effect of size and size distribution on the setting parameters and mechanical properties of acrylic bone cements. Biomaterials. 1996;17(5):509–16.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Clements, J., Walker, G., Pentlavalli, S. et al. Optimisation of a two-liquid component pre-filled acrylic bone cement system: a design of experiments approach to optimise cement final properties. J Mater Sci: Mater Med 25, 2287–2296 (2014). https://doi.org/10.1007/s10856-014-5260-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-014-5260-y