Abstract

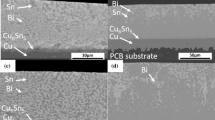

Thermal deformation during soldering between the chip and the substrate is an important factor affecting the quality of high-density packaging of organic circuit boards. This study proposes a low-temperature pre-connection, package reinforcement, and secondary reflow process based on SAC305 and Sn-58Bi solders, which melts SnBi solder paste at a minimum temperature of 150 °C to connect the SAC305 solder ball and the substrates initially. In the subsequent packaging process, the composite solder joint undergoes a second high-temperature soldering process. Due to the reinforcement of the package structures, the deformation of the substrate at high temperatures is limited. This study investigates the effects of different pre-soldering temperatures on the microstructure and shear behavior of composite solder joints before and after secondary soldering. The results show that the boundary between the SAC region and the mixed region can be clearly observed in the pre-soldered joint. As the temperature increases, the melting degree of the SAC305 solder ball intensifies, and the area of the mixed microstructure increases. In the shear test, the average shear strength of the pre-soldered joints was about 50 MPa. As the pre-soldering temperature increased, the fracture mode changed from composite fracture to brittle fracture. After secondary reflow at 260 °C, SAC305 and Sn-58Bi were completely melted and fully mixed, and each phase was evenly distributed in the solder joints. The average shear strength increased to about 60 MPa.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

M. Waldrop, Nat. News. 530, 144 (2016). https://doi.org/10.1038/530144a

J. Lau, Semicond. Adv. Packag. (2021). https://doi.org/10.1007/978-981-16-1376-09

E. Lin, D. Chang, D. Jiang, Y. Wang, C. Hsiao, Int. Microsyst. Packag. Assem. Circ. Technol. (2007). https://doi.org/10.1109/IMPACT.2007.4433633

C. Chiu, K. Chang, J. Wang, C. Lee, K. Shen, L. Wang, 2007 Proc. 57th Electron. Compon. Technol. Conf. (2007). https://doi.org/10.1109/ECTC.2007.373771

Q. Wei, C. Ting, W. Liu, N. Sun, Q. Fang, J. Liu, H. Yang, X. Ma, 22nd Int. Conf. Electron. Packag. Technol. (ICEPT) (2021). https://doi.org/10.1109/ICEPT52650.2021.9568069

S. Cho, T. Chang, J. Lee, H. Park, Y. Ko, G. Park, Microelectron. Reliab. 50, 242–250 (2010). https://doi.org/10.1016/j.microrel.2009.10.009

T. Wang, C. Wang, Y. Lai, K. Chang, C. Lee, Microelectron. Eng. 85, 659–664 (2008). https://doi.org/10.1016/j.mee.2007.12.022

Q. Zhang, W. Long, X. Yu, Y. Pei, P. Qiao, J. Alloys Compd. 622, 973–978 (2015). https://doi.org/10.1016/j.jallcom.2014.11.030

N. Jiang, L. Zhang, L. Gao, X. Song, P. He, J. Mater. Sci.: Mater. Electron. 32, 22731–22759 (2021). https://doi.org/10.1007/s10854-021-06820-7

Y. Goh, A. Haseeb, H. Liew, M. Sabri, J. Mater. Sci. 50, 4258–4269 (2015). https://doi.org/10.1007/s10853-015-8978-0

O. Mokhtari, H. Nishikawa, Mater. Sci. Eng.: A 651, 831–839 (2016). https://doi.org/10.1016/j.msea.2015.11.038

L. Shen, A. Foo, S. Wang, Z. Chen, J. Alloys Compd. 729, 498–506 (2017). https://doi.org/10.1016/j.jallcom.2017.09.177

M. Genanu, F. Hadian, R. Owen, E. Cotts, J. Electron. Mater. 50, 209–216 (2021). https://doi.org/10.1007/s11664-020-08474-3

Y. Liu, J. Chang, Y. Xue, R. Cao, H. Li, S. Zheng, X. Zeng, J. Mater. Sci.: Mater. Electron. 33, 8270–8280 (2022). https://doi.org/10.1007/s10854-022-07981-9

O. Chen, J. Gao, T. Pan, K. Tang, R. Aspandiar, K. Byrd, B. Zhou, S. Mokler, A. Molina, Proceedings of the 2016 SMTA International Conference. 216–228, (2016)

Y. Liu, R. Xu, H. Zhang, F. Sun, J. Mater. Sci.: Mater. Electron. 30, 14077–14084 (2019). https://doi.org/10.1007/s10854-019-01773-4

Y. Shen, S. Zhou, J. Li, C. Yang, S. Huang, S. Lin, H. Nishikawa, Mater. Design. 183, 108144 (2019). https://doi.org/10.1016/j.matdes.2019.108144

P. Chen, C. Li, C. Yang, A. Hu, M. Li, L. Gao, H. Ling, T. Hang, Y. Wu, Mater. Lett. 313, 131743 (2022). https://doi.org/10.1016/j.matlet.2022.131743

L. Yang, X. Shi, S. Quan, Mater. Res. Express. 6, 076518 (2019). https://doi.org/10.1088/2053-1591/ab1334

S. Wang, X. Chen, K. Luo, H. Zhou, R. Li, P. He, K. Paik, S Zhang J. Mater. Res. Technol. 27, 5332–5339 (2023). https://doi.org/10.1016/j.jmrt.2023.11.066

Funding

This work is supported by National Natural Science Foundation of China (Grant No. U22B2044).

Author information

Authors and Affiliations

Contributions

SL: investigation, writing-original draft. YL: conceptualization, methodology. YX: supervision. XZ: investigation. NL: writing-review & editing. ZZ: investigation. CX: supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lv, S., Liu, Y., Xue, Y. et al. Effect of pre-soldering temperatures on the microstructures and shear behaviors of SnBi-SAC/ENIG solder joints. J Mater Sci: Mater Electron 35, 928 (2024). https://doi.org/10.1007/s10854-024-12702-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12702-5