Abstract

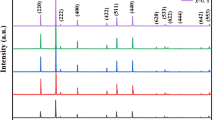

In this study, Zn2+-substituted Sr0.15Ca0.3La0.55Fe11.65−xCo0.35ZnxO19 (0 ≤ x ≤ 0.15) ferrites were synthesized by the ceramic method. The effects of Zn2+ substitution on the structural and magnetic performance of samples were studied. The X-ray diffraction results show that ferrite samples with the high purity M-type phase can be obtained when the substitution amount of Zn2+ is x = 0–0.1. Further increasing the Zn content to x = 0.15, the impurity soft magnetic phase of ZnFe2O4 is detected, which harms the hard magnetic properties. The Mössbauer results show that Zn2+ ions enter the crystal lattice of the M-type phase and solely occupy the 4f1 site, thereby promoting the conversion of Fe2+ to Fe3+ at the 2a position. It is observed that the particle size of the sintered samples slightly increases as x increases from 0 to 0.1, but decreases when x = 0.15. Ultimately, we achieved an optimal magnetic performance with the highest maximum energy product of 5.75 MGOe, which is highly competitive within the ferrite family.

Similar content being viewed by others

Data availability

All relevant data are within the paper.

References

S. Chenlong Lei, Y. Tang, Du, Ceram. Int. 42, 15511–15516 (2016)

M.K. Manglam, M. Kar, J. Alloys Compd. 899, 163367 (2022)

F. Kools, A. Morel, R. Grössinger, J.M. Le Breton, P. Tenaud, J. Magn. Magn. Mater. 242, 1270–1276 (2002)

N. Langhof, M. Gobbels, J. Solid State Chem. 182, 2725–2732 (2009)

A. Muddassara Kanwal, J. Riaz, I. Ahmad, Ahmad, J. Magn. Magn. Mater. 530, 167873 (2021)

P. Tenaud, A. Morel, F. Kools, J.M. Le Breton, L. Lechevallier, J. Alloy Compd. 370, 331–334 (2004)

P. Sharma, A. Verma, R.K. Sidhu, O.P. Pandey, J. Magn. Magn. Mater. 307, 157–164 (2006)

M. Manikandan, C. Venkateswaran, J. Magn. Magn. Mater. 358, 82–86 (2014)

P.E. Kazin, L.A. Trusov, D.D. Zaitsev, Y.D. Tretyakov, M. Jansen, J. Magn. Magn. Mater. 320, 1068–1072 (2008)

A. Gupta, M. Kar, P.K. Roy, Mater. Chem. Phys. 292, 126842 (2022)

P. Sharma, A. Verma, R.K. Sidhu, O.P. Pandey, J. Alloys Compd. 361, 257–264 (2003)

H.K. Singh, P.P. Mohapatra, S. Sahu, P. Dobbidi, Mater. Sci. Eng. B 284, 115876 (2022)

N. Miyajima, K. Akasaka, T. Waki, Y. Tabata, Y. Kobayashi, H. Nakamura, Hyperfine Interact. 206, 115–118 (2012)

Y. Shifan Lu, Q. Liu, J. Yin, J. Chen, J. Li, Wu, J. Magn. Magn. Mater. 564, 170068 (2022)

L.-Z. Li, A. Sokolov, C.-J. Yu, Q.-F. Li, Q.-F. Li, K. Qian, V.G. Harris, Ceram. Int. 47, 25514–25519 (2021)

W.J. Zhang, Y. Bai, X. Han, L. Wang, X.F. Lu, L.J. Qiao, J. Alloy Compd. 546, 234–238 (2013)

K. Wandee Onreabroy, G. Papato, K. Rujijanagul, T. Pengpat, Tunkasiri, Ceram. Int. 38S, S415–S419 (2012)

M.I. Oliva, P.G. Bercoff, H.R. Bertorello, J. Magn. Magn. Mater. 320, e100–e103 (2008)

K. Uji, T. Waki, Y. Tabata, H. Nakamura, J. Solid State Chem. 245, 17–12 (2017)

X. Li, W. Yang, D. Bao, X. Meng, B. Lou, J. Magn. Magn. Mater. 329, 1–5 (2013)

X. Xin Huang, Y. Liu, K. Yang, X. Huang, D. Niu, S. Jin, Y. Gao, F. Ma, F. Huang, S. Lv, Feng, J. Magn. Magn. Mater. 378, 424–428 (2015)

A. Baykal, H. Sözeri, H. Güngünes, I. Auwal, S.E. Shirsath, M. Sertkol, M. Amir, J. Supercond Nov Magnetism. 30, 1585–1592 (2017)

V. Banihashemi, M.E. Ghazi, M. Izadifard, Phys. B: Phys. Condens. Matter. 605, 412670 (2021)

T. Schmidt, D. Seifert, J. Töpfer, J. Magn. Magn. Mater. 508, 166887 (2020)

W. Li Yuping, B. Yunfei, Daxin, J. Mater. Sci.: Mater. Electron. 27, 4433–4436 (2016)

C. Liu, X. Kan, F. Hu, X. Liu, S. Feng, J. Hu, W. Wang, K.M. Ur Rehman, M. Shezad, C. Zhang, H. Li, S. Zhou, Q. Wu, J. Alloys Compd. 784, 1175–1186 (2019)

A. Morel, J.M. Le Breton, J. Kreisel, G. Wiesinger, F. Kools, P. Tenaud, J. Magn. Magn. Mater. 242, 1405–1407 (2002)

D.H. Choi, S.W. Lee, I.-B. Shim, C.S. Kim, J. Magn. Magn. Mater. 304, e243–e24 (2006)

B.K. Rai, S.R. Mishra, V.V. Nguyen, J.P. Liu, J. Alloys Compd. 581, 275–281 (2013)

V.M.H. Peijiang Liu, Z. Ng, J. Yao, Y. Zhou, Z. Lei, Yang, Hualiang Lv, and Ling Bing Kong. ACS Appl. Mater. Interfaces. 9, 16404–16416 (2017)

M.S. Abdelmajid Lassoued, F. Lassoued, Karolak, Santiago García-Granda, Brahim Dkhil, Salah Ammar, Abdellatif Gadri. J. Mater. Sci.: Mater. Electron. 32, 2650 (2021)

Z. Peijiang Liu, J. Yao, Z. Zhou, Yang, Ling Bing Kong. J. Mater. Chem. C 4, 9738–9749 (2016)

L. Lechevallier, J.M. Le Breton, A. Morel, J. Teillet, J. Alloys Compd. 359, 310–314 (2003)

S. Pawandeep Kaur, S. Bindra Narang, Bahel, Ceram. Int. 42, 9830–9835 (2016)

L. Peng, L. Li, R. Wang, Y. Hu, X. Tu, X. Zhong, J. Magn. Magn. Mater. 393, 399–403 (2015)

G. Turilli, F. Licci, J. Magn. Magn. Mater. 75, 111–114 (1988)

B. Li Yuping, W. Daxin, Y. Zhangzhong, C. Zhang, Z. Lizhao, W. Guangcheng, Mengling, J. Alloys Compd. 734, 130–135 (2018)

Acknowledgements

This research is supported by the ten thousand talents project of Zhejiang Province (2019R52056).

Funding

This work was supported by ten thousand talents project of Zhejiang Province [2019R52056].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by LY, ZY, ZZ, and HJ. The first draft of the manuscript was written by LY, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflicts of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuping, L., Yujing, Z., Zhen, Z. et al. Structural and magnetic properties of Sr0.15Ca0.3La0.55Fe11.65-xCo0.35ZnxO19 ferrites synthesized through the ceramic process. J Mater Sci: Mater Electron 34, 1859 (2023). https://doi.org/10.1007/s10854-023-11317-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11317-6