Abstract

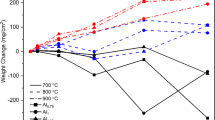

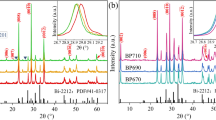

The regularities of the influence on the magnetic properties of temperature and the strength of the longitudinal magnetic field, which is much less than the saturation field, during annealing of an amorphous soft magnetic alloy based on Fe were studied. The possibility of efficiency of such treatment in comparison with traditional annealing without a field is demonstrated. It is shown that the change in magnetic properties during annealing is not related to the crystallization processes of the amorphous alloy. Annealing in unsaturated field at a temperature of 410 °C showed the greatest efficiency in achieving the highest soft magnetic properties of the alloy (low coercive force Hc = 3 A/m, high maximum and low-field permeability µmax = 101,000, µ2 = 5019) among short-term treatments with a holding time of 10 min. The results obtained are discussed taking into account the processes of magnetic anisotropy induction and stress relaxation in the alloy.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Z. Hou, P. Yan, B. Sun, H. Elshekh, B. Yan, Results Phys. 14, 102498 (2019). https://doi.org/10.1016/j.rinp.2019.102498

K. Suzuki, H. Fujimori, K. Hashimoto, Amorphous Metals (Butterworths, London, 1983), p.300

Y.N. Starodubtsev, Physical Properties and Application of Soft Magnetic Materials (Goryachaya liniya - Telekom, Moscow, 2020), p.384

J. Degro, P. Vojtanik, J. Filipensky, P. Duhaj, Mater. Sci. Eng. B 14, 81 (1992). https://doi.org/10.1016/0921-5107(92)90333-90335

J. Li, X.H. Lin, X.H. Wang, M. Tang, Adv. Mater. Res. 926–930, 137 (2014). https://doi.org/10.4028/www.scientific.net/AMR.926-930.137

H. Li, A. He, A. Wang et al., J. Magn. Magn. Mater. 471, 110 (2019). https://doi.org/10.1016/j.jmmm.2018.09.072

C.X. Wang, Z. Wu, X. Feng et al., Intermetallics 118, 106689 (2020). https://doi.org/10.1016/j.intermet.2019.106689

F.E. Luborsky, in Amorphous Metallic Alloys. ed. by F.E. Luborsky (Butterworths, London, 1983), p.356

P. Marín, A. Hernando, Appl. Phys. Lett. 94, 122507 (2009). https://doi.org/10.1063/1.3091401

M. Liu, Z. Wang, Y. Xu, IEEE Trans. Magn. 51, 2004704 (2015). https://doi.org/10.1109/TMAG.2015.2439295

I. Škorvánek, J. Marcin, J. Turčanová, J. Kováč, P. Švec, J. Alloys Compds. 504S, S135 (2010). https://doi.org/10.1016/j.jallcom.2010.04.033

D. Mishra, P. Saravanan, A. Perumal, A. Srinivasan, J. Appl. Phys. 109, 07A306 (2011). https://doi.org/10.1063/1.3533256

M.J. Garcia-Prieto, E. Pina, A. Zhukov et al., Sens. Actuator A Phys. 81, 227 (2000). https://doi.org/10.1016/S0924-4247(99)00129-6

C.K. Kim, I.H. Lee, Y.C. Chung, R.C. O’Handley, Mater. Sci. Eng. A 76, 211 (2000). https://doi.org/10.1016/S0921-5107(00)00450-5

M. Vargaa, R. Vargaa, P. Vojtaníka et al., Acta Phys. Pol. 118, 804 (2010). https://doi.org/10.12693/APhysPolA.118.804

O. Kohmoto, H. Fujishima, K. Shibata, Mater. Sci. Eng. 99, 53 (1988). https://doi.org/10.1016/0025-5416(88)90290-X

O.I. Boriskin, D.I. Blagoveshchenskiy, VYu. Vvedenskiy, G.A. Nuzhdin, Chernye Metally 1045(1), 60 (2019)

VYu. Vvedenskiy, G.A. Nuzhdin, E.A. Shuvaeva, Kontrol’ Diagnostika 1, 51 (2013)

F.E. Luborsky, Amorphous Metallic Alloys (Butterworths, London, 1983), p.534

Y. Zhang, Y. Yang, Z. Wu et al., Intermetallics 134, 107200 (2021). https://doi.org/10.1016/j.intermet.2021.107200

P.S. Mogilnikov, Izvestiya. Ferrous Metall. 59(11), 837 (2016). https://doi.org/10.17073/0368-0797-2016-11-837-839

F. Luborsky, J. Walter, Mater. Sci. Eng. 35(2), 255 (1978). https://doi.org/10.1016/0025-5416(78)90127-1

Y.H. Xu, Z.H. Zhu, L. Yin, J.L. Liu, Mater. Sci. Eng. 242, 012024 (2017). https://doi.org/10.1088/1757-899X/242/1/012024

X.F. Liang, A.N. He, A.D. Wang et al., J. Alloys Compds. 694, 1260 (2017). https://doi.org/10.1016/j.jallcom.2016.10.107

VYu. Vvedenskiy, I.B. Kekalo, Phys. Met. Metallogr. 81(1), 73 (1996)

A.M. Severino, A.D. Santos, E.P. Missell, J. Magn. Magn. Mater. 96, 167 (1991). https://doi.org/10.1016/0304-8853(91)90625-K

VYu. Vvedenskiy, I.B. Kekalo, Phys. Met. Metallogr. 86(5), 80 (1998)

K. Suzuki, G. Herzer, Scr. Mater. 67, 548 (2012). https://doi.org/10.1016/j.scriptamat.2012.03.006

Acknowledgements

We are grateful to M.V. Gorshenkov and I.V. Schetinin for their assistance in conducting the EDX analysis.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors read and approved the final manuscript. ET—Writing—Original draft; Investigation; Visualization; Formal analysis. VV—Writing—Review and Editing; Conceptualization; Supervision.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tokmakova, E.N., Vvedenskiy, V.Y. Effect of annealing in unsaturated magnetic field on the magnetic properties of an amorphous alloy Fe77Ni1Si9B13. J Mater Sci: Mater Electron 34, 1509 (2023). https://doi.org/10.1007/s10854-023-10931-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10931-8