Abstract

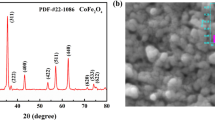

Multiferroic materials have attracted much attention because of their magnetoelectric coupling effect. In this paper, MnFe2O4 (MFO) magnetic particles and PbZr0.52Ti0.48O3 (PZT) ferroelectric particles were prepared by hydrothermal method and sol–gel method, respectively. PZT particles with different sizes were produced by tuning the sintering temperature, and on this basis, MFO-PZT multiferroic liquid was prepared by using monoamino ethoxy-coupling agent as the surfactants and dimethyl silicone oil as the carrier liquid. The effect of PZT particle size on magnetoelectric properties was studied. XRD and SEM show that the PZT particle and the MFO particle have no secondary phase, the size of MFO particle is 52 nm, and the PZT particle sizes are 0.38 μm, 1.07 μm, 1.68 μm, and 1.79 μm, respectively. When the particle size of PZT is 0.38 μm, a large dielectric constant of 8.39 of the multiferroic liquid was observed at low frequency (250 Hz). When the size of PZT is 1.79 μm, the liquid has the maximum saturation polarization intensity Ps ~ 0.0191 μC/cm2 and the maximum residual polarization intensity Pr ~ 0.0063 μC/cm2 was obtained. When a magnetic field is applied, the value of both Pr and Ps increases. When the size of PZT is 1.07 μm, the maximum magnetoelectric coupling coefficient of the liquid is 54.82 V/(cm·Oe). Compared with the same series of magnetoelectric materials, the magnetoelectric composite multiferroic liquid has a potential application prospect.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

J.G. Wu, D.Q. Xiao, J.G. Zhu, J. Appl. Phys. 112, 094109 (2012)

J.G. Wu, J.H. Wang, D.Q. Xiao, J.G. Zhu, IEEE T. Ultrason. Ferr. 59, 14–20 (2012)

H. Wu, R.C. Xu, C. Zhou, S.L. Xing, Z.X. Zeng, H. Ao, W.C. Li, X.F. Qin, R.L. Gao, J. Phys. Chem. Solids 160, 110314 (2022)

Y.Z. Xue, R.C. Xu, Z.H. Wang, R.L. Gao, C.Y. Li, G. Chen, X.L. Deng, W. Cai, C.L. Fu, J. Electron. Mater. 48, 4806–4817 (2019)

H. Wu, Z.X. Zeng, S.L. Xing, M.S. Lan, W.C. Li, Q. Zhang, H. Ao, C. Zhou, R.C. Xu, R. L. Gao, X.L. Deng. Adv. Eng. Mater., 23, 2100410 (2021)

W.C. Li, H. Wu, H. Ao, Z.X. Zeng, R.L. Gao, W. Cai, C.L. Fu, X.L. Deng, G. Chen, Z.H. Wang, X. Lei, Appl. Phys. A. 127, 1–13 (2021)

R.L. Gao, Y.Z. Xue, Z.H. Wang, G. Chen, C.L. Fu, X.L. Deng, X. Lei, W. Cai, J. Mater. Sci. 31, 9026–9036 (2020)

J. Yu, L. Bai, R.L. Gao, Process. Appl. Ceram. 14, 336–345 (2020)

C.Y. Li, R.C. Xu, R.L. Gao, Z.H. Wang, G. Chen, X.L. Deng, W. Cai, C.L. Fu, Q.T. Li, Mater. Chem. Phys. 249, 123144 (2020)

R.L. Gao, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, G. Chen, X.L. Deng, C.L. Fu, W. Cai, Compos. B 166, 204–212 (2019)

J.G. Wu, Z. Fan, D.Q. Xiao, J.G. Zhu, J. Wang, Prog. Mater. Sci. 84, 335–402 (2016)

R.L. Gao, X.F. Qin, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, C.L. Fu, G. Chen, X.L. Deng, W. Cai, J. Alloy. Compd. 795, 501–512 (2019)

X.D. Luo, H. Wang, R.L. Gao, X.L. Li, J. Zhang, H. Ban, Process. Appl. Ceram. 14, 91–101 (2020)

R.L. Gao, X.F. Qin, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, C.L. Fu, G. Chen, X.L. Deng, W. Cai, Mater. Chem. Phys. 232, 428–437 (2019)

Z. Shi, J. Zhang, D. Gao, Z. Zhu, Z. Yang, Z. Zhang, RSC Adv. 10, 27242–27248 (2020)

R.L. Gao, Z.H. Wang, G. Chen, X.L. Deng, W. Cai, C.L. Fu, Ceram. Int. 44, S84–S87 (2018)

W.Y. Yang, Z.Y. Wang, Z.P. Zhou, T.P. Wang, M.L. Jin, J.Y. Xu, Y.L. Sui, J. Supercond. Nov. Magn. 30, 665–673 (2017)

Z.X. Zeng, H. Wu, C. Zhou, X.F. Qin, J.Z. He, C. Ji, X.L. Deng, R.L. Gao, C.L. Fu, W. Cai, G. Chen, Z.H. Wang, X. Lei, J. Asian. Ceram. Soc. 8, 1206–1215 (2020)

N. Sowmya, A. Srinivas, K. Reddy, J. Praveen, D. Das, S. Kumar, V. Subramanian, S. Kamat, Ceram. Int. 43, 2523–2528 (2017)

S. Dabas, M. Kumar, P. Chaudhary, O.P. Thakur, J. Appl. Phys. 126, 134102 (2019)

T. Woldu, B. Raneesh, B.K. Hazra, S. Srinath, P. Saravanan, M.V. RamanaReddya, K. Nandakumar, J. Alloys. Compd. 691, 644–652 (2017)

Z.Q. Zheng, P. Zhou, Y. Liu, K. Liang, R.G. Tanguturi, H. Chen, G. Srinivasan, Y.J. Qi, T.J. Zhang, J. Alloy. Compd. 818, 152871 (2020)

R. Revathy, N. Kalarikkal, M. Varma, K. Surendran, J. Alloy. Compd. 889, 161667 (2022)

C. Vaz, J. Hoffman, C. Ahn, R. Ramesh, Adv. Mater. 22, 2900–2918 (2010)

R.L. Gao, Q.Z. Leng, Z.H. Wang, G. Chen, C.L. Fu, X.L. Deng, W. Cai, Mater. Res. Express. 6, 026308 (2018)

R.L. Gao, Z.Y. Xu, L. Bai, Q.M. Zhang, Z.H. Wang, W. Cai, G. Chen, X.L. Deng, X.L. Cao, X.D. Luo, C.L. Fu, Adv. Electron. Mater. 4, 1800030 (2018)

R.L. Gao, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, W. Cai, G. Chen, X.L. Deng, X.L. Cao, X.D. Luo, C.L. Fu, Nanoscale 10, 11750–11759 (2018)

H. Wu, H. Ao, W.C. Li, Z.X. Zeng, R.L. Gao, C.L. Fu, G. Chen, X.L. Deng, Z.H. Wang, X. Lei, W. Cai, Mater. Today. Chem. 21, 100511 (2021)

B. Gao, Z.H. Yao, D.Y. Lai, Q.H. Guo, W.G. Pan, H. Hao, M.H. Cao, H.X. Liu, J. Alloy. Compd. 836, 155474 (2020)

S.C. Panigrahi, P.R. Das, R. Padhee, Pramana-J Phys. 95, 1–12 (2021)

A. Jain, Y.G. Wang, N. Wang, Y. Li, F.L. Wang, Ceram. Int. 46, 7576–7585 (2020)

K. Kiran, S. Thakur, S. Kumar, N. Kumar, J. Thakur, Alloy. Compd. 857, 158251 (2021)

Z.X. Li, Z.H. Wang, R.L. Gao, W. Cai, G. Chen, X.L. Deng, C.L. Fu, Process. Appl. Ceram. 12, 394–402 (2018)

H. Wu, R.C. Xu, X.F. Qin, R.L. Gao, S.L. Zhang, C. Zhou, S.L. Xing, W. Cai, J. Mater. Sci. 31, 885–895 (2020)

N. Zhang, T. Zheng, J.G. Wu, ACS Omega 5, 3099–3107 (2020)

Y.N. Zou, Y.G. Wu, X.Z. Guo, S.A. Tong, Z.Y. Wang, L. Zhang, Phys. Status. Solidi. A. 209, 243–247 (2012)

S.D. Cho, J.Y. Lee, K.W. Paik, Adv. Electr. Mater. Packag. (Cat. No.01EX506) 63–68 (2001)

X.F. Liu, H.J. Sun, M. Wei, C.X. Xiong, Adv. Mater. Res. 66, 238–241 (2009)

E. Climent, R.M. Maxey, G.E. Karniadakis, Langmuir 20, 507–513 (2004)

F.G. Rosales, App. Sci. 6, 206 (2016)

Funding

The present work has been supported by the Scientific and Technological Research Program of Chongqing Municipal Education Commission (Grant No. KJZD-M201901501), the Chongqing Research Program of Basic Research and Frontier Technology (Grant Nos. cstc2019jcyj-msxmX0071, cstc2021jcyj-msxmX0008, cstc2021jcyj-msxmX0039, cstc2021jcyj-msxmX0599), the Program for Creative Research Groups in University of Chongqing (Grant No. CXQT19031), the Natural Science Foundation of Chongqing (Grant No. cstc2020jcyj-zdxmX0008, cstc2020jcyj-msxmX0030), the Leading Talents of Scientific and Technological Innovation in Chongqing (Grant No. CSTCCXLJRC201919), the special project of Chongqing technology innovation and application development (Grant No. cstc2020jscx-msxmX0218), the Provincial and Ministerial Co-constructive of Collaborative Innovation Center for MSW Comprehensive Utilization, the Scientific and Technological Research Young Program of Chongqing Municipal Education Commission (Grant No. KJQN202001528), the Research Foundation of Chongqing University of Science and Technology (Grant No. Ckrc2019020), the Postgraduate technology innovation project of Chongqing (Grant No. CYS21501), the Postgraduate technology innovation project of Chongqing University of Science & Technology (Grant Nos. YKJCX2120525, YKJCX2120510, YKJCX2120531, YKJCX2120201), and the Postgraduate Technology Innovation Project of the Chongqing University of Science and Technology(Grant No. 2021187).

Author information

Authors and Affiliations

Contributions

HA: Conceptualization, Methodology, Investigation, Writing—original draft. WL: Validation, Formal analysis, Visualization. YZ: Validation, Formal analysis, Visualization, Writing—review & editing. SZ: Validation, Formal analysis—review & editing. HW: Resources, Writing—review & editing. RG, CF: Resources, Writing—review & editing. GC: Formal analysis, Writing—review & editing. XD: Writing—review & editing. ZW: Resources, Writing—review & editing, Supervision, Data curation. XL: Resources, Writing—review & editing, Supervision, Data curation. WC: Writing—review & editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

No human and/or animal studies are involved. Manuscript is approved by all authors for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ao, H., Li, W., Zhang, Y. et al. Effect of particle size of ferroelectric phase on multiferroic properties of MnFe2O4–PbZr0.52Ti0.48O3 multiferroic liquid. J Mater Sci: Mater Electron 33, 18472–18486 (2022). https://doi.org/10.1007/s10854-022-08700-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08700-0