Abstract

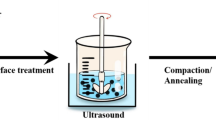

The high-quality TiO2 insulating layer on the commercial gas-atomized FeSiAl powder surface was efficiently prepared within a total time of 1 h at room temperature via a one-pot sol–gel method based on a developed industry-oriented coating equipment. The core-shell structure for the chemically coated FeSiAl powders was detected by the joint tools of SEM, EDS, and FTIR. Combined with the establishment of loss separation fitting model, the regulation mechanism analysis on soft magnetic properties was carried out for the FeSiAl powder cores insulated with different TiO2 coating amounts. It is found that the interface-pinning effect, which is closely related to the core’s density, is an important factor affecting the magnetic properties of powder cores. With the elevating TiO2 coating amount, the hysteresis loss, the excess loss, and DC-bias property of the core specimen exhibit the same increasing tendency, while the real part of complex permeability at 100 kHz gradually decreases owing to the increase of non-magnetic gap between the particles in the core, which can impede the domain-wall motion during magnetization. Correspondingly, the eddy current loss persistently decreases and contributes only 18.7% ~ 21.6% of total core loss when the precursor concentration is over 0.08 ml/g due to the formation of the intergranular insulated structure blocking the inter-particle eddy current flows in the composites. These results offer insights into subtly regulating magnetic properties when the adjusting process parameters for the soft magnetic composites are used in high-power and high-frequency applications.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

J.M. Silveyra, E. Ferrara, D.L. Huber, T.C. Monson, Science 362, eaao0195 (2018)

E.A. Périgo, B. Weidenfeller, P. Kollár, J. Füzer, Appl. Phys. Rev. 5, 031301 (2018)

F. Onderko, Z. Birčáková, S. Dobák, P. Kollár, M. Tkáč., M. Fáberová, J. Füzer, R. Bureš, J. Szabó, A. Zeleňáková, J. Magn. Magn. Mater. 543, 168640 (2022)

M. Lauda, J. Füzer, P. Kollár, M. Strečková, R. Bureš, J. Kováč, M. Baťková, I. Baťko, J. Magn. Magn. Mater. 411, 12 (2016)

Z.L. Guo, J.H. Wang, W.H. Chen, D.C. Chen, H.B. Sun, Z.L. Xue, C. Wang, Mater. Des. 192, 108769 (2020)

J.H. Wang, S.Q. Song, H.B. Sun, G.H. Hang, Z.L. Xue, C. Wang, D.C. Chen, J. Magn. Magn. Mater. 519, 167496 (2021)

W.C. Li, H.W. Cai, Y. Kang, Y. Ying, J. Yu, J.W. Zheng, L. Qiao, Y. Jiang, S.L. Che, Acta Mater. 167, 267 (2019)

O. Gutfleisch, M.A. Willard, E. Bruck, C.H. Chen, S.G. Sankar, J.P. Liu, Adv. Mater. 23, 821 (2011)

B. Zhou, Q. Chi, Y. Dong, L. Liu, Y. Zhang, L. Chang, Y. Pan, A. He, J. Li, X. Wang, J. Magn. Magn. Mater. 494, 165827 (2020)

M. Liu, K.Y. Huang, L. Liu, T. Li, P.P. Cai, Y.Q. Dong, X.M. Wang, J. Mater. Sci.-Mater. Electron. 29, 6092 (2018)

K.R. Yang, W.J. Chen, Y.S. Zhao, L.J. Ding, B. Du, S. Zhang, W. Yang, Compos. Sci. Technol. 221, 109178 (2021)

Z.D. Wang, T. Zhang, J.K. Wang, G.Q. Yang, M.L. Li, G.L. Wu, Nanomaterials 12, 446 (2022)

M. Yaghtin, A.H. Taghvaei, B. Hashemi, J. Janghorban, J. Alloys Compd. 581, 293 (2013)

J. Wang, X.A. Fan, Z.Y. Wu, G.Q. Li, Adv. Powder Technol. 27, 1189 (2016)

Z.Y. Wu, Z. Jiang, X.A. Fan, L.J. Zhou, W.L. Wang, K. Xu, J. Alloys Compd. 742, 90 (2018)

B. Zhou, Y.Q. Dong, L. Liu, L. Chang, F.Q. Bi, X.M. Wang, J. Magn. Magn. Mater. 474, 1 (2019)

D.H. Luo, C. Wu, M. Yan, J. Magn. Magn. Mater. 452, 5 (2019)

M.M. Zhou, Y. Han, W.W. Guan, S.J. Han, Q.S. Meng, T.T. Xu, H.L. Su, X. Guo, Z.Q. Zou, F.Y. Yang, Y.W. Du, J. Magn. Magn. Mater. 482, 148 (2019)

J.H. Wang, Z.L. Xue, S.Q. Song, H.B. Sun, J. Mater. Sci.-Mater. Electron. 32, 20401 (2021)

L.Y. Li, Q.L. Chen, Z. Gao, Y.C. Ge, J.H. Yi, J. Alloys Compd. 805, 609 (2019)

Z.G. Luo, X.A. Fan, W.T. Hu, F. Luo, Y.W. Li, J. Wang, X. Liu, J. Solid State Chem. 270, 311 (2019)

Z.G. Luo, X.A. Fan, W.T. Hu, F. Luo, J. Wang, Z.Y. Wu, X. Liu, G.Q. Li, Y. Li, J. Magn. Magn. Mater. 496, 165937 (2019)

Y.D. Peng, Y. Yi, L.Y. Li, J.H. Yi, J.W. Nie, C.X. Bao, Mater. Des. 109, 390 (2016)

K. Sun, S. Feng, Q. Jiang, X.F. Li, Y.P. Li, R.H. Fan, Y. An, J.Q. Wang, J. Magn. Magn. Mater. 493, 165705 (2020)

B.Y. Meng, J.X. Hou, F.Z. Ning, B. Yang, B.H. Zhou, R.H. Yu, J. Magn. Magn. Mater. 492, 165651 (2019)

H.B. Sun, C. Wang, J.H. Wang, M.G. Yu, Z.L. Guo, J. Magn. Magn. Mater. 502, 166548 (2020)

C. Wang, Z.L. Guo, J. Wang, H.B. Sun, X. Liu, J. Magn. Magn. Mater. 509, 166924 (2020)

M. Mahdiani, A. Sobhani, M. Salavati-Niasari, Sep. Purif. Technol. 185, 140 (2017)

F.S. Razavi, A. Sobhani, O. Amiri, M.G. Arani, M. Salavati-Niasari, Int J. Hydrog. Energy 45, 17662 (2020)

M.G. González, J.C. Cabanelas, J. Baselga, Infrared Spec. 2, 261 (2011)

J. Xie, H. Sun, X. Zhang, Z. Xie, Z. Zhang, Phosphorus Sulfur Silicon Relat. Elem. 190, 277 (2015)

H.E. Wang, J. Jin, Y. Cai, J.M. Xu, D.S. Chen, X.F. Zheng, Z. Deng, Y. Li, I. Bello, B.L. Su, J. Colloid Interface Sci. 417, 144 (2014)

M.T. Johnson, E.G. Visser, IEEE Trans. Magn. 26, 1987 (1990)

T. Gheiratmand, H.R.M. Hosseini, S.M.S. Reihani, J. Magn. Magn. Mater. 429, 241 (2017)

L.F. Sun, Z.R. Jia, S. Xu, M.B. Ling, D.Q. Hu, X.H. Liu, C.H. Zhang, G.L. Wu, Compos. Commun. 29 100993 (2022)

J. Fuzerova, J. Fuzer, P. Kollar, L. Hegedüs, R. Bures, M. Faberova, IEEE Trans. Magn. 48, 1545 (2012)

T.Q. Hou, Z.R. Jia, Y.H. Dong, X.H. Liu, G.L. Wu, Chem. Eng. J. 431, 133919 (2022)

C.X. Wang, Z.R. Jia, S.Q. He, J.X. Zhou, S. Zhang, M.L. Tian, B.B. Wang, G.L. Wu, J. Mater. Sci. Technol. 108, 236 (2022)

G. Bertotti, IEEE Trans. Magn. 24, 621 (1988)

L. Dakova, J. Fuzer, S. Dobak, P. Kollar, Y. Osadchuk, M. Streckova, M. Faberova, R. Bures, P. Kurek, M. Vojtko, IEEE Trans. Magn. 54, 1 (2018)

P. Kollar, Z. Bircakova, J. Fuzer, R. Bures, M. Faberova, J. Magn. Magn. Mater. 327, 146 (2013)

Acknowledgements

This research was funded by the Natural Science Foundation of Guangdong Province (Grant No. 2021A1515011796), Guangdong Province Key Project of Foundation and Application Foundation Research Joint Fund (Grant No. 2019B1515120020), and Foshan Municipal Key Technology Tackling Program (Grant No. 1920001001392).

Author information

Authors and Affiliations

Contributions

This work was planned by HS, executed by CW and ZG. GZ, CZ, and JW analyzed the data. HS and JW wrote the final paper.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, H., Zhou, G., Guo, Z. et al. Efficient synthesis of TiO2-coated layer for Fe-based soft magnetic composites and their regulation mechanism analysis on magnetic properties. J Mater Sci: Mater Electron 33, 13956–13967 (2022). https://doi.org/10.1007/s10854-022-08326-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08326-2