Abstract

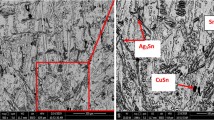

A novel alloying elements of TeFeCoBi have been anticipated to modify Sn–3Ag–0.7Cu SAC(307) alloys in various attributes. This study inspects the influence of slight/trace addition of Te, Fe, and Co besides 2 wt% Bi on the enhancement of microstructural solidification, thermal behavior, and tensile properties of SAC(307) alloy. Using field emission-scanning electron microscopy (FE-SEM), microstructural analysis indicated that the addition of Te, Fe, Co, and Bi not only inhibited the growth of large platelet Ag3Sn IMC phase, but also the new TeSn, FeSn2, and (Cu, Co)6Sn5 phases together with Co3Sn and Bi particles were formed in the eutectic regions and verified from EDS analysis. The synergetic influence of these precipitates results in significant combination of high strength and large ductility of the new solder. The ultimate tensile strength of the SAC(307)-TeFeCoBi alloy is found to be 58.3 MPa, which is 1.7 times higher than the corresponding of SAC(307) alloy. Moreover, the ductility was improved by ~ 46% with high reliability, which enriched its dissipation ability of plastic energy at various processing situations. The addition of TeFeCoBi elements also markedly increased the undercooling while maintaining the eutectic temperature and pasty range to the same SAC(307) levels.

Similar content being viewed by others

References

M. Abtew, G. Selvaduray, Mater. Sci. Eng. R 27, 95–141 (2000)

Y. Li, C.P. Wong, Mater. Sci. Eng. R 51, 1–35 (2006)

H.K. Kim, K.N. Tu, Appl. Phys. Lett. 67, 2002–2004 (1995)

B.S.S. Chandra Rao, J. Weng, L. Shen, T.K. Lee, K.Y. Zeng, Microelectron. Eng. 87, 2416–2422 (2010)

M. Maleki, J. Cugnoni, J. Botsis, Acta Mater. 61, 103–114 (2013)

S.Y. Chang, Y.C. Huang, Y.M. Lin, J. Alloys Compds. 490, 508 (2010)

B.L. Silva, A. Garcia, J.E. Spinelli, Microelectron. Reliab. 54, 2929–2934 (2014)

T.E. Quested, A.L. Greer, Acta Mater. 52, 3859–3868 (2004)

J. Shen, Y.C. Chan, J. Alloy. Compds. 477, 909–914 (2009)

E.H. El-Khawas, H. El-Hosainy, A.A. El-Daly, J. Mater. Sci Mater. Electron. 28, 12176–12183 (2017)

H.Y. Chang, S.W. Chen, D.S.H. Wong, H.F. Hsu, J. Mater. Res. 18, 1420–1428 (2003)

S.K. Kang, D.Y. Shih, D. Leonard, D.W. Henderson, T. Gosselin, S.I. Cho, J. Yu, W.K. Choi, JOM 56, 34–38 (2004)

Y. Takamatsu, H. Esaka, K. Shinozuka, Mater. Trans. 52, 189–195 (2011)

K.S. Kim, S.H. Huh, K. Suganuma, J. Alloys Compds. 352, 226–236 (2003)

J.M. Song, J.J. Lin, C.F. Huang, H.Y. Chuang, Mater. Sci. Eng. A. 466, 9–17 (2007)

I.E. Anderson, J. Walleser, J.L. Harringa, JOM 59, 38–43 (2007)

A.A. El-Daly, A.A. Ibrahiem, J. Alloys Compds. 740, 801–809 (2018)

S.M.L. Nai, J.V.M. Kuma, M.E. Alam, X.L. Zhong, P. Babaghorbani, M. Gupta, J. Mater. Eng. Perform. 19, 335–341 (2010)

S. Chen, L. Zhang, J. Liu, Y. Gao, Q. Zhai, Mater. Trans. A 51, 1720–1726 (2010)

G. Ren, M.N. Collins, J. Alloys Compds. 791, 559–566 (2019)

G. Zeng, S.D. McDonald, Q. Gu, Y. Terada, K. Uesugi, H. Yasuda, K. Nogita, Acta Mater. 83, 357–371 (2015)

T. Laurila, V. Vuorinen, M.P. Kröckel, Mater. Sci. Eng. R 68, 1–38 (2010)

Z.L. Ma, S.A. Belyakov, C.M. Gourlay, J. Alloys Compds. 682, 326–337 (2016)

F. Gao, T. Takemoto, H. Nishikawa, Mater. Sci. Eng. A 420, 39–46 (2006)

M.A. Fazal, N.K. Liyana, S. Rubaiee, A. Anas, J. Int. Meas. Confed. 134, 897–907 (2019)

Y. Tang, Q.W. Guo, S.M. Luo, Z.H. Li, G.Y. Li, C.J. Hou, Z.Y. Zhong, J.J. Zhuang, J. Alloys Compds. 778, 741–755 (2019)

J. Wu, S. Xue, J. Wang, J. Wang, S. Liu, J. Mater. Sci. Mater. Electron. 28, 10230–10244 (2017)

V.L. Niranjani, B. Chandra Rao, R. Sarkar, S.V. Kamat, J. Alloy Compds. 542, 136–141 (2012)

S.H. Kim, J. Yu, Scr. Mater. 69, 254–257 (2013)

D. Shnawah, M. Sabri, I. Badruddin, S. Said, T. Ariga, F. Che, J. Electron. Mater. 42, 470–484 (2013)

M.L. Huang, L. Wang, Metall. Mater. Trans. A 36, 1439–1446 (2005)

M.G. Cho, H.Y. Kim, S.K. Seo, H.M. Lee, Appl. Phys. Lett. 95, 021905 (2009)

A.A. El-Daly, A.M. El-Taher, S. Gouda, Mater. Des. 65, 796–805 (2015)

G. Saad, S.A. Fayek, A. Fawzy, H.N. Soliman, Gh Mater, Sci. Eng. A 527, 904–910 (2010)

A.A. El-Daly, A.M. El-Taher, T.R. Dalloul, J. Alloys Compds. 587, 32–39 (2014)

A.A. El-Daly, A.A. Ibrahiem, M.A. Abdo, N.A.M. Eid, J. Mater. Sci. 30, 12937–12949 (2019)

M. Yang, Y.H. Ko, J.H. Bang, T.S. Kim, C.W. Lee, M.Y. Li, Mater. Charact. 124, 250–259 (2017)

S.A. Belyakov, C.M. Gourlay, Acta Mater. 71, 56–68 (2014)

S.A. Belyakov, Z.L. Ma, C.M. Gourlay, J. Alloys Compds. 682, 326–337 (2016)

K. Nogita, C.M. Gourlay, T. Nishimura, Jom 61, 45–51 (2009)

X. Chen, J. Zhou, F. Xue, J. Bai, Y. Yao, J. Electron. Mater. 44(2), 725–732 (2015)

A.F. da Silveira, W.B. de Castro, B.A. Luciano, C.S. Kiminami, Mater. Sci. Eng. A 375–377, 473–478 (2004)

I.E. Anderson, J.L. Harringa, J. Electron. Mater. 33, 1485–1496 (2004)

K.S. Kim, S.H. Huh, K. Suganuma, Microelectron. Reliab. 43, 259–267 (2003)

H. Xie, N. Chawla, K. Mirpuri, J. Electron. Mater. 41, 3249–3258 (2012)

Z.L. Ma, S.A. Belyakov, C.M. Gourlay, J. Alloys Compds 682, 326–337 (2016)

Y. Liu, F. Sun, Y. Liu, X. Li, J. Mater. Sci. Mater. Electron. 25, 2627–2633 (2014)

A.A. El-Daly, A.M. El-Taher, Mater. Des. 47, 607–614 (2013)

A.A. El-Daly, A.E. Hammad, Mater. Des. 40, 292–298 (2012)

S.W. Wu, G. Wang, Q. Wang, Y.D. Jia, J. Yi, Q.J. Zhai, J.B. Liu, B.A. Sun, H.J. Chu, J. Shen, P.K. Liaw, C.T. Liu, T.Y. Zhang, Acta Mater. 165, 444–458 (2019)

J.R. Croteau, S. Griffiths, M.D. Rossell, C. Leinenbach, C. Kenel, V. Jansen, D.N. Seidman, D.C. Dunand, N.Q. Vo, Acta Mater. 153, 35–44 (2018)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

El-Taher, A.M., Ibrahiem, A.A. & Razzk, A.F. Viscoplastic characterization of novel (Fe, Co, Te)/Bi containing Sn–3.0Ag–0.7Cu lead-free solder alloy. J Mater Sci: Mater Electron 31, 5521–5532 (2020). https://doi.org/10.1007/s10854-020-03117-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03117-z