Abstract

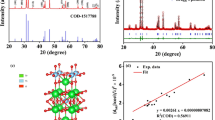

Sm2/3Cu3Ti4O12 ceramics with giant dielectric constant were successfully prepared by the traditional solid-state sintering process. The dielectric characteristics and relevant mechanism were systematically investigated. The dielectric constants of Sm2/3Cu3Ti4O12 ceramics can reach to 104 at 298 K and 1 kHz, and also exhibited two distinct thermal-activated dielectric relaxations in different temperature ranges. The dielectric relaxation at low temperatures was regarded as the effect of the polyvalence structures (Cu2+/Cu3+ and Ti3+/Ti4+) in grains due to the oxygen compensation during the sintering process, while the dielectric relaxation at high temperatures was induced by the grain boundary effects. The giant dielectric response in Sm2/3Cu3Ti4O12 ceramics can be associated with the heterogeneous structure and combined effect of the grain and grain boundary.

Similar content being viewed by others

References

C.C. Homes, T. Vogt, S.M. Shapiro, S. Wakimoto, A.P. Ramirez, Science 293, 673 (2001)

M.A. Subramanian, A.W. Sleight, Solid State Sci. 4, 347 (2002)

L. Ni, X.M. Chen, Appl. Phys. Lett. 91, 122905 (2007)

P. Lunkenheimer, R. Fichtl, S.G. Ebbinghaus, A. Loidl, Phys. Rev. B 70, 172101 (2004)

L. Zhang, Z.J. Tang, Phys. Rev. B 70, 174306 (2004)

Y. Zhu, J.C. Zheng, L. Wu, A.I. Frenkel, J. Hanson, P. Northrup, W. Ku, Phys. Rev. Lett. 99, 037602 (2007)

S.Y. Chung, Appl. Phys. Lett. 87, 052901 (2005)

C.C. Wang, L.W. Zhang, Appl. Phys. Lett. 88, 042906 (2006)

W. Li, R.W. Schwartz, Phys. Rev. B 75, 012104 (2007)

T.T. Fang, H.K. Shiau, J. Am. Ceram. Soc. 87, 2072 (2010)

R. Schmidt, M.C. Stennett, N.C. Hyatt, J. Pokomy, J.P. Gonjua, M. Li, D.C. Sinclair, J. Eur. Ceram. Soc. 32, 3313 (2012)

S.H. Hong, D.Y. Kim, H.M. Park, Y.M. Kim, J. Am. Ceram. Soc. 90, 2118 (2007)

M. Li, G. Cai, D.F. Zhang, W.Y. Wang, W.J. Wang, X.L. Chen, J. Appl. Phys. 104, 074107 (2008)

P. Thongbai, B. Putasaeng, T. Yamwong, S. Maensiri, Mater. Res. Bull. 47, 2257 (2012)

J. Jumpatam, B. Putasaeng, T. Yamwron, P. Thongbai, S. Maensiri, Ceram. Int. 39, 1057 (2013)

C.H. Mu, Y.Q. Song, H.B. Wang, X.N. Wang, J. Appl. Phys. 117, 17B723 (2015)

J. Yang, C.P. Yang, X.J. Luo, D.W. Shi, H.B. Xiao, L.F. Xu, K. Bȁrner, Ceram. Int. 42, 10866 (2016)

J. Boonlakhorn, P. Thongbai, Ceram. Int. 43, 12736 (2017)

Z.H. Peng, J.W. Li, P.F. Liang, Z.P. Yang, X.L. Chao, J. Eur. Ceram. Soc. 37, 4637 (2017)

R.Z. Xue, G.Y. Zhao, J. Chen, Z.P. Chen, D.W. Liu, Mater. Res. Bull. 76, 124 (2016)

J. Boonlakhorn, P. Kidkhunthod, M. Chanlek, P. Thongbai, J. Eur. Ceram. Soc. 38, 137 (2018)

J. Wang, Z.Y. Lu, T.F. Deng, C.F. Zhong, Z.W. Chen, J. Am. Ceram. Soc. 100, 4021 (2017)

Z.H. Peng, P.F. Liang, X. Wang, H. Peng, X.F. Chen, Z.P. Yang, X.L. Chao, Mater. Lett. 210, 301 (2018)

P.F. Liang, Z.P. Yang, X.L. Chao, Z.H. Liu, J. Am. Ceram. Soc. 95, 2218 (2012)

J.J. Liu, C.G. Duan, W.N. Mei, R.W. Smith, J.R. Hardy, J. Appl. Phys. 98, 093703 (2005)

H.M. Ren, P.F. Liang, Z.P. Yang, Mater. Res. Bull. 45, 1608 (2010)

P. Kum-onsa, P. Thongbai, B. Putasaeng, T. Yamwong, S. Maensiri, J. Eur. Ceram. Soc. 35, 1441 (2015)

L. Ni, M.S. Fu, Y. Liu, T.Y. Tang, S. Wang, B. Zou, S.G. Zhao, J. Mater. Sci. 27, 111 (2016)

P.S. Neelakantaswamy, B.V.R. Chowdari, A. Rajaratnam, J. Phys D 16, 1785 (1983)

Acknowledgements

This work was financially supported by the National Science Foundation of China (Grand Number 51501017), and the fund of State Key Laboratory of Solidification Processing in NWPU (Grand Number KP201524) of China and the fund of National College Students’ Innovative and Entrepreneurial Training Program (Grand Number 201510710085). Authors are grateful to the Laboratory of Dielectric Materials in Zhejiang University for the support in performing the measurement of dielectric properties.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ni, L., Fu, M. & Zhang, Y. Dielectric relaxation and relevant mechanism in giant dielectric constant Sm2/3Cu3Ti4O12 ceramics. J Mater Sci: Mater Electron 29, 17737–17742 (2018). https://doi.org/10.1007/s10854-018-9880-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9880-8