Abstract

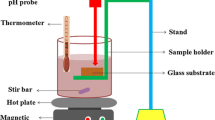

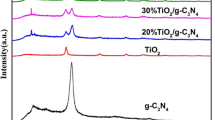

A sol–gel method is used to synthesize Ce–S codoped TiO2–SiO2 composite nanocrystalline films on the glass substrates in this paper. The influence of the metal/nonmetal ions codoping on both the physicochemical characteristics and photocatalytic performance of the composite film was studied. It was found that ions codoping induces a better charge separation and a smaller band gap energy, which are responsible for the improvement in the photo-degradation with respect to the acid naphthol red aqueous solution under visible light illumination. Moreover, the morphology, crystalline structures and compositions of the films were analyzed, and the doping mechanism was also investigated.

Similar content being viewed by others

References

J. Yan, T. Wang, G. Wu et al., Adv. Mater. 27, 1580 (2015). doi:10.1002/adma.201404792

C. Kaewtip, K. Accanit, N-a-n Chaowai, K. Areerat, P. Reanjaruan, V. Boonumnauyvitaya, Adv. Mater. Phys. Chem. 02, 40 (2012). doi:10.4236/ampc.2012.24B012

C. Kaewtip, P. Chadpunyanun, V. Boonamnuayvitaya, Water Air Soil Pollut. 223, 1455 (2011). doi:10.1007/s11270-011-0957-8

Y. Yao, N. Zhao, J.-J. Feng, M.-M. Yao, F. Li, Ceram. Int. 39, 4735 (2013). doi:10.1016/j.ceramint.2012.11.035

L. Zhang, X. Li, Z. Chang, D. Li, Mater. Sci. Semicond. Process. 14, 52 (2011). doi:10.1016/j.mssp.2011.01.004

K. Das, S.N. Sharma, M. Kumar, S.K. De, J. Phys. Chem. C 113, 14783 (2009)

J. Xu, X. Xiao, A.L. Stepanov et al., Nanoscale Res. Lett. (2013). doi:10.1186/1556-276X-8-73

J. Zhou, Y. Cheng, J. Yu, J. Photochem. Photobiol. A 223, 82 (2011). doi:10.1016/j.jphotochem.2011.07.016

J. Zhou, F. Ren, S. Zhang et al., J. Mater. Chem. A 1, 13128 (2013). doi:10.1039/c3ta12540h

F. Dong, W. Zhao, Z. Wu, Nanotechnology 19, 365607 (2008). doi:10.1088/0957-4484/19/36/365607

J. Xu, B. Yang, M. Wu, Z. Fu, Y. Lv, Y. Zhao, J. Phys. Chem. 114, 15251 (2010)

W.J. Lee, J.M. Lee, S.T. Kochuveedu et al., ACS Nano 5, 935 (2012)

D. Chen, Z. Jiang, J. Geng, Q. Wang, D. Yang, Ind. Eng. Chem. Res. 46, 2741 (2007)

F. Li, H. Li, L-x Guan, M-m Yao, Chem. Eng. J. 252, 1 (2014). doi:10.1016/j.cej.2014.04.107

N. Zhang, S. Liu, X. Fu, Y.-J. Xu, J. Phys. Chem. C 115, 9136 (2011). doi:10.1021/jp2009989

X. Ye, C. Zheng, X. Xiao, S. Cai, Mater. Lett. 141, 191 (2015). doi:10.1016/j.matlet.2014.11.085

P. Qiu, W. Li, B. Thokchom et al., J. Mater. Chem. A 3, 6492 (2015). doi:10.1039/c4ta06891b

W. Li, J. Yang, Z. Wu et al., J. Am. Chem. Soc. 134, 11864 (2012). doi:10.1021/ja3037146

J. Du, J. Qi, D. Wang, Z. Tang, Energy Environ. Sci. 5, 6914 (2012). doi:10.1039/c2ee21264a

X.W. Lou, L.A. Archer, Adv. Mater. 20, 1853 (2008). doi:10.1002/adma.200702379

X. Wu, G.Q. Lu, L. Wang, Energy Environ. Sci. 4, 3565 (2011). doi:10.1039/c0ee00727g

J. Xu, M. Chen, D. Fu, Appl. Surf. Sci. 257, 7381 (2011). doi:10.1016/j.apsusc.2011.02.030

M.M. Momeni, M. Hakimian, A. Kazempour, Surf. Eng. 32, 514 (2016). doi:10.1179/1743294415y.0000000073

M.M. Momeni, Y. Ghayeb, Z. Ghonchegi, Surf. Eng. 32, 520 (2016). doi:10.1179/1743294415y.0000000061

M.M. Momeni, Mater. Res. Innov. 20, 317 (2016). doi:10.1080/14328917.2016.1138585

M.M. Momeni, Y. Ghayeb, J. Solid State Electrochem. 20, 683 (2015). doi:10.1007/s10008-015-3093-3

M.M. Momeni, Y. Ghayeb, J. Electroanal. Chem. 751, 43 (2015). doi:10.1016/j.jelechem.2015.05.035

M.M. Momeni, Y. Ghayeb, M. Davarzadeh, J. Solid State Electrochem. 739, 149 (2015). doi:10.1016/j.jelechem.2014.12.030

M.M. Momeni, Y. Ghayeb, J. Alloys Compd. 637, 393 (2015). doi:10.1016/j.jallcom.2015.02.137

M.M. Momeni, Z. Nazari, Ceram. Int. 42, 8691 (2016). doi:10.1016/j.ceramint.2016.02.103

M.M. Momeni, M. Hakimian, A. Kazempour, Ceram. Int. 41, 13692 (2015). doi:10.1016/j.ceramint.2015.07.158

M.M. Momeni, Y. Ghayeb, Z. Ghonchegi, Ceram. Int. 41, 8735 (2015). doi:10.1016/j.ceramint.2015.03.094

M.M. Momeni, Appl. Surf. Sci. 357, 160 (2015). doi:10.1016/j.apsusc.2015.09.015

M.M. Momeni, M. Mirhosseini, M. Chavoshi, A. Hakimizade, J. Mater. Sci.: Mater. Electron. 27, 3941 (2016). doi:10.1007/s10854-015-4246-y

M.M. Momeni, Y. Ghayeb, J. Mater. Sci.: Mater. Electron. 27, 3318 (2016). doi:10.1007/s10854-015-4161-2

M.M. Momeni, I. Ahadzadeh, A. Rahmati, J. Mater. Sci.: Mater. Electron. 27, 8646 (2016). doi:10.1007/s10854-016-4885-7

M.M. Momeni, Y. Ghayeb, J. Mater. Sci.: Mater. Electron. 26, 5509 (2015). doi:10.1007/s10854-015-3108-y

M.M. Momeni, Y. Ghayeb, Appl. Phys. A Mater. Sci. Process. 122, 1 (2016). doi:10.1007/s00339-016-0145-1

S. Zhang, M. Han, J. Zhang, Y. Li, Z. Hu, J. Chu, ACS Appl. Mater. Interfaces 5, 3191 (2013). doi:10.1021/am400196c

I.K. Battisha, J. Non Cryst. Solids 353, 1748 (2007). doi:10.1016/j.jnoncrysol.2007.01.043

M.-L. Dai, L.-X. Guan, F. Li, M.-M. Yao, Ceram. Int. 40, 7651 (2014). doi:10.1016/j.ceramint.2013.12.045

M. Yousefi, M. Amiri, R. Azimirad, A.Z. Moshfegh, J. Electroanal. Chem. 661, 106 (2011). doi:10.1016/j.jelechem.2011.07.022

X. Ren, Q. Ma, H. Fan et al., Chem. Commun. (Camb.) 51, 15997 (2015). doi:10.1039/c5cc06847a

Y.S. Hu, L. Kienle, Y.G. Guo, J. Maier, Adv. Mater. 18, 1421 (2006). doi:10.1002/adma.200502723

J. Liu, R. Han, Y. Zhao et al., J. Phys. Chem. C 115, 4507 (2011). doi:10.1021/jp110814b

Y. Yao, F. Ji, M. Yin et al., ACS Appl. Mater. Interfaces 28, 18165 (2016). doi:10.1021/acsami.6b04692

M.J. Muñoz-Batista, M.N. Gómez-Cerezo, A. Kubacka, D. Tudela, M. Fernández-García, ACS Catal. 4, 63 (2014). doi:10.1021/cs400878b

N.A. Joy, M.I. Nandasiri, P.H. Rogers et al., Anal. Chem. 84, 5025 (2012). doi:10.1021/ac3006846

M.M. Momeni, Indian J. Chem. 55A, 686 (2016)

W. Li, P. Da, Y. Zhang et al., ACS Nano 8, 11770 (2014). doi:10.1021/nn5053684

R. Adhikari, G. Gyawali, T.H. Kim, T. Sekino, S.W. Lee, J. Environ. Chem. Eng. 2, 1365 (2014). doi:10.1016/j.jece.2014.02.019

M.M. Momeni, M. Mirhosseini, M. Chavoshi, Ceram. Int. 42, 9133 (2016). doi:10.1016/j.ceramint.2016.03.002

D. Sánchez-Martínez, C. Gomez-Solis, L.M. Torres-Martinez, Mater. Res. Bull. 61, 165 (2015). doi:10.1016/j.materresbull.2014.10.034

G.-H. He, G.-L. He, A.-J. Li et al., J. Mol. Catal. A Chem. 385, 106 (2014). doi:10.1016/j.molcata.2014.01.022

Acknowledgments

The authors acknowledge supports from the Key Project of Ningxia Normal University Research Grant (Grant No. NXSFZD1516) and the Liupanshan Resources Engineering Technology Research Center.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yao, Y., Guan, Lx., Ma, Y. et al. Ce–S codoped TiO2–SiO2 composite nanocrystalline film with visible light photocatalytic activity. J Mater Sci: Mater Electron 28, 3013–3019 (2017). https://doi.org/10.1007/s10854-016-5887-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5887-1