Abstract

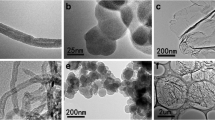

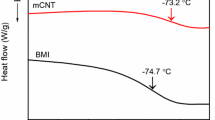

Nature rubber (NR)/carbon black (CB)/multi-walled carbon nanotubes (MWNTs) electrical conductive composites were prepared through latex compounding technique assisted by anionic surfactants containing phenyl ring moieties, NR/MWNTs masterbatch treated with silane coupling agent containing polysulphide bond and mixed with commercial NR, CB, sulphur and other ingredients and vulcanization. When MWNTs were dispersed in sodium dodecylbenzene sulfonate (SDBS) water solution, SDBS assembly on the surface of MWNTs prevent aggregation of MWNTs in water forming a stable MWNTs suspension. After MWNTs suspension mixed with NR latex, NR-MWNTs latex compound was co-coagulated to obtain the well dispersed NR/MWNTs masterbatch. In order to strengthen interface bonding between MWNTs and NR matrix, MWNTs in the masterbatch were treated with silane coupling agent by melt mixing process. During rubber mixing process, MWNTs dispersed in masterbatch thoroughly mixed with all the components and MWNTs homogenously embedded in NR matrix. Owing to homogenous dispersion of MWNTs, interfacial bonding between MWNTs and NR matrix as well as synergistic reinforcing effect between MWNTs and CB, NR/CB/MWNTs composites exhibited improved mechanical properties, dynamical storage modulus, glass transition temperature, electrical and thermal conductivity. Tensile strength, stress at 300 % strain, tear strength and steady state thermal conductivity of NR/CB/MWNTs composite with 4 phr MWNTs loading were increased by 12.36, 26.02, 16.95 and 102 %, respectively, and volume resistivity at room temperature of the composite was decreased by four orders of magnitude compared with NR/CB composite.

Similar content being viewed by others

References

V.V. Rajan, W.K. Dierkes, R. Joseph, J.W.M. Noordermeer, Prog. Polym. Sci. 31, 811 (2006)

A. Das, K.W. Stöckelhuber, R. Jurk, M. Saphiannikova, J. Fritzsche, H. Lorenz, M. Klüppel, G. Heinrich, Polymer 49, 5276 (2008)

S. Kohjiya, A. Kato, Y. Ikeda, Prog. Polym. Sci. 33, 979 (2008)

J.J.C. Busfield, C. Deeprasertkul, A.G. Thomas, Polymer 41, 9219 (2000)

L. Bokobza, J.P. Chauvin, Polymer 46, 4144 (2005)

H.H. Cai, S.D. Li, T.G. Rian, H.B. Wang, J.H. Wang, J. Appl. Polym. Sci. 87, 982 (2003)

C.A. Rezende, F.C. Braganc, T.R. Doi, L.T. Lee, F. Galembeck, F. Boué, Polymer 51, 3644 (2010)

L. Bokobza, O. Rapoport, J. Appl. Polym. Sci. 85, 2301 (2002)

S.K. Peddini, C.P. Bosnyak, N.M. Henderson, C.J. Ellison, D.R. Paul, Polymer 56, 443 (2015)

O. Breuer, U. Sundararaj, Polym. Compos. 25, 630 (2004)

P.C. Ma, J.-K. Kim, B.Z. Tang, Compos. Sci. Technol. 67, 2965 (2007)

S. Bhattacharyya, C. Sinturel, O. Bahloul, M.L. Saboungi, S. Thomas, J.P. Salvetat, Carbon 46, 1037 (2008)

N. Grossiord, J. Loos, C.E. Koning, J. Mater. Chem. 15, 2349 (2005)

C.F. Matos, F. Galembeck, A.J.G. Zarbin, Carbon 50, 4685 (2012)

Y.H. Zhan, G.Q. Liu, H.S. Xia, N. Yan, Plast. Rubber Compos. 40, 32 (2011)

A. Mohamed, A.K. Anas, S.A. Bakar, T. Ardyani, W.M.W. Zin, S. Ibrahim, M. Sagisaka, P. Brown, J. Eastoe, J. Colloid interface Sci. 455, 179 (2015)

A.M. Shanmugharaj, J.H. Bae, K.Y. Lee, W.H. Noh, S.H. Lee, S.H. Ryu, Compos. Sci. Technnol. 67, 1813 (2007)

N. Yan, J.K. Wu, Y.H. Zhan, H.S. Xia, Plast. Rubber Compos. 38, 290 (2009)

O.A. Al-Hartomy, A.A. Al-Ghamdi, F. Al-Salamy, N. Dishovsky, R. Shtarkova, V. Iliev, F. El-Tantawy, Plast. Rubber Compos. 41, 408 (2012)

B. Guo, Y. Lei, F. Chen, X.L. Liu, M. Du, D. Jia, Appl. Surf. Sci. 255, 7329 (2009)

R. Stephen, S. Jose, K. Joseph, S. Thomas, Z. Oommen, Polym. Degrad. Stab. 91, 1717 (2006)

T. Pojanavaraphan, R. Magaraphan, Eur. Polym. J. 44, 1968 (2008)

M.A. Kader, K. Kim, Y.S. Lee, C. Nah, J. Mater. Sci. 41, 7341 (2006)

S.-Y. Wu, S.-M. Yuen, C.-C.M. Ma, C.-L. Chiang, J. Appl. Polym. Sci. 115, 3481 (2010)

J. Xu, P. Yao, Z. Jiang, H. Liu, X. Li, L. Liu, M. Li, Y. Zheng, J. Appl. Polym. Sci. 125, E334 (2012)

Z. Peng, C. Feng, Y. Luo, Y. Li, L.X. Kong, Carbon 48, 4497 (2010)

J. Xu, J. Li, Y. Wu, S. Bai, J. Mater. Sci. Mater. Electron. 25, 233 (2014)

L. Bokobza, M. Rahmani, C. Belin, J.-L. Bruneel, N.-E. El Bounia, J. Polym. Sci. Part B Polym. Phys. 46, 1939 (2008)

P. Kueseng, P. Sae-oui, N. Rattanasom, Polym. Test. 32, 731 (2013)

Acknowledgments

We acknowledge financial support by National Training Programs of Innovation and Entrepreneurship for college student (No. 201510059006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, J., Li, S., Li, Y. et al. Preparation, morphology and properties of natural rubber/carbon black/multi-walled carbon nanotubes conductive composites. J Mater Sci: Mater Electron 27, 9531–9540 (2016). https://doi.org/10.1007/s10854-016-5005-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5005-4