Abstract

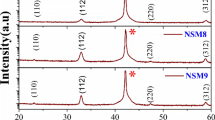

Colossal magnetoresistance La5/8Sr3/8MnO3 (LSMO) thin films were directly grown on MgO(100), Si(100) wafer and glass substrates by pulsed laser deposition technique. The films were characterized using X-ray diffraction (XRD), field emission-scanning electron microscope and atomic force microscopy (AFM). The electrical and magnetic properties of the films are studied. From the XRD patterns, the films are found to be polycrystalline single-phases. The surface appears porous and cauliflower-like morphology for all LSMO films. From AFM images, the LSMO films deposited on glass substrate were presented smooth morphologies of the top surfaces as comparing with the films were deposited on Si(100) and MgO(100). The highest magnetoresistance (MR) value obtained was −17.21 % for LSMO/MgO film followed by −15.65 % for LSMO/Si and −14.60 % for LSMO/Cg films at 80 K in a 1T magnetic field. Phase transition temperature (TP) is 224 K for LSMO/MgO, 200 K for LSMO/Si and above room temperature for films deposited on glass substrates. The films exhibit ferromagnetic transition at a temperature (TC) around 363 K for LSMO/MgO, 307 K for LSMO/Si and 352 K for LSMO/Cg thin film. TC such as 363 and 352 K are the high TC that has ever been reported for LSMO films deposited on MgO substrate with high lattice mismatch parameter and glass substrates with amorphous nature.

Similar content being viewed by others

References

K. Pan, S. Halim, K. Lim, W. Daud, S. Chen, M. Navasery, J. Mater. Sci. Mater. Electron. 24, 1869–1874 (2013)

Y. Xu, U. Memmert, U. Hartmann, Sens. Actuators A Phys. 91, 26–29 (2001)

M. Navasery, S.A. Halim, K.P. Lim, S.K. Chen, R. Abd-Shukor, Mod. Phys. Lett. B 26, 1150039–1150048 (2012)

M.B. Salamon, M. Jaime, Rev. Mod. Phys. 73, 583 (2001)

S.S. Balevičius, S. Keršulis, M. Schneider, O. Liebfried, V. Plaušinaitienė, A. Abrutis, IEEE Trans. Plasma Sci. 39, 411–416 (2011)

D. Liu, W. Liu, Ceram. Int. 38, 2579–2581 (2012)

Y. Yamada, O. Hino, S. Nohdo, R. Kanao, T. Inami, S. Katano, Phys. Rev. Lett. 77, 904–907 (1996)

A. Ramirez, J. Phys. Condens. Matter 9, 8171 (1997)

D. Liu, W. Liu, Ceram. Int. 37, 3531–3534 (2011)

D. Sahu, J. Phys. Chem. Solids 73, 622–625 (2012)

X. Zhu, H. Shen, K. Tsukamoto, T. Yanagisawa, M. Okutomi, N. Higuchi, Ceram. Int. 38, 6405–6410 (2012)

Z. Yang, L. Sun, C. Ke, X. Chen, W. Zhu, O. Tan, J. Cryst. Growth 311, 3289–3294 (2009)

S. Seo, H. Kang, H. Jang, D. Noh, Phys. Rev. B 71, 012412–012415 (2005)

T. Tsuchiya, K. Daoudi, T. Manabe, I. Yamaguchi, T. Kumagai, Appl. Surf. Sci. 253, 6504–6507 (2007)

Y. Jiang, G. Gao, Y. Wang, H. Chan, Solid State Commun. 150, 2028–2031 (2010)

M. Spankova, S. Chromik, I. Vavra, K. Sedlackova, P. Lobotka, S. Lucas, S. Stancek, Appl. Surf. Sci. 253, 7599–7603 (2007)

R. Gangineni, J. Kim, K. Nenkov, L. Schultz, J. Magn. Magn. Mater. 324, 1151–1153 (2012)

Z.P. Shaojie Fang, F. Wang, L. Lin, S. Han, J. Mater. Sci. Technol. 27, 223–226 (2011)

D. Sahu, J. Phys. Chem. Solids 73, 622–625 (2012)

D. Sahu, D. Mishra, J.L. Huang, B. Roul, Phys. B 396, 75–80 (2007)

D.R. Sahu, Appl. Surf. Sci. 255, 1870–1873 (2008)

S. Yang, W. Kuang, Y. Liou, W. Tse, S. Lee, Y. Yao, J. Magn. Magn. Mater. 268, 326–331 (2004)

L. Martin, Y.H. Chu, R. Ramesh, Mater. Sci. Eng. R Rep. 68, 89–133 (2010)

S.Y. Pai Li, L. Liu, X. Wang, Y. Wang, Z. Tian, J. He, K.L. Shijun Yuan, S. Ying, C. Wang, Solid State Commun. 146, 515–521 (2008)

X. Zhu, H. Shen, K. Tsukamoto, T. Yanagisawa, M. Okutomi, N. Higuchi, Ceram. Int. 38, 6405–6410 (2012)

P.M. Leufke, A.B. Ajay Kumar Mishra, Di. Wang, Christian. Kübel, Robert. Kruk, Horst. Hahn, Thin Solid Films 520, 5521–5527 (2012)

I. Gomes, B. Almeida, A. Lopes, J. Araújo, J. Barbosa, J. Mendes, J. Magn. Magn. Mater. 322, 1174–1177 (2010)

M. Sirenaa, M.G.N. Haberkorna, L.B. Steren, J. Guimpel, J. Magn. Magn. Mater. 272–276, 1171–1173 (2004)

S. Majumdar, H.S.M.H. Huhtinen, P. Paturi, J. Alloy. Compd. 512, 332–339 (2012)

J.H. Hongwei Qin, J. Chen, L. Zhu, H. Niu, Mater. Trans. 45, 1251–1254 (2004)

D.R. Sahu, J. Phys. Chem. Solids 73, 622–625 (2012)

S.A.H.M. Navasery, N. Soltani, G. Bahmanrokh, A. Dehzangi, M. Erfani, A. Kamalianfar, S.K. Chen, K.Y. Pan, Int. J. Electrochem. Sci. 8, 467–476 (2013)

S.A.H.M. Navasery, G. Bahmanrokh, M. Erfani, N. Soltani, A. Dehzangi, F.U.D.A. Kamalianfar, S. Abdolmohammadi, S.K. Chen, K.P. Lim, L.A. Mehdipour, A. Anuar, Int. J. Electrochem. Sci. 8, 6905–6921 (2013)

Acknowledgments

The Ministry of Science, Technology and Innovation of Malaysia is gratefully acknowledged for the grant under Science Fund vote: 5527047.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Navasery, M., Halim, S.A., Soltani, N. et al. Growth and characterization of La5/8Sr3/8MnO3 thin films prepared by pulsed laser deposition on different substrates. J Mater Sci: Mater Electron 25, 1317–1324 (2014). https://doi.org/10.1007/s10854-014-1729-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-1729-1