Abstract

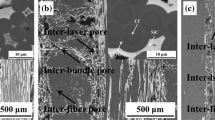

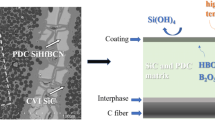

The microstructure and elemental composition evolution of Cf/SiC–Al composites prepared by combined precursor infiltration pyrolysis (PIP) and vacuum-pressure infiltration processes after high-temperature oxidation for different times was investigated. Meanwhile, the mechanical properties of the composites after oxidation treatment were characterized by nanoindentation and compressive performance tests. The results show that when the oxidation temperature was 400 °C and above, the weight loss rate of the composites gradually increased with the prolongation of the oxidation time, and the interface separation between the carbon fiber and SiC matrix became more obvious. Moreover, the nanoindentation elastic modulus of the Al alloy matrix and the SiC matrix decreased significantly with the increase in oxidation time, while the nanoindentation hardness of the aluminum alloy hardly changed. After oxidizing at 400 °C for 7 h, the in-plane compressive strength of the composites reached the maximum (584.7 MPa), and after oxidizing at 500 °C for 9 h, the compressive strength decreased to the minimum (347.8 MPa).

Similar content being viewed by others

Data availability

Data can be obtained by requesting the corresponding author.

References

Qi LH, Ma YQ, Zhou JM, Hou XH, Li HJ (2015) Effect of fiber orientation on mechanical properties of 2D-Cf/Al composites by liquid-solid extrusion following Vacuum infiltration technique. Mater Sci Eng A 625:343–349

Zhou JM, Yuan MQ, Li Z, Meng HM, Zhang T, Qi LH (2019) A great improvement of tensile properties of Cf/AZ91D composite through grafting CNTs onto the surface of the carbon fibers. Mater Sci Eng A 762:138061

Ma YQ, Qi LH, Zheng WQ, Zhou JM, Ju LY (2013) Effect of specific pressure on fabrication of 2D-Cf/Al composite by vacuum and pressure infiltration. Trans Nonferrous Met Soc China 23:1915–1921

Li DG, Chen GQ, Jiang LT, Lin X, Wu GH (2015) Mechanical Property of M40Jf/5A06Al Composite at Elevated Temperatures. Acta Metall Sin 28:1175–1182

Xu ZG, Li DG, Wang PP, Jiang LT, Chen GQ, Wu GH (2021) Effect of TM (TM =Fe, Mn, Cr) alloying on the high temperature properties and strengthening mechanism of Cf/Al composites. Compos B Eng 211:108622

Hou LG, Cui C, Zhang JS (2010) Optimizing microstructures of hypereutectic Al-Si alloys with high Fe content via spray forming technique. Mater Sci Eng A 527:6400–6412

Kim JT, Soprunyuk V, Chawake N, Zheng YH, Spieckermann F, Hong SH, Kim KB, Eckert J (2020) Outstanding strengthening behavior and dynamic mechanical properties of in-situ Al-Al3Ni composites by Cu addition. Compos B Eng 189:107891

Ezatpour HR, Sajjadi SA, Chaichi A, Ebrahimi GR (2017) Mechanical and microstructure properties of deformed Al-Al2O3 nanocomposite at elevated temperature. J Mater Res 32:1118–1128

Fei WD, Yue HY, Wang LD (2010) Equicohesive temperature of the interface and matrix and its effect on the tensile plasticity of Al18B4O33 whiskers reinforced aluminum composite at elevated temperature. Mater Chem Phys 119:515–518

Saadallah S, Cablé A, Hamamda S, Chetehouna K, Sahli M, Boubertakh A, Revo S, Gascoin N (2018) Structural and thermal characterization of multiwall carbon nanotubes (MWCNTs) / aluminum (Al) nanocomposites. Compos B Eng 151:232–236

Zhong H, Wang Z, Zhou HJ, Ni DW, Kan YM, Ding YS, Dong SM (2017) Properties and microstructure evolution of Cf/SiC composites fabricated by polymer impregnation and pyrolysis (PIP) with liquid polycarbosilane. Ceram Int 43:7387–7392

Li BB, Liao JH, Chen ZF, Liu JB, Mao BX, Huang HQ, Yuan XS (2019) High-performance Cf/SiC composites with a novel needle-punched carbon fiber fabric fabricated by PIP process. Mater Res Express 6:115622

Uhlmann F, Wilhelmi C, Schmidt-Wimmer S, Beyer S, Badini C, Padovano E (2017) Preparation and characterization of ZrB2 and TaC containing Cf/SiC composites via Polymer-Infiltration-Pyrolysis process. J Eur Ceram Soc 37:1955–1960

Liao JH, Chen ZF, Li BB, Liu JB, Guan TR, Yu SJ, Tang KY, Wu Q, Wang Y (2019) Microstructure and mechanical properties of Cf/SiC-Al composites fabricated by PIP and vacuum pressure infiltration processes. J Alloys Compd 803:934–941

Xue LP, Chen ZF, Liao JH, Xiao QQ, Li YH (2021) Compressive strength and damage mechanisms of 3D needle-punched Cf/SiC-Al composites. J Alloys Compd 853:156934

Snijiders PC, Jeurgens LPH, Sloof WG (2002) Structure of thin aluminium-oxide films determined from valence band spectra measured using XPS. Surf Sci 496:97–109

Shin SE, Ko YJ, Bae DH (2016) Mechanical and thermal properties of nanocarbon-reinforced aluminum matrix composites at elevated temperatures. Compos B Eng 106:66–73

Sun Z, Shan ZD, Shao TM, Li JH, Wu XH (2021) A multiscale modeling for predicting the thermal expansion behaviors of 3D C/SiC composites considering porosity and fiber volume fraction. Ceram Int 47:7925–7936

Zhu JB, Wang YW, Bao CG, Lu BH (2021) Effect of oxidization of 3D-SiC preforms on the interfacial structure and mechanical properties of co-continuous SiC/Al composites. Ceram Int 47:14635–14646

Jia JH, Bai SX, Xiong DG, Chen Q, Li C, Gao MQ (2022) Microstructure and ablation behaviour of a Cf/SiC-Al composite prepared by infiltrating Al alloy into Cf/SiC. J Alloy Compd 895:162430

Ma Y, Wang S, Chen ZH (2010) Raman spectroscopy studies of the high-temperature evolution of the free carbon phase in polycarbosilane derived SiC ceramics. Ceram Int 36:2455–2459

Li Y, Xiao P, Zhou W, Luo H, Li Z (2018) Microstructure and properties of plain-weave carbon fabric reinforced ceramic composites containing Cu-Si alloy. Compos B Eng 145:129–135

Maleki K, Alizadeh A, Hajizamani M (2021) Compressive strength and wear properties of SiC/Al6061 composites reinforced with high contents of SiC fabricated by pressure-assisted infiltration. Ceram Int 47:2406–2413

Li LH, Zhang CY, Zhang C, Wang KJ, Bai H, Han D, Li M (2018) Compressive strength and damage mechanisms of 2D-C/SiC composites at high temperatures. Ceram Int 44:14026–14031

Suo T, Fan XL, Hu GL, Li YL, Tang ZB, Xue P (2013) Compressive behavior of C/SiC composites over a wide range of strain rates and temperatures. Carbon 62:481–492

Levin I, Brandon D (1998) Metastable alumina polymorphs: crystal structures and transition sequences. J Am Ceram Soc 81:1995–2012

Xiang Y, Cao F, Peng ZH, Wang Y, Li GD (2017) Evolution of microstructure and mechanical properties of PIP-C/SiC composites after high-temperature oxidation. J Asian Ceram Soc 5:370–376

Evertsson J, Bertram F, Zhang F, Rullik L, Merte LR, Shipilin M (2015) The thickness of native oxides on aluminum alloys and single crystals. Appl Surf Sci 349:826–832

Nakamura K, Sato Y, Takase T (2016) Analysis of oxidation behavior of vapor-grown carbon fiber (VGCF) under dry air. Mater Lett 180:302–304

Li B, Wang XY, Jin X, Li Q, Han B, Guo CJ (2022) Study on thermal damage properties of carbon fiber composite high-pressure hydrogen tank under fire scenarios. Acta Energiae Solaris Sinica 43:398–404

Huang JG, Guo LJ, Li KJ, Yan NN, Zhou L, Li YY (2021) Microstructures and oxidation behaviors of Al-modified and Al2O3-modified SiC coatings on carbon/carbon composites via pack cementation. Ceram Int 47:8105–8112

Urena A, Martinez EE, Rodrigo P, Gil L (2004) Oxidation treatments for SiC particles used as reinforcement in aluminium matrix composites. Compos Sci Technol 64:1843–1854

Liu GF, Chen TJ, Wang ZJ (2021) Effects of solid solution treatment on microstructure and mechanical properties of SiCp/2024 Al composite: a comparison with 2024 Al alloy. Mater Sci Eng A 817:141413

Dai JX, Sha JJ, Zu YF, Zhang ZF, Zhou X, Lei MK (2019) Microstructural tailoring and its influence on oxidation resistance of carbon fiber-reinforced C-SiC matrix composites. Ceram Int 45:2044–2052

Zhang Y, Zheng HL, Liu Y, Shi L, Xu RF, Tian XL (2014) Cluster-assisted nucleation of silicon phase in hypoeutectic Al-Si alloy with further inoculation. Acta Mater 70:162–173

Mandal D, Viswanathan S (2013) Effect of heat treatment on microstructure and interface of SiC particle reinforced 2124 Al matrix composite. Mater Charact 85:73–81

Acknowledgements

This research work was supported by the National Natural Science Foundation of China (Grant No. 92160202 and Grant No. U2167214), Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX20_0197), and Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Contributions

JL: Conceptualization, Methodology, Investigation, Formal analysis, Visualization, Writing—original draft, Writing—review & editing, Funding acquisition. LY: Supervision, Project administration, Funding acquisition, Writing-review & editing. ZC: Supervision, Project administration, Funding acquisition. TG: Resources, Data Curation. TL: Methodology, Visualization, Resources.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

The experiment in this paper does not involve human tissue.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liao, J., Yang, L., Chen, Z. et al. Effect of oxidation time on microstructure and mechanical properties of Cf/SiC–Al composites after high-temperature oxidation. J Mater Sci 58, 3171–3186 (2023). https://doi.org/10.1007/s10853-023-08242-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08242-8