Abstract

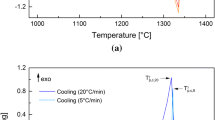

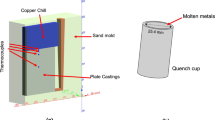

In this study, MeltFlow software was used to simulate the vacuum arc remelting of C700R-1 alloy and examine the effect of cooling rate on ingot properties. In situ observations, optical microscopy, field emission scanning electron microscopy, and electron probe microanalysis were performed to investigate the evolution of the solid–liquid interface, alloy microstructure, segregation characteristics, and back diffusion at various cooling rates from 1 to 20 °C/min. The obtained results revealed that with an increase in the alloy cooling rate, the dendrites were considerably refined, and the size of precipitates decreased. The composition of the μ phase did not change significantly with the cooling rate, whereas the MC carbides composition depended on the solidification temperature. W, Ti, Nb, and Mo elements demonstrated a distinct segregation trend, and their segregation degrees first increased and then decreased with an increase in the cooling rate. In contrast, the segregation degrees of Al, Ni, Cr, and Co elements were very small. Additionally, the effective partition coefficients of Ti, Nb, and Mo first decreased and then increased with increasing cooling rate. The alloy segregation degree reached a maximum value at a cooling rate of 6.8 °C/min. Finally, back diffusion in the solid observed at a very low cooling rate reduced the degree of dendrite segregation and volume of the precipitated phase. The findings of this study can help evaluate the microsegregation behavior of large-sized C700R-1 alloy ingots.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also constitute a part of an ongoing study.

References

Adam BM, Tucker JD, Tewksbury G (2020) Comparative study of the hot processing behavior in advanced Ni-based superalloys for use in A-USC applications. J Alloy Compd 818:152907

Di Gianfrancesco A (2017) A-USC R&D programs in other countries. In: Materials for ultra-supercritical and advanced ultra-supercritical power plants. Woodhead Publishing, Sawston, pp 755–772

Di Gianfrancesco A (2017) Alloy 263. In: Materials for ultra-supercritical and advanced ultra-supercritical power plants. Woodhead Publishing, Sawston, pp 571–599

Kruger KL (2017) HAYNES 282 alloy. In: Materials for ultra-supercritical and advanced ultra-supercritical power plants. Woodhead Publishing, Sawston, pp 511–545

Di Gianfrancesco A (2017) New Japanese materials for A-USC power plants. In: Materials for ultra-supercritical and advanced ultra-supercritical power plants. Woodhead Publishing, Sawston, pp 423–468

Liu Z, Xie X (2017) The Chinese 700 °C A-USC development program. In: Materials for ultra-supercritical and advanced ultra-supercritical power plants. Woodhead Publishing, Sawston, pp 715–731

Di Gianfrancesco A, Blum R (2017) A-USC programs in the European Union. In: Materials for ultra-supercritical and advanced ultra-supercritical power plants. Woodhead Publishing, Sawston, pp 773–846

Shingledecker JP (2017) The US DOE/OCDO A-USC materials technology R&D program. In: Materials for ultra-supercritical and advanced ultra-supercritical power plants. Woodhead Publishing, Sawston, pp 689–713

Shi C, Zheng X, Yang Z, Lan P, Li J, Jiang F (2020) Effect of melting rate of electroslag rapid remelting on the microstructure and carbides in a hot work tool steel. Met Mater Int 27:3603–3616

Tarenkova NY, Vykhodets VB, Krashaninin VA, Kurennykh TE, Fishman AY (2011) Formation of gas-saturated defects in titanium alloys during vacuum-arc remelting. Russ Metall (Metally) 2011:127–132

Manikandan SGK, Sivakumar D, Prasad Rao K, Kamaraj M (2014) Microstructural characterization of liquid nitrogen cooled Alloy 718 fusion zone. J Mater Process Technol 214:3141–3149

Han J, Ren N, Zhou Y, Zhang R, Li J, Huang X, Li J (2022) Melt convection and macrosegregation in the vacuum arc remelted Ti2AlNb ingot: Numerical methods and experimental verification. J Mater Process Technol 308:117729

Manikandan SGK, Sivakumar D, Rao KP, Kamaraj M (2014) Effect of weld cooling rate on Laves phase formation in Inconel 718 fusion zone. J Mater Process Technol 214:358–364

Ren N, Li J, Panwisawas C, Xia M, Dong H, Li J (2021) Thermal-solutal-fluid flow of channel segregation during directional solidification of single-crystal nickel-based superalloys. Acta Mater 206:116620

El-Bagoury N, Yamamoto K, Miyahara H, Ogi K (2005) Influence of rhenium and cooling rate on the solidification of Ni base superalloys, Inconel 718. Mater Trans 46:909–915

Seo SM, Lee JH, Yoo YS, Jo CY, Miyahara H, Ogi K (2011) A comparative study of the γ/γ′ eutectic evolution during the solidification of Ni-base superalloys. Metall Mater Trans A 42:3150–3159

Liang Q, Chen XC, Ren H, Shi CB, Guo HJ (2012) Numerical simulation of electroslag remelting process for producing GH4169 under different current frequency. Adv Mater Res 482–484:1556–1565

Shi X, Duan S-C, Yang W-S, Guo H-J, Guo J (2018) Effect of cooling rate on microsegregation during solidification of superalloy INCONEL 718 under slow-cooled conditions. Metall Mater Trans B 49:1883–1897

Huang Z, He X, Chen K, Wang X (2022) Solidification and segregation characteristics of Ni-based superalloy C700R–1 for ultra-supercritical steam turbine rotor. J Alloy Compd 912:165107

Gong L, Chen B, Du Z, Zhang M, Liu R, Liu K (2018) Investigation of solidification and segregation characteristics of cast Ni-base superalloy K417G. J Mater Sci Technol 34:541–550

Auburtin P, Wang T, Cockcroft SL, Mitchell A (2000) Freckle formation and freckle criterion in superalloy castings. Metall Mater Trans B 31:801–811

Lou Z-J, Zhu Z-L, Jia S, Liu H, Yang G-J, Wen Y-Y, Li Y (2022) Stray grain formation associated with constitutional supercooling during plasma re-melting of Ni-based single crystal superalloy based on temperature field simulation and actual substrate orientation. J Alloy Compd 890:161865

Mitani T, Hasegawa T, Watanabe C, Monzen R (2008) Effect of nitrogen on fatigue behavior of a high-speed steel. J Jpn Inst Met 72:105–110

Zhou D, Wang J, Lu Y, Bai Z, Li X, Huang Y (2020) Optimization of homogenization treatment parameters and microstructural evolution of large size DC AA2014 aluminum alloy. Mater Trans 61:1210–1219

Sathishkumar M, Manikandan M (2019) Preclusion of carbide precipitates in the Hastelloy X weldment using the current pulsing technique. J Manuf Process 45:9–21

Krishna R, Hainsworth SV, Gill SPA, Strang A, Atkinson HV (2012) Topologically close-packed μ phase precipitation in creep-exposed Inconel 617 alloy. Metall Mater Trans A 44:1419–1429

Sung PK, Poirier DR (1999) Liquid-solid partition ratios in nickel-base alloys. Metall Mater Trans A 30:2173–2181

Wang C, Su H, Guo Y, Guo J, Zhou L (2017) Solidification characteristics and segregation behavior of a P-containing Ni–Fe–Cr-based alloy. Appl Phys A 123:1–11

Wang C, Su H, Guo Y, Guo J, Zhou L (2018) Solidification characteristics and segregation behavior of a Ni–Fe–Cr based alloy. Rare Met Mater Eng 47:3816–3823

Clyne TW, Kurz W (1981) Solute redistribution during solidification with rapid solid state diffusion. Metall Trans A 12:965–971

Tong X, You G, Luo J, Ebrahimi M, Wu G (2021) Rapid cooling effect during solidification on macro- and micro-segregation of as-cast Mg–Gd alloy. Prog Nat Sci Mater Int 31:68–76

Li Y, Zou D, Chen W, Zhang Y, Zhang W, Xu F (2021) Effect of cooling rate on solidification and segregation characteristics of 904L super austenitic stainless steel. Met Mater Int 28:1907–1918

Shi Z, Dong J, Zhang M, Zheng L (2013) Solidification characteristics and segregation behavior of Ni-based superalloy K418 for auto turbocharger turbine. J Alloy Compd 571:168–177

Geng S, Jiang P, Shao X, Mi G, Wu H, Ai Y, Wang C, Han C, Chen R, Liu W, Zhang Y (2018) Effects of back-diffusion on solidification cracking susceptibility of Al–Mg alloys during welding: A phase-field study. Acta Mater 160:85–96

Larouche D (2007) Computation of solidification paths in multiphase alloys with back-diffusion. Calphad 31:490–504

Acknowledgements

This work was financially supported by the Chinese government under Grant Nos. 2021YFB3704102 and S20T61180ZD.

Author information

Authors and Affiliations

Contributions

ZH contributed to investigation, writing—original draft, data curation, and formal analysis. XW contributed to supervision, writing—review and editing, and formal analysis. KC contributed to investigation. XH contributed to supervision and funding acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, Z., He, X., Chen, K. et al. Effect of different cooling rates on the segregation of C700R-1 alloy during solidification. J Mater Sci 58, 3307–3322 (2023). https://doi.org/10.1007/s10853-023-08215-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08215-x