Abstract

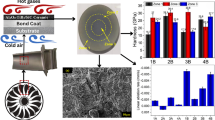

Ultra-high temperature ceramics, especially di-borides, are regarded as potential candidates for thermal protection system in hypersonic vehicles by virtue of their high thermal conductivity. However, studies on thermal conductivity behaviour of ultra-high temperature ceramic di-borides exhibit scattered data at high temperatures. Herein, we report a systematic study of a range of di-boride compositions aiming at multiple aspects including the effect of temperature on thermal conductivity of monolithic di-borides (ZrB2 and HfB2), effect of SiC and carbon nanotubes (CNTs) addition on ZrB2 and HfB2 with increasing temperature till 1200 °C, and effect on thermal conductivity with systematic incorporation of ZrB2 and HfB2 into each another. Highest experimental thermal conductivity (63–83 W m−1 K−1) observed in 20 vol% SiC reinforced ZrB2 composite (in the temperature range of 50–1200 °C) witnessed crossover (and drop) than that of monolithic sample (above 900 °C) due to increased phonon–phonon scattering in SiC with the rise in temperature. Concurrently, agglomerated CNT reinforcement further decreased thermal conductivity due to increased inhomogeneity in solid solutioning and enhanced phonon scattering.

Graphical abstract

Similar content being viewed by others

References

Harrington GJ, Hilmas GE (2014) Thermal conductivity of ZrB2 and HfB2. Ultra-high temperature ceramics: materials for extreme environment applications. Wiley, pp 197–235

Lawson JW, Daw MS, Bauschlicher CW (2011) Lattice thermal conductivity of ultra high temperature ceramics ZrB2 and HfB2 from atomistic simulations. J Appl Phys 110(8):083507

Guérineau V, Julian-Jankowiak A (2018) Oxidation mechanisms under water vapour conditions of ZrB2–SiC and HfB2–SiC based materials up to 2400 °C. J Eur Ceram Soc 38(2):421–432

Kubota Y et al (2017) Oxidation behavior of ZrB2–SiC–ZrC at 1700 °C. J Eur Ceram Soc 37(4):1187–1194

Bai Y et al (2019) Sintering temperature effect on microstructure, mechanical and electrical properties of multi-layered ZrB2-based ceramics with thin Ti interlayer. J Eur Ceram Soc 39(14):3938–3948

Gasch M, Johnson S, Marschall J (2008) Thermal conductivity characterization of hafnium diboride-based ultra-high-temperature ceramics. J Am Ceram Soc 91(5):1423–1432

Van Wie D et al (2004) The hypersonic environment: required operating conditions and design challenges. J Mater Sci 39(19):5915–5924. https://doi.org/10.1023/B:JMSC.0000041688.68135.8b

Kong Q et al (2022) Novel (Zr, Ti)B2–(Zr, Ti)C–SiC ceramics via reactive hot pressing. J Eur Ceram Soc 42(10):4045–4052

Kurbatkina V et al (2018) Self-propagating high-temperature synthesis of refractory boride ceramics (Zr, Ta) B2 with superior properties. J Eur Ceram Soc 38(4):1118–1127

Asl MS et al (2022) An interfacial survey on microstructure of ZrB2-based ceramics codoped with carbon fibers and SiC whiskers. Mater Chem Phys 275:125322

Wang H, Lee S-H, Feng L (2014) The processing and properties of (Zr, Hf)B2–SiC nanostructured composites. J Eur Ceram Soc 34(15):4105–4109

Xia C et al (2020) Enhanced fracture toughness of ZrB2–SiCw ceramics with graphene nano-platelets. Ceram Int 46(16):24906–24915

Ahmadi Z et al (2020) Phase transformation in spark plasma sintered ZrB2–V–C composites at different temperatures. Ceram Int 46(7):9415–9420

Nguyen TP et al (2020) Influence of SiAlON addition on the microstructure development of hot-pressed ZrB2–SiC composites. Ceram Int 46(11):19209–19216

Nguyen V-H et al (2021) ZrB2–SiCw composites with different carbonaceous additives. Int J Refract Metal Hard Mater 95:105457

Namini AS et al (2021) Role of TiCN addition on the characteristics of reactive spark plasma sintered ZrB2-based novel composites. J Alloy Compd 875:159901

Samsonov G et al (1973) Thermal conductivity of diborides of group IV–VI transition metals. High temperature (USSR) (English translation), vol 10, pp 1193–1195

Branscomb T, Hunter O Jr (1971) Improved thermal diffusivity method applied to TiB2, ZrB2, and HfB2 from 200–1300 °C. J Appl Phys 42(6):2309–2315

Thompson MJ, Fahrenholtz WG, Hilmas GE (2012) Elevated temperature thermal properties of ZrB2 with carbon additions. J Am Ceram Soc 95(3):1077–1085

McClane DL, Fahrenholtz WG, Hilmas GE (2014) Thermal properties of (Zr, TM) B2 solid solutions with TM = Hf, Nb, W, Ti, and Y. J Am Ceram Soc 97(5):1552–1558

Zimmermann JW et al (2008) Thermophysical properties of ZrB2 and ZrB2–SiC ceramics. J Am Ceram Soc 91(5):1405–1411

Chakraborty S et al (2014) Mechanical and thermal properties of hot-pressed ZrB2-SiC composites. Metall Mater Trans A 45(13):6277–6284

Zhang L et al (2011) Thermal and electrical transport properties of spark plasma-sintered HfB2 and ZrB2 ceramics. J Am Ceram Soc 94(8):2562–2570

Ikegami M et al (2010) Effect of SiC particle dispersion on thermal properties of SiC particle-dispersed ZrB2 matrix composites. J Mater Sci 45(19):5420–5423. https://doi.org/10.1007/s10853-010-4641-y

Hu C et al (2010) Microstructure and properties of ZrB2–SiC and HfB2–SiC composites fabricated by spark plasma sintering (SPS) using TaSi2 as sintering aid. J Ceram Soc Jpn 118(1383):997–1001

Hassan R, Omar S, Balani K (2019) Solid solutioning in ZrB2 with HfB2: effect on densification and oxidation resistance. Int J Refract Metal Hard Mater 84:105041

Nisar A, Balani K (2017) Phase and microstructural correlation of spark plasma sintered HfB2-ZrB2 based ultra-high temperature ceramic composites. Coatings 7(8):110

Zhang C et al (2017) Solid solution synthesis of tantalum carbide-hafnium carbide by spark plasma sintering. J Am Ceram Soc 100(5):1853–1862

Zhang C (2016) High temperature oxidation study of tantalum carbide-hafnium carbide solid solutions synthesized by spark plasma sintering. Florida International University, Miami

Zhang C et al (2017) Thermal analysis of tantalum carbide-hafnium carbide solid solutions from room temperature to 1400 °C. Coatings 7(8):111

Sitler SJ, Raja KS, Charit I (2017) ZrB2-HfB2 solid solutions as electrode materials for hydrogen reaction in acidic and basic solutions. Mater Lett 188:239–243

Dubey S et al (2022) Domination of phononic scattering in solid solutioning and interfaces of HfB2–ZrB2–SiC-carbon nanotube based ultra high temperature composites. Scr Mater 218:114776

Hassan R, Balani K (2020) Oxidation kinetics of ZrB2-and HfB2-powders and their SiC reinforced composites. Corros Sci 177:109024

Hassan R, Balani K (2021) Densification mechanism of spark plasma sintered ZrB2 and ZrB2-SiC ceramic composites. Mater Charact 179:111320

Ruys AJ (2020) Metal-reinforced ceramics. Woodhead Publishing

E‐13, A (2013) Standard test method for thermal diffusivity by the flash method. ASTM International West Conshohocken, PA

Clark Iii L, Taylor RE (1975) Radiation loss in the flash method for thermal diffusivity. J Appl Phys 46(2):714–719

Rhee S (1975) Porosity—thermal conductivity correlations for ceramic materials. Mater Sci Eng 20:89–93

Zapata-Solvas E et al (2013) Mechanical properties of ZrB2-and HfB2-based ultra-high temperature ceramics fabricated by spark plasma sintering. J Eur Ceram Soc 33(7):1373–1386

Monteverde F et al (2010) Densification, microstructure evolution and mechanical properties of ultrafine SiC particle-dispersed ZrB2 matrix composites. Boron rich solids. Springer, pp 261–272

Deschamps JR, Flippen-Anderson JL (2002) Crystallography. In: Meyers RA (ed) Encyclopedia of physical science and technology. Academic

Yin J et al (2017) Pressurelessly densified (Zr, Hf) B2-SiC ceramics by co-doping hafnium-boron carbides. J Alloys Compd 727:706–710

Silvestroni L, Sciti D (2011) Densification of ZrB2–TaSi2 and HfB2–TaSi2 ultra-high-temperature ceramic composites. J Am Ceram Soc 94(6):1920–1930

Patel M, Prasad VB, Jayaram V (2013) Heat conduction mechanisms in hot pressed ZrB2 and ZrB2–SiC composites. J Eur Ceram Soc 33(10):1615–1624

Nilsson O et al (1997) Determination of the thermal diffusivity and conductivity of monocrystalline silicon carbide (300–2300 K). High Temp High Press 29(1):73–79

Patil K, Gupta G (2019) Thermal investigations of multiwall carbon nanotubes. Int J Manag Technol Eng 9:1–6

Smith DS et al (2018) Grain boundary thermal resistance and finite grain size effects for heat conduction through porous polycrystalline alumina. Int J Heat Mass Transf 121:1273–1280

Harris GL (1995) Properties of silicon carbide.: Institution of Engineering and Technology. P p 297

Prochazka S (1975) Sintering of silicon carbide. Mass transport phenomena in ceramics. Springer, pp 421–431

Raju K, Yoon D-H (2016) Sintering additives for SiC based on the reactivity: a review. Ceram Int 42(16):17947–17962

McClane DL (2014) Thermal properties of zirconium diboride-transition metal boride solid solutions. In Materials science and engineering. Missouri University of Science and Technology, p. 127.

Chakraborty S et al (2014) Mechanical and thermal properties of hot pressed ZrB2 system with TiB2. Int J Refract Metals Hard Mater 46:35–42

Kumanek B, Janas D (2019) Thermal conductivity of carbon nanotube networks: a review. J Mater Sci 54(10):7397–7427. https://doi.org/10.1007/s10853-019-03368-0

Hassanzadeh-Aghdam MK, Mahmoodi MJ, Safi M (2019) Effect of adding carbon nanotubes on the thermal conductivity of steel fiber-reinforced concrete. Compos Part B Eng. 174:106972

Tian W-B et al (2008) Effect of carbon nanotubes on the properties of ZrB2–SiC ceramics. Mater Sci Eng A 487(1–2):568–573

Touloukian Y, C Ho, D Dewitt (1977) Thermophysical properties of matter. In: Touloukian (ed) Thermal expansion-nonmetallic solids, IFI Plenum, New York, pp 784–789

Fahrenholtz WG et al (2014) Ultra-high temperature ceramics: materials for extreme environment applications. The American Ceramic Society, Wiley

Chai Z et al (2021) Thermal conductivity of spark plasma sintered SiC ceramics with Alumina and Yttria. J Eur Ceram Soc 41(6):3264–3273

Acknowledgements

Space Technology Cell-IIT Kanpur of Indian Space Research Organisation is acknowledged for funding this project. Rubia Hassan at IIT Kanpur acknowledges MHRD, Government of India for funding through Prime Ministers Research Fellowship. Kantesh Balani acknowledges Yadupati Singhania Memorial Chair from J.K. Cotton Limited. Advanced Centre for Materials Science (ACMS) at IIT Kanpur is acknowledged for extending XRD, SEM and Indentation facilities. Vikram Sarabhai Space Centre (VSSC) is acknowledged for extending thermal conductivity measurement facility.

Funding

This work was supported by Space Technology Cell-IIT Kanpur of Indian Space Research Organisation and MHRD Govt. of India through Prime Minister Research Fellowship.

Author information

Authors and Affiliations

Contributions

RH designed the experiments, analysed the data and wrote the paper. Vincent Xavier performed the thermal conductivity tests. TV, KB conceived the idea. TV, KB and SO edited the paper. KB guided in organising the paper and procured the funding.

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that they have complied with the instructions on declaring interest in the guide for authors.

Additional information

Handling Editor: David Cann.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hassan, R., Xavier, V., Thiruvenkatam, V. et al. Crossover of thermal conductivity in SiC-reinforced ZrB2–HfB2 composites at elevated temperatures. J Mater Sci 58, 1505–1522 (2023). https://doi.org/10.1007/s10853-022-08132-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-08132-5