Abstract

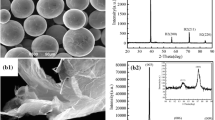

For the sake of reducing the interface reaction between graphene (GR) reinforcement and Ti6Al4V (TC4) alloys matrix, the nano-TiB2 particles were incorporated into GR/Ti interface after 3D dynamic mixing process, and TiB whiskers (TiBw) were formed by the subsequent reaction between TiB2 and Ti after spark plasma sintering (SPS) process. The network structured GR-TiBw/TC4 composites were fabricated by 3D dynamic mixing and SPS with a subsequent hot rolling deformation. Effects of GR-TiBw hybrid reinforcement and hot rolling on the microstructure and mechanical properties of the composites were investigated. The results showed that the in situ formed TiBw reduced GR/Ti interface reaction and the content of GR-TiBw hybrid reinforcements had a great influence on the interface structure and mechanical properties of the composites. The suitable GR content combined with low content of nano-TiBw can form a quasi-continuous network interface structure and achieve a good trade-off between strength and ductility with a higher tensile strength and acceptable ductility. After obtaining a high rolling reduction, the quasi-continuous network interface structure was reconstructed and brought a noticeable increase of tensile strength with a slight loss of ductility.

Graphical abstract

Similar content being viewed by others

References

Banerjee D, Williams JC et al (2013) Perspectives on titanium science and technology. Acta Mater 61:844–879

Attar H, Bönisch M et al (2014) Comparative study of microstructures and mechanical properties of in situ Ti–TiB composites produced by selective laser melting, powder metallurgy, and casting technologies. J Mater Res 29:1941–1950

Morsia K, Patela VV et al (2007) Processing and properties of titanium–titanium boride (TiBw) matrix composites—A review. J Mater Sci 42:2037–2047

Hayat MD, Singh H et al (2019) Titanium metal matrix composites: An overview. Compos A Appl Sci Manuf 121:418–438

Yetim AF, Celik A et al (2010) Improving tribological properties of Ti6Al4V alloy with duplex surface treatment. Surf Coat Technol 205:320–324

Ahmad SI, Hamoudi H et al (2020) Graphene reinforced bulk metal matrix composites: synthesis, microstructure, and properties. Rev Adv Mater Sci 59:67–114

Sivakumar G, Ananthi V et al (2017) Production and mechanical properties of nano SiC particle reinforced Ti-6Al-4V matrix composite. Trans Nonferrous Met Soc China 27:82–90

Wei S, Zhang ZH et al (2013) Effect of Ti content and sintering temperature on the microstructures and mechanical properties of TiB reinforced titanium composites synthesized by SPS process. Mater Sci Eng A 560:249–255

Huang LJ, Geng L et al (2011) In situ TiC particles reinforced Ti6Al4V matrix composite with a network reinforcement architecture. Mater Sci Eng A 528:2859–2862

Kundu S, Hussain M et al (2018) Direct metal laser sintering of TiN reinforced Ti6Al4V alloy based metal matrix composite: Fabrication and characterization. Int J Adv Manuf Technol 97:2635–2646

Huang LJ, Wang S et al (2012) Tailoring a novel network reinforcement architecture exploiting superior tensile properties of in situ TiBw/Ti composites. Mater Sci Eng 545:187–193

Huang LJ, Geng L et al (2009) In situ TiBw/Ti-6Al-4V composites with novel reinforcement architecture fabricated by reaction hot pressing. Scrip Mater 60:996–999

Young RJ, Kinloch IA et al (2012) The mechanics of graphene nanocomposites: a review. Compos Sci Technol 72:1459–1476

Liu J, Wu MX et al (2018) Preparation and mechanical performance of graphene platelet reinforced titanium nanocomposites for high temperature applications. J Alloys Compd 765:1111–1118

Abkowitz S, Abkowitz SM et al (2004) Discontinuously reinforced Ti-matrix composites: manufacturing, properties and applications. J O M 56:37–41

Yan Q, Chen B et al (2021) Super-high-strength graphene/titanium composites fabricated by selective laser melting. Carbon 174:451–462

Mu XN, Cai HN et al (2018) Uniform dispersion and interface analysis of nickel coated graphene nanoflakes/pure titanium matrix composites. Carbon 137:146–155

Mu XN, Zhang HM et al (2021) Towards high performance GNFs/Ti composite through simultaneously manipulating laminated microstructure and interface reaction. Mater Sci Eng A 814:141230

Jiang RR, Liu ZP et al (2017) Electroless Ni-plated graphene for tensile strength enhancement of copper. Mater Sci Eng 679:323–328

Zhang FM, Wang J et al (2020) Enhanced mechanical properties of few-layer graphene reinforced titanium alloy matrix nanocomposites with a network architecture. Mater Des 186:108–130

Feng YJ, Cui GR et al (2018) High temperature tensile fracture characteristics of the oriented TiB whisker reinforced TA15 matrix composites fabricated by pre-sintering and canned extrusion. J Alloy Compd 738:164–172

Chen WZ, Yang JL (2017) Influence of TiBw volume fraction on microstructure and high-temperature properties of in situ TiBw/Ti6Al4V composites with TiBw columnar reinforced structure fabricated by pre-sintering and canned extrusion. Adv Powder Technol 28:2346–2356

Li SF, Kondoh K (2016) Strengthening behavior of in situ synthesized (TiC+TiB)/Ti composites by powder metallurgy and hot extrusion. Mater Des 95:127–132

Mu XN, Cai HN et al (2018) Interface evolution and superior tensile properties of multi-layer graphene reinforced pure Ti matrix composite. Mater Des 140:431–441

Zhang B, Zhang FM et al (2021) Graphene-TiC hybrid reinforced titanium matrix composites with 3D network architecture: Fabrication, microstructure and mechanical properties. J Alloys Compd 859:157777

Zhang XN, Lu WJ et al (1999) In situ technique for synthesizing (TiB+TiC)/Ti composites. Scrip Mater 41:3946

Qin LY, Men JH et al (2021) Effect of TiB2 content on microstructure and mechanical properties of TiB Ti-6Al-4V composites formed by elective laser melting. Chin J Laser 48:2102–2108

Shang CY, Zhang FM et al (2020) Interface microstructure and strengthening mechanisms of multilayer graphene reinforced titanium alloy matrix nanocomposites with network architectures. Mater Des 196:109–119

Liu L, Li YK et al (2021) Simultaneously enhancing strength and ductility in graphene nanoplatelets reinforced titanium (GNPs/Ti) composites through a novel three-dimensional interface design. Compos Part B 2016:108851

Cui GR, Yang B et al (2020) The sticking out mechanism and growth of TiB whiskers from TiBw/Ti-6Al-4V composites during Sintering. Metals 10:1467

Pan D, Zhang X et al (2021) TiB nano-whiskers reinforced titanium matrix composites with novel nano-reticulated microstructure and high performance via composite powder by selective laser melting. Mater Sci Eng A 799:140137

Huang LJ, Geng L et al (2015) Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal? Prog Mater Sci 71:93–168

Mu XN, Cai HN et al (2018) Uniform dispersion of multi-layer graphene reinforced pure titanium matrix composites via flake powder metallurgy. Mater Sci Eng A 725:541–548

Chen B, Shen J et al (2017) Solid-state interfacial reaction and load transfer efficiency in carbon nanotubes (CNTs)-reinforced aluminum matrix composites. Carbon 114:198–208

Li SF, Sun B et al (2013) Powder metallurgy Ti–TiC metal matrix composites prepared by in situ reactive processing of Ti-VGCFs system. Carbon 61:216–228

Singha N, Ummethala R et al (2021) Spark plasma sintering of Ti6Al4V metal matrix composites: Microstructure, mechanical and corrosion properties. J Alloy Compd 865:158875

Huang LJ, Cui XP et al (2012) Effects of rolling deformation on microstructure and mechanical properties of network structured TiBw/Ti composites. Trans Nonferrous Met Soc China 22:79–83

Acknowledgements

This work was financed by the National Natural Science Foundation of China-Joint Fund of Advanced Aerospace Manufacturing Technology Research (No.U1737103) and Scientific Research Foundation for the Returned Overseas Chinese Scholars at State Education Ministry (No.2015-1098).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence this work in this paper.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wan, Q., Zhang, B., Zhang, F. et al. Interface-reaction reduction and hot rolling deformation of network structured graphene-TiB whiskers/Ti6Al4V composites by spark plasma sintering. J Mater Sci 57, 20601–20614 (2022). https://doi.org/10.1007/s10853-022-07936-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07936-9