Abstract

Some key structural parts made of welding titanium alloys usually serve in hydrogen environment in aerospace, ship building and chemical industries. To investigate the hydrogen embrittlement (HE) behaviors of the welded titanium alloy joints and the impact factors, the TC4 titanium alloy joints welded by laser welding method were first treated by ultrasonic surface rolling process (USRP). Then, slow-rate tensile tests were conducted under electrochemical hydrogen charging condition to compare the mechanical properties of the TC4 laser welded joints before and after USRP. On this basis, the HE behaviors and mechanisms of the USRP-treated TC4 laser welded joint and the USRP-untreated one were discussed in detail. The results show that USRP could significantly improve the anti-hydrogen embrittlement behaviors of the TC4 laser welded joint, which could be attributed to the grain refinement and residual compressive stress in the deformation layer induced by USRP. The results of this paper provide a theoretical basis for the design of anti-hydrogen embrittlement metal materials.

Similar content being viewed by others

References

Boyer R (1996) An overview on the use of titanium in the aerospace industry. Mater Sci Eng A 213:103–114. https://doi.org/10.1016/0921-5093(96)10233-1

Lütjering G, William JC (2003) Titanium. Springer, NewYork, p 56

Leyens C, Peters M (2006) Titanium and titanium alloys: fundamentals and applications. Wiley-Vch, Germany, p 247

Liu H, Nakata K, Zhang JX et al (2012) Microstructural evolution of fusion zone in laser beam welds of pure titanium. Mater Charact 65:1–7. https://doi.org/10.1016/j.matchar.2011.12.010

Xu P (2012) Microstructure characterization of Ti–6Al–4V titanium laser weld and its deformation. Trans Nonferrous Met Soc China 22(9):2118–2123. https://doi.org/10.1016/S1003-6326(11)61437-4

Jijun H, Junhui D, Qiliang Z (2016) Analysis on microstructure and fracture of TC4 titanium alloy laser welded joints. Hot Work Technol 45(03):35-37+41. https://doi.org/10.14158/j.cnki.1001-3814.2016.03.009

Donghai C, Zhao F, Ming W, Yiping C (2015) Research on numerical simulation of lateral superplastic deformation of TC4 titanium alloys laser welded joint. Hot Work Technol 44(17):199–202. https://doi.org/10.14158/j.cnki.1001-3814.2015.17.060

Donghai C, Jihua H, Yiping C, Dean H (2012) Microstructure evolution characterization of superplastic deformation of titanium alloy. Trans China Weld Inst 33(07):89–92. https://doi.org/10.1007/s11783-011-0280-z

Donghai C, Yiping C, Dean H, Qiang W (2011) Microstructure analysis of superplastic deformation on laser butt weld Ti–6Al–4V joint. Trans China Weld Inst 32(09):81-84+117. https://doi.org/10.1016/S1005-0302(11)60031-5

Denny PE, Metzbower EA (1989) Laser beam welding of titanium. Weld J 68(8): 342s–346s. https://www.researchgate.net/publication/293625247_Laser_beam_welding_of_titanium

Baeslack III WA, Banas CM (1981) Comparative evaluation of laser and gas tungsten arc welding in high temperature titanium alloys. Weld J 60(7):121s–130s

Dos Santos J, Çam G, Torster F et al. (2000) Properties of power beam welded steels, Al- and Ti-alloys: significance of strength mismatch. Weld world 44(60): 42–64. https://www.researchgate.net/publication/279909975_Properties_of_power_beam_welded_steels_al-and_ti-alloys_Significance_of_strength_mismatch

Xian W, Rongtao Z, Chaoyong L, Xiang W, Pengfei H (2020) Hydrogen embrittlement behavior and mechanisms of Ti–6Al–4V alloy based on small punch test. Rare Metal Mater Eng 49(11): 3769–3775. https://kns.cnki.net/kcms/detail/detail.aspx?FileName=COSE202011015&DbName=CJFQ2020

Long Wang et al (2020) Effect of hydrogen content on microstructure and hardness of TC4 titanium alloy laser welded joints. J Mater Heat Treat 41(04):181–187. https://doi.org/10.13289/j.issn.1009-6264.2019-0467

Lu G, Kaxiras E (2005) Hydrogen embrittlement of aluminum: the crucial role of vacancies. Phys Rev Lett 94:155501. https://doi.org/10.1103/PhysRevLett.94.155501

Hosseini E, Kazeminezhad M, Mani A (2009) On the evolution of flow stress during constrained groove pressing of pure copper-sheet. Comput Mater Sci 45(9):855–859. https://doi.org/10.1016/j.commatsci.2008.12.004

Jiang W, Xiuquan C, Qinxiang X, Jiayu L (2017) Experimental research on influence of restraint layer materials on surface strengthening of 7075 aluminum alloy laser shot peening. Surf Technol 46(3):124–129. https://doi.org/10.16490/j.cnki.issn.1001-3660.2017.03.019

Wei L, Shirong Y, Le Z (2017) Effects of surface shot peening strengthening on fatigue property of TC11 titanium alloy. Surf Technol 46(3):172–176. https://doi.org/10.16490/j.cnki.issn.1001-3660.2017.03.026

Fan Z, Xu H, Li D et al (2012) Surface nanocrystallization of 35# type carbon steel induced by ultrasonic impact treatment (UIT). Procedia Eng 27:1718–1722. https://doi.org/10.1016/j.proeng.2011.12.641

Xin Z, Tianfu J, Yuwei G, Wei W, Jifeng Z (2004) Grain-refining mechanism of severe rolling to lath martensite. J Iron Steel Res 12(16):69–73. https://doi.org/10.13228/j.boyuan.issn1001-0963.2004.06.015

Bozdana AT, Gindy NNZ, Li H (2005) Deep cold rolling with ultrasonic vibrations: a new mechanical surface enhancement technique. Int J Mach Tools Manuf 45(6):713–718. https://doi.org/10.1016/j.ijmachtools.2004.09.017

Tsuji N, Tanaka S, Takasugi T (2009) Effect of combined plasmac-arburizing and deep-rolling on notch fatigue property of Ti–6Al–4V alloy. Mater Sci Eng A 499(1–2):482–488. https://doi.org/10.1016/j.msea.2008.09.008

Guangyi LV, Youli Z, Li L, Xiaoguang H (2007) The effect of ultrasonic deep rolling (UDR) on surface topography and surface roughness of TC4 Titanium alloy. China Surf Eng 20(4): 38–41. https://kns.cnki.net/kcms/detail/detail.aspx?FileName=BMGC200704010&DbName=CJFQ2007

Guizhi X, Jin Z, Conghui Z, Ying L (2019) Surface performance of ultrasonic impact-rolling commercial titanium welded joints. Chin J Rare Met 43(9):959–966. https://doi.org/10.13373/j.cnki.cjrm.xy18070004

Yanfeng G, Long L (2018) Surface quality determination of TC4 alloy treated by ultrasonic rolling process through nano-indentation. Tool Eng 52(6):33–36. https://doi.org/10.16567/j.cnki.1000-7008.2018.06.016

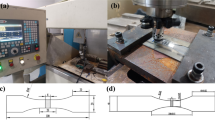

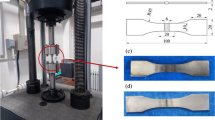

GB/T 2651-2008, Tensile test methods for welded joints

Shi JP, Song G, Chi JY (2018) Effect of active gas on weld appearance and performance in laser-TIG hybrid welded titanium alloy. Int J Lightweight Mater Manuf 1(1):47–53. https://doi.org/10.1016/j.ijlmm.2018.03.002

Zhi LX, Bing HS, Zhong XJ, Long-bo J (2011) Effects of the heterogeneity in the electron beam welded joint on fatigue crack growth in Ti−6Al−4V alloy. Mater Sci Eng A 529:170–176. https://doi.org/10.1016/j.msea.2011.09.014

Böhme T, Dornscheidt C, Pretorius T, et al. (2012) Modeling, simulation and experimental studies of distortions, residual stresses and hydrogen diffusion during laser welding of as-rolled steels. InTech

Liu J, Zhan X, Gao Z et al (2020) Microstructure and stress distribution of TC4 titanium alloy joint using laser-multi-pass-narrow-gap welding. Int J Adv Manuf Technol 108(3):1–11. https://doi.org/10.1007/s00170-020-05623-0

Guedes D, Oudriss A, Frappart S et al (2014) The influence of hydrostatic stress states on the hydrogen solubility in martensitic steels. Scripta Mater 84–85:23–26

Chen Y, Microstructures L F, University S (2015) Kinetics of hydrogen diffusion in Ti–6Al–4V Alloy. Rare Met Mater Eng 44(3):553–556. https://doi.org/10.1016/S1875-5372(15)30037-0

Fan K, Liu D, Zhang X, Liu D, Zhao W, Yang J, Ma A, Li M, Qi Y, Xiang J, Wahab MA (2022) Effect of residual stress induced by ultrasonic surface rolling on fretting fatigue behaviors of Ti–6Al–4V alloy. Eng Fract Mech 259:108150. https://doi.org/10.1016/j.engfracmech.2021.108150

Kumar GR, Muralidharan A, Rajyalakshmi G et al (2021) Atom probe tomography analysis of hydrogen distribution in laser peened Ti6Al4V alloy to control hydrogen embrittlement. Int J Adv Manuf Technol 114:1395–1408. https://doi.org/10.1007/s00170-021-06951-5

Wu W, Wang Y, Tao P et al (2018) Cohesive zone modeling of hydrogen-induced delayed intergranular fracture in high strength steels. Results Phys 11:591–598. https://doi.org/10.1016/j.rinp.2018.10.001

Wang Y, Wang X, Gong J et al (2014) Hydrogen embrittlement of catholically hydrogen-precharged 304L austenitic stainless steel: effect of plastic pre-strain. Int J Hydrogen Energy 39(25):13909–13918. https://doi.org/10.1016/j.ijhydene.2014.04.122

Acknowledgements

This work was supported by Fundamental Research Funds for the Central Universities (China University of Mining and Technology) (2019GF08).

Funding

Fundamental Research Funds for the Central Universities (China University of Mining and Technology), 2019GF08, Rongtao Zhu, Postgraduate Research & amp; Practice Innovation Program of Jiangsu Province, KYCX21_2206, Shu Ma.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest, and manuscript is approved by all authors for publication. I would like to declare on behalf of my co-authors that the work described was original research that has not been published previously, and not under consideration for publication elsewhere, in whole or in part. All the authors listed have approved the manuscript that is enclosed.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, R., Ma, S., Wang, X. et al. Effect of ultrasonic surface rolling process on hydrogen embrittlement behavior of TC4 laser welded joints. J Mater Sci 57, 11997–12011 (2022). https://doi.org/10.1007/s10853-022-07348-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07348-9