Abstract

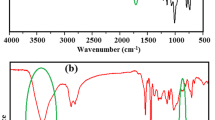

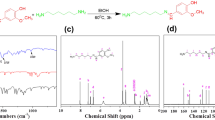

The designing of low-cost, high-performance, bio-based epoxy thermosets that can cope with the global oil crisis and climate change is a challenge. A bio-based epoxy resin was synthesized from gallic acid using epichlorohydrin, and a carboxylic acid-modified tannic acid (CATA) was obtained using simple esterification in which the gallic acid-based epoxy resin (GA-EP)/methyl nadic anhydride (MNA)/2-ethyl-4-methylimidazole (2,4-EMI) curing system was used as a toughener. Moreover, the structural characterization, mechanical performance, curing behavior, and thermal properties of epoxy thermosets were investigated. Consequently, the addition of only 1.0 wt% CATA increased the toughness from 9.9 to 17.3 kJ/m2 by ~ 74.7% relative to the GA-EP/MNA/2,4-EMI system. Furthermore, the 1.0 wt% CATA-toughened GA-EP/MNA/2,4-EMI showed considerable tensile strength of 52.1 MPa. Such toughness and tensile property of the epoxy thermoset was primarily attributed to CATA participating in the cross-linking network and forming a homogenous system after curing. Our study provides a novel strategy for developing cost-effective high-performance bio-based epoxy thermosets.

Graphical abstract

Similar content being viewed by others

References

Wan J, Gan B, Li C, Molina-Aldareguia J, Li Z, Wang X (2015) A novel biobased epoxy resin with high mechanical stiffness and low flammability: synthesis, characterization and properties. J Mater Chem A 3(43):21907–21921

Zhang Q, Molenda M, Reineke T-M (2016) Epoxy resin thermosets derived from trehalose and β-cyclodextrin. Macromolecules 49(22):8397–8406

Yang J, He X, Wang H, Liu X, Lin P, Yang S, Fu S (2020) High-toughness, environment-friendly solid epoxy resins: Preparation, mechanical performance, curing behavior, and thermal properties. J Appl Polym Sci 137(17):48596

Aouf C, Lecomte J, Villeneuve P (2012) Chemo-enzymatic functionalization of gallic and vanillic acids: synthesis of bio-based epoxy resins prepolymers. Green Chem 14(8):2328–2336

Yang J, Wang H, Liu X (2021) A nano-TiO2/regenerated cellulose biohybrid enables simultaneously improved strength and toughness of solid epoxy resins. Compos Sci Technol 212:108884

Lou G, Ma Z, Dai J (2021) Fully biobased surface-functionalized microcrystalline cellulose via green self-assembly toward fire-retardant, strong, and tough epoxy biocomposites. ACS Sustain Chem/Eng 9(40):13595–13605

Wan J, Zhao J, Gan B (2016) Ultrastiff biobased epoxy resin with high Tg and low permittivity: from synthesis to properties. ACS Sustain Chem/Eng 4(5):2869–2880

Auvergne R, Caillol S, David G (2013) Biobased thermosetting epoxy: present and future. Chem Rev 114(2):1082–1115

Ma S, Liu X, Fan L (2014) Synthesis and properties of a bio-based epoxy resin with high epoxy value and low viscosity. Chemsuschem 7(2):555–562

Ma S, Liu X, Jiang Y (2013) Bio-based epoxy resin from itaconic acid and its composites cured with anhydride and comonomers. Green Chem 15(1):245–254

Maiorana A, Spinella S, Gross R-A (2015) Bio-based alternative to the diglycidyl ether of bisphenol A with controlled materials properties. Biomacromol 16(3):1021–1031

Flint S, Markle T, Thompson S (2012) Bisphenol A exposure, effects, and policy: a wildlife perspective. J Environ Manag 104:19–34

Jiang H, Sun L, Zhang Y (2018) Estrogenic activity research of a novel fluorinated bisphenol and preparation of an epoxy resin as alternative to bisphenol a epoxy resin. Eur Polym J 108:507–516

Yang G, Rohde B-J, Tesefay H (2016) Biorenewable epoxy resins derived from plant-based phenolic acids. ACS Sustain Chem/Eng 4(12):6524–6533

Ma Q, Liu X, Zhang R (2013) Synthesis and properties of full bio-based thermosetting resins from rosin acid and soybean oil: the role of rosin acid derivatives. Green Chem 15(5):1300–1310

Nouailhas H, Aouf C, Le Guernevé C (2011) Synthesis and properties of biobased epoxy resins. Part 1. Glycidylation of flavonoids by epichlorohydrin. J Polym Sci Part A Polym Chem 49(10):2261–2270

Huang K, Liu Z, Zhang J (2014) Epoxy monomers derived from tung oil fatty acids and its regulable composites cured in two synergistic ways. Biomacromol 15(3):837–843

Pan X, Sengupta P, Webster D-C (2011) Novel biobased epoxy compounds: epoxidized sucrose esters of fatty acids. Green Chem 13(4):965–975

Kristufek SL, Yang G, Link LA (2016) Synthesis, characterization, and cross-linking strategy of a quercetin-based epoxidized monomer as a naturally-derived replacement for BPA in epoxy resins. Chemsuschem 9(16):2135–2142

Rajan VK, Muraleedharan K (2017) A computational investigation on the structure, global parameters and antioxidant capacity of a polyphenol, Gallic acid. Food chem 220:93–99

Aouf C, Nouailhas H, Fache M (2013) Multi-functionalization of gallic acid. Synthesis of a novel bio-based epoxy resin. Eur Polym J 49(6):1185–1195

Xu J, Yang J, Wang H (2019) Bio-based hyperbranched toughener from tannic acid and its enhanced solvent-free epoxy resin with high performance. J Renew Mater 7(12):1333–1346

Ma S, Liu X, Jiang Y (2013) Bio-based epoxy resin from itaconic acid and its thermosets cured with anhydride and comonomers. Green Chem 15(1):245–254

Shibata M, Enjoji M, Sakazume K (2016) Bio-based epoxy/chitin nanofiber composites cured with amine-type hardeners containing chitosan. Carbohydr polym 144:89–97

Liu T, Nie Y, Chen R (2015) Hyperbranched polyether as an all-purpose epoxy modifier: controlled synthesis and toughening mechanisms. J Mater Chem A 3(3):1188–1198

Xiao L, Liu Z, Hu F (2019) A renewable tung oil-derived nitrile rubber and its potential use in epoxy-toughening modifiers. Rsc Adv 9(44):25880–25889

Kumar S, Samal SK, Mohanty S (2018) Recent development of biobased epoxy resins: a review. Polym-Plast Technol Eng 57(3):133–155

Boro U, Karak N (2017) Tannic acid based hyperbranched epoxy/reduced graphene oxide nanocomposites as surface coating materials. Prog Org Coat 104:180–187

Rivero S, Garcia MA, Pinotti A (2010) Crosslinking capacity of tannic acid in plasticized chitosan films. Carbohyd Polym 82(2):270–276

Fei X, Wei W, Zhao F (2017) Efficient toughening of epoxy–anhydride thermosets with a biobased tannic acid derivative[J]. ACS Sustain Chem/Eng 5(1):596–603

Li L, Liao X, Sheng X (2019) Effect of structure regulation of hyper-branched polyester modified carbon nanotubes on toughening performance of epoxy/carbon nanotube nanocomposites. Rsc Adv 9(23):12864–12876

Shibata M, Teramoto N, Makino K (2011) Preparation and properties of biocomposites composed of epoxidized soybean oil, tannic acid, and microfibrillated cellulose. J Appl Polym Sci 120(1):273–278

Shibata M, Nakai K (2010) Preparation and properties of biocomposites composed of bio-based epoxy resin, tannic acid, and microfibrillated cellulose. J Polym Sci Part B Polym Phys 48(4):425–433

Fei X, Zhao F, Wei W (2016) Tannic acid as a bio-based modifier of epoxy/anhydride composites. Polymers 8(9):314

Patil D-M, Phalak G-A, Mhaske S-T (2017) Synthesis of bio-based epoxy resin from gallic acid with various epoxy equivalent weights and its effects on coating properties. J Coat Technol Res 14(2):355–365

Bagheri R, Marouf B-T, Pearson R-A (2009) Rubber-toughened epoxies: a critical review. Polym Rev 49(3):201–225

Luo L, Meng Y, Qiu T (2013) An epoxy-ended hyperbranched polymer as a new modifier for toughening and reinforcing in epoxy resin. J Appl Polym Sci 130(2):1064–1073

Liu W, Zhou R, Goh H-L-S (2014) From waste to functional additive: toughening epoxy resin with lignin. ACS Appl Mater Inter 6(8):5810–5817

Huang D-D, Xu F, Du X-S (2017) Temperature effects on rigid nano-silica and soft nano-rubber toughening in epoxy under impact loading. J Appl Polym Sci 134(38):45319

Lv J, Meng Y, He L (2013) Novel epoxidized hyperbranched poly (phenylene oxide): synthesis and application as a modifier for diglycidyl ether of bisphenol A. J Appl Polym Sci 128(1):907–914

Liu Y, Ramirez C, Zhang L (2017) In situ direct observation of toughening in isotropic nanocomposites of alumina ceramic and multiwall carbon nanotubes. Acta Mater 127:203–210

Xu J, Yang J, Liu X (2018) Preparation and characterization of fast-curing powder epoxy adhesive at middle temperature. Roy Soc Open Sci 5(8):180566

Zhang D, Zhang X, Jing T (2019) Tunable thermal, mechanical, and controlled-release properties of epoxy phenolic novolac resin microcapsules mediated by diamine crosslinkers. Rsc Adv 9(17):9820–9827

Kissinger H-E (1957) Reaction kinetics in different thermal analysis. Anal Chem 29:1702–1706

Ozawa T (1965) New method of analyzing thermogravimetric data. Bull Chem Soc Jpn 38:1881–1886

Wang F, Kuai J, Pan H (2018) Study on the demethylation of enzymatic hydrolysis lignin and the properties of lignin–epoxy resin blends. Wood Sci Technol 52(5):1343–1357

Shang L, Zhang X, Zhang M (2018) A highly active bio-based epoxy resin with multi-functional group: synthesis, characterization, curing and properties. J Mater Sci 53(7):5402–5417

Thanki J-D, Parsania P-H (2017) Dynamic DSC curing kinetics and thermogravimetric study of epoxy resin of 9, 9′-bis (4-hydroxyphenyl) anthrone-10. J Therml Anal Calorim 130(3):2145–2156. https://doi.org/10.1007/s10973-017-6761-y

Kumar S, Samal SK, Mohanty S (2019) Curing kinetics of bio-based epoxy resin-toughened DGEBA epoxy resin blend. J Therm Anal Calorim 137(5):1567–1578

Fei X, Wei W, Zhao F (2017) Efficient toughening of epoxy–anhydride thermosets with a biobased tannic acid derivative. ACS Sustain Chem/ Eng 5(1):596–603

Acknowledgements

We greatly acknowledge the financial support from the Special Fund for the Program for Zhejiang Provincial Natural Science Foundation of China (Grant No: LZ16C160001). We would like to thank Dr. Jiayao Yang for assistance in revising the manuscript.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xu, J., Liu, X. & Fu, S. Bio-based epoxy resin from gallic acid and its thermosets toughened with renewable tannic acid derivatives. J Mater Sci 57, 9493–9507 (2022). https://doi.org/10.1007/s10853-022-07174-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07174-z