Abstract

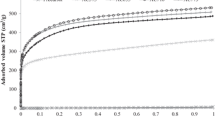

The effect of thermal pretreatment on the porous structure and adsorption properties of asphalt-based carbons activated with potassium hydroxide was investigated by FTIR, Raman spectroscopy, TEM, N2 and CO2 adsorption. Two series of the activated carbons were prepared by a one-stage method using KOH as the activating agent and a two-stage method including pretreatment of asphalt at 450 °C. A cross-effect of the KOH/asphalt ratio and pretreatment conditions on the characteristics of the porous structure of the activated carbons was revealed. The pretreatment of asphalt before activation is demonstrated to be a necessary stage for the effective control of the carbon porous structure by variation the KOH/asphalt ratio from 2 to 4. The porous carbon derived from petroleum asphalt exhibited the high CO2 adsorption capacity of 3.8 mmol/g at 25 °C and 1 atm and good selectivity for CO2 over N2, indicating possible applications in CO2 capture technology.

Graphical abstract

Similar content being viewed by others

References

Lozano-Castelló D, Cazorla-Amorós D, Linares-Solano A, Quinn D (2002) Activated carbon monoliths for methane storage: influence of binder. Carbon 40:2817–2825

García-Díez E, Castro-Muñiz A, Paredes JI, Maroto-Valer MM, Suárez-García F, García S (2021) CO2 capture by novel hierarchical activated ordered micro-mesoporous carbons derived from low value coal tar products. Microporous Mesoporous Mater 318:110986–110996

Chen H, Zhang YJ, He PY, Li CJ, Liu LC (2020) Novel activated carbon route to low-cost geopolymer based porous composite with high mechanical resistance and enhanced CO2 capacity. Microporous Mesoporous Mater 305:110282–110289

Parka J, Attia NF, Junga M, Lee K, Oh H (2020) Biobased derived nanoporous carbon for hydrogen isotope separation. Microporous Mesoporous Mater 304:109291–109296

Park H-Y, Lee CH, Cho D-W, Lee C-H, Park J-H (2020) Synthesis of porous carbon derived from poly(vinylidenefluoride) and its adsorption characteristics for CO2 and CH4. Microporous Mesoporous Mater 299:110121–110129

Moreno-Castilla C, Rivera-Utrilla J (2001) Carbon materials as adsorbents for the removal of pollutants from the aqueous phase. MRS Bull 26(11):890–894

Jang E, Choi SW, Lee KB (2019) Effect of carbonization temperature on the physical properties and CO2 adsorption behavior of petroleum coke-derived porous carbon. Fuel 248:85–92

Marsh H, Rodríguez-Reinoso F (2006) Activated carbon, 1st edn. Elsevier

Javed H, Luong DX, Lee C-G, Zhang D, Tour JM, Alvarez PJJ (2018) Efficient removal of bisphenol-A by ultra-high surface area porous activated carbon derived from asphalt. Carbon 140:441–448

Liang W, Zhang Y, Wang X, Wu Y, Zhou X, Xiao J, Li Y, Wang H, Li Z (2017) Asphalt-derived high surface area activated porous carbons for the effective adsorption separation of ethane and ethylene. Chem Eng Sci 162:192–202

Asphalt binder testing (2007) Asphalt institute, 1st edn. MA-25 USA

Hunter RN, Self A, Read J (2014) The shell bitumen handbook, 6th edn. ICE Publishing, London

Spiecker PM, Gawrys KL, Kilpatrick PK (2003) Aggregation and solubility behavior of asphaltenes and their subfractions. J Colloid Interface Sci 267:178–193

Gawrys KL, Kilpatrick PK (2005) Asphaltenic aggregates are polydisperse oblate cylinders. J Colloid Interface Sci 288:325–334

Liu J, Liu Y, Li P, Wang L, Zhang H, Liu H, Liu J, Wang Y, Tian W, Wang X, Li Z, Wu M (2018) Fe-N-doped porous carbon from petroleum asphalt for highly efficient oxygen reduction reaction. Carbon 126:1–8

Strausz OP, Peng P, Murgich J (2002) About the colloidal nature of asphaltenes and the MW of covalent monomeric units. Energy Fuels 16:809–822

Groenzin H, Mullins OC, Eser S, Mathews J, Yang MG, Jones D (2003) Molecular size of asphaltene solubility fractions. Energy Fuels 17:498–503

Jalilov AS, Ruan G, Hwang C-C, Schipper DE, Tour JJ, Li Y, Fei H, Samuel ELG, Tour JM (2015) Asphalt-derived high surface area activated porous carbons for carbon dioxide capture. ACS Appl Mater Interfaces 7:1376–1382

Jalilov AS, Li Y, Tian J, Tour JM (2016) Ultra-high surface area activated porous asphalt for CO2 capture through competitive adsorption at high pressures. Adv Energy Mater 7:1600693–1600700

Thommes M, Kaneko K, Neimark AV, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, Sing KSW (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution. Pure Appl Chem 87:1051–1069

Guan T, Li K, Zhao J, Zhao R, Zhang G, Zhang D, Wang J (2017) Template-free preparation of layer-stacked hierarchical porous carbons from coal tar pitch for high performance all-solid-state supercapacitors. J Mater Chem A 5:15869–15878. https://doi.org/10.1039/C7TA02966G

Mothé MG, Leite LFM, Mothé CG (2008) Thermal characterization of asphalt mixtures by TG/DTG, DTA AND FTIR. J Therm Anal Calorim 93:105–109

Bernasconi S, Bokhoven JA, Krumeich F, Pirngruber GD, Prins R (2003) Formation of mesopores in zeolite beta by steaming: a secondary pore channel system in the plane. Microporous Mesoporous Mater 66:21–26

Gorbunova OV, Baklanova ON, Gulyaeva TI (2020) Porous structure of PEG-mediated silica controlled by solution pH. Microporous Mesoporous Mater 307:110468–110472

Tenney CM, Lastoskie CM (2006) Molecular simulation of carbon dioxide adsorption in chemically and structurally heterogeneous porous carbons. Environ Prog 25:343–354

Abd AA, Naji SZ, Hashim AS, Othman MR (2020) Carbon dioxide removal through physical adsorption using carbonaceous and non-carbonaceous adsorbents: a review. J Environ Chem Eng 8:104142–1014164

He J, To JWF, Psarras PC, Yan H, Atkinson T, Holmes RT, Nordlund D, Bao Z, Wilcox J (2016) Tunable polyaniline-based porous carbon with ultrahigh surface area for CO2 capture at elevated pressure. Adv Energy Mater 6:1502491–1502501

Zhang Z, Schott JA, Liu M, Chen H, Lu X, Sumpter BG, Fu J, Dai S (2019) Prediction of carbon dioxide adsorption via deep learning. Angew Chem Int Ed 58:259–263

Acknowledgements

We thank G.G. Savel’eva, Dr. A.V. Babenko and Dr. A.V. Vasilevich from the Center of New Chemical Technologies BIC, Boreskov Institute of Catalysis for their valuable contribution to this research. This work was supported by the Ministry of Science and Higher Education of the Russian Federation within the governmental order for Boreskov Institute of Catalysis (project AAAA-AA21-121011890076-8). The research was performed using equipment of the Shared-Use Center “National Center for the Study of Catalysts” at the Boreskov Institute of Catalysis and Shared-Use Center at the Omsk Scientific Center, Siberian Branch of the Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Annela M. Seddon.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gorbunova, O.V., Baklanova, O.N., Gulyaeva, T.I. et al. Effect of thermal pretreatment on porous structure of asphalt-based carbon. J Mater Sci 57, 7239–7249 (2022). https://doi.org/10.1007/s10853-022-07106-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07106-x