Abstract

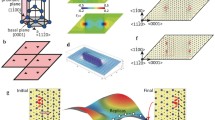

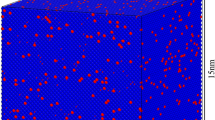

Discrete dislocation dynamics (DDD) codes enable researchers and scientists to explore the mechanical behavior of a material as impacted by its composition and microstructure. Understanding the strengthening mechanisms is very important for the development of new materials with improved and desired mechanical properties. One of the material strengthening/hardening mechanisms is solution hardening, and this method can be fundamentally understood from particle misfit models and the theory/implementation of dislocation dynamics. The overlapping of the eigenstrain fields of the misfit particles or solutes and the dislocations impedes the motion of dislocations and results in material hardening. This article incorporates the misfit particle model in a 3D DDD code in an attempt to capture this phenomenon and find the strength of solid solutions (for a binary Cu–Ni system) from the simulated stress–strain diagram. This study/research finds a good agreement between the simulation results and experimental data. The authors also correlate the strength differentials as a function of solute concentrations and compare them with relations in the literature.

Similar content being viewed by others

References

Fleischer RL (1967) The flow stress of body-centered cubic metals: inherent lattice hardening or solution hardening? Acta Metall 15(9):1513–1519. https://doi.org/10.1016/0001-6160(67)90182-4

Fleischer RL (1961) Solution hardening. Acta Metall 9(11):996–1000. https://doi.org/10.1016/0001-6160(61)90242-5

Fleischer RL (1962) Solution hardening by tetragonal dist ortions: Application to irradiation hardening in F.C.C. crystals. Acta Metall 10(9):835–842. https://doi.org/10.1016/0001-6160(62)90098-6

Fleischer RL (1963) Substitutional solution hardening. Acta Metall 11(3):203–209. https://doi.org/10.1016/0001-6160(63)90213-X

Riddhagni BR, Asimow RM (1968) Solid-solution hardening due to the size effect. J Appl Phys 39(11):5169–5173. https://doi.org/10.1063/1.1655939

Eshelby JD (1959) The elastic field outside an ellipsoidal inclusion. Proc R Soc A Math Phys Eng Sci 252(1271):561–569. https://doi.org/10.1007/1-4020-4499-2_25

John Douglas Eshelby (1957) The determination of the elastic field of an ellipsoidal inclusion and related problems. Proc R Soc A Math Phys Eng Sci 241(1226):376–396

Weeks RW, Pati SR, Ashby MF, Barrand P (1969) The elastic interaction between a straight dislocation and a bubble or a particle. Acta Metall 17(12):1403–1410. https://doi.org/10.1016/0001-6160(69)90002-9

Mura T (1987) Micromechanics on defects in solids. Martinus Nijhoff Publishers, Dordrecht

Lerma JD, Khraishi TA, Shen Y-L (2007) Elastic fields of 2D and 3D misfit particles in an infinite medium. Mech Res Commun 34(1):31–43. https://doi.org/10.1016/j.mechrescom.2006.06.002

Lerma JD, Khraishi TA, Shen Y-L, Wirth BD (2004) A distributed-dislocation method for generalized eigenstrain problems. High Perform Struct Mater 6:185–194

Lerma JD, Khraishi TA, Kataria S, Shen Y-L (2015) Distributed dislocation method for determining elastic fields of 2D and 3D volume misfit particles in infinite space and extension of the method for particles in half space. J Mech 31(3):249–260. https://doi.org/10.1017/jmech.2014.85

Lerma JD, Khraishi TA, Shen YL, Wirth BD (2003) The elastic fields of misfit cylindrical particles: a dislocation-based numerical approach. Mech Res Commun 30(4):325–334. https://doi.org/10.1016/S0093-6413(03)00035-1

Kubin LP, Canova GR, Condat M, Devincre B, Pontikis V, Bréchet Y (1992) Dislocation microstructures and plastic flow: a 3D simulation. Solid State Phenom 23–24:455–472. https://doi.org/10.4028/www.scientific.net/ssp.23-24.455

Lépinoux J, Kubin LP (1987) The dynamic organization of dislocation structures: a simulation. Scr Metall 21(6):833–838. https://doi.org/10.1016/0036-9748(87)90332-2

Khraishi TA, Yan L, Shen Y-L (2004) Dynamic simulations of the interaction between dislocations and dilute particle concentrations in metal-matrix composites (MMCs). Int J Plast 20(6):1039–1057. https://doi.org/10.1016/j.ijplas.2003.10.003

Khraishi TA, Zbib HM (2001) Dislocation dynamics simulations of the interaction between a short rigid fiber and a glide circular dislocation pile-up. Comput Mater Sci 24:310–322. https://doi.org/10.1016/S0927-0256(01)00253-1

Khraishi TA, Zbib HM, De La Rubia TD, Victoria M (2002) Localized deformation and hardening in irradiated metals: three-dimensional discrete dislocation dynamics simulations. Metall Mater Trans B Process Metall Mater Process Sci 33(2):285–296. https://doi.org/10.1007/s11663-002-0012-7

liu FX, Cocks ACF, Tarleton E (2021) Dislocation dynamics modelling of the creep behaviour of particle-strengthened materials. Proc R Soc A Math Phys Eng Sci 477(2250):20210083. https://doi.org/10.1098/rspa.2021.0083

Zbib HM, Rhee M, Hirth JP (1998) On plastic deformation and the dynamics of 3D dislocations. Int J Mech Sci 40(2–3):113–127. https://doi.org/10.1016/S0020-7403(97)00043-X

Hirth JP, Lothe J (1982) Theory of dislocations, 2nd edn. Krieger Publishing Company, Malabar, Florida

Gilman JJ (2007) The peierls stress for pure metals (evidence that it is negligible). Philos Mag 87(35):5601–5606. https://doi.org/10.1080/14786430701678922

Leger RW, Khraishi TA, Shen YL (2004) A dislocation dynamics study of strength differential in particle-containing metals during cyclic loading. J Mater Sci 39(11):3593–3604. https://doi.org/10.1023/B:JMSC.0000030711.66044.92

Déprés C, Prasad Reddy GV, Robertson C, Fivel M (2014) An extensive 3D dislocation dynamics investigation of stage-I fatigue crack propagation. Philos Mag 94(36):4115–4137. https://doi.org/10.1080/14786435.2014.978830

Van Der Giessen E, Deshpande VS, Cleveringa HHM, Needleman A (2001) Discrete dislocation plasticity and crack tip fields in single crystals. J Mech Phys Solids 49(9):2133–2153. https://doi.org/10.1016/S0022-5096(01)00040-0

Kacher J, Eftink BP, Cui B, Robertson IM (2014) Dislocation interactions with grain boundaries. Curr Opin Solid State Mater Sci 18(4):227–243. https://doi.org/10.1016/j.cossms.2014.05.004

Jiang M, Devincre B, Monnet G (2019) Effects of the grain size and shape on the flow stress: a dislocation dynamics study. Int J Plast 113:111–124. https://doi.org/10.1016/j.ijplas.2018.09.008

Shen Z, Wagoner RH, Clark WAT (1988) Dislocation and grain boundary interactions in metals. Acta Metall 36(12):3231–3242. https://doi.org/10.1016/0001-6160(88)90058-2

Siddique AB, Khraishi TA (2020) Numerical methodology for treating static and dynamic dislocation problems near a free surface. J Phys Commun 4(5):055005. https://doi.org/10.1088/2399-6528/ab8ff9

Siddique AB, Khraishi TA (2021) A mesh-independent brute-force approach for traction-free corrections in dislocation problems. Model Numer Simul Mater Sci 11(01):1–18. https://doi.org/10.4236/mnsms.2021.111001

Siddique AB, Khraishi TA (2021) “Screw dislocations around voids of any shape: A generalized numerical approach. Forces Mech 3:100014. https://doi.org/10.1016/j.finmec.2021.100014

Siddique AB, Khraishi TA (2021) A holed-plate with material dislocations: formulation and verification. Math Mech Solids. https://doi.org/10.1177/10812865211053369

Deng J, El-Azab A, Larson BC (2008) On the elastic boundary value problem of dislocations in bounded crystals. Philos Mag 88(30–32):3527–3548. https://doi.org/10.1080/14786430802558544

El-Azab A (2000) The boundary value problem of dislocation dynamics. Model Simul Mater Sci Eng 8(1):37–54

Crone JC, Munday LB, Knap J (2015) Capturing the effects of free surfaces on void strengthening with dislocation dynamics. Acta Mater 101:40–47. https://doi.org/10.1016/j.actamat.2015.08.067

Frank FC, Read WT (1950) Multiplication processes for slow moving dislocations. Phys Rev 79(4):722–723. https://doi.org/10.1103/PhysRev.79.722

Callister W, Rethwisch DG (2017) Materials Science and Engineering An Introduction, 10th edn. Wiley, Hoboken, New Jersey

Mises Rv (1913) Mechanik der festen Körper im plastisch- deformablen Zustand Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen. Math. Klasse 1913(4):582–592

Jenkins WD, Digges TG (1934) C R Johnson (1957) Tensile properties of Copper Nickel and 70-percent-Copper-30-percent-Nickel and 30-percent-Copper- 70-percent Nickel alloys at high temperatures. J Res Natl Bur Stand 58(4):201–211

Kaw AK (2013) Micromechanics of Composite Materials, 2nd edn. Taylor & Francis, London

Yan L, Khraishi TA, Shen Y-L, Horstemeyer MF (2004) A distributed-dislocation method for treating free-surface image stresses in three-dimensional dislocation dynamics simulations. Model Simul Mater Sci Eng 12(4):S289–S301. https://doi.org/10.1088/0965-0393/12/4/S01

Khraishi TA, Zbib HM (2002) Free-surface effects in 3D dislocation dynamics: formulation and modeling. J Eng Mater Technol 124(3):342–351. https://doi.org/10.1115/1.1479694

Khraishi TA, Zbib HM, De La Rubia TD (2001) The treatment of traction-free boundary condition in three-dimentional dislocation dynamic using generalized image stress analysis. Mater Sci Eng A 309–310:283–287. https://doi.org/10.1016/S0921-5093(00)01727-5

Siddique AB, Lim H, Khraishi TA (2021) The effect of multipoles on the elasto-plastic properties of a crystal: theory and 3D dislocation dynamics modeling. J Eng Mater Technol 144(1):1–22. https://doi.org/10.1115/1.4052168

Fang T-H, Huang C-C, Chiang T-C (2016) Effects of grain size and temperature on mechanical response of nanocrystalline copper. Mater Sci Eng A 671:1–6. https://doi.org/10.1016/j.msea.2016.06.042

Hull D, Bacon DJ (2011) Introduction to Dislocations, 5th edn. Butterworth-Heinemann, New York

Arsenault RJ, Patu S, Esterling DM (1989) Computer simulation of solid solution strengthening in Fcc alloys: Part II. at absolute zero temperature. Metall Trans A 20(8):1419–1428. https://doi.org/10.1007/BF02665499

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Siddique, A.B., Khraishi, T.A. Multi-scale modeling of solute atom strengthening using 3D discrete dislocation dynamics. J Mater Sci 57, 10613–10626 (2022). https://doi.org/10.1007/s10853-022-07077-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07077-z