Abstract

Decomposition and precipitation processes in a binary Al–Li alloy and a technical Al–Li–Cu–Mg alloy were investigated using differential scanning calorimetry and X-ray Raman spectroscopy (XRS). The formation of \(\delta \)’ and T1 precipitates in the Al–Li and the T8 heat-treated Al–Li–Cu–Mg alloy, respectively, was confirmed using DSC. The XRS measurements complemented by simulated spectra allowed for probing specifically Li and its environment within the Al matrix. Based on linear combination fits of the XRS spectra, the relative contributions of \(\delta '\) and T1 precipitates were quantified. These results are in agreement with estimates of the relative amount of Li taking part in the precipitation process. Difficulties and limitations of the application of XRS to Al alloy systems are also discussed.

Similar content being viewed by others

Introduction

The relevance of several aluminum alloy systems is based on their ability to form solute clusters and precipitates upon appropriate heat treatment. Such clusters and precipitates generally improve the mechanical properties of these light metal alloys significantly and, thus, have led to a broad application of age hardenable Al alloys in weight sensitive applications. Al alloy systems such as e.g., Al–Cu–(Mg) and Al–Mg–Si, which are technologically well established [1], have been investigated for decades with particular emphasis on the respective precipitation sequence and the early stages of decomposition and cluster formation. The toolbox commonly used for their analysis ranges from rather classical methods such as hardness measurements [2], differential scanning calorimetry [3, 4], diffraction techniques [5], and positron annihilation spectroscopy [4, 6] to (transmission) electron microscopy [7,8,9], atom probe tomography [10, 11] and small angle X-ray scattering [8, 9]. Extensive combinations of these methods are also utilized [4, 12]. Despite these experimental efforts, the decomposition sequences of age hardenable Al alloys are still not thoroughly understood due to several reasons. Apparently, ternary, quaternary or even more complex Al alloys represent a huge parameter space which generates complex precipitation sequences with countless potential pathways through phase space. However, the smallness of clusters, which in the early stages consist of only two or three atoms, the little (electronic) contrast between Al and important alloying elements such as Mg or Si, and the low atomic number of other solute atoms such as Li are even more demanding from an analytical perspective (including well established imaging techniques). Accordingly, experimental techniques facilitating access to specific solute atoms are desirable. Synchrotron-based X-ray absorption spectroscopy was already used for investigating Al–Cu-based alloys [13,14,15] but faces difficulties for elements such as Mg, Al, Si or Li due to their absorption edges at low energies, which entail very low X-ray penetration depths (at least with respect to bulk material) of about 6 \(\mu \)m (in the case of Mg). The latter challenge, however, can in principle be met using X-ray Raman spectroscopy (XRS) which utilizes high-energy X-ray radiation in order to probe low energy absorption edges (the absorption length of X-rays with 9700 eV–as used herein–is about 94 \(\mu \)m with respect to Al alloys). As such experiments require intense X-ray beams and sophisticated detection schemes, XRS is a rather new method and crucially depends on third generation synchrotrons [16].

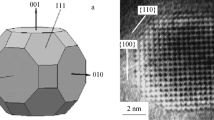

In light of the renewed interest in Al–Li–Cu–Mg-based alloys for aerospace and space applications [17], this Al alloy system containing low atomic number Li is a good test case for the applicability and analytical capabilities of XRS with respect to light metal alloys. Al–Li–Cu–Mg alloys exhibit a favorable combination of high specific strength and low mass density, both of which are caused by the addition of Li. The precipitation sequence in these alloys is complex and covers a variety of stable, Al\(_2\)Cu (\(\theta \)), AlLi (\(\delta \)), Al\(_2\)CuLi (T1), Al\(_6\)CuLi\(_3\) (T2), and metastable phases such as Guinier–Preston (GP) zones and Al\(_3\)Li (\(\delta '\)) amongst others [18]. The high strength of Al–Li–Cu alloys is associated with a fine distribution of T1 precipitates which can be produced by artificial aging at temperatures from 150 to 200\(^{\circ }\)C. The structure of T1 phase precipitates has been discussed intensively with several structures proposed in the last decades [8, 19,20,21,22, 23, 24]. At the same time, the amount of Li that actually takes part in the decomposition and precipitation processes yet remains to be directly quantified in different stages of aging. Considering these questions (which cannot be answered by more conventional methods such as microstructure imaging), we herein report on aging processes in a binary Al–Li and a technical Al–Li–Cu–Mg alloy. Using a combination of differential scanning calorimetry and X-ray Raman spectroscopy, bulk properties of the alloys and a Li centered stance on clustering were probed at the same time.

Materials and methods

A binary Al–Li alloy containing 2.0 wt% (7.8 at%) Li and a commercial Al–Cu–Mg–Li alloy AA2198 (2.9–3.5 wt% Cu, 0.25–0.8 wt% Mg, 0.8–1.1 wt% Li), the latter provided by Rio Tinto Alcan, were investigated. For information concerning other alloying elements in AA2198 we refer to Table S2 in the Online Resource Sect. 4.

The binary alloy was solution-heat-treated at 540 °C and quenched in ice-water and, from a phase diagram perspective, into its (\(\alpha +\delta '\)) phase region [12, 25,26,27,28]. As-quenched (AQ) samples of this alloy were stored, transported and measured at sufficiently low temperatures below − 70 °C, in order to suppress aging kinetics. The same procedure was applied for samples artificially aged at 70 °C for one and five hours. Samples artificially aged for longer times or at higher temperatures were stored and investigated at room temperature (RT), as no significant precipitation processes are expected at RT afterward.

Rolled sheets of AA2198 were subjected to a T8 heat treatment after quenching [29], i.e., 14 h at 155 \(^{\circ }\)C and a subsequent cold deformation of 2% plastic strain. Sheets were then friction stir welded by Airbus (Bremen, Germany). Samples were taken from the center of the joint region and from parts completely unaffected by the welding process, which are referred to as weld-nugget (WN) and base material (BM), respectively, throughout this manuscript.

Samples were investigated by means of differential scanning calorimetry (DSC) and XRS. Additional X-ray diffraction (XRD) and small angle X-ray scattering (SAXS) results, to which is referred here, are described and shown in the Online Resource. DSC measurements were taken using a Netzsch 204 F1 Phoenix apparatus (heat-flux type) under nitrogen atmosphere with a heating rate of 20 Kmin\(^{-1}\) from −20 to 400 °C for the binary alloy and from −20 to 530 °C for the commercial alloy. Note that no (DSC) cooling curves were measured, as heating curves are sufficient for the detection of existing phases in accordance with the objective of this study. Further details of sample preparation for DSC and the respective data analysis are described in the Online Resource Sect. 1.

In order to access the Li K-edge at about only 54.7 eV and to probe bulk material at the same time, X-ray Raman spectroscopy (XRS) was performed using the experimental setup at beamline P01, PETRAIII, Germany. In XRS experiments, high-energy photons (about 9700 eV in this case) are scattered inelastically by core electron excitations involving energy and momentum transfer to the electronic system. The energy of scattered photons is subsequently analyzed using spherically bent analyzer crystals (bending radius of 1 m) at fixed energy and scattering angle (here \(155^{\circ }\), yielding a scattering vector \(q \approx 9.6\) Å\(^{-1}\)), whereas the Bragg angle was kept close to 90°. At low scattering angles, dipole transitions dominate and XRS is similar to X-ray absorption near-edge structure (XANES) measurements. At higher scattering angles, higher-order transitions contribute which is, however, taken into account by simulation codes such as FDMNES [30]. Although the cross section of aforementioned events is rather small, XRS experiments are well feasible at third generation synchrotrons. For further information, we refer to reviews of XRS [16, 31, 32]. XRS measurements of aged samples were taken at room temperature, whereas as-quenched samples were investigated at −70 °C. Theoretical XRS spectra of different Li containing phases and structures were simulated using the FDMNES code [30, 33]. The qualitative suitability of FDMNES to model experimental XRS spectra has already been shown using several compounds [30, 34,35,36]. Additionally, the known XRS spectrum [37] of Li metal is compared to a FDMNES calculation in the Online Resource, Sect. 3 (Fig. S6). Further details of the usage of the FDMNES code are also summarized in Sect. 3 of the Online Resource. Both experimental and theoretical XRS spectra were processed and fitted using the Demeter software package ATHENA [38].

Results and discussion

Differential scanning calorimetry

DSC thermograms of the binary Al–Li2.0 (wt%) alloy at different aging conditions. The red curve indicates the AQ state, whereas the blue curves show the thermograms of the artificially aged samples at 70\(^{\circ }\)C and 180\(^{\circ }\)C sorted ascending from bottom to top in order to its time and temperature. The grey-shaded boxes illustrate the regions of the aging temperatures (70 and 180\(^{\circ }\)C), whereas the letters A to C denote the relevant endothermal reactions which take place during the evolution

Figure 1 shows the DSC thermograms obtained from the binary alloy at different aging conditions: AQ and artificially aged at 70 and 180 °C. Three endothermic peaks (dashed vertical lines A, B, C in Fig. 1) can be distinguished for samples aged at 70\(^{\circ }\)C. With increasing aging time, the area of peak B increases and the peak position shifts to higher temperatures. These changes are interpreted as growth of metastable \(\delta \)’ precipitates with respect to volume fraction and average size, which is corroborated by XRD patterns obtained for the sample aged at 70 °C for 20 h (cf. the Online Resource Fig. S2). An endothermic peak A at about 110\(^{\circ }\)C signifies no significant change of the heat flux signal during artificial aging from one hour to two days. It might correspond to either the disordering of a precursory ordered structure, possibly close to Guinier–Preston (GP) zones as present in binary Al-Cu alloys or the dissolution of subcritical \(\delta \)’ precipitates formed directly after quenching or during the early DSC heating ramp [39,40,41]. However, its origin is controversially discussed, as the supersaturated solid solution (SSSS) of binary Al-Li alloys could pass different transformation pathways after quenching into the \(\alpha + \delta \)’ two-phase field depending on the Li concentration [42, 43]. Moreover, the early decomposition in quenched Al–Li alloys is too fast for direct experimental observations [42, 44,45,46] as clearly evidenced by the AQ DSC curve (Fig. 1, red curve) showing no exothermal reaction for the formation of \(\delta \)’ precipitates at temperatures below 100 °C. On the other hand, \(\delta \)’ could also be formed simultaneously with the corresponding endothermal reaction of peak A and, hence, the resulting signal might be overlapped by two concurrent thermal processes.

When aging at 180 °C for 2.5 and 7 h, peaks B and C overlap and shift to higher temperatures (240–250 °C). This indicates the coarsening stage (Ostwald ripening) of \(\delta \)’ precipitates, which is quickly reached when aging at temperatures near the \(\delta \)’ solvus boundary of about 200–250 °C for 2 wt.% Li [25, 27, 45,46,47,48,49]. Peak B corresponds to the dissolution of \(\delta \)’ of higher volume fraction at the cost of \(\delta \)’ of smaller volume fraction but larger average size whose dissolution is associated with peak C. This interpretation is supported by SAXS measurements, which indicate an increase of \(\delta \)’ precipitate radius from 13 Å in the sample aged at 70 °C for 20 h to 51 Å in the one aged at 180\(^{\circ }\)C for 7 h (cf. Online Resource Sect. 2 and Fig. S3). Additionally, the presence of \(\delta \)’ precipitates in these stages can also be verified by XRD (cf. Online Resource Sect. 2 and Fig. S2). Peak A is not observed for samples aged at 180 °C, which is above the endothermic reaction observed at approximately 110 °C. This contrasts with DSC measurements published in Ref. [50], in which it was concluded that this endothermic reaction (peak A) cannot result from the dissolution of subcritical \(\delta \)’ precipitates, as no change in the signal at about 110 °C had been observed during aging at 150\(^{\circ }\)C for about 1.7 hrs.

Figure 2 shows the DSC thermograms of the friction-stir-welded commercial Al–Cu–Mg–Li alloy AA2198 for BM and WN samples. A, B and C indicate the exothermal and endothermal reactions relevant for the subsequent discussion of the XRS spectra obtained for the same samples. The exothermic peak C at 250–275 °C corresponds to the formation of T1 precipitates as very thin plates of approximately one unit-cell thickness (about 1.3 nm) in the {111} planes of the Al matrix [23, 51, 52]. The exothermic amplitude of peak C in the BM sample is much weaker than the one in the WN sample, which shows that T1 precipitates have already been formed in the BM sample during the T8 heat treatment (14 h at 155 °C) [11, 52] (T1 precipitates cause the high strength of the BM alloy) but are formed in the WN sample during DSC measurement. In the WN sample, T1 precipitates are not present (before DSC measurement) as the welding temperature, which is close to the solution heat treatment temperature of about 500 °C, causes its complete dissolution [53]. Instead, Cu–Mg-rich clusters and/or GP(B), i.e., Guinier–Preston–Bagaryatsky, zones have been formed during natural aging and give rise to the strength in the WN region. Their dissolution corresponds to the endothermic peak B at temperatures between 125 and 175 °C [54,55,56]. Peak A, which appears for both the BM and WN samples, can be associated with the endothermal reaction A in the binary alloy as it appears at identical temperatures. In any case, \(\delta \)’ precipitates are thus not expected to be present in this alloy in line with Ref. [9].

X-ray raman spectroscopy

Representative XRS measurement data are shown in Fig. 3. The Li K-edge around 54 eV is superimposed and surmounted by the Al L2/L3-edges around 72 eV which restricts the useful energy interval to 15 eV above the Li K-edge. Moreover due to the Al L2/L3-edges, data reduction/extraction schemes based on Hartree–Fock Compton profiles such as outlined in Ref. [16] are effectively prevented. Thus, a minimalist approach for data reduction was taken: The background was modeled by a linear function, which was fitted to the energy loss interval from 35 to 45 eV, and sample self-absorption as well as sample composition were corrected for. The resulting XRS spectra are shown in Fig. 4.

XRS spectra of the binary alloy (top) and the technical alloy AA2198 (bottom) samples. In the bottom part, the spectrum of the as-quenched binary alloy is replicated in order to facilitate an easy comparison. Dashed lines indicate base lines. The slight increase of the XRS spectra of AA2198 starting at about 50 eV can be attributed to a small contribution of the Mg K-edge

In general, the XRS spectra of the binary and the technical alloys are rather similar with two maxima within the observed energy loss region yet differing relative peak height ratios. The inflection points of the XRS spectra are slightly below the Li K-edge of elemental Li, i.e., below 54.7 eV [57], within the energy interval between 54 and 54.4 eV. Although the statistics of the XRS spectra of the technical alloys AA2198 are inferior to those of the binary alloy, the spectra of the as-quenched binary alloy and the weld nugget of AA2198 are almost indistinguishable (cf. Fig. 4). This is in line with DSC results as the welding process dissolves most Li containing precipitates in AA2198 (cf. "Differential scanning calorimetry" Section) and, thus, both the as-quenched binary alloy and the weld nugget of AA2198 contain mostly Li atoms in solution without any further Li containing structure. However, it should also be noted that in case of AA2198 Mg L2/L3-edges at about 49 eV may contribute to some extent as the Li and Mg scattering cross sections are comparable and the Li to Mg ratio of about six to one (assuming that the alloy composition is in the middle of the respective compositional ranges) is not safely negligible. In the case of the weld nugget sample, the scatter of the data at about 49 eV covers any potential Mg L2/L3-edge contribution, whereas in the case of sample AA2198 BM a small edge like increase can be observed (cf. Fig. 4). Assuming that this increase represents the Mg L2/L3 contribution, the ratio of Li K-edge step to the edge step related to the Mg L2/L3-edges is slightly larger than six to one. This indicates that the Mg L2/L3-edges indeed contribute, but this contribution is neglected due to the low statistics and the dominating Li contribution.

For further analysis, XRS spectra of distinct Li containing structures were simulated using FDMNES. Among these structures are:

-

a single Li atom in an Al matrix (designated S-1Li),

-

a Li dimer in an Al matrix (designated S-2Li),

-

the \(\delta \)’ phase (designated S-\(\delta \)’),

-

different T1 structures proposed by Donnadieu et al. [8], Howe et al. [20], Huang et al. [21], Kim et al. [24], van Smaalen et al. [19], and Dwyer et al. [23] (designated S-T1-Don, S-T1-Howe, S-T1-Hua, S-T1-Kim, S-T1-vanS, and S-T1-Dwyer, respectively).

For the simulation of the XRS spectra of structures S-1Li and S-2Li, relaxed atomic coordinates calculated using SIESTA [58] were used. As the \(\delta \)’ phase is coherent with the Al matrix and the change of lattice plane distances is only minimal with about 1%, the corresponding XRS spectrum was simulated using its crystal structure [45, 59]. In contrast, the T1 structures were simulated using supercells embedded in few Al layers (without further relaxation except for the structure of Dwyer et al. [23]), in order to mimic both the finite size of T1 precipitates potentially present in the alloys and to account for Li rich interface layers. More details are summarized in the Online Resource Sect. 3. The calculated XRS spectra are shown in Fig. 5. In general, the simulated spectra can be roughly categorized in two groups: simulations of structures in which Li is exclusively surrounded by Al and/or Li, and of structures also containing Cu in the Li neighborhood. While the first group is made up from the single Li and the Li dimer each in an Al matrix as well as from the \(\delta '\) phase, the other group consists of spectra simulated for T1 structures. Within each group, the shapes of simulated spectra are not completely different which is not to be expected considering their respective structural similarities (cf. the Online Resource Sect. 3 for the different structural models). However, a rather clear distinction can still be made with respect to S-T1-Don which is likely due to Li neighborhood being predominantly occupied by Al in this specific T1 structure model [8]. Moreover, both groups are well distinguishable from each other and, thus, offer a potential way of discriminating T1-rich samples from samples without this phase.

Linear combination fits of the XRS spectra of the artificially aged binary alloy (top) and the base material of AA2198 (bottom). In the former case, the experimental spectrum was fitted using a linear combination of the as-quenched sample spectrum and the simulated spectrum of the \(\delta '\) phase, whereas the experimental weld nugget and S-T1-Dwyer spectra were used in the latter case

Following a common approach of X-ray absorption spectroscopy analysis [60], the experimental XRS spectra were fitted using a linear combination of both experimental and/or simulated spectra. Notably, no satisfactory linear combination fit could be obtained for the as-quenched binary alloy and the weld nugget of the technical alloy. This indicates that the structures present after quenching or equivalently after the significant heat input during welding are more complex than the single Li atom or the Li dimer in an Al matrix. Thus, the latter experimental spectra were used as representations of the most homogeneous solid solutions achievable for these alloys for subsequent linear combination fitting of the aged binary alloy and the base material of AA2198. By this means, the aged binary alloy can be fitted (see Fig. 6) using its as-quenched counterpart and the simulated \(\delta '\) one with relative contribution of 36(2)% and 64(2)%, respectively. The energy shift of the calculated spectrum is −1.5(1) eV in this case. Following the same approach, a reasonable fit of the spectrum of the bulk material of AA2198 could only be obtained using the S-T1-Dwyer and S-T1-Howe simulations. In these cases, the relative T1 contributions are 36(3)% and 30(10)% and the energy shifts are 2.2(4) eV and 3.0(5) eV for the S-T1-Dwyer (see Fig. 6) and S-T1-Howe-based fits, respectively. The reported energy shifts (of calculated XRS spectra) are not insignificant, but seem to be compatible with energy shifts between experimental XRS spectra and calculations performed using FDMNES [30, 36]. All other simulated T1 spectra are subject to very large energy shifts (> 6 eV), which effectively shift them out of the accessible energy loss region, and are, thus, discarded. As the structure of Dwyer et al. [23] was shown to be the energetically most stable one [24], the further discussion is restricted to S-T1-Dwyer and the respective results.

Concerning the binary alloy, the dissimilarity between the XRS spectra of the simulated solute Li atoms, S-1Li and S-2Li, and the as-quenched binary alloy spectrum is not unexpected. Statistically, a mixture of single Li atoms, i.e., with only Al neighbors, Li dimers and clusters containing more Li atoms can be expected for a solid solution. Besides, it is known that decomposition and ordering in binary Al–Li takes place already during quenching [44], which is also corroborated by the DSC results presented in Fig. 1 (red curve). For the relative \(\delta '\) contribution of 64(2)% in the aged binary alloy determined using linear combination fitting, there are–to the best of our knowledge–no (comparable) data such as volume fractions or similar available, although data on \(\delta '\) sizes were published [44, 61]. In light of the very fast decomposition in binary Al–Li, however, the determined \(\delta '\) contribution seems plausible and is qualitatively in line with the DSC results shown in Fig. 1 which indicate the presence of \(\delta '\). In the case of the technical alloy, the microstructure is also known to be complex consisting of structurally different T1 precipitates in the same alloy [62, 63]. In a similarly aged alloy for example, Häusler et al. [62] could identify (at least) two different T1 states. However, for AA2198, the volume fraction of T1 in a comparably aged alloy was determined to be about 2.5% using small angle X-ray scattering [52]. Using this particular volume fraction and the different T1 crystal structures, the percentage of Li in solution (and not embedded in a T1 precipitate) can be estimated (cf. details of the calculation in the Online Resource Sect. 5) to range from 77 to 98% for the S-T1-vanS and S-T1-Don crystal structures, respectively. Considering that the microstructure surely does not solely consist of T1 precipitates and solute Li atoms but of a variety of structures (dimers, clusters, and the like), the result of a T1 contribution of 36(3)%, which corresponds to a 64(3)% contribution of Li atoms in solution, based on the linear combination fit using the S-T1-Dwyer simulation is plausible with respect to the estimate of 78% based on the respective crystal structure (see Online Resource Sect. 5). Under the assumption of a T1 volume fraction of 3.7%, which is arguably close to 2.5% within small angle scattering limits [52], in combination with the structure of Dwyer et al. [23], the contribution of Li atoms in solution is estimated to be 67% which is in agreement with the 64(3)% determined using the linear combination of the XRS results.

Conclusion

The decomposition of Al alloys and the involved structures are notoriously complex and difficult to access, particularly at early stages and if light elements are involved. Herein, we have investigated a binary Al–Li alloy and a technical AA2198 alloy using a combination of differential scanning calorimetry and X-ray Raman spectroscopy (including respective simulations). While the former method allows for deriving information about the occurrence of different phases and precipitates on a macroscopic or global level, the latter facilitates a Li centered perspective similar to X-ray absorption spectroscopy. Based on this combination, \(\delta '\) and T1 precipitates were detected in the binary and the technical alloy, respectively, and their respective contributions (in terms of atomic percentage) were quantified using XRS. Considering the limited possibilities of comparison, the determined contributions of 64(2)% for \(\delta '\) in the binary alloy and 36(3)% for T1 (assuming the Dywer et. al structure [23]) in AA2198 are reasonable. At the same time, one should bear in mind that this analysis might be affected by the usage of FDMNES calculations, for which no experimental reference is available (as in the case of T1 precipitates), and by weak, yet present Mg L2/L3-edge contributions. Still, despite the limited energy range extractable for the Li K-edge, the aforementioned considerations, and the complex and likely multistructural nature of precipitates in Al-Li-Cu-based alloys, XRS is a useful addition to the toolbox for light metal investigation.

References

Polmear I (2004) Mater Forum 28:1

Gumbmann E, Lefebvre W, De Geuser F, Sigli C, Deschamps A (2016) Acta Mater 115:104. https://doi.org/10.1016/j.actamat.2016.05.050

Ghosh K, Das K, Chatterjee U (2007) Metall Mater Trans A 38(9):1965. https://doi.org/10.1007/s11661-007-9250-2

Petschke D, Staab TEM (2017) Mater Sci Forum 877:387. https://doi.org/10.4028/www.scientific.net/MSF.877.387

Sitdikov VD, Murashkin MY, Khasanov MR, Kasatkin IA, Chizhov PS, Bobruk EV (2014) IOP Conf Ser-Mat Sci 63:012087. https://doi.org/10.1088/1757-899X/63/1/012087

Dlubek G, Krause S, Krause H, Beresina AL, Mikhalenkov VS, Chuistov KV (1992) J Phys-Condens Mat 4(29):6317. https://doi.org/10.1088/0953-8984/4/29/015

Williams DB, Edington JW (1974) Philos Mag 30(5):1147. https://doi.org/10.1080/14786437408207266

Donnadieu P, Shao Y, De Geuser F, Botton G, Lazar S, Cheynet M, de Boissieu M, Deschamps A (2011) Acta Mater 59(2):462. https://doi.org/10.1016/J.ACTAMAT.2010.09.044

Deschamps A, Garcia M, Chevy J, Davo B, De Geuser F (2017) Acta Mater 122:32. https://doi.org/10.1016/J.ACTAMAT.2016.09.036

Deschamps A, Bigot A, Livet F, Auger P, Bréchet Y, Blavette D (2001) Philos Mag A 81(10):2391. https://doi.org/10.1080/01418610108217154

de Geuser F, Dorin T, Lefebvre W, Gault B, Deschamps A (2014) Mater Sci Forum 794–796:926. https://doi.org/10.4028/www.scientific.net/MSF.794-796.926

Neibecker P, Leitner M, Kushaim M, Boll T, Anjum D, Al-Kassab T, Haider F (2017). Sci Rep. https://doi.org/10.1038/s41598-017-03203-z

Klobes B, Staab TEM, Dudzik E (2008) Phys Status Solidi (RRL) 2(4):182. https://doi.org/10.1002/pssr.200802067

Petschke D, Lotter F, Bläss E, Staab TEM (2018) J Appl Crystallogr 51(5):1339. https://doi.org/10.1107/S1600576718011214

Petschke D, Lotter F, Staab TEM (2019) Materialia 6:100341. https://doi.org/10.1016/j.mtla.2019.100341

Sahle CJ, Mirone A, Niskanen J, Inkinen J, Krisch M, Huotari S (2015) J Synchrotron Radiat 22:400. https://doi.org/10.1107/S1600577514027581

Rioja RJ, Liu J (2012) Metall Mater Trans A 43(9):3325. https://doi.org/10.1007/s11661-012-1155-z

Wang SC, Starink MJ (2005) Int Mater Rev 50(4):193. https://doi.org/10.1179/174328005X14357

Van Smaalen S, Meetsma A, De Boer J, Bronsveld P (1990) J Solid State Chem 85(2):293. https://doi.org/10.1016/S0022-4596(05)80086-6

Howe JM, Lee J, Vasudivan AK (1988) Metall Trans A 19:2911

Huang JC, Ardell AJ (1987) Mater Sci Tech Ser 3(3):176. https://doi.org/10.1179/mst.1987.3.3.176

Cassada WA, Shiflet GJ, Starke EA Jr (1987) J Phys Colloq 48(C3):C3. https://doi.org/10.1051/jphyscol:1987345

Dwyer C, Weyland M, Chang LY, Muddle BC (2011) Appl Phys Lett 98(20):201909. https://doi.org/10.1063/1.3590171

Kim K, Zhou BC, Wolverton C (2018) Acta Mater 145:337. https://doi.org/10.1016/j.actamat.2017.12.013

Khushaim M, Gemma R, Al-Kassab T (2016) Microsc Res Techniq 79(8):727. https://doi.org/10.1002/jemt.22691

Gayle F.W, Vander Sande J.B, McAlister A.J (1984) Bull Alloy Phase Diagr 5(1), 19. https://doi.org/10.1007/BF02868711

Shaiu BJ, Li HT, Lee HY, Chen H (1990) Metall Trans A 21(4):1133. https://doi.org/10.1007/BF02656533

Sigli C, Sanchez J (1986) Acta Metall Mater 34(6):1021. https://doi.org/10.1016/0001-6160(86)90211-7

Katgerman L (1981) D. Eskin. In: Totten GE, MacKenzie DS (eds) Handbook of aluminum, vol 1. Marcel Dekker Inc, New York, pp 259–304

Joly Y, Cavallari C, Guda SA, Sahle CJ (2017) J Chem Theory Comput 13:2172. https://doi.org/10.1021/acs.jctc.7b00203

Sinha SK (2001) J Phys-Condens Mat 13:7511. https://doi.org/10.1088/0953-8984/13/34/304

Bergmann U, Glatzel P, Cramer SP (2002) Microchem J 71:221

Bunau O, Joly Y (2009) J Phys-Condens Mat 21:345501. https://doi.org/10.1088/0953-8984/21/34/345501

Fukui H, Hiraoka N (2018) Phys Chem Miner 45(2):211. https://doi.org/10.1007/s00269-017-0909-y

Fehse M, Sahle CJ, Hogan MP, Cavallari C, Kelder EM, Alfredsson M, Longo A (2019) J Phys Chem C 123(40):24396. https://doi.org/10.1021/acs.jpcc.9b06552

Voigt K, Zhang M, Ramakrishna K, Amouretti A, Appel K, BrambrinkE, Cerantola V, Chekrygina D, Döppner T, Falcone R.W,. Falk K,Fletcher L.B, Gericke D.O, Göde S, Harmand M, Hartley N.J,Hau-Riege S.P, Huang L.G, Humphries O.S, Lokamani M, Makita M, PelkaA, Prescher C, Schuster A.K, Šmíd M, ToncianT, Vorberger J, Zastrau U, Preston T.R, Kraus D (2021) Phys Plasmas28(8), 082701. https://doi.org/10.1063/5.0048150

Miedema PS, Ngene P, van der Eerden AMJ, Weng TC, Nordlund D, Sokaras D, Alonso-Mori R, Juhin A, de Jongh PE, de Groot FMF (2012) Phys Chem Chem Phys 14:5581. https://doi.org/10.1039/c2cp24025d

Ravel B, Newville M (2005) J Synchrotron Radiat 12(4):537. https://doi.org/10.1107/S0909049505012719

Papazian J, Sigli C, Sanchez J (1986) Scripta Mater Metall 20(2):201. https://doi.org/10.1016/0036-9748(86)90126-2

Livet F, Bloch D (1985) Scripta Mater Metall 19(10):1147. https://doi.org/10.1016/0036-9748(85)90225-X

Landvai J, Gudladt HJ, Gerold V (1989) Z Metallkd 80:310

Hono K, Babu SS, Hiraga K, Okano R, Sakurai T (1992). Acta Metall Mater. https://doi.org/10.1016/0956-7151(92)90466-R

Okuda H, Tanaka I, Osamura K, Osawa M, Ito K, Amemiya Y (1997) IUCr, J Appl Crystallogr 30(5), 586. https://doi.org/10.1107/S0021889897002409

Shaiu B, Li H, Lee H, Chen H (1990) Metall Trans A 21(4):1133. https://doi.org/10.1007/BF02656533

Noble B, Thompson GE (1971) Met Sci 5(1):114. https://doi.org/10.1179/030634571790439333

Baumann S, Williams D (1985) Acta Metall Mater 33(6):1069. https://doi.org/10.1016/0001-6160(85)90200-7

Noble B, Bray S (1998) Acta Mater 46(17):6163. https://doi.org/10.1016/S1359-6454(98)00263-8

Williams DB, Edington JW (1975) Metal Sci 9(1):529

Cocco G, Fagherazzi G, Schiffini L (1977) IUCr, J Appl Crystallogr 10(4), 325. https://doi.org/10.1107/S0021889877013557

Okuda H, Tanaka I, Matoba T, Osamura K, Amemiya Y (1998) Mater T JIM 39(1):62. https://doi.org/10.2320/matertrans1989.39.62

Decreus B, Deschamps A, De Geuser F, Donnadieu P, Sigli C, Weyland M (2013) Acta Mater 61(6):2207. https://doi.org/10.1016/J.ACTAMAT.2012.12.041

Dorin T, Deschamps A, De Geuser F, Lefebvre W, Sigli C (2014) Philos Mag 94(10):1012. https://doi.org/10.1080/14786435.2013.878047

de Geuser F, Malard B, Deschamps A (2014) Philos Mag 94(13):1451. https://doi.org/10.1080/14786435.2014.887862

Ivanov R, Deschamps A, De Geuser F (2017) IUCr, J Appl Crystallogr 50(6), 1725. https://doi.org/10.1107/S1600576717014443

Ivanov R, Deschamps A, De Geuser F (2018) Scripta Mater 150:156. https://doi.org/10.1016/J.SCRIPTAMAT.2018.03.024

Lotter F, Petschke D, De Geuser F, Elsayed M, Sextl G, Staab TEM (2019) Scripta Mater 168:104. https://doi.org/10.1016/j.scriptamat.2019.04.031

Thompson A, Lindau I, Attwood D, Liu Y, Gullikson E, Pianetta P, Howells M, Robinson A, Kim KJ, Scofield J, Kirz J, Underwood J, Kortright J, Williams G, Winick H (2009) X-ray data booklet. Lawrence Berkeley National Laboratory, Berkeley

Soler JM, Artacho E, Gale JD, García A, Junquera J, Ordejón P, Sánchez-Portal D (2002) J Phys-Condens Mat 14(11):2745. https://doi.org/10.1088/0953-8984/14/11/302

Silcock J.M (1960) J Inst Metals 88. https://www.osti.gov/biblio/4138237

Bunker G (2010) Introduction to XAFS. Cambridge University Press, Cambridge

Pletcher BA, Wang KG, Glicksman ME (2012) Acta Mater 60(16):5803. https://doi.org/10.1016/j.actamat.2012.07.021

Häusler I, Kamachali R, Hetaba W, Skrotzki B (2018) Materials 12(1):30. https://doi.org/10.3390/ma12010030

Lv K, Zhu C, Zheng J, Wang X, Chen B (2019) J Mater Res 34(20):3535. https://doi.org/10.1557/jmr.2019.136

Acknowledgements

We acknowledge DESY (Hamburg, Germany), a member of the Helmholtz Association HGF, for the provision of experimental facilities. Parts of this research were carried out at Petra III, and we would like to thank Hasan Yavas and Erdinc Oz for assistance in using beamline P01. Beamtime was allocated for proposal I-20170026. The authors also thank Dr. T. Schubert (Fraunhofer IFAM Dresden) for casting the Al–Li alloy. Moreover, we would also like to thank Dr. G. Tempus and H. Ostersehlte from Airbus Bremen for providing us the FS-welded structure of the commercial alloy AA2198.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Yaroslava Yingling.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Klobes, B., Petschke, D., Lotter, F. et al. The Li stance on precipitation in Al–Li-based alloys: an investigation by X-ray Raman spectroscopy. J Mater Sci 57, 6157–6166 (2022). https://doi.org/10.1007/s10853-022-07018-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07018-w