Abstract

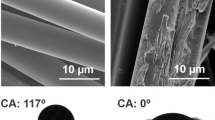

To show the effect of surface texture on transfer film growth of continuous carbon fiber-reinforced thermoplastic poly(ether ether ketone) (CCF-PEEK), tribological behaviors of untextured and laser-engraved-dimple-textured WC–Co, TiN and DLC surfaces dry-sliding against CCF-PEEK pin were studied in ambient atmosphere (pv = 0.46 MPa•m/s). Little tribo-film formed on untextured WC–Co, TiN and DLC, but continuous, relatively uniform CCF-PEEK transfer films with micron-level thickness grew from the majority of dimples along the sliding direction on textured WC–Co, TiN and DLC. A stable reduction in coefficient of friction by nearly 38.3% was achieved by textured WC–Co compared to the untextured. Texturing also yielded significant friction reduction to TiN, but almost did not lower the friction of DLC. Micro-cutting effect from the dimple texture edges probably caused considerable material removal of the counterpart CCF-PEEK pin and the repetitive friction cycles shaped the CCF-PEEK wear debris into the tribo-films. The friction reduction could be primarily attributed to the substantial mediation of tribological CCF-PEEK transfer films on the sliding interface. This study indicates that surface texture can facilitate the growth of polymeric transfer films with tribological application potentials in dry-sliding conditions.

Similar content being viewed by others

References

Nunez EE, Gheisari R, Polycarpou AA (2019) Tribology review of blended bulk polymers and their coatings for high-load bearing applications. Tribol Int 129:92–111

Padhan M, Marathe U, Bijwe J (2020) Tribology of poly(etherketone) composites based on nano-particles of solid lubricants. Compos Pt. B-Eng 201:108323

Oladapo BI, Zahedi SA, Ismail SO, Omigbodun FT (2021) 3D printing of PEEK and its composite to increase biointerfaces as a biomedical material − A review. Colloid Surface B 203:111726

Yao S-S, Jin F-L, Rhee KY, Hui D, Park S-J (2018) Recent advances in carbon-fiber-reinforced thermoplastic composites: a review. Compos Pt B-Eng 142:241–250

Yao C, Qi Z, Chen W, Zhang C (2021) Experimental study on CF/PEEK thermoplastic fastener: Effects of fastener matrix crystallinity and fibre content on the strength of single-lap joint. Compos. Pt. B-Eng. 213:108737

Souza JCM, Correia MST, Oliveira MN, Silva FS, Henriques B, Novaes de Oliveira AP, Gomes JR (2020) PEEK-matrix composites containing different content of natural silica fibers or particulate lithium−zirconium silicate glass fillers: coefficient of friction and wear volume measurements. Biotribol 24:100147

Bahadur S (2000) The development of transfer layers and their role in polymer tribology. Wear 245:92–99

Ruckdäschel H, Sandler JKW, Altstädt V (2008) Chapter 8 − On the friction and wear of carbon nanofiber–reinforced PEEK–based polymer composites. In Tribology and Interface Engineering Series, Elsevier 55: 149–208

Ovaert TC, Cheng HS (1991) Counterface topographical effects on the wear of polyetheretherketone and a polyetheretherketone-carbon fiber composite. Wear 150:275–287

Zhang G, Wetzel B, Jim B, Oesterle W (2015) Impact of counterface topography on the formation mechanisms of nanostructured tribofilm of PEEK hybrid nanocomposites. Tribol Int 83:156–165

Nunez EE, Polycarpou AA (2015) The effect of surface roughness on the transfer of polymer films under unlubricated testing conditions. Wear 326–327:74–83

Ovaert TC, Cheng HS (1991) The unlubricated sliding wear behavior of polyetheretherketone against smooth mild-steel counterfaces. J Tribol 113:150–157

Feng X, Lu Z, Zhang R (1999) Analysis of electron spectroscopy for chemical analysis of the transferred film formed during sliding wear for carbon fibre reinforced polyetheretherketone and its composites. J Mater Sci 34:3513–3524

Ramachandra S, Ovaert TC (1997) The effect of controlled surface topographical features on the unlubricated transfer and wear of PEEK. Wear 206:94–99

Laux KA, Schwartz CJ (2013) Influence of linear reciprocating and multi-directional sliding on PEEK wear performance and transfer film formation. Wear 301:727–734

Lin L, Pei X-Q, Bennewitz R, Schlarb AK (2018) Friction and wear of PEEK in continuous sliding and unidirectional scratch tests. Tribol Int 122:108–113

Placette MD, Roy S, White D, Sundararajan S, Schwartz CJ (2019) The effect of surface roughness orientation on PEEK (polyetheretherketone) transfer film volume in multi-directional and linear sliding. Wear 426–427:1345–1353

Guo L, Pei X, Zhao F, Zhang L, Li G, Zhang G (2020) Tribofilm growth at sliding interfaces of PEEK composites and steel at low velocities. Tribol. Int. 151:106456

Kurtz SM, Devine JN (2007) PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomater 28:4845–4869

Sonntag R, Reinders J, Kretzer JP (2012) What’s next? Alternative materials for articulation in total joint replacement. Acta Biomater 8:2434–2441

Koh Y-G, Park K-M, Lee J-A, Nam J-H, Lee H-Y, Kang K-T (2019) Total knee arthroplasty application of polyetheretherketone and carbon-fiber-reinforced polyetheretherketone: a review. Mater Sci Eng C 100:70–81

Allen Q, Raeymaekers B (2020) Surface texturing of prosthetic hip implant bearing surfaces: a review. J Tribol 143

Cho SM, Park J-W, Han H-S, Seok H-K, Moon M-W, Kim YC (2013) Multifunctional composite coating as a wear-resistant layer for the bearing in total hip joint replacement. ACS Appl Mater Inter 5:395–403

Li L, Li Q, Zhao M, Dong L, Wu J, Li D (2019) Effects of Zn and Ag ratio on cell adhesion and antibacterial properties of Zn/Ag coimplanted TiN. ACS Biomater Sci Eng 5:3303–3310

Herbster M, Döring J, Nohava J, Lohmann CH, Halle T, Bertrand J (2020) Retrieval study of commercially available knee implant coatings TiN, TiNbN and ZrN on TiAl6V4 and CoCr28Mo6. J Mech Behav Biomed Mater 112:104034

Escudeiro A, Wimmer MA, Polcar T, Cavaleiro A (2015) Tribological behavior of uncoated and DLC-coated CoCr and Ti-alloys in contact with UHMWPE and PEEK counterbodies. Tribol Int 89:97–104

Liao TT, Deng QY, Li SS, Li X, Ji L, Wang Q, Huang N (2017) Evaluation of the size-dependent cytotoxicity of DLC (diamondlike carbon) wear debris in arthroplasty applications. ACS Biomater Sci Eng 3:530–539

Wang S, Liao Z, Lu J, Feng P, Liu W (2016) The biotribological behaviour of an artificial cervical disc model with ball-on-socket contact type under different material configurations. Tribol Lett 65:8

Ranjan P, Hiremath SS (2019) Role of textured tool in improving machining performance: a review. J Manuf Process 43:47–73

Machado AR, da Silva LRR, de Souza FCR, Davis R, Pereira LC, Sales WF, Ezugwu EO (2021) State of the art of tool texturing in machining. J Mater Process Tech 293:117096

Du J, Zhang H, Geng Y, Ming W, He W, Ma J, Liu K (2019) A review on machining of carbon fiber reinforced ceramic matrix composites. Ceram Int 45:18155–18166

Bobzin K (2017) High-performance coatings for cutting tools. CIRP J Manuf Sci Tech 18:1–9

Geier N, Davim JP, Szalay T (2019) Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: a review. Compos Pt. A-Appl Sci Manuf 125:105552

Gropper D, Wang L, Harvey TJ (2016) Hydrodynamic lubrication of textured surfaces: a review of modeling techniques and key findings. Tribol Int 94:509–529

Mao B, Siddaiah A, Liao Y, Menezes PL (2020) Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: a review. J Manuf Process 53:153–173

Hutchings I, Shipway P, (2017) Chapter 7 - Surface engineering. In Tribology (2nd edition), Hutchings, I., Shipway, P., Eds. Butterworth-Heinemann: ;pp 237–281

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Lin L, Schlarb AK (2019) Recycled carbon fibers as reinforcements for hybrid PEEK composites with excellent friction and wear performance. Wear 432–433, 202928

Lin L, Ecke N, Huang M, Pei X-Q, Schlarb AK (2019) Impact of nanosilica on the friction and wear of a PEEK/CF composite coating manufactured by fused deposition modeling (FDM). Compos Pt. B-Eng 177:107428

Barba D, Arias A, Garcia-Gonzalez D (2020) Temperature and strain rate dependences on hardening and softening behaviours in semi-crystalline polymers: Application to PEEK. Int J Solids Struct 182–183:205–217

Lei M, Hamel CM, Chen K, Zhao Z, Lu H, Yu K, Qi HJ (2021) Thermomechanical behaviors of polyether ether ketone (PEEK) with stretch-induced anisotropy. J Mech Phy Solids 148:104271

Acknowledgements

This study was funded by National Key Research and Development Project of China (grant number 2018YFB2002201); the China Postdoctoral Science Foundation (grant numbers BX20190048, 2021M693724); and the National Natural Science Foundation of China (grant numbers 52005061, 51771037).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Jaime Grunlan.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cao, H., Dong, X., Qu, D. et al. Transfer film growth of continuous carbon fiber reinforced thermoplastic poly(ether ether ketone) facilitated by surface texture during dry sliding. J Mater Sci 57, 383–397 (2022). https://doi.org/10.1007/s10853-021-06595-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06595-6