Abstract

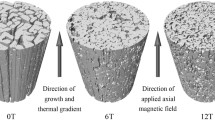

In this study, the Al-1.9 wt.% Fe alloy was directionally solidified at different growth velocities under various high magnetic fields. The effect of high magnetic fields on microstructural evolution of the alloys during directional solidification and their dependence on the growth velocity were investigated. The microstructures near the transition growth regions of the alloys between two different growth velocities were observed. With increasing growth velocity, the microstructure exhibited a eutectic to cellular eutectic to hypoeutectic structure transformation. Applying high magnetic fields increased the spacing of the eutectic Al3Fe phase and decreased the alignment degree of the eutectic Al3Fe phase at 1 µm/s, decreased the size of the eutectic cells at 10 µm/s, and promoted development and branching of the primary Al dendrites at 100 µm/s. Near the transition growth region, applying high magnetic fields stopped the growth of existing eutectic Al3Fe and promoted nucleation of the new eutectic Al3Fe phase for 1–10 μm/s, and accelerated transformation of the growth behavior from cellular eutectic to hypoeutectic for 10–100 μm/s. The evolution of the eutectic growth behavior caused by the high magnetic fields can be attributed to suppression of convection and the corresponding decrease in solute migration owing to the Lorentz force.

Similar content being viewed by others

References

Hunt JD, Jackson KA (1966) Binary eutectic solidification. Trans Metall Soc AIME 236:843–852

Nourbakhsh S, Sahin O, Rhee WH, Margolin H (1992) Microstructural characterization of a zirconia-toughened alumina fiber reinforced niobium aluminide composite. Acta Metall Mater 40:285–294. https://doi.org/10.1016/0956-7151(92)90303-V

Mendiratta MG, Dimiduk DM (1993) Strength and toughness of a Nb/Nb5Si3 composite. Metall Trans A 24:501–504. https://doi.org/10.1007/BF02657338

Faivre G (1996) Morphological instabilities of lamellar eutectic growth fronts: a survey of recent experimental and numerical results. J Cryst Growth 166:29–39. https://doi.org/10.1016/0022-0248(96)00072-3

Magnin P, Trivedi R (1991) Eutectic growth: a modification of the Jackson and Hunt theory. Acta Metall Mater 39:453–467. https://doi.org/10.1016/0956-7151(91)90114-G

Rios CT, Milenkovic S, Ferrandini PL, Caram R (2005) Directional solidification, microstructure and properties of the Al3Nb-Nb2Al eutectic. J Cryst Growth 275:e153–e158. https://doi.org/10.1016/j.jcrysgro.2004.10.100

Sun Z, Guo M, Vleugels J, Van der Biest O, Blanpain B (2013) Processing of non-ferromagnetic materials in strong static magnetic field. Curr Opin Solid State Mater Sci 17:193–201. https://doi.org/10.1016/j.cossms.2013.05.001

Liu T, Wang Q, Yuan Y, Wang K, Li G (2018) High-gradient magnetic field-controlled migration of solutes and particles and their effects on solidification microstructure: a review. Chin Phys B. https://doi.org/10.1088/1674-1056/27/11/118103

Wang J, Li J, Wang J, Bu F, Kou H, Li C, Zhang P, Beaugnon E (2018) Effect of solidification on microstructure and properties of FeCoNi(AlSi)0.2 high-entropy alloy under strong static magnetic field. Entropy. https://doi.org/10.3390/e20040275

Dong S, Liu T, Dong M, Guo X, Yuan S, Wang Q (2020) Enhanced magnetostriction of Tb-Dy-Fe via simultaneous 〈111〉-crystallographic orientation and -morphological alignment induced by directional solidification in high magnetic fields. Appl Phys Lett 116:053903

Wang Q, Liu T, Wang K, Gao P, Liu Y, He J (2014) Progress on High magnetic field-controlled transport phenomena and their effects on solidification microstructure. ISIJ Int 54:516–525. https://doi.org/10.2355/isijinternational.54.516

Utech HP, Flemings MC (1996) Elimination of solute banding in indium antimonide crystals by growth in a magnetic field. J Appl Phys 37:2021. https://doi.org/10.1063/1.1708664

Liu T, Miao L, Wang K, Wang L, Sun J, Wang Q (2018) High magnetic-field-induced solute interception among dendrite arms in the mushy zone of a Mn-Sb alloy. J Appl Phys. https://doi.org/10.1063/1.5031047

Li X, Fautrelle Y, Ren Z (2007) Influence of thermoelectric effects on the solid-liquid interface shape and cellular morphology in the mushy zone during the directional solidification of Al-Cu alloys under a magnetic field. Acta Mater 55:3803–3813. https://doi.org/10.1016/j.actamat.2007.02.031

Wang J, Fautrelle Y, Ren ZM, Li X, Nguyen-Thi H, Mangelinck-Noël N, Salloum Abou Jaoude G, Zhong YB, Kaldre I, Bojarevics A, Buligins L (2012) Thermoelectric magnetic force acting on the solid during directional solidification under a static magnetic field. Appl Phys Lett 25:251904

Liu T, Wang Q, Gao A, Zhang C, Wang C, He J (2007) Fabrication of functionally graded materials by a semi-solid forming process under magnetic field gradients. Scr Mater 57:992–995. https://doi.org/10.1016/j.scriptamat.2007.08.011

Liu T, Wang Q, Gao A, Zhang H, Wang K, He J (2010) Distribution of alloying elements and the corresponding structural evolution of Mn-Sb alloys in high magnetic field gradients. J Mater Res 25:1718–1727. https://doi.org/10.1557/JMR.2010.0226

Liu T, Wang Q, Hirota N, Liu Y, Chen S, He J (2011) In situ control of the distributions of alloying elements in alloys in liquid state using high magnetic field gradients. J Cryst Growth 335:121. https://doi.org/10.1016/j.jcrysgro.2011.08.045

Wu M, Liu T, Dong M, Sun J, Dong S, Wang Q (2017) Directional solidification of Al-8 wt. %Fe alloy under high magnetic field gradient. J Appl Phys 12:064901

Qin J, Bian X, Sliusarenko S, Wang W (1998) Pre-peak in the structure factor of liquid Al-Fe alloy. J Phys Condens Mat 10:1211–1218. https://doi.org/10.1088/0953-8984/10/6/004

Suk MJ, Moon IH (1991) Coupled region and area fraction of primary phases in Sb-InSb eutectic alloys. J Mater Sci 26:4931–4936. https://doi.org/10.1007/BF00549873

Wang Q, Dong M, Sun J, Liu T, Yuan Y (2018) Control of solidification process and fabrication of functional materials with high magnetic fields. Acte Metall Sin 54(2018):742–756. https://doi.org/10.11900/0412.1961.2017.00535

Li X, Gagnoud A, Ren Z, Fautrelle Y, Moreau R (2009) Investigation of thermoelectric magnetic convection and its effect on solidification structure during directional solidification under a low axial magnetic field. Acta Mater 57:2180–2197. https://doi.org/10.1016/j.actamat.2009.01.016

Hunt JD (1999) Pattern formation in solidification. Mater Sci Technol 15:9–14. https://doi.org/10.1179/026708399773002755

Kang HS, Yoon WY, Kim KH, Kim MH, Yoon YP (2005) Microstructure selections in the undercooled hypereutectic Al-Si alloys. Mater Sci Eng A 404:117–123. https://doi.org/10.1016/j.msea.2005.05.041

da Silveira AF, de Castro WB, Luciano BA, Kiminami CS (2004) Microstructure of under-cooled Sn-Bi and Al-Si alloys. Mater Sci Eng A 375–377:473–478. https://doi.org/10.1016/j.msea.2003.10.017

Plapp M, Karma A (1999) Eutectic colony formation: a stability analysis. Phys Rev E 60:6865. https://doi.org/10.1103/PhysRevE.60.6865

Acknowledgements

This work is supported by the National Natural Science Foundation of China (NNSFC) (51774086, 51690161, and 21701022), Fundamental Research Funds for the Central Universities (N170902002, N180915002 and N170908001), and Liaoning Innovative Research Team in University, China (LT2017011).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work and there is no professional or other personal interest of any nature or kind in any product, service and company.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tang, P., Tian, Y., Liu, S. et al. Microstructure development in eutectic Al–Fe alloy during directional solidification under high magnetic fields at different growth velocities. J Mater Sci 56, 16134–16144 (2021). https://doi.org/10.1007/s10853-021-06298-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06298-y