Abstract

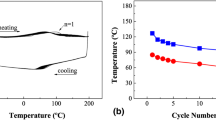

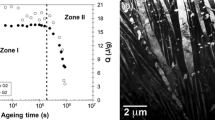

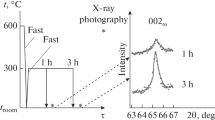

Metastable phase diagrams of β (BCC)-Ti high-temperature shape memory alloys (HTSMAs) have been investigated extensively, where however β→isothermal ω (iso-ω, hexagonal) transition upon heating has not been accessed. Following α” (orthorhombic)→β reverse martensitic transformation on heating, iso-ω precipitation is commonly encountered. These two transitions may overlap within certain composition range, but have not been clearly differentiated. It is of vital importance for the understanding of the subsequent transition behaviors. In this paper, phase transformations upon heating at various heating rates were characterized in quenched Ti-(16–25 at.%)Nb HTSMAs. In contrast to the linear increase in As (the starting temperature of α”→β transition) with decreasing Nb-content, ωs (the starting temperature of β→iso-ω transition) exhibits normal decrease firstly and shows abnormal increase below 20Nb. It is because iso-ω precipitates only in the reversed β phase but not in α” martensite proved by transmission electron microscopy observations. Namely, β→iso-ω transition is postponed to higher temperature due to the suppression of α” martensite below 20Nb. On this basis, the characteristics of both transformations can be determined for Ti-Nb below 20Nb by proper peak deconvolution. New metastable phase diagrams of Ti-Nb are formulated, including both α”→β and β→iso-ω transitions upon heating. Moreover, effective activation energies for β→iso-ω transition during isochronal annealing are determined by the Kissinger method.

Graphical abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Ma J, Karaman I, Noebe RD (2010) High temperature shape memory alloys. Int Mater Rev 55:257–315. https://doi.org/10.1179/095066010x12646898728363

Zhang J, Chen T, Li W, Bednarcik J, Dippel A-C (2020) High temperature superelasticity realized in equiatomic TiNi conventional shape memory alloy by severe cold rolling. Mater Design 193:108875. https://doi.org/10.1016/j.matdes.2020.108875

Zhao X, Niinomi M, Nakai M, Hieda J (2012) Beta type Ti–Mo alloys with changeable Young’s modulus for spinal fixation applications. Acta Biomater 8:1990–1997. https://doi.org/10.1016/j.actbio.2012.02.004

Gao J, Nutter J, Liu X, Guan D, Huang Y, Dye D, Rainforth WM (2018) Segregation mediated heterogeneous structure in a metastable β titanium alloy with a superior combination of strength and ductility. Sci Rep. https://doi.org/10.1038/s41598-018-25899-3

Dong R, Kou H, Wu L, Yang L, Zhao Y, Hou H (2020) β to ω transformation strain associated with the precipitation of α phase in a metastable β titanium alloy. J Mater Sci. https://doi.org/10.1007/s10853-020-05231-z

Zhang J, Rynko R, Frenzel J, Somsen C, Eggeler G (2014) Ingot metallurgy and microstructural characterization of Ti-Ta alloys. Int J Mater Res 105:156–167. https://doi.org/10.3139/146.111010

Rynko R, Marquardt A, Paulsen A, Frenzel J, Somsen C, Eggeler G (2015) Microstructural evolution in a Ti–Ta high-temperature shape memory alloy during creep. Int J Mater Res 106:331–341. https://doi.org/10.3139/146.111189

Ferrari A, Paulsen A, Frenzel J, Rogal J, Eggeler G, Drautz R (2018) Unusual composition dependence of transformation temperatures in Ti-Ta-X shape memory alloys. Phys Rev Mater 2:073609. https://doi.org/10.1103/PhysRevMaterials.2.073609

Moffat DL, Larbalestier DC (1988) The competition between the alpha-phases and omega-phases in aged Ti-Nb alloys. Metall Trans A 19:1687–1694. https://doi.org/10.1007/bf02645136

Kim HY, Ikehara Y, Kim JI, Hosoda H, Miyazaki S (2006) Martensitic transformation, shape memory effect and superelasticity of Ti-Nb binary alloys. Acta Mater 54:2419–2429. https://doi.org/10.1016/j.actamat.2006.01.019

Obbard EG, Hao YL, Talling RJ, Li SJ, Zhang YW, Dye D, Yang R (2011) The effect of oxygen on alpha ’ ’ martensite and superelasticity in Ti-24Nb-4Zr-8Sn. Acta Mater 59:112–125. https://doi.org/10.1016/j.actamat.2010.09.015

Sun B, Meng XL, Gao ZY, Cai W (2019) Study on the deformation mechanism of the martensitic Ti–16Nb high temperature shape memory alloy. Mater Sci Eng A 742:590–596. https://doi.org/10.1016/j.msea.2018.07.051

Bönisch M, Panigrahi A, Stoica M, Calin M, Ahrens E, Zehetbauer M, Skrotzki W, Eckert J (2017) Giant thermal expansion and alpha-precipitation pathways in Ti-alloys. Nat Commun 8:1429. https://doi.org/10.1038/s41467-017-01578-1

Al-Zain Y, Kim HY, Hosoda H, Nam TH, Miyazaki S (2010) Shape memory properties of Ti-Nb-Mo biomedical alloys. Acta Mater 58:4212–4223. https://doi.org/10.1016/j.actamat.2010.04.013

Gao J, Huang Y, Guan D, Knowles AJ, Ma L, Dye D, Rainforth WM (2018) Deformation mechanisms in a metastable beta titanium twinning induced plasticity alloy with high yield strength and high strain hardening rate. Acta Mater 152:301–314. https://doi.org/10.1016/j.actamat.2018.04.035

Xiong C, Li Y, Zhang J, Wang Y, Qu W, Ji Y, Cui L, Ren X (2021) Superelasticity over a wide temperature range in metastable β-Ti shape memory alloys. J Alloys Compd 853:157090. https://doi.org/10.1016/j.jallcom.2020.157090

Bönisch M, Panigrahi A, Calin M, Waitz T, Zehetbauer M, Skrotzki W, Eckert J (2017) Thermal stability and latent heat of Nb–rich martensitic Ti-Nb alloys. J Alloys Compd 697:300–309. https://doi.org/10.1016/j.jallcom.2016.12.108

Wang W, Zhang X, Mei W, Sun J (2020) Role of omega phase evolution in plastic deformation of twinning-induced plasticity β Ti–12V–2Fe–1Al alloy. Mater Design 186:108282. https://doi.org/10.1016/j.matdes.2019.108282

Prima F, Vermaut P, Texier G, Ansel D, Gloriant T (2006) Evidence of α-nanophase heterogeneous nucleation from ω particles in a β-metastable Ti-based alloy by high-resolution electron microscopy. Scr Mater 54:645–648. https://doi.org/10.1016/j.scriptamat.2005.10.024

Nag S, Banerjee R, Srinivasan R, Hwang JY, Harper M, Fraser HL (2009) ω-Assisted nucleation and growth of α precipitates in the Ti–5Al–5Mo–5V–3Cr–0.5Fe β titanium alloy. Acta Mater 57:2136–2147. https://doi.org/10.1016/j.actamat.2009.01.007

Li T, Kent D, Sha G, Dargusch MS, Cairney JM (2015) The mechanism of ω-assisted α phase formation in near β-Ti alloys. Scr Mater 104:75–78. https://doi.org/10.1016/j.scriptamat.2015.04.007

Liang Q, Zheng Y, Wang D, Hao Y, Yang R, Wang Y, Fraser HL (2019) Nano-scale structural non-uniformities in gum like Ti-24Nb-4Zr-8Sn metastable β-Ti alloy. Scr Mater 158:95–99. https://doi.org/10.1016/j.scriptamat.2018.08.043

Zháňal P, Harcuba P, Hájek M, Smola B, Stráský J, Šmilauerová J, Veselý J, Janeček M (2018) Evolution of ω phase during heating of metastable β titanium alloy Ti–15Mo. J Mater Sci 53:837–845. https://doi.org/10.1007/s10853-017-1519-2

Zhang J, Tasan CC, Lai MJ, Dippel AC, Raabe D (2017) Complexion-mediated martensitic phase transformation in Titanium. Nat Commun 8:14210. https://doi.org/10.1038/ncomms14210

Nag S, Devaraj A, Srinivasan R et al (2011) Novel Mixed-Mode Phase Transition Involving a Composition-Dependent Displacive Component. Phys Rev Lett 106:245701. https://doi.org/10.1103/PhysRevLett.106.245701

Otsuka K, Ren X (2005) Physical metallurgy of Ti-Ni-based shape memory alloys. Prog Mater Sci 50:511–678. https://doi.org/10.1016/j.pmatsci.2004.10.001

Huang L-F, Grabowski B, Zhang J, Lai M-J, Tasan CC, Sandlöbes S, Raabe D, Neugebauer J (2016) From electronic structure to phase diagrams: A bottom-up approach to understand the stability of titanium–transition metal alloys. Acta Mater. https://doi.org/10.1016/j.actamat.2016.04.059

Frenzel J, George EP, Dlouhy A, Somsen C, Wagner MFX, Eggeler G (2010) Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater 58:3444–3458. https://doi.org/10.1016/j.actamat.2010.02.019

Kim HY, Hashimoto S, Kim JI, Inamura T, Hosoda H, Miyazaki S (2006) Effect of Ta addition on shape memory behavior of Ti-22Nb alloy. Mater Sci Eng A 417:120–128. https://doi.org/10.1016/j.msea.2005.10.065

Mantani Y, Tajima M (2006) Phase transformation of quenched alpha ’ ’ martensite by aging in Ti-Nb alloys. Mater Sci Eng A 438:315–319. https://doi.org/10.1016/j.msea.2006.02.180

Cremasco A, Andrade PN, Contieri RJ, Lopes ESN, Afonso CRM, Caram R (2011) Correlations between aging heat treatment, ω phase precipitation and mechanical properties of a cast Ti–Nb alloy. Mater Design 32:2387–2390. https://doi.org/10.1016/j.matdes.2010.11.012

Lopes ESN, Cremasco A, Afonso CRM, Caram R (2011) Effects of double aging heat treatment on the microstructure, Vickers hardness and elastic modulus of Ti–Nb alloys. Mater Charact 62:673–680. https://doi.org/10.1016/j.matchar.2011.04.015

Bönisch M, Calin M, Waitz T, Panigrahi A, Zehetbauer M, Gebert A, Skrotzki W, Eckert J (2013) Thermal stability and phase transformations of martensitic Ti–Nb alloys. Sci Technol Adv Mater 14:055004. https://doi.org/10.1088/1468-6996/14/5/055004

Zhang J, Fan GL, Zhou YM, Ding XD, Otsuka K, Nakamura K, Sun J, Ren XB (2007) Does order-disorder transition exist in near-stoichiometric Ti-Ni shape memory alloys? Acta Mater 55:2897–2905. https://doi.org/10.1016/j.actamat.2006.12.028

Kent D, Pas S, Zhu SM, Wang G, Dargusch MS (2012) Thermal analysis of precipitation reactions in a Ti-25Nb-3Mo-3Zr-2Sn alloy. Appl Phys A 107:835–841. https://doi.org/10.1007/s00339-012-6778-9

Li Q, Ma G, Li J et al (2019) Development of low-young’s modulus Ti–Nb-based alloys with Cr addition. J Mater Sci 54:8675–8683. https://doi.org/10.1007/s10853-019-03457-0

Wang CH, Jiang H, Cao GH (2018) Effects of step-quenching on the α″ martensitic transformation, α precipitation, and mechanical properties of multiphase Ti–10Mo alloy. J Mater Sci 53:11765–11778. https://doi.org/10.1007/s10853-018-2438-6

Wang HL, Shah SAA, Hao YL et al (2017) Stabilizing the body centered cubic crystal in titanium alloys by a nano-scale concentration modulation. J Alloys Compd 700:155–158. https://doi.org/10.1016/j.jallcom.2016.12.406

Niendorf T, Krooß P, Batyrsina E et al (2014) Functional and structural fatigue of titanium tantalum High temperature shape memory alloys (HT SMAs). Mater Sci Eng A 620:359–366. https://doi.org/10.1016/j.msea.2014.10.038

Moffat DL (1985) Materials ScienceUniversity of Wisconsin, Madison

Okunishi E, Kawai T, Mitsuhara M, Farjami S, Itakura M, Hara T, Nishida M (2013) HAADF-STEM studies of athermal and isothermal ω-phases in β-Zr alloy. J Alloys Compd 577:S713–S716. https://doi.org/10.1016/j.jallcom.2011.12.115

Zhang JL, Tasan CC, Lai ML, Zhang J, Raabe D (2015) Damage resistance in gum metal through cold work-induced microstructural heterogeneity. J Mater Sci. https://doi.org/10.1007/s10853-015-9105-y

Zhang Y, Liu H, Jin Z (2001) Thermodynamic assessment of the Nb-Ti system. Calphad 25:305–317. https://doi.org/10.1016/S0364-5916(01)00051-7

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702–1706. https://doi.org/10.1021/ac60131a045

Lu K, Lück R, Predel B (1993) Temperature vs. heating rate transformation diagram for a transition from the amorphous to the nanocrystalline state. J Alloys Compd 201:229–234. https://doi.org/10.1016/0925-8388(93)90889-U

Wang H (2018) Ex situ and in situ TEM investigations of carbide precipitation in a 10Cr martensitic steel. J Mater Sci 53:7845–7856. https://doi.org/10.1007/s10853-018-2075-0

Mittemeijer EJ (2010) Fundamentals of materials science: the microstructure-property relationship using metals as model systems. Springer, Berlin Heidelberg, Berlin

Acknowledgements

This work was supported by the National Key Research and Development Program of China [grant number 2016YFB0701302] and National Natural Science Foundation of China [grant numbers 51621063, 51831006, 51931004, 51501145]. We thank Dr. Guo Shengwu, Dr. Zhu Ruihua, Dr. Zhou Shanlin, Dr. Wang Wei, Dr. Ren Zijun and Dr. Huang Chang for their kind assistances during experiments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Sophie Primig.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, J., Li, Y. & Li, W. Metastable phase diagram on heating in quenched Ti-Nb high-temperature shape memory alloys. J Mater Sci 56, 11456–11468 (2021). https://doi.org/10.1007/s10853-021-05814-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05814-4