Abstract

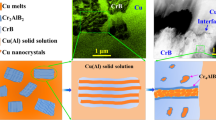

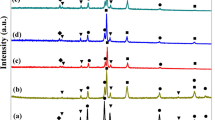

Pure Cu matrix composite reinforced by CrxOy-CNT hybrid was prepared via powder metallurgy in the present work. Microstructural analysis revealed that the formation of Cu2O nanoparticles at the interface is contributed to the interfacial bonding. The CrxOy-CNT/Cu composite of 1.0 vol% hybrid reinforcement exhibited excellent ultimate strength of 402.6 MPa, which was ~ 90.0% higher than that of unreinforced Cu (211.9 MPa). Meanwhile, the ultimate strength of the hybrid reinforcement was much higher than those of the separate components, which were 238.4 MPa of 1.0 vol% CNT/Cu composite and 339.1 MPa of 1.0 vol% CrxOy/Cu composite, respectively. Furthermore, the quantitative analysis indicated that Orowan looping system contributed the most to strength in CrxOy/Cu and CrxOy-CNT/Cu composites, whereas load transfer then contributed the most strength for CNT/Cu composite.

Similar content being viewed by others

References

Mallikarjuna HM, Ramesh CS, Koppad PG (2017) Nanoindentation and wear behaviour of copper based hybrid composites reinforced with SiC and MWCNTs synthesized by spark plasma sintering. Vacuum 145:320–333

Qu JP, Zhang CJ, Han J (2017) Microstructure evolution and mechanical properties of near α-Ti matrix composites reinforced by hybrid (TiB+Y2O3) with bimodal size. Vacuum 144:203–206

Zeng X, Yu YG, Fu DF (2018) Wear characteristics of hybrid aluminum-matrix composites reinforced with well-dispersed reduced graphene oxide nanosheets and silicon carbide particulates. Vaccum 155:364–375

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Treacy MMJ, Ebbesen TW, Gibson JM (1996) Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 381:678–680

Yu MF, Lourie O, Dyer MJ, Moloni K, Kelly TF, Ruoff RS (2000) Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 287:637–640

Wen J, Li YT, Wen Y (2014) Facile fabrication of three-dimensional graphene/carbon nanotube sandwich structure. Vacuum 101(3):271–274

Wong EW, Sheehan PE, Lieber CM (1997) Nanobeam mechanics: elasticity, strength, and toughness of nanorods and nanotubes. Science 277:1971–1975

Ibrahim IA, Mohamed FA, Lavernia EJ (1991) Particulate reinforced metal matrix composites- a review. J Mater Sci 26:1137–1156. https://doi.org/10.1007/BF00544448

Kaczmar JW, Pietrzak K, Wlosinski W (2000) The production and application of metal matrix composite materials. J Mater Proc Technol 106:58–67

Wong WLE, Gupta M (2006) Simultaneously improving strength and ductility of magnesium using nano-sized SiC particulates and microwaves. Adv Eng Mater 8:735–740

Hassan SF, Gupta M (2005) Development of high performance magnesium nano-composites using nano-Al2O3 as reinforcement. Mater Sci Eng A 392:163–168

Zhou X, Su DP, Wu CG (2012) Tensile mechanical properties and strengthening mechanism of hybrid carbon nanotube and silicon carbide nanoparticle-reinforced magnesium alloy composites. J. Nonamater 2012:1–7

Kim HH, Babu JSS, Kang CG (2014) Hot extrusion of A356 aluminum metal matrix composite with carbon nanotube/Al2O3 hybrid reinforcement. Metall Mater Trans A 45:2636–2645

Xiong N, Bao R, Yi JH (2019a) Interface evolution and its influence on mechanical properties of CNTs/Cu-Ti composite. Mater Sci Eng A 755:75–84

Ni ZL, Zhao HJ, Ye FX (2015) Influence of sintering temperature on the mechanical properties and thermal expansion of SiCp/Al-30Si composites. Vaccum 120:101–106

Wu Y, Kim GY, Anderson IE, Lograsso TA (2010) Fabrication of Al6061 composite with high SiC particle loading by semi-solid powder processing. Acta Mater 58:4398–4405

Wang XH, Liang SH, Yang P, Fan ZK (2009) Effect of Al2O3 particle size on vacuum breakdown behavior of Al2O3/Cu composite. Vaccum 83:1475–1480

Habibi MK, Hamouda AS, Gupta M (2013) Hybridizing boron carbide (B4C) particles with aluminum (Al) to enhance the mechanical response of magnesium based nano-composites. J Alloy Comp 550:83–93

Liu RF, Wang WX, Chen HS (2018) Microstructure evolution and mechanical properties of micro-/nano-bimodal size B4C particles reinforced aluminum matrix composites prepared by SPS followed by HER. Vacuum 151:39–50

Boorse RS, Burlitch JM (1994) MOCVD route to stable, oxygen-rich, chromium oxide films and their conversion to epitaxial Cr2O3. Chem Mater 6:1509–1515

Venkatraman M, Neumann JP (1990) The C-Cr (Carbon-Chromium) System. Bulletin Alloy Phase Diagr 11:152–159

Chang YN, Huang SF, Huang MC (2001) Polycrystalline and Amorphous Chromium Oxide MOCVD. Mat Res Soc. https://doi.org/10.1557/PROC-685-D5.14.1

Barshilia HC, Selvakumar N, Rajam KS (2008) Structure and optical properties of pulsed sputter deposited CrxOy/Cr/Cr2O3 solar selective coatings. J Appl Phys 103:023507

Chen ML, Fan GL, Tan ZQ, Zhang D (2018) Design of an efficient flake powder metallurgy route to fabricate CNT/6061Al composites. Mater Des 142:288–296

Xiong N, Bao R, Yi JH (2019b) CNTs/Cu-Ti composited fabrication through the synergistic reinforcement of CNTs and in situ generated nano-TiC particles. J Alloy Comp 770:204–213

Bakshi SR, Lahiri D, Agarwal A (2010) Carbon nanotube reinforced metal matrix composites- a review. Int Mater Rev 55:41–64

Li H, Wang X, Chai L (2018) Microstructure and mechanical properties of an in-situ TiB2/Al-Zn-Mg-Cu-Zr composite fabricated by Metal-SHS process. Mater Sci Eng A 720:60–68

Zhang ZY, Yang R, Guo Y, Chen G (2017) Microstructure evolution and mechanical properties of ZrB2/6061Al nanocomposites processed by multil-pass friction stir processing. Mater Sci Eng A 689:411–418

Fan PP, Li Q, Liang ST (2015) Effect of calcination temperature on the color performance of Cr2O3 green pigment. Applied Chemical Industry 44:23–25

Chen XF, Tao JM, Liu YC, Bao R (2019) Interface interaction and synergistic strengthening behavior in pure copper matrix composites reinforced with functionalized carbon nanotube-graphene hybrids. Carbon 146:736–755

Kim KT, Cha SI, Geming T (2008) The Role of Interfacial Oxygen Atoms in the Enhanced Mechanical Properties of Carbon-Nanotube-Reinforced Metal Matrix. Small 4:1936–1940

Cha SI, Kim KT, Lee KH, Mo CB, Hong SH (2005) Strengthening and toughening of carbon nanotube reinforced by molecular level mixing process. Scr Mater 53:793–797

Bramfitt BL (1970) The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron. Metallurgical Transaction 1:1987–1995

Bahador A, Umeda J, Hamzah E, Yusof F, Li X, Kondoh K (2020) Synergistic strengthening mechanisms of copper matrix composites with TiO2 nanoparticles. Mat Sci Eng A 772:138797

Park JG, Keum DH, Lee YH (2015) Strengthening mechanisms in carbon nanotube-reinforced aluminum composites. Carbon 95:690–698

Hansen N (2004) Hall-Petch relation and boundary strengthening. Scripta Mater 51:801–806

Chen B, Shen J, Ye X, Jia L, Umeda J, Takahashi M (2017) Length effect of carbon nanotubes on the strengthening mechanisms in metal matrix composites. Acta Mater 140:317–325

Shin SE, Bae DH (2015) Deformation behavior of aluminum alloy matrix composites reinforced with few-layer grapheme. Compos Part A 78:42–47

Arsenault RJ, Shi N (1986) Dislocation generation due to differences between the coefficients of thermal expansion. Mater Sci Eng A 81:175–187

Kim WJ, Lee TJ, Han SH (2014) Multi-layer graphene/copper composites: Preparation using high-ratio differential speed rolling, microstructure and mechanical properties. Carbon 69:55–65

Kelly A, Tyson WR (1996) Tensile properties of fibre reinforced metals-II. Creep of silver-tungsten. J. Mech. Phy. Solid. 14:177–184

Peng B, Locascio M, Zapol P, Li SY, Mielke SL, Schatz GC, Espinosa HD (2008) Measurements of near-ultimate strength for multiwalled carbon nanotubes and irradiation-induced crosslinking improvements. Nat Nanotechnol 3:626–631

Le YK, Bai L, Ma NH (2006) Mechanical properties and microstructure of in site TiB2-7055 composites. Chin J Aeronaut 19:66–70

Cheng BW, Bao R, Yi JH, Li CJ, Tao JM, Liu YC (2017) Interface optimization of CNT/Cu composite by forming TiC nanoprecipitation and low interface energy structure via spark plasma sintering. J Alloy Comp 722:852–858

Chu K, Wang F, Li YB, Wang XH, Huang DJ, Zhang H (2018) Interface structure and strengthening behavior of graphene/CuCr composites. Carbon 133:127–139

Zhang X, Shi C, Liu E, He F, Ma L, Li Q (2017) In-situ space-confined synthesis of well-dispersed three-dimensional graphene/carbon nanotube hybrid reinforced copper nanocomposites with balanced strength and ductility. Compos Appl Sci Manuf 103:178–187

Shuai J, Xiong L, Zhu L, Li W (2016) Enhanced strength and excellent transport properties of a superaligned carbon nanotubes reinforced copper matrix laminar composite. Compos A 88:148–155

Chu K, Wang F, Li YB, Wang XH, Huang DJ, Geng ZR (2018) Interface and mechanical/thermal properties of graphene/copper composite with Mo2C nanoparticles grown on graphene. Compos A Appl Sci Manuf 109:267–279

Acknowledgement

This work is supported by the Yunnan science and technology projects Grants (Grant No. 2019ZE001, No. 202002AB080001), Yunnan Ten Thousand Talents Plan Young & Elite Talents Project (YNWR-QNBJ-2018-005).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, X., Bao, R., Yi, J. et al. Enhancing mechanical properties of pure copper-based materials with CrxOy nanoparticles and CNT hybrid reinforcement. J Mater Sci 56, 3062–3077 (2021). https://doi.org/10.1007/s10853-020-05440-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05440-6