Abstract

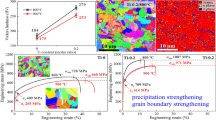

The as-spun structure, thermal stability, crystallization structure and soft magnetic properties of Fe81.3SixB17-xCu1.7 (x = 0–8) alloys were investigated. The Fe–Si–B–Cu amorphous alloys contain α-Fe nanocrystals with a high number density (Nd) in as-spun state and show uniform nanocrystalline structure and typical soft magnetic characteristics after annealing. The rise of Si content from 0 to 4 at% increases the Nd, while the further rise to 8 at% shows an adverse effect. The increased Nd enhances competitive growth between the crystals during crystallization process, then refines structure and improves soft magnetic properties of the nanocrystalline alloys. Contrarily, the decreased Nd results in coarsened nanostructure and deteriorated magnetic softness. The alloy with Si content of 4 at% contains α-Fe crystals with a high Nd of 2.2 × 1023 m−3 in as-spun state and possesses fine α-Fe grains with an average size (D) of 14 nm, low coercivity (Hc) of 7.1 A/m, high effective permeability (at 1 kHz) of 16,500 and saturation magnetic flux density of 1.77 T after annealing at 668 K for 60 min. In addition, the Hc of present Fe–Si–B–Cu nanocrystalline alloys is almost proportional to D3 due to the high ratio of uniaxial anisotropy to average random anisotropy.

Similar content being viewed by others

References

Herzer G (2013) Modern soft magnets: amorphous and nanocrystalline materials. Acta Mater 61:718–734. https://doi.org/10.1016/j.actamat.2012.10.040

Yoshizawa Y, Oguma S, Yamauchi K (1988) New Fe-based soft magnetic alloys composed of ultrafine grain structure. J Appl Phys 64:6044–6046. https://doi.org/10.1063/1.342149

McHenry ME, Willard MA, Laughlin DE (1999) Amorphous and nanocrystalline materials for applications as soft magnets. Prog Mater Sci 44:291–433. https://doi.org/10.1016/S0079-6425(99)00002-X

Yoshizawa Y (2001) Magnetic properties and applications of nanostructured soft magnetic materials. Scripta Mater 44:1321–1325. https://doi.org/10.1016/s1359-6462(01)00700-x

Makino A (2012) Nanocrystalline soft magnetic Fe-Si-BP-Cu alloys with high B of 1.8–1.9T contributable to energy saving. IEEE Trans Magn 48:1331–1335. https://doi.org/10.1109/tmag.2011.2175210

Makino A, Men H, Kubota T, Yubuta K, Inoue A (2009) FeSiBPCu nanocrystalline soft magnetic alloys with high Bs of 1.9 tesla produced by crystallizing hetero-amorphous phase. Mater Trans JIM 50:204–209. https://doi.org/10.2320/matertrans.MER2008306

Suzuki K, Kataoka N, Inoue A, Makino A, Masumoto T (1990) High saturation magnetization and soft magnetic properties of bcc Fe–Zr–B alloys with ultrafine grain structure. Mater Trans JIM 31:743–746. https://doi.org/10.2320/matertrans1989.31.743

Willard MA, Laughlin DE, McHenry ME, Thoma D, Sickafus K, Cross JO, Harris VG (1998) Structure and magnetic properties of (Fe0.5Co0.5)88Zr7B4Cu1 nanocrystalline alloys. J Appl Phys 84:6773–6777. https://doi.org/10.1063/1.369007

Ohta M, Yoshizawa Y (2008) Cu addition effect on soft magnetic properties in Fe–Si–B alloy system. J Appl Phys 103:07E722–13. https://doi.org/10.1063/1.2829240

Makino A, Kubota T, Yubuta K, Inoue A, Urata A, Matsumoto H, Yoshida S (2011) Low core losses and magnetic properties of Fe85-86Si1-2B8P4Cu1 nanocrystalline alloys with high B for power applications. J Appl Phys 109:07A302–15. https://doi.org/10.1063/1.3535169

Zhang Y, Sharma P, Makino A (2014) Effects of cobalt addition in nanocrystalline Fe83.3Si4B8P4Cu0.7 soft magnetic alloy. IEEE Trans Magn 50:2003004–2003014. https://doi.org/10.1109/TMAG.2013.2286617

Sharma P, Zhang X, Zhang Y, Makino A (2015) Competition driven nanocrystallization in high Bs and low coreloss Fe-Si-B-P-Cu soft magnetic alloys. Scripta Mater 95:3–6. https://doi.org/10.1016/j.scriptamat.2014.08.023

Suzuki K, Parsons R, Zang BW, Onodera K, Kishimoto H, Kato A (2017) Copper-free nanocrystalline soft magnetic materials with high saturation magnetization comparable to that of Si steel. Appl Phys Lett 110:012407–12414. https://doi.org/10.1063/1.4973772

Zang BW, Parsons R, Onodera K, Kishimoto H, Kato A, Liu ACY, Suzuki K (2017) Effect of heating rate during primary crystallization on soft magnetic properties of melt-spun Fe-B alloys. Scripta Mater 132:68–72. https://doi.org/10.1016/j.scriptamat.2017.01.030

Fan XD, Zhang T, Jiang MF, Yang WM, Shen BL (2019) Synthesis of novel FeSiBPCCu alloys with high amorphous forming ability and good soft magnetic properties. J Non-Cryst Solids 503–504:36–43. https://doi.org/10.1016/j.jnoncrysol.2018.09.021

Li YH, Jia XJ, Xu YQ, Chang CT, Xie GQ, Zhang W (2017) Soft magnetic Fe-Si-B-Cu nanocrystalline alloys with high Cu concentrations. J Alloy Compd 722:859–863. https://doi.org/10.1016/j.jallcom.2017.06.128

Jia XJ, Li YH, Wu LC, Zhang Y, Xie L, Zhang W (2019) The role of Cu content on structure and magnetic properties of Fe-Si-B-P-Cu nanocrystalline alloys. J Mater Sci 54:4400–4408. https://doi.org/10.1007/s10853-018-3131-5

Hono K, Ping DH, Ohnuma M, Onodera H (1999) Cu clustering and Si partitioning in the early crystallization stage of an Fe73.5Si13.5B9Nb3Cu1 amorphous alloy. Acta Mater 47:997–1006. https://doi.org/10.1016/S1359-6454(98)00392-9

Matsuura M, Nishijing M, Takenaka K, Takeuchi A, Ofuchi H, Makino A (2015) Evolution of fcc Cu clusters and their structure changes in the soft magnetic Fe85.2Si1B9P4Cu0.8 (NANOMET) and FINEMET alloys observed by X-ray absorption fine structure. J Appl Phys 117:17A324. https://doi.org/10.1063/1.491693

Zuo MQ, Meng SY, Li Q, Li HX, Chang CT, Sun YF (2017) Effect of metalloid elements on magnetic properties of Fe-based bulk metallic glasses. Intermetallics 83:83–86. https://doi.org/10.1016/j.intermet.2016.12.010

Xu YQ, Li YH, Zhu ZW, Zhang W (2018) Formation and properties of Fe25Co25Ni25(P, C, B, Si)25 high-entropy bulk metallic glasses. J Non-Cryst Solids 487:60–64. https://doi.org/10.1016/j.jnoncrysol.2018.02.021

Hibino T, Bitoh T (2017) Ternary Fe-BC and quaternary Fe-BC-Si amorphous alloys with glass transition and high magnetization. J Alloy Compd 707:82–86. https://doi.org/10.1016/j.jallcom.2016.12.060

Zhang ZQ, Sharma P, Makino A (2012) Role of Si in high Bs and low core-loss Fe85.2B10-xP4Cu0.8Six nano-crystalline alloys. J Appl Phys 112:103902–103908. https://doi.org/10.1063/1.4765718

Li YH, Jia XJ, Zhang W, Zhang Y, Xie GQ, Qiu ZY, Luan JH, Jiao ZB (2020) Formation manner and crystallization behavior of Fe-based amorphous precursors with pre-existing α-Fe nanoparticles. J Mater Sci Technol. https://doi.org/10.1016/j.jmst.2020.05.049

Suzuki K, Herzer G, Cadogan JM (1998) The effect of coherent uniaxial anisotropies on the grain-size dependence of coercivity in nanocrystalline soft magnetic alloys. J Magn Magn Mater 177:949–950. https://doi.org/10.1016/S0304-8853(97)00987-6

Herzer G (1990) Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans Magn 26:1397–1402. https://doi.org/10.1109/20.104389

Jia XJ, Li YH, Wu LC, Zhang W (2020) A study on the role of Ni content on structure and properties of Fe-Ni-Si-B-P-Cu nanocrystalline alloys. J Alloy Compd 822(152784):152786. https://doi.org/10.1016/j.jallcom.2019.152784

Wu C, Chen HP, Lv HP, Yan M (2016) Interplay of crystallization, stress relaxation and magnetic properties for FeCuNbSiB soft magnetic composites. J Alloy Compd 673:278–282. https://doi.org/10.1016/j.jallcom.2016.02.239

Allia P (1993) Kinetics of the amorphous-to-nanocrystalline transformation in Fe73.5Cu1Nb3Si13.5B9. J Appl Phys 74:3137–3143. https://doi.org/10.1063/1.354581

Wang WH (2007) Roles of minor additions in formation and properties of bulk metallic glasses. Prog Mater Sci 52:540–595. https://doi.org/10.1016/j.pmatsci.2006.07.003

Inoue A (2000) Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater 48:279–306. https://doi.org/10.1016/S1359-6454(99)00300-6

Senkov ON, Miracle DB (2001) Effect of the atomic size distribution on glass forming ability of amorphous metallic alloys. Mater Res Bull 36:2183–2198. https://doi.org/10.1016/S0025-5408(01)00715-2

Takeuchi A, Inoue A (2000) Calculations of mixing enthalpy and mismatch entropy for ternary amorphous alloys. Mater Trans JIM 41:1372–1378. https://doi.org/10.2320/matertrans1989.41.1372

Takeuchi A, Inoue A (2005) Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans 46:2817–2829. https://doi.org/10.2320/matertrans.46.2817

Zhang W, Jia XJ, Li YH, Fang CF (2014) Effects of Mo addition on thermal stability and magnetic properties of a ferromagnetic Fe75P10C10B5 metallic glass. J Appl Phys 115:17A768–23. https://doi.org/10.1063/1.4869161

Ohta M, Yoshizawa Y (2009) High Bs nanocrystalline Fe84-x-yCuxNbySi4B12 alloys (x = 0.0–1.4, y = 0.0–2.5). J Magn Magn Mater 321:2220–2224. https://doi.org/10.1016/j.jmmm.2009.01.018

Graham CD, Egami T (1979) Magnetic properties of amorphous ribbon. IEEE Trans Mag 15(6):1398–1403. https://doi.org/10.1109/TMAG.1979.1060428

Shi RM, Wang Z, Jia YY, Wen ZP, Wang BW, Zhang T (2012) Superior magnetic softness at elevated temperature of Si-rich Fe-based nanocrystalline alloy. J Appl Phys 112:083922–83924. https://doi.org/10.1063/1.4759243

Fan XD, Men H, Ma AB, Shen BL (2012) The influence of Si substitution on soft magnetic properties and crystallization behavior in Fe83B10C6-xSixCu1 alloy system. Sci China Technol Sc 55:2416–2419. https://doi.org/10.1007/s11431-012-4929-z

Sharma P, Zhang X, Zhang Y, Makino A (2014) Influence of microstructure on soft magnetic properties of low coreloss and high Bs Fe85Si2B8P4Cu1 nanocrystalline alloy. J Appl Phys 115:17A340–23. https://doi.org/10.1063/1.4868188

Suzukia K, Herzer G (2012) Magnetic-field-induced anisotropies and exchange softening in Fe-rich nanocrystalline soft magnetic alloys. Scripta Mater 67:548–553. https://doi.org/10.1016/j.scriptamat.2012.03.006

Herzer G (2005) Anisotropies in soft magnetic nanocrystalline alloys. J Magn Magn Mater 294:99–106. https://doi.org/10.1016/j.jmmm.2005.03.020

Parsons R, Garitaonandia JS, Yanai T, Onodera K, Kishimoto H, Kato A, Suzuki K (2017) Effect of Si on the field-induced anisotropy in Fe-rich nanocrystalline soft magnetic alloys. J Alloy Compd 695:3156–3162. https://doi.org/10.1016/j.jallcom.2016.11.330

Tejedor M, GarcmHa JA, Carrizo J, Elbaile L, Santos JD (1999) Stress relief and magnetic properties of magnetostrictive Fe79B16Si5 amorphous magnetic ribbons. J Magn Magn Mater 202:485–491. https://doi.org/10.1016/S0304-8853(99)00378-9

Acknowledgements

This research was supported by the National Key Research and Development Program of China [Grant No. 2016YFB0300500], the National Natural Science Foundation of China [Grant No. 51571047], Ningbo Major Special Projects of the Plan "Science and Technology Innovation 2025" [Grant No. 2018B10084].

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jia, X., Zhang, W., Dong, Y. et al. Effects of Si content on structure and soft magnetic properties of Fe81.3SixB17-xCu1.7 nanocrystalline alloys with pre-existing α-Fe nanocrystals. J Mater Sci 56, 2539–2548 (2021). https://doi.org/10.1007/s10853-020-05404-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05404-w